Today, not a single car can do without power steering (power steering), the equipment of which was carried out with a focus on the modern level of driving comfort. The hydraulic mechanism facilitates physical control of the machine while maintaining optimal feedback and compliance with safety requirements.

This is achieved by introducing an auxiliary mechanism into the steering wheel system, the technical condition of which must be regularly monitored. If, after a certain time of using a machine with such equipment, deviations in the operation of the mechanism are noticed, then you should prepare for its repair. For example, if the power steering is hard to turn, there may be several options to resolve the situation. But first you should consider the design of the mechanism and the principle of its operation.

How does power steering work?

The hydraulic booster system is multi-component, but closed. This device is partly responsible for the difficulty of repairing the structure. A typical mechanism includes a pump, a reservoir with liquid in the form of a tank, a pressure regulator, a power unit and a spool. The pump is connected to the drive system of the machine’s engine, and the pressure regulator ensures that the force flow is balanced relative to the spool. The operating pressure difference depends on the supply of control fluid.

It is this part of the functionality that in most cases leads to problems that require power steering repair in the form of correcting the position of individual parts of the structure or by updating the oil. In turn, the hydraulic cylinder interacts with the steering rack, transmitting additional force. In order for the final load required to activate the steering wheel to be balanced, the spool itself is installed on the column - in the future it will react to the torque when the driver performs manipulations.

Rear suspension design

In order to determine what could be knocking in the suspension, you should know what this element of the car consists of.

- Guide structure.

- Twisted coil springs.

- Shock absorbers.

- Rubber bushings and mounting cups.

A sound in the rear suspension may appear when one of the above elements fails. At the same time, we note that if there is a constant knocking, it is imperative to carry out diagnostics of the suspension. If working with a car causes many problems, then you can entrust the diagnostics to specialists from a car service center. Note that the rear suspension has a very simple design and you can dismantle the worn part yourself.

Possible causes not related to suspension

Before determining what might be knocking, you should make sure that there is a problem with the suspension. Often, a knock may appear due to a minor malfunction of another element, but with strong vibration on the road, it seems that the problem is with the chassis elements. Possible causes of knocking include the following:

- The exhaust pipe in most cases becomes the cause of the knocking, as its fastening wears out over time.

- poorly secured items in the cabin or luggage compartment. You need to check the contents of the trunk, especially the mounting of the spare wheel. If during the first inspection no obvious problems are identified, we proceed to diagnosing the suspension.

What are the signs that indicate a problem?

The feeling of heaviness when steering the steering wheel does not always appear suddenly and at once. This can be a long process, during which warning signs may arise. In particular, initial diagnostics will help detect problems due to the formation of leaks, noise and excessive vibrations. Over time, a tight steering wheel will be added to this list if the same leak is not stopped and the fluid supply is replenished. Of course, the above signs may also indicate the appearance of other problems, and not only with the hydraulic booster. Therefore, general diagnostics in this case will not be superfluous. It will also allow you to more accurately determine the possible cause of the weighting of the steering wheel.

Drive belt

If the steering wheel in a car begins to rotate tightly, not sharply, but gradually over a month or more, then the cause of this trouble is the slipping of the drive belt and, as a result, the power steering pump not performing its functions.

To diagnose this malfunction, it is necessary to visually inspect the belt with the car turned off and running.

When inspecting the car with the car turned off, it is necessary to check the belt tension, the absence of oil leaks, cracks, wear and unevenness. When the engine is running, there should be no whistling or slipping from the power steering pump drive belt.

If the belt wears out too quickly, you need to pay attention to the condition of the pump. With the drive belt removed, you must rotate the pulley by hand. Rotation should be easy and smooth without jamming.

The main reasons for a tight steering wheel

There are many factors that can lead to difficulty steering due to power steering. Each of them involves its own approach to repair. One of the most common reasons is the presence of air in the niches of the hydraulic booster. Its presence not only eliminates the main function of the mechanism, but also has the opposite effect, making the movements of the steering wheel heavier.

Another common reason is the aforementioned emptying of the expansion tank with liquid. If it was not possible to determine the reason why the power steering is difficult to turn, then it makes sense to turn to the technical condition of the individual components of the system. For example, wear of parts, especially the drive belt, could indirectly provoke a decrease in hydraulic function. In this case, a complete revision of the mechanism and, possibly, its replacement cannot be avoided. The possibility of a problem with the steering wheel itself should not be ruled out. For example, a rack connected to a gearbox can cause even more trouble in terms of repairs.

After replacing the steering rack, the steering wheel of a VAZ 2114 turns hard

- To the beginning of the forum

- Forum Rules

- Old design

- FAQ

- Search

- Users

We went through the rack (tenth). We replaced spare parts from the repair kit. We also installed an SS20 disc spring. At the same time, the steering tips were changed.

