The windshield cleaning system on your car should be serviced periodically. This is necessary for its proper operation, because the system can fail at the most inopportune moment. To prevent this from happening, you need to follow a few simple recommendations. Let's look at how the wiper motor is serviced and repaired, what are the weak points of the system and what to pay attention to first.

Road safety comes first

Whatever electronic security systems the car is equipped with, it is necessary to monitor it all. As practice shows, the least attention is paid to wipers and elements of this system.

Many people ignore the symptoms of failure of the same motor, wiper blade or injectors. As long as it works, it's good. That is why the system remains maintenance-free from purchase to sale of the car. However, the wiper motor has its own specific resource, which increases significantly if the unit is periodically serviced.

Possible breakdowns

Various factors can cause a windshield wiper motor to fail, leading to disruption in the connections between the brushes and the commutator, a wedge in the gearbox, unstable operation of the motor, etc. At the same time, the windshield wiper motor does not always require replacement, leaving the possibility of maintaining the working condition by correcting the position system components - this applies, for example, to a bimetallic fuse. Malfunctions in speed modes usually result from failures in resistors or switches.

Problems with brushes can also be eliminated by simple manipulations with the stopping mechanism - in most cases, their adjustment allows you to restore the functionality of the cleaning elements. Aesthetic problems, including squeaking, grinding and other unpleasant sounds, are almost always solved by cleaning the brushes themselves. In addition, dry glass also leads to unfortunate noise.

Wipers do not work: ways to fix the problem

In the event of a failure of this unit, it is recommended that you first pay attention to the mounting block and the integrity of the fuse and relay. If everything is in order there, then we move on to the next stage. When fluid is not supplied to the windshield, you should immediately check the lines. It is likely that one of the tubes has come off the tee and the washer fluid is simply pouring out under the hood.

Correcting this situation is quite simple. It is necessary to remove the trim under the hood and connect the hose to the tee. In some cases, the procedure can be performed without dismantling the protection, simply bending its edge.

After checking the lines, we move on to the injectors. Over a long period of use, they can become clogged. To clean them, you can use the most ordinary needle. If after this the wipers do not work, then we move on to the motor.

Methods for attaching brushes

Before 1999, most car manufacturers used a type of mounting for OEM windshield wiper blades called a "hook" or "hook". This is a universal device in the shape of the letter “U”, which allows you to snap the brush into place and not worry about the reliability of its installation. The following types of mounts are currently gaining popularity:

- Side pin - appeared in 2005 on BWM, Volvo and other cars. Allows brushes to be fixed using a special 22 or 17 mm side pin.

- Button or “Push Button” is an adapter for standard 16 mm wide wiper blades. It is enough to snap the device into place for fastening, and to remove it you need to press a special button.

- Pin lock - fixation of brushes using a special built-in lock. Used in Audi cars.

“Push Button” mounting scheme

Despite the relative simplicity of windshield wipers, it is difficult to imagine a modern car without them. Drivers can control the operation of the wipers directly from the cabin, remove dirt and improve visibility of the road situation. And electronic systems automatically monitor the cleanliness of the glass, increasing the comfort and safety of driving without human intervention.

Source

Windshield wiper motor repair

In most cases, this unit is maintenance-free, that is, not dismountable. But this does not stop experienced motorists. This is especially true in cases where there is no extra money for a new motor. To do this, take a metal cloth. It is necessary to cut the motor at the transition point (step). We separate it into two parts and see the armature, winding and core.

All these parts are usually not in the best condition and usually show signs of corrosion. It is necessary to thoroughly clean the motor elements. Fine-grained sandpaper or another similar product is suitable for this. For example, the VAZ wiper motor has such a weak point as the oil seal. Over time, it cracks and leaks liquid into the body, causing the parts to become covered with dirt and begin to rust. This may damage the device.

What is a windshield wiper motor?

How to stop wipers squeaking on a car window

All cars, trucks and other vehicles are already equipped from the factory with mechanisms for cleaning glass, including windshield wiper blades. In its standard form, it consists of two holders with rubber bands on the windshield and one holder on the rear window (for cars with a station wagon or hatchback body). All windshield wipers have three modes of operation, during which they move quickly, slowly or at an intermittent pace.

All windshield wipers are equipped with a special electric motor with geared torque transmission. Two mechanisms designed to operate the windshield wipers are attached to the motor shaft. One rotates the wipers to a certain position on the windshield, and the second is responsible for moving the wipers to their original position. The lever system supports the wipers throughout operation.

In fact, the electric motor rotates without stopping, and a special mechanism is responsible for moving the wipers, which allows them to rotate and quickly return to their original position. This mechanism is called a trapezoid wiper. It consists of a set of levers that move the wipers across the windshield.

In addition to the windshield wipers, the glass washer system is also responsible for a normal view of the front of the road. It is a tank with a special liquid, which, under the action of a pump installed in the tank, is pumped into the system and sprayed on the windshield

It is extremely important that these mechanisms are always in good working order. This is due to the fact that on the planned day of the trip the weather can easily turn bad and driving with a faulty windshield wiper system can become very dangerous.

Rubber seals

Gaskets and seals are made of rubber. Over time, they lose their positive properties. Due to temperature changes, they become tanned and crack; this also happens due to an aggressive environment. For this simple reason, seals need to be changed periodically.

If you do not do this, it is quite possible that the device will fail. The next time you service the glass cleaning system, it is advisable to change the seals and rubber gaskets.

Don't forget that the wiper blades themselves are also rubber and should also be checked regularly. Often replacement is performed once a year. If the brushes are made of silicone and of high quality, then they can last a couple of years, but hardly more. This is due, again, to temperature changes.

Checking the functionality of the mechanisms

How to give new life to worn out windshield wipers.

how to change rubber bands on frameless wipers: video instructions and advice from professionals replacing rubber bands in frame wipers At the repair stage or during a preventative check of windshield wipers, you can identify problems in the device in several ways. The quality of the mechanism is primarily determined by the function of the brush and its position in the brush holder. The cleaning elements must move freely and easily at the specified speed. The electric motor itself is checked by a tester. In particular, such diagnostics makes it possible to detect irregularities in contacts and connections. When disassembled, the device allows you to evaluate the condition of the gearbox gear - in particular, the mentioned teeth and threads on the rollers are checked. The remaining components can be checked with the naked eye, even with a superficial inspection.

Replacing the wiper motor

If you don’t have the time or desire to do independent repairs, then you can simply purchase a new motor and install it in place of the old one. But first of all, you need to make sure that it is faulty. Often the problem is in the wiring, a fuse has burned out or the contacts have oxidized. All this can lead to the fact that the motor will not show signs of life.

We check the wiring where it connects to the motor. You can also use a multimeter. If voltage is supplied to the contacts, then the problem is in the motor itself. If not, then first check the condition of the fuse, and then look for an open circuit.

All these procedures will not take much time, but there should be a result in the end. For such work, a service station can charge several thousand rubles, or even more. Therefore, it makes sense to do this yourself. If the problem is still in the motor, then it needs to be changed or repaired.

What are rear wipers: main types

1. In what cars are they used?.

This type of windshield wiper is installed on the windows of many station wagons and hatchbacks. This need can be explained quite simply: road dirt flies onto the rear window due to the specific shape of the car body. However, drivers use it infrequently; they only remember it when driving backwards, when parking. At the same time, the brush is constantly covered with dust and hard particles that can ruin the wiper blade. Replacement is usually carried out once or twice a year.

2. Original and non-original.

Original parts for a car are those that are manufactured under the brand name of the vehicle manufacturer. For example, windshield wiper blades produced by Bosch or Valeo under their own brand are so-called non-original. However, the same Bosch or Valeo devices in a box with the BMW logo are already considered original and cost an order of magnitude more.

Popular companies that produce car components make custom-made windshield wiper systems, which car manufacturers then sell under their logo for much more. For many vehicles, you can purchase a rear window wiper from Bosch, SWF, Valeo or Trico. However, for some brands of cars such a rear wiper does not work, because they have a rather unusual blade that can only be replaced with an original device. For example, Honda Pilot since 2008, Opel Antara.

3. Models and method of mounting the windshield wiper.

According to the structure, the rear window wiper is available in frame, plastic, or frameless. The method of attaching the rear windshield wiper blade is non-standard, so installing a frameless blade instead of a frame one will not work.

- Frame brushes.

The rear frame wiper is a short brush (regular, frame), which is fastened with a hook. This type of windshield wiper blade is typical for cars manufactured before 2000 and some modern brands. There are options when the hook has a standard look or one that is installed on the “classic” one. It happens that this type of brush without a plastic adapter is inserted directly into the leash, for example, like on a Range Rover.

Drivers who want to change the frame type of brush to a frameless one should pay attention to the fact that if its fastening is a simple hook, the replacement cannot be made. As a rule, the leash is installed quite close to the rear window and can interfere with the installation of the frameless type of windshield wiper blade, because it is higher than the frame type due to the plugs.

For example, these cars are equipped with a rear frame wiper: Nissan Juke, Ford Focus I, Chevrolet Lacetti and Trailblazer, Range Rover, Mercedes-Benz G-Class, X-Trail T30, Smart, Honda CR-V until 2006.

We recommend

“Frameless wipers: rules for selection and operation” Read more

- Plastic wipers for rear window.

Many modern cars have a rear wiper with a plastic frame. The brush is mounted on a plastic leash, and outwardly they look like a single unit. A distinctive feature of such a device is a special fastening, which comes in several types, but in fact there is no guarantee that they will fit, without having common fastening standards.

In most cases, to remove the rear brush, you need to open the arm, then bend the wiper approximately 30° and, with some force, snap it off the arm. Some Lexus crossovers are equipped with a nut that must be unscrewed to remove the rear windshield wiper.

We list the vehicles that have a plastic brush: Toyota Rav4 until 2012, Ford Focus II, Mazda 3, Nissan Qashqai, Kia Sportage, Honda CR-V, Opel Astra, Corsa, Skoda Octavia, Nissan X-Trail, Note.

- Frameless rear wipers.

Such models are not equipped with a spoiler and have a rather low profile. At the same time, the fastening of frameless brushes is quite non-standard. Recently, some vehicle manufacturers have begun installing special frameless wipers on modern cars instead of plastic ones.

For example, they can be seen on the BMW X5 E70, Volvo XC70, XC90, Skoda Fabia since 2006.

Malfunctions of the steering column switch

This unit often fails on cars with high mileage. It is usually maintained throughout the entire life of the vehicle. Over time, the contacts burn out, which becomes the main reason for the malfunction of the steering column switch.

You can either repair it yourself or simply replace it with a new one. The second option is naturally expensive. Depending on the make of the car, the switch can cost from 2 to 20 thousand rubles. In this case, it is quite logical to do repairs, especially since there is nothing complicated about it.

We dismantle the switch and carry out a visual inspection for defects. If there are burnt contacts, then take a soldering iron and correct the situation. Almost always, the steering column switch can be repaired, the only exceptions being cases of board failure, although there are craftsmen here too.

Instructions for replacing the windshield wiper motor

If, as a result of diagnostics, you determine that the windshield wiper motor does not work, then the failed unit will need to be replaced. There is nothing difficult about this; even a beginner can cope with this task. But you need to take into account that the replacement procedure may be different for a particular vehicle. Therefore, before changing the unit, familiarize yourself with the technical features of the system and read the service manual for the car. We will describe the procedure using the example of a traditional VAZ.

How to properly change the rear or front wiper motor:

- First, you need to unscrew the nuts that secure the windshield wiper arms; to do this, use a wrench. After this, remove it from the installation site. If you are having trouble dismantling at this stage, try using a penetrating lubricant.

- Next, the wiper lever drives are removed; to do this, the nuts securing them must be unscrewed. Having done this, you can dismantle the plastic bushings, as well as the rubber seals.

- After performing these steps, you need to disconnect the connector with the wires in the harness and lift one part of the seal through the hole formed in the partition of the engine compartment.

- Now you can remove the wiper itself. Subsequently, the washer is removed from it, as well as the spring fastening. After completing these steps, you will need to disconnect the pull rod. Next, all you have to do is unscrew the three screws that secure the electric motor and remove it. The unit is repaired and put back or replaced with a new one.

Loading …

Price issue

1. Electric wiper motor for Toyota (average price - 900 rubles)

2. Device for VAZ (price - around 600 rubles)

3. Unit for the Kia Ceed car (price - about 1500 rubles)

Let's sum it up

The price of a windshield wiper motor varies significantly depending on the car. Usually it costs several thousand rubles for a VAZ and more expensive for foreign cars. If only the pump is changed, then everything is simpler. When the entire assembly with the electric motor is replaced, the cost of such pleasure is not small.

In any case, it makes sense to audit the system, find faulty parts and try to repair them; if that doesn’t work, replace them with new ones. It is worth highlighting the following main malfunctions of the glass cleaning system according to the main features:

- The wipers do not work at all speeds - most likely the fuses have blown or their contacts have oxidized;

- the system operates only in intermittent mode - the relay may fail;

- the gearbox works, but the brushes do not move - the gear teeth are licked or the nut securing the crank on the gear is not tightened.

As for other breakdowns, everything is individual. In one case, the problem may lie in a faulty nozzle, in another - in the pump. A thorough inspection from small to large will in any case lead you to the unit that has failed.

For example, the rear wiper motor breaks down extremely rarely, since it is not used so intensively. Modern cars are equipped with one pump for both the windshield and rear window. This simplifies the task somewhat, because the fewer parts in the assembly, the more reliable and simpler it is.

Operating principle and purpose of the motor

The windshield wiper motor is one of the main components of the entire system. Its purpose is to ensure the movement of the brushes along the windshield and rear window (if we are talking about a hatchback or station wagon). The windshield wiper motor itself supports operation in several modes - slow, intermittent, and the fastest.

In general, the design of the wipers includes an electric wiper motor with a gearbox, a unit that returns the blades to their place, as well as levers and the brushes themselves. As a rule, a washer device also functions with the brushes, providing water supply to the glass. The windshield wiper motor itself is considered one of the most unreliable components, which fails quite often.

Electric motor for the domestic "ten" in removed form

Do-it-yourself windshield wiper repair

Windshield wipers, better known as windshield wipers, are not vital vehicle systems. But their breakdown causes serious inconvenience in bad weather and threatens traffic safety due to poor visibility. Fortunately, most windshield wiper malfunctions can be fixed fairly quickly with your own hands; repairing them is much easier than, say, repairing an automatic transmission.

Windshield wipers, better known as windshield wipers, are not vital vehicle systems. But their breakdown causes serious inconvenience in bad weather and threatens traffic safety due to poor visibility. Fortunately, most windshield wiper malfunctