An option for reducing noise or hum from wheel arches is a non-trivial method, i.e. in a way that is not usual for everyone (additional sound insulation of the arch area of the Lada Granta and Lada Kalina 2 with our own hands), we use vibration dampers. This technology for reducing structural noise is used on some business class cars.

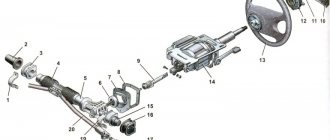

Let's look at the design of the front suspension of the LADA Granta

. The front suspension is independent with telescopic hydraulic shock absorbers, coil springs, wishbones, two braces and a stabilizer bar. The basis of the suspension is a telescopic hydraulic shock absorber strut, which serves as a guide and load-bearing device for the front suspension. The transverse arms of the suspension are connected to each other by a stabilizer bar through struts with rubber and rubber-metal hinges.

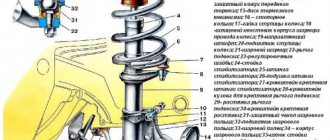

Theoretically and experimentally, it was found that the effect of the vibration damper should most effectively be applied to the shock absorber and to the areas where the levers are attached to the body. The photo shows a vibration damper used for installation on the front suspension side member brackets and a support cup for the shock absorber spring, weighing 350 g. The dimensions are selected to optimally fit into the space. Attached to the existing front spar bracket and directly through the existing hole onto the shock absorber suspension spring cup (depending on the model and brand of shock absorber, wheel offset, tire width - through an existing hole or a newly drilled one with a diameter of 8 mm).

Appearance of the vibration damper on the front suspension shock absorber (on the left is a new-style vibration damper, on the right is an old-style damper):

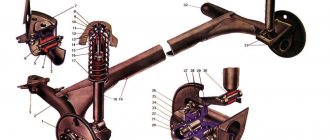

Appearance of the installed vibration damper on the front spar brackets:

Vibration dampers must be used on a car with a technically sound suspension; they do not eliminate all noise, but only reduce their negative influence and impact.

List of useful accessories

for: ✔Kia Rio 3 - link; ✔Kia Rio 4 - link; ✔Hyundai Solaris - link; ✔Hyundai Solaris 2 - link; ✔Lada Vesta - link; ✔Jetta 6 - link;

The mileage at the moment is a little more than 87 thousand km, it's time to update the front suspension. The struts held the blow when hitting large holes, but on the ridge and a series of small holes it was felt that the wheels were losing contact with the road (the wheel bounces due to the fact that the shock absorbers are no longer able to dampen small vibrations), especially on the right, and there were knocks I'm pretty tired of lights out. Before compiling a list of everything needed, I considered three options: 1. Don’t change anything in the suspension, just buy everything new for the Kalina1 suspension. 2. Buy a Kalina1 stand and install a better-designed support from Granta. 3. Install both the stand and support from Granta. After much deliberation, the third option was finally chosen. Since I have a car with a 16kL engine, the so-called “barrel” spring was installed from the factory; the same ones are installed on the Grant. Below is a list of part numbers for the Grant suspension assembly. Taken from Lada Kalina Club.

Front suspension "Lada Grants"

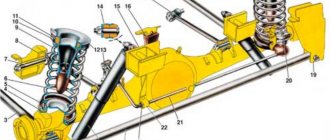

It has an independent suspension with wishbones and a stabilizer bar. Damping of vibrations is carried out by hydraulic shock absorbers. The main structural element is the stand. It includes a swivel bearing, shock absorber and spring. The latter uses coils of variable diameter. The spring itself is made of a metal rod with a circular cross-section. It can have variable and constant hardness.

The pillar support has also been improved. Suspension creaking on the Lada Granta appears much less frequently than on Kalinas and Priors. To reduce roll, the design includes a stabilizer bar. It is made of spring steel. The stabilizer is installed with its ends to the lower suspension arms. Its middle part is fixed to the body.

Oporniki SEVI EXPERT Granta vs SS-20 MASTER Kalina

SUPPORTS 1119 Demfi gas-oil Supports 2190 SEVI Expert Springs 1119 barrel Mubea (Czech Republic) Cups 1118 AK3M (dural) Gaskets 1119 (rubber) Support bearing SKF (France) Studs SS-20 (49mm) Washers: compression (lower) 1118, rebound upper SS-20 (58mm) if the SUPPORTS are BMRT, then put them on rebound from Priora (60mm) on compression (54mm) STRETCHING racks TechnoMaster and AMPLIFIERS of supports Lada-SPORT useful DIAGRAM based on Murzilka

about extras The guy is chasing the puck)) About the boot from 2110 instead of a plastic cap, this is the norm TOPIC. You can find it yourself by the name and numbers ;)

Next comes the agony of choosing between manufacturers; I will give the main examples...