As a result, the steering wheel became very tight. It's hard to turn with one hand. When released, it does not return to the straight position. As you put it, that’s how it’s worth. Loosening the adjusting bolt doesn't help, it's still tight. If you let go too much, it starts to slip, even if the wheels are on spinning stands (at camber).

I heard that after installing the SS20 disc spring the steering becomes stiff. But to what extent? is it possible? And why then does it start to slip even when the forces on the wheels are minimal? The repairman suggested that the fluoroplastic bushing was very tight.

So far, the master and I have agreed to travel for a couple of days, hoping that it will work out. But will it work out (especially if it’s a bushing)?

If you let go too much, it starts to skip

How to disassemble a tight steering wheel?

To verify the reasons why the steering wheel could become heavier, you should disassemble the mechanism. The event begins with disconnecting the pipelines that lead to the expansion tank and steering system. At this point, you can drain the liquid. Next, the drive belt from the pump is removed - again, if it is in an unusable condition, then you will have to put on a new belt.

Here, three blocks for fixing the pulley suitable for the pump unit are unscrewed. But depending on the type of fastening system, there may be more. After this, access to the fixing elements of the pump itself may open. As you can see, power steering repair can be performed already at this stage by replacing the fluid, updating the hoses and the drive belt. But this may not be enough. Special attention should be paid to the filter system. Even if it performs its function properly, a violation at the cleaning stage is possible, which cannot be determined in a garage environment. Therefore, if there are no other obvious causes of the problem, it makes sense to have the filters checked in a professional workshop.

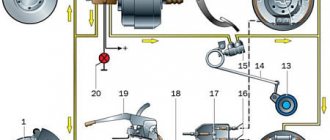

The “dimensions” do not light up on the VAZ 2108, 2109, 21099

Let's look at how to quickly find the reason for the failure of the "dimensions" on VAZ 2108, 2109, 21099 cars. The side lights are part of the vehicle's external lighting system and its operation with non-functioning "dimensions" is difficult, especially at night. We are looking for the reason for the non-functioning dimensions, as is customary in such situations, from simple to complex.

Causes of malfunction

The side light bulb in the socket has burned out

One light bulb, or several at once, can suddenly burn out. In some cases, it may be impossible to visually identify a burnt-out light bulb. Therefore, we replace the burnt out one with a known good one. You can use a similar one from a nearby headlight.

The contacts in the side light bulb socket have oxidized.

We rotate the light bulb in the socket several times to remove the oxidized layer and restore contact. In the future, you can clean everything with sandpaper.

The contacts in the connecting blocks of the headlight or tail light unit have oxidized

We remove and put on the connecting blocks several times to remove the oxidized layer and restore contact. More radically, we remove the pads and clean the contacts.

No "mass"

The “negative” wires of the front headlights and rear lights with side lights on VAZ 2108, 2109, 21099 cars are attached to the car body. It is necessary to clean the mounting location to ensure good contact with ground. Usually the negative wire is the black wire from the headlight connection block, attached to the body next to the headlight or taillight.

Weight of the front headlight, place of attachment to the body of the VAZ 2108, 2109, 21099

Fuse blown

If fuse 10 (F11) is blown, the side lights of the right headlight and right rear light will not work. If fuse 9 (F10) is blown, the left headlight and left rear light of the vehicle will not work. We replace them with new ones, and then look for the cause of the burnout (possibly a short circuit somewhere).

Relay K4 is faulty (monitoring the health of the lamps)

A faulty K4 lamp control relay can be replaced with jumpers. We connect the holes for relay terminals 1-7-8, 9-10-11, 4-5. On some VAZ 2108, 2109, 21099 vehicles, jumpers are already installed instead of lamp health monitoring relays.

The tracks in the rear light circuit boards have crumbled

Visually inspect the tracks in the rear light circuit boards for shedding, rust, or burnout. If necessary, we check their integrity using a test lamp or tester. A faulty track can be repaired by soldering wire onto its frayed edges.

The pads in the mounting block have come off or the wire tips have oxidized.

It is necessary to check the secure fit of the connecting blocks in the fuse mounting block. For an electrical circuit of “dimensions” these are plugs Ш4 (Х4), Ш6 (Х6), Ш9 (Х9), Ш11 (х11). If necessary, the wire tips present in them should be cleaned from oxidation.

The external lighting switch on the instrument panel is faulty

You should remove the exterior lighting switch and connect the black and yellow-red wires together. The black current flows into the switch, and the yellow-red current flows out. If the lights light up, replace the switch with a new one. If not, we look for a fault in the electrical circuit further.

"Open" or short circuit in the wiring

It is necessary to check the presence of electric current on the external lighting switch (circuit from the ignition switch to the switch), fuses (circuit switch - mounting block) and on the lamp control relay (functionality of the mounting block).

Notes and additions

- The side light lamps are located in the front headlights and rear lights of the car. The front lights use an A12-4-1 bulb, and the rear lights use an A12-5 bulb.

- The electrical circuit for turning on the external lighting (“dimensions”) is the same for all these cars. The only difference is in the fuse mounting blocks used: on old Samaras, before 1999. this is 17.3722 with finger fuses, on cars after 1999. modifications of the mounting block 2114 with flag fuses. Accordingly, fuses 9 and 10 are used in the external lighting circuit with the old mounting block, with the new F10, F11.

- “Dimensions” of the right side of VAZ 2108, 2109, 21099 cars on the 10th (F11) fuse. “Dimensions” of the left side on the 9th (F10) fuse.

Getting rid of excess air

If the reason is the presence of excess air in the system, then in a sense we can talk about luck. True, everything here is ambiguous. Most often, this problem is solved by several turns of the steering wheel, brought to the stop. Moreover, this action is performed in both directions. As practice shows, this allows you to push out excess air from the hydraulic communications. But if even after this action the steering wheel turns hard, then the tank is more likely to become airy. This means that the system works with liquid in which bubbles are present. This factor determines the lack of ease of use of the steering wheel. A complete renewal of the fluid in the expansion tank will help eliminate this problem.

Filling oil into the steering gear

As mentioned above, the steering gear housing is sealed. Oil is poured inside, which can significantly reduce friction of parts. Any GL5 or GL4 class oil is suitable for a VAZ gearbox. The viscosity class should be SAE80-W90. Many owners of “sixes” fill in the old Soviet TAD17 oil, which also has an acceptable viscosity and is cheaper. To fill the gearbox completely, you will need 0.22 liters of gear oil.

How to check the oil level in the steering gear

In order for the steering gear parts to last as long as possible, the driver must periodically monitor the oil level in this device and, if necessary, add lubricant.

- The gearbox cover has a hole for filling oil, closed with a plug. The plug is unscrewed using an 8-mm open-end wrench.

Oil filling sequence

If the driver needs to add a little oil to the gearbox or change the oil completely, he will need an empty plastic bottle, a piece of plastic tube and a medical syringe of the largest volume. It should be noted here that the operating instructions for the machine say: the oil in the steering gear should be changed once a year.

- The oil plug on the gearbox cover is unscrewed. A plastic tube is placed over the syringe. The other end of the tube is inserted into the drain hole of the gearbox, the oil is drawn out into a syringe and poured into an empty plastic bottle.

Video: we change the oil in the steering gear of a “classic” ourselves

So, the steering gearbox on the “six” is a very important part. Not only the controllability of the car, but also the safety of the driver and passengers depends on its condition. Even a novice car enthusiast can replace the gearbox. No special skills or knowledge are required for this. You just need to know how to use wrenches and strictly follow the recommendations outlined above.

Defects accompanied by tight steering are a common occurrence for a wide variety of car models. A tight steering wheel creates discomfort and makes it difficult to control the car, which can be very unsafe. In this article, we will look at the main causes of problems in the steering system, and also identify the characteristic signs of malfunctions, one way or another, related to the problem when the steering wheel turns tightly.

Over-tightening

Often, inexperienced drivers try to tightly tighten the adjustment screws to eliminate large play in the steering wheel. In worm gearboxes, which are most often used on rear-wheel drive and all-wheel drive vehicles, the first step is to adjust the displacement of the bipod shaft along the axis of the steering unit shaft. On VAZ series models, by rotating the adjusting screw with a locknut, you can quickly eliminate play in the bipod shaft bearings.

Adjustments are made in a similar manner on many foreign cars. The common problem in such cases is the over-tightening of the tapered bearings that support the aforementioned shafts. To prevent the steering wheel from moving stiffly, it is necessary to rotate the adjusting screws until slight forces appear on the screwdriver or wrench used for calibration. Remember that with this type of bearing it is better to leave a little clearance than to overtighten it a little. Even the slightest tightening can lead to significant forces on the steering wheel.

Fluid replacement

To do this, it is not necessary to completely disassemble the mechanism. First of all, you should free the two pipes leading to the expansion tank from the clamps. Also, if necessary, additional fasteners and belt communications are removed, which make access to the tank difficult.

The fluid can be directly replaced without completely dismantling the tank. The spent mixture is simply pumped out, after which all that remains is to pour in new auto chemicals. However, if the power steering steering wheel turns tightly and has not been checked for a long time, then it is advisable to dismantle the reservoir for subsequent diagnostics. It should be checked for leaks, then thoroughly washed and rinsed with clean water. The dried tank is installed in its place, filled with new working fluid and secured with fasteners.

After replacing the steering rack, the steering wheel of a VAZ 2114 turns hard

Post by zhekasin » April 12, 2011, 5:11 pm

Messages: 157 Registered: July 28, 2007, 00:00 From: Tyumen Experience: since 2000

| Rating: 187 |

| Reputation: 0 |

Posted by carovec » April 12, 2011, 05:13 pm

Barguzin tires 13″ regular wheels

I drove it and this never happened

Messages: 23 Registered: 02 Sep 2010, 00:00 From: Tyumen Experience: 2007

| Rating: 23 |

| Reputation: 0 |

Post by zhekasin » April 12, 2011, 6:50 pm

Messages: 634 Registered: August 29, 2008, 00:00 From: Tobolsk/Tyumen Experience: 2004 Car: 407 coupe, Solaris :

Awards: 1

| Rating: 727 |

| Reputation: 0 |

Post by ser097 » April 12, 2011, 07:31 pm

Messages: 16 Registered: February 11, 2010, 00:00 From: Dzerzhinsky Experience: 2003 Car: 21140

| Rating: 16 |

| Reputation: 0 |

Message IL-14 » April 12, 2011, 8:23 pm

Messages: 215 Registered: Oct 20, 2008, 00:00 From: 72RUS Car: TAZ

| Rating: 365 |

| Reputation: +1 |

Thanked: 1 time

Post by KAMATO3 » April 12, 2011, 21:14

Messages: 157 Registered: July 28, 2007, 00:00 From: Tyumen Experience: since 2000

| Rating: 187 |

| Reputation: 0 |

Posted by carovec » April 13, 2011, 10:03 am

How do you know if the support bearings need to be replaced?

Messages: 15196 Registered: Dec 06, 2010, 00:00 From: Tyumen Center Experience: 1976 Car: really like it :

Awards: 3

| Rating: 105 182 |

| Reputation: +197 |

Thanked: 1224 times Thanked: 1332 times

Post by Grigoryich » April 13, 2011, 10:19

We will never get what we want until we are grateful for what we have!

Osim haim!

Messages: 216 Registered: Feb 18, 2010, 00:00 Experience: 2008

| Rating: 216 |

| Reputation: 0 |

Post by VipKlient » Apr 13, 2011, 10:22 am

Messages: 259 Registered: 08 Oct 2009, 00:00 Car: 21102 :

Awards: 1

| Rating: 530 |

| Reputation: 0 |

Thanked: 23 times Thanked: 5 times

Post by kuller » April 13, 2011, 10:39 am

Messages: 989 Registered: Oct 11, 2009, 00:00 From: Nizhnevartovsk-Tyumen Experience: 1998 Car: NISSAN QASHQAI+2 :

Awards: 1

| Rating: 1 257 |

| Reputation: 0 |

Thanked: 5 times

Post by Martin1 » April 13, 2011, 11:05 am

Messages: 435 Registered: Feb 20, 2011, 00:00 Experience: 2006

| Rating: 435 |

| Reputation: 0 |

Post by Mr_Sedoy » April 13, 2011, 12:44 pm

Source

Which liquid do you prefer?

The issue of choosing power steering fluid also imposes considerable responsibility. It is advisable to give preference to synthetic hydraulic mixtures made from high-quality components. Regular machine oil is not suitable in this case. Features of specialized compositions include a sufficient degree of fluidity, viscosity and the ability to work at extreme temperatures.

Often problems of this kind occur precisely in winter, when the filled liquid simply cannot cope with its tasks due to freezing. Therefore, the question of which oil should be poured into the power steering should only be decided in favor of special synthetic or semi-synthetic mixtures, which usually have a dark green tint. If we talk about manufacturers, high-quality auto chemicals of this type are produced by Motul, Castrol, Pentosin, Liqui Moly, etc. The cost of the liquid is about 800-1000 rubles, but even a small canister will last for a long time, so it’s not worth saving on this resource.

After replacing the steering rack, the steering wheel of a VAZ 2114 turns hard

- To the beginning of the forum

- Forum Rules

- Old design

- FAQ

- Search

- Users

People, I want to tell you a tragic story as a result of which I can’t drive.

On Tuesday I decided to do a wheel alignment. I went to the service center on Suschevsky Val (there is a store and service there). We did it, I decided to take a circle around the area, it didn’t seem to work, but the steering wheel turned about twenty degrees to the left when moving straight ahead. I returned to them, I said, I want everything to be straight - they began to redo it. They said that they were in a hurry, the alignment could not be done at all, because... the right steering tip is in the trash. I bought 2 tie rod ends, went to the service center and installed them. Well, I think now I’ll do the wheel alignment and there will be happiness.