Failure of the “vacuum seal” is a rather rare failure, but unpleasant - to slow down and stop the car, the driver has to press the brake pedal hard. A sudden failure of the mechanism while driving can provoke an accident - the driver does not have time to change lanes and apply the required force at the right time. To identify signs of critical wear of an element, it is proposed to consider the operating principle of a vacuum brake booster (VBR) and diagnostic methods in a regular garage.

Design and principle of operation of the vacuum amplifier

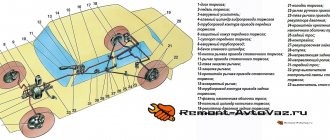

A vacuum booster (or VUT) is the most common type of brake booster mechanism. It operates on the principle of reducing pressure or simply vacuuming. Structurally, it forms a single whole with the main cylinder and includes several important components:

- a housing divided by a diaphragm into 2 parts - a vacuum and an atmospheric chamber;

- a valve that closes the bridge between the parts of the vacuum chamber;

- a mechanical (or electric) pump necessary to ensure uninterrupted operation as the main or additional source of vacuum (may not be present on some gasoline cars);

- return type spring - needed to move the diaphragm to its initial position after pressing the brake pedal.

Some VUT models are also equipped with an electromagnetic drive. This is an additional element for emergency braking.

The operation of a vacuum unit is based on the vacuum or difference in air pressure in both chambers. In the initial position it is the same, but after pressing the brake, the channel connecting both halves of the VUT is blocked. In this case, air begins to flow into the atmospheric section, where the vacuum decreases. This creates a force on the diaphragm, which moves the master cylinder piston against the spring force.

How to replace a check valve?

The vacuum booster is responsible for creating vacuum pressure that can be used by the engine to increase pressure. If the valve fails, the vacuum pressure generated by the booster cannot be used effectively to power the brakes.

In the event of a malfunction, the pressure in the brakes is usually less than necessary. This can lead to accidents as the brakes will not be able to function to their full potential.

Step 1 - Locate the brake check valve.

Find your brake check valve to start working on it. The brake check valve is usually located in the engine area of the car where the engine connects to the vacuum booster. This connection can be further identified by searching for the vacuum line.

Step 2 - Remove the clips.

Most vacuum lines have clamps to hold them in place. Before you remove the vacuum line to move to the next step, you need to carefully remove all the clips. Remove the clamps carefully to avoid damaging the vacuum line. You will connect the same vacuum line at the end of the process.

Step 3 - Remove the brake check valve.

Once the vacuum line is removed, you will have full access to the brake check valve. Now you can easily remove the valve. Use a screwdriver to loosen the screws around it and a wrench for the valves. Once you do this, you can easily pull the valve out. Then use a hand vacuum pump to apply vacuum to the inlet end of the valve. The vacuum should be between 15 and 20 degrees. If the pump shows loss, it means the valve is faulty.

Step 4 - Install the new brake check valve.

Reverse the process you went through to remove the old brake check valve, install the new one on the booster. Tighten the valve with a wrench and the screws with a screwdriver. Once the new valve is installed, reconnect the vacuum line, reversing the process you used to disconnect it.

Step 5 - Check the brakes.

Once installation is complete, start the engine and check the brakes. If the brake pressure and power still seem low, the problem may be with the vacuum booster.

Why does the VUT fail?

If the VUT breaks down, the brake system remains operational, but it is difficult to depress the pedal. There are two typical reasons for mechanism failure: loss of tightness of chambers/tubes and damage to the check valve.

A special hose connects the vacuum unit to the vehicle’s intake manifold, from which in most cases it receives a vacuum. Some amplifier models are equipped with an additional pump. But still, the VUT takes the main part of its energy from the collector. Therefore, if the tube breaks or its connections become loose, the mechanism stops working.

What to do with a faulty device?

As usual, there are two options: repair and replacement . Their choice depends on the degree of damage to the VUT. To eliminate them, you need to know the amplifier well and have a repair kit suitable for the specific model of the device in your garage.

If the vacuum booster fails, you will have to spend more effort to brake, and the response of the braking system will be very slow. In some situations, this can lead to an accident, so if signs of failure of the VUT are observed, it should be replaced. Note that at home there is no point in trying to get the amplifier into working condition without a special set of spare parts and tools.

Signs of VUT malfunction

The main symptom is the hissing sound made by the amplifier after pressing the brake pedal, which in turn becomes incredibly tight. But there is another typical sign - unstable engine operation caused by a lean fuel mixture. This happens due to air being sucked into the intake manifold. By the way, the whistle can also be caused by wear of the vacuum valve seals.