I looked at all the available options for prices and designs. First, on the standard supports for Kalina

I looked at the photo to see how the support rod sits in the cup (burdock) or the spar mudguard. Namely, I was interested in displacement (caster), elasticity, resource, price.

I chose them based on price-quality ratio

So, everyone who knows understands why the support needs to be shifted from the axis of the rack. Increase the caster angle even more +. The maximum can be increased to 3g. You need to remove all the washers or install wishbones. Last year I had a caster angle of 1.30 with these mounts with a 12mm doom offset. get 2 or maybe 2.30. I will definitely remove half of the 4 washers...

So I settled on this support configuration SEVI Expert and Support Amplifiers Lada-SPORT. in the summer, while the roads are strewn with small bumps and small holes, and pothole repairs are making themselves felt everywhere. That’s why I’m tired of the good old SS-20, crushing my teeth and disturbing my butt))

Last year I assembled a gear-crushing suspension in the spring, with excellent handling. FOR HIGHWAYS and smooth roads in the city. But our roads are basically smooth, but I went a little off the road and it was a complete mess ((So this year I decided to pack a ride and try a softer cofig, but on gas-oil struts. The result was COMFORT+, if I may say so

The amplifiers can be seen in the photo. And how come they didn’t think of putting them in at the factory? They save on everything! The burdocks (spar mudguard, to be precise) on Kalina are weak and after 10 years they crack, rust, etc. Reminds me of Samara's disease. Chisel family VAZ-2108-09-99 Sputnik ADA)) And Kalina there too. But still, the rigidity of the body is an order of magnitude greater, about 10500N versus 8000N. And thresholds with holes do not rust so quickly.

Along the supports. I lost controllability, but retained stability due to the struts (fortunately there is an appropriate wheel alignment). But I bought myself inexpensive soft comfortable SUPPORTS. Now I’ll drive like a penser)) but I’ll keep the body longer and I can move the fifth point in comfort. SUPPORTS SS-20 and everything they do at the SS-20 company is treated with LOVE: I RESPECT YOU - RESPECT! No one could do so much for the patronymic in terms of SPORTS on walking for so many years you remain the BEST and indestructible like ROCK 'N ROLL))

This photo is just for comparison. not on the topic of my Kalina’s BZ, but on the topic of the SS-20! By the way, the supports are cracked (like duralumin. Rubber doesn’t care. The bearing there is huge comparatively. And also intact) Why and how the SS-20 supports could crack - THEY STANDED on the dude’s PNEUMA at 2112. They would have stood for a long time if not for the damned BPAN. I am not indifferent to the tall ones, the understated ones, the lowered ones. I wanted to take pictures of all the cracks on the body and distortions such as twisted tips, sawed side members, but the car was sold. so I can say one thing to BPAN lovers - this is PPC. I read snap214 from one user and I’m pressing his conclusions for comparison

Good luck to all! Don't break! And not a nail or a rod! PEACE, KINDNESS and faithful FRIENDS TO ALL! Anyone interested in my blog will be MUTUALLY interested;)

Source

Rear suspension

Unlike the front, it has undergone virtually no changes. Here, just like on the first Soviet G8s, a semi-independent beam is used. It is attached to the body on hinges (fortunately, there are no “crabs” in the design). A helical spring with constant stiffness is used as an elastic element. To dampen vibrations and prevent swinging, two shock absorbers are used.

- High reliability. The design does not have additional levers, which, in addition, can bend when falling into a large hole.

- Energy intensity. The Lada Granta absorbs all bumps perfectly, especially if oil shock absorbers are installed at the rear.

- Cheap maintenance. Due to its simple design, this pendant can be rebuilt even with your own hands. And the cost of new rubber-metal elements is unlikely to empty the pockets of even the most stingy car owner.

The main difference between the “Grant” suspension is the wheel alignment angles.

Innovations in the suspension system

Despite the different types of front suspension designs used (differences depend on the configuration), the developers took measures aimed at improving the performance indicators displayed by the front suspension. So the basic version of the Lada Granta served to create a modification with a more comfortable design of both elements - the front suspension and, accordingly, the rear suspension. Modernization includes:

1. Front suspension:

- the presence of a spring with an oversized coil diameter;

- gas-filled shock absorbers;

- reinforced longitudinal brace structures;

- increase in the diameter of the transverse stabilizer bar by a significant 2 mm.

2. Rear suspension:

- reinforced springs;

- gas-filled versions of shock absorbers.

An addition to the factory tuning was improved sound insulation. Due to these upgrades, the car began to confidently hold onto the road at increased speeds - up to 150 km per hour. Now sharp maneuvers in turns and bad surfaces are not a problem for him.

Shock absorber

This element is a damping device. The shock absorber serves to reduce the range of vibrations of the car body. In other words, the element prevents spontaneous rocking. The work of the shock absorber is based on hydraulic resistance. Inside it there is a liquid of a certain viscosity. It moves through a special valve. Thus, the device absorbs sharp impacts while preserving vulnerable suspension parts. Therefore, the shock absorber is one of the most important components in the chassis. On our roads, this element lasts about 60-80 thousand kilometers. But this period may be shorter, even with careful driving. It is enough just to damage the protective boot, and all the dirt will accumulate in the rod seal.

Supports SS20 gold Kalina 2 and grant with EUR, “HARD”, a story of several days.

Good day to everyone, my dears!

I advise you to read to the end. I wrote earlier that based on diagnostics, we were given supports. The factory ones in the showroom are expensive, so we decided to buy them ourselves and took the SS20 GOLD at the same price as the factory ones, 100 rubles more expensive. I made an appointment for a replacement and wheel alignment, spent 3-4 hours in the service and it was done.

Satisfied, I went home, the road was smooth and nothing bothered me... At the entrance to my area there were speed bumps, bumps and holes, and then my satisfied face changed... All that was left of the quiet suspension was a memory... A clink, noise, dribbling... The feeling that... , the wheels will fall off... I understand everything, the ss20 specializes in a sporty style (that is, a tougher slope), but there are limits to everything and such an effect of the entire suspension being depraved, I did not expect...

I called them (dav-auto) and explained, they offered to come at a time convenient for me to diagnose the entire suspension, without an appointment.

The next day I went to them, everything was checked manually, on a stand, etc. the suspension is ideal, with the exception of the supports (rejected, play in the rotary supports, they gave a conclusion)

and the right ball joint starts to hurt. They changed the ball joint, took it for a spin and all the faults remained. The result is props!

Before the purchase, I read the notes on the drive and everyone is happy with them, but only a few, like me, read the comments and it seems like after the purchase and installation... In a bunch of comments with questions and enthusiastic answers, I found the only one in which the person was very surprised that Everyone writes positively, but in reality he faced the same problem as me.

Result: again replacement with standard factory supports. There is silence and comfort in the car, as if I bought a new one.

I will not recommend ss20 gold! It is possible, not excluding the fact that they work perfectly with racks from the same company, but not with factory ones!

Next, Dove-auto gives the marriage contract and we go to the store to return it. The store accepted (no complaints), but before that they called the management for advice. The management recommended installing the ss20 in a company service center, where they are tested/checked before installation and with the return/replacement everything happens faster... Then the management checks the information, calls Dove-Auto and clarifies whether I installed it correctly from them and whether it passed the diagnostics with rejection. supports After all this, they accept them for examination. There are no exact deadlines and dates for the end of the examination.

Please do not confuse the Management and the store. The store only informed management. There are no complaints about the store, they immediately went to the meeting!

Special thanks to the Altais store on Geroev Khasana 54. Experienced sellers, good relationships, reasonable prices. To the car dealership/car service “Dav-Auto” on the Brodovsky tract, 15 managers (Alexander Fefilov, Alexander Bykov, Daniil Valov) and mechanics (Alexander Grachev, Alexander Trushnikov, Alexander Kovalev, Pavel Matyshev), everything is neat, informative, clean and leisurely, that very important!

The price of my mistake is 7315 rubles. To date. After the examination it may change, or it may remain the same...

To be continued... www.drive2.ru/l/580215035830206890/ (continued) We are waiting for the expert opinion. Based on the results, there will be an entry in the B/F.

Good luck to everyone on the roads and take care of yourself and your loved ones!

Source

Silent blocks

By 100 thousand, the silent blocks of the cross member and lower arms fail. Signs of a malfunction are a dull knock from the front suspension of the Lada Granta. Motorists recommend replacing these elements with polyurethane ones.

The silent blocks of the anti-roll bar also fail. These bushings are also replaced with polyurethane ones.

At least walk

In the city of Zlatoust, about 60% of the territory is occupied by the private sector, and the roads there are dirt, consisting of crushed stone mixed with earth. Driving on such a road is not much fun. If you have ever driven on a washboard, you will understand what I mean. It would be nice to “shake up” on such a path once again, but the specifics of working in a taxi forces you to ride over such potholes many times a day.

If you add to such a shake the unbearable rattling sound that the car makes, you just want to walk. How to deal with this? I can’t “win” the road, so we will “fight” with the source of the chatter.

Photo 1: Lada Granta before starting diagnostics

Cause of malfunction

The main cause of element malfunction is a violation of the boot seal. Once it starts to crack, dirt and dust will get inside. They act on the ball like an abrasive. As a result, play appears and the support begins to break on its own. Is it possible to repair it? The Lada Granta suspension is designed in such a way that the ball joints cannot be restored and must be replaced entirely with new ones.

Obvious benefits

To extend the service life of parts and reduce operating costs, it is necessary to regularly, at each scheduled maintenance, carry out diagnostics of the Lada Granta FL suspension.

Malfunctions are like diseases, the more advanced they are, the more difficult it is to cope with them. Repairing damage identified at an early stage requires significantly less effort and resources than complex repairs. This is true for any car.

Wheel bearing

This element serves for uniform rotation of the car wheels. There are 4 such bearings on the Grant. On average, their resource is 100 thousand kilometers. What are the signs of a problem? The main symptom is a characteristic hum when moving. It may get worse as the car turns. The hum can occur on either side of the car, depending on which bearing has fallen apart. The entire assembly is replaced with a new one, and it doesn’t matter whether the Lada Granta’s rear suspension or the front one. It is pressed out using a puller with special paws. Pressing takes place in a vice. It is important to maintain alignment when pressing. If a bearing is installed crookedly, it will be subjected to high loads and may fall apart after just a thousand kilometers.

Removing the front shock absorber strut and disassembling it Lada Granta

- Driver for socket attachment

- Torx wrench attachment E12

- Torx wrench attachment E14

- Attachment for Torx E8 wrench

- Large flat screwdriver

- Large hammer

- 17 mm straight box spanner

- 22 mm straight box spanner

- 6 mm hex key

- Ratchet wrench

- 13 mm head

- 19 mm head

- Adjustable stop or puller for pressing out the ball pin

- Chisel or marker

- Spring tie - 2 pcs.

- Worm clamp

Parts and consumables:

Remove and disassemble the shock absorber strut when it is necessary to replace the upper support, bearing, spring, telescopic strut. The telescopic stand is non-removable and cannot be repaired. Carry out the work on a lift, but you can get by on a flat platform. There are two options for removing the shock absorber strut. The first allows you to avoid subsequent adjustment of the steering wheel alignment angles, the second method requires less work, but after it requires adjustment of the steering wheel alignment angles. Replace the telescopic stand using the second option.

Removing the shock absorber strut without the need for subsequent adjustment of the steering wheel angles

In the first option, remove the strut together with the steering knuckle, without loosening the nuts of the upper (adjusting) and lower bolts securing the strut to the steering knuckle. At the same time, disconnect the tie rod end from the shock absorber strut swing arm.

1. Disconnect the ball joint from the steering knuckle as described in this article.

2. Remove the outer CV joint from the wheel hub, and also remove the pad guide with the caliper and cylinder.

3. Tie the clamp to the brake hose bracket, making sure there is no tension on the hose.

4. If the strut is to be disassembled, use a 13 mm socket to unscrew the three nuts securing the strut's upper support to the body.

5. Remove the shock absorber strut along with the knuckle.

6. Using a 22 mm spanner, loosen the rod nut while holding the rod from turning with a 6 mm hex key.

Removing the shock absorber strut with the need for subsequent adjustment of the steering wheel angles

To remove the shock absorber strut using the second method, disconnect the tie rod end from the shock absorber strut swing arm.

1. Unscrew the nut securing the ball joint of the tie rod end.

2. Place the adjustable stop under the pin, tighten it and, hitting the swing arm with a hammer, press the pin out of the lever or use a puller to press out the ball pin.

3. Using a 22 mm spanner, loosen the rod nut, holding the rod from turning with a 6 mm hex key, and with a 13 mm socket, unscrew the three nuts securing the upper support of the strut to the body (see point 6 above).

4. If the car is equipped with an ABS system, use the E-8 head to unscrew the sensor mounting bolt.

5. Remove the sensor from its mounting location.

6. Remove the brake hose coupling and sensor wire from the shock absorber strut holder.

7. Use a chisel or marker to mark the location of the adjusting bolt relative to the rack.

With this method, after assembly, the deviation of the wheel camber angle from the original value will be insignificant.

8. Using a 19 mm socket, unscrew the nuts of the bolts securing the strut to the steering knuckle, holding the bolt from turning with a 17 mm wrench.

9. Remove the bolts and take out the shock absorber strut.

The eccentric top bolt is needed to adjust the camber, so do not lose the washer from it, it often sticks to the strut. This bolt must then be put in its place, so do not mix it up. Wheel alignment will have to be done in any case, so remembering the rotation of the eccentric along the axis is pointless.

10. Remove the upper support support plate.

Preparatory procedures

Many car owners are interested in which racks are best to install, as well as how to do everything correctly. Before you repair the front struts, you will need:

- We stop the LADA Granta car using the handbrake and place wheel chocks under the stern wheels.

- Under the hood we find a shock-absorbing support rod, into the hexagonal recess of which, located at the end, we insert a key of the corresponding profile.

- Using the second wrench, we loosen the tightening torque of the nut securing the suspension element to the body. In the meantime, we use a hex wrench to keep the rod from trying to turn in conjunction with the nut.

- We “dive” into the wheel arch of the LADA Granta and find a bracket that holds the brake hose on the strut body.

- We unscrew the specified fastening unit, removing the hose itself from the holding bracket. This will provide space for unscrewing the lower point of the shock absorber strut. You will have to work in tandem with a key “17” size.

You should dare to replace the struts in cases where a leak of working fluid from the shock absorber is detected, as well as if there is a knock, deformation of the rod or destruction of the silent block.

You should remember the rule that implies replacing the struts as a whole on one axis, even if the second shock-absorbing element is in good condition.

Motors

Common problems

Grant's main problem is his service style. The use of the cheapest components and fluids, service literally in Petrovich’s garage, bypass technologies and more.

At the same time, we can safely say about any VAZ engine that it is very good. Maintainability and service life are high, especially if you maintain it as carefully as foreign cars and monitor the control system. The cost of maintenance and repair is minimal.

The design itself is extremely simple and has no obvious weak points. Almost all regular problems are due to not very successful components, and not to the design. Well, relatively often you come across motors with obvious defects - for 40 years the quality control system has not been fully established.

“Minor” electrical troubles are present in full - from poorly laid wiring to the service life of fans and sensors, weak connectors in the engine compartment and crooked radiators. And even branded thermostats have to be changed on a schedule, every second year, often together with expansion tanks after the first three years of operation. And if you’re unlucky, then right away.

Eight valve engines

The majority of cars are equipped with eight-valve engines of the 11183 and 11186 series. The simplest engine, 1183-50, is in practice one of the most durable. And even though the factory claims that it only lasts 200 thousand, in practice the service life is usually at least 300, and this is with the odometers constantly being twisted (most likely the market is full of copies with real mileage “over 500”). In any decent oil and under almost any load, except extreme.

A heavy piston group and an old timing mechanism with a wide belt look unfashionable, but in practice the fact that the engine is “not plug-in” and the service life of the piston group is very good outweigh almost all the positive factors of the modernized 11186 engines. Even a mechanical throttle with a troublesome IAC and an old thermostat in practice, there are not such terrible disadvantages, except that the consumption is higher and a little more hassle. But on 11186, during repairs, they often install just the old piston group, because the difference in fuel consumption and power is small, but it does not bend the valve, and you don’t have to worry about oil leaks. And if you need agility at the top, then there are 16-valve engines.

Unfortunately, there are also disadvantages here, and many. Almost everyone is familiar with VAZ cars of previous generations. The engine regularly leaks along the valve cover, it has a low resource of ignition modules, a short service life of the DPKV, a simple VKV, it constantly requires small hands, since the attachment requires regular checking. The fasteners either sour or unscrew, the valve clearances go away quite quickly in modern times, you need to check them every 30 thousand, the speed fluctuates, and the catalytic collector is rough and cracks.

Motors of the 11186 series are a product of deep modernization of the 83rd family. There's a new piston group from Federal-Mogul, fancy T-shaped pistons and lightweight connecting rods, as well as new liners. New sealed timing case so that the belt can last 120+ thousand kilometers. The new thermostat is installed directly on the cylinder head. The throttle is now electronically controlled. It is all optimized, lightweight and... ultimately more sensitive to oil change intervals and its quality, and after 200 thousand it easily falls into the sin of oil-guzzling.

True, there is usually no wear on the piston group, and decarbonization helps a lot. It has more delicate ignition coils, and the spark plugs should be changed more often. Its valves bend when the timing belt breaks, and the timing mechanism has not become super reliable, it just works a little quieter, but it’s still better to change the belt every 60 thousand, because it may not live up to 90, and it definitely won’t live up to 120, especially since the pumps The quality hasn't improved much.

New thermostats are unexpectedly no better in quality than old ones, but more expensive. The leapfrog with replacements begins even at mileages of up to hundreds of thousands. And the temperature sensor in the thermostat housing initially had a bad habit of leaking. The problem was fixed quickly, but the sensor is still being “ground in” in the housing.

A new fuel pump and power supply without “return” are a little simpler than the classic scheme, but the RTD is located in the tank, on the pump flask, and any replacement causes a lot of trouble. And the quality of the RTD is not at all foreign-made; the fuel pressure fluctuates noticeably even on new cars. Later versions have modernized “stickless” pistons and the same performance characteristics, but the other shortcomings have not gone away. One of the clear advantages is that the engine is noticeably quieter, and fuel consumption is lower than that of the 1183 family by almost a liter on average. In general, this is a good option for the development of eight-valve engines.

16 valve engines

16-valve engines are represented by variants 21126 with 98 horsepower, which are also equipped with cars with automatic transmission, and the newer 21127 (only cars with AMT). The newer engines are not only a little more powerful (as much as 106 horsepower), but also have a significantly redesigned design with a new adjustable intake manifold, a new control system with an absolute pressure sensor, as well as minor changes to the attachments and cylinder head.

Motors 21126 are a very successful “Prior” motor. With good power, boost reserves and quite resourceful. Like all 16-valve engines, it is equipped with hydraulic compensators, and also has a “federal” piston group and an optimized timing mechanism.

Actually, the shortcomings of the motor are a continuation of its advantages. Poor oil drainage from the pistons and slight coking, a high-temperature thermostat as much as 104 degrees, a timing mechanism with a thin pin, not very durable rollers and a pump and a thin belt in combination with “butt-in” pistons cause a lot of dissatisfaction.

The engine requires high-quality and regular maintenance, good oil and control. With 250+ miles and typical Zhiguli maintenance, oil appetite can no longer be attributed to leaks. And you need to constantly monitor the timing belt, the quality of the components is very unstable, belt breaks have happened at 40 thousand miles, and you shouldn’t ignore the howling of the pump or rollers, even if the car is completely new.

You can install a thermostat at 85 degrees, STK plug-free pistons, a high-quality pump and a reinforced belt - these are the main areas of improvement, in addition to updating the firmware. The latter, by the way, is not of the best quality in principle, from the point of view of driving pleasure. With noticeable delays in traction work, and the consumption is not so low, especially with an automatic transmission. As a result, engine performance can be significantly improved and the risk of serious breakdowns can be reduced.

"Shesnari" is significantly more complicated and more expensive to operate than 8-valve options, but the difference in power is clearly noticeable. In addition, the shortcomings are completely removable, and tuning fans adore it. Since July 2022, the piston group has been updated, pistons cost from 21129, and the valves no longer bend when the timing is out of order.

The engines of the 21127 line are newer, they have better VSKh, lower consumption, and the build quality has noticeably improved in recent years. A more complex intake manifold made it possible to make the engine noticeably more torquey at the bottom and a little more powerful, now the engine is more torquey than the old eight-valve engines.

The control system with an absolute pressure sensor is almost not subject to aging, while the mass air flow sensor is highly dependent on the cleanliness of the intake air, and the Bosch thin-film sensor is almost impossible to clean without opening it. Otherwise, it has the same disadvantages and advantages as 21126.