In particularly severe cases, when the mechanism completely fails, the brake pedal cannot be fully pressed at all. And when the engine is running, its speed can drop to a complete stop or, on the contrary, unexpectedly increase. There may also be an increase in fuel consumption, engine tripping, loss of acceleration dynamics, and difficulty starting the engine.

A sign of damage to a mechanical amplifier is a knocking sound. It is produced by the drive rod. As for the electric pump, if there is a problem, it starts to get very hot.

Let's sum it up

So, we found out what a vacuum brake booster is. This is a very important element in any car. In general, a vacuum brake booster rarely fails. This is a fairly reliable and simple mechanism. Sometimes it is not changed for 10 years. It does not have a specific resource. And malfunctions most often relate to air leaks due to the hose through which the vacuum flows from the engine to the amplifier. But if during diagnostics the pedal does not behave as it should, it is worth making an urgent replacement. Indeed, in emergency situations, you simply may not have enough distance to stop the car.

Failure of the “vacuum seal” is a rather rare failure, but unpleasant - to slow down and stop the car, the driver has to press the brake pedal hard. A sudden failure of the mechanism while driving can provoke an accident - the driver does not have time to change lanes and apply the required force at the right time. To identify signs of critical wear of an element, it is proposed to consider the operating principle of a vacuum brake booster (VBR) and diagnostic methods in a regular garage.

Checking the vacuum booster: all methods

There are several effective ways to check VUT. The procedures are simple, you can do it yourself, you don’t need to dismantle anything from the car.

First way

The simplest option:

- start the engine and let it run for about 10 minutes;

- turn off the engine;

- depress the brake completely, creating a vacuum in the booster;

- release the pedal and press it again.

A decrease or heavier pedal stroke when pressed again will indicate problems in the operation of the vacuum pump. On the contrary, if the second pressing occurs without any differences from the first, one can judge the serviceability of the VUT and successful discharge.

Second way

This time, during diagnostics, you should press the pedal several times - 6 or 8. For the last time, press it to the limit and start the engine. If everything is fine with the vacuum system, the pedal should drop even lower - almost halfway. If it does not move, there is a problem with the valve.

Third way

This checks the tightness of the housing. You need to start the engine, squeeze the brake all the way and turn off the engine. If the pedal begins to press on your foot, trying to return to its original position, this will indicate a malfunction. When there is an air leak in the amplifier, the pressure inside the chamber increases.

Fourth method

Here's what else you can do:

- disconnect the hose from the intake manifold;

- plug the fitting with a rubber plug - you don’t have to remove the tube, but simply squeeze it with your hand;

- start the engine, let it run for 10 minutes;

- release the brake.

If the engine speed changes - increases or decreases - the amplifier poisons air and needs to be repaired. First of all, you should check the pinched hose - maybe there are cracks in it. When testing, it is better to remove it and close the fitting securely.

Damage to the vacuum seal requires urgent repair. If you need to dismantle the device, be careful not to damage the tube connecting the amplifier to the collector!

Engine misfire (misfire) when pressing the brake pedal

An air leak through the brake booster can cause misfires while the engine is running. Damage to the diaphragm or internal valve leads to the fact that the optimal ratio of air and fuel is disrupted. Misfire usually occurs when you press the brake pedal while idling.

If checking the vacuum hose, connections and check valve does not reveal anything, you need to perform the following check:

- start the engine at idle speed;

- tighten the handbrake;

- ask another person to press the brake pedal;

- pinch the vacuum hose using pliers (do not forget to place a rag so as not to damage the hose);

- If the engine does not stall and its operation stabilizes, the vacuum brake booster is the culprit for misfires.

Checking engine vacuum using a vacuum gauge

Sometimes the VUT copes well with its tasks, but the motorist still has certain doubts that it is fully operational. If the amplifier on your car did not pass or barely passed the previous tests, you need to make sure that there is enough vacuum. Such diagnostics are performed using a vacuum gauge.

- Disconnect the vacuum hose from the brake booster and connect it through a tee so that you can use a vacuum gauge.

- Start the power unit.

- The sensor should display approximately 400-540 mmHg. Art. If you see a lower value, there is a vacuum leak through the intake manifold (gaskets or crack), hose, engine (cylinder head gasket, etc.) or other components.

Best driving instructors:

Automotive instructor Svetlana Automatic transmission: Hyundai AccentTeaches in Northern Administrative Okrug, North-Western Administrative Okrug, Khimki REVIEWS

Driving instructor Elena Automatic transmission: Chevrolet Lacetti Manual transmission: Chevrolet LanosTeaches in the Southern Administrative District, South-Eastern Administrative District, Vidnoye, Domodedovo REVIEWS

Driving instructor Marina Automatic transmission: Kia Cerato Manual transmission: Chevrolet LanosTeaches in the Northern Administrative Okrug, Dolgoprudny REVIEWS

Driving instructor Elena Automatic transmission: Kia Cerato Manual transmission: Chevrolet LanosTrains in the Northern Administrative Okrug, North-Western Administrative Okrug, Khimki REVIEWS

Driving instructor Natalya Automatic transmission: Kia Spectra Teaches in the Eastern Administrative District, Balashikha, Reutov REVIEWS

Driving instructor Oleg Automatic transmission: Chevrolet Lacetti Manual transmission: Chevrolet LanosTeaches in the Northern Administrative District, Dolgoprudny REVIEWS

Driving instructor Yana Automatic transmission: Kia Spectra Teaches in the Northern Administrative Okrug, Dolgoprudny REVIEWS

Driving instructor Yulia Automatic transmission: Chevrolet Lacetti Manual transmission: Chevrolet LanosTrains in the Eastern Administrative District, South-Eastern Administrative District, Lyubertsy, Reutov, Zheleznodorozhny REVIEWS

Automotive instructor Svetlana Automatic transmission: Chevrolet Lacetti Trains at Northwestern Administrative Okrug REVIEWS

Driving instructor Tatyana Manual transmission: Chevrolet Lanos Automatic transmission: Kia SpectraTeaches in Krasnogorsk REVIEWS

Driving instructor Peter Manual: Daewoo Nexia Trains at Northwestern Administrative Okrug REVIEWS

Automotive instructor Oksana Automatic transmission: Hyundai Accent Teaches in North-Eastern Administrative District, Mytishchi, Korolev, Pushkin REVIEWS

Driving instructor Dmitry Automatic transmission: Volkswagen Golf Manual transmission: Chevrolet Lanos Trains in North-East Administrative District, Northern Administrative District, North-Western Administrative District, Dolgoprudny REVIEWS

Driving instructor Oksana Automatic transmission: Kia Spectra Manual transmission: Chevrolet Lanos Trains in the Southern Administrative District, South-Western Administrative District, Vidnoye, Podolsk REVIEWS

Automotive instructor Dmitry Manual transmission: Lada Granta Teaches in the South-East Administrative District, Lyubertsy REVIEWS

Diesel fuel system air leak

Typically, airing in the fuel system of a diesel engine is caused by damage at the junction of the tubes connecting the fuel tank and filter or the filter and high-pressure fuel pump.

On diesel cars that have been produced in recent years, air penetration into the fuel system occurs more often compared to older type diesel engines. The reason lies in the different design of the hoses, the service life of which has been noticeably reduced. Previously, these elements were made of brass, but now they are made of plastic. Constant vibrations lead to wear of the plastic and rubber seals. Most often, owners of cars with a mileage of about 150-200 thousand kilometers encounter such difficulties, and suction often appears in winter.

The most popular causes of suction in such cases:

- wear of clamps and hoses;

- damage to the fuel filter seal;

- damage to the fuel pump cover seals or drive shaft;

- leaking fuel pipelines;

- damage to the return fuel line;

Signs of air leaks on a diesel car

Most often, the engine does not want to start after long periods of inactivity. The driver is forced to repeatedly turn the key in the ignition using the starter. This is accompanied by the appearance of smoke from the exhaust pipe, which is a sign of normal fuel supply. If the suction is very significant, the engine will not only have difficulty starting in the morning, but also stall while driving.

The reason is that the pump cannot operate normally at idle speed because too much air enters the chamber. At higher speeds, the fuel injection pump copes even more or less well. Such symptoms are not always caused by suction, so we advise you to check the “diagnosis” by installing transparent fuel pipes.

How to find air leaks in the fuel system of a diesel engine

Air may enter the system through a connection, fuel tank, or pipe. The search is performed quite simply - by applying pressure or by exclusion. In the first case, you need to apply pressure to the fuel tank, after which you will hear a characteristic hissing sound or see drops of fuel at the leak point. The second method is to check the elements of the fuel system one by one, ensuring that fuel is supplied from the container, not the tank. First we connect to the fuel pump and move on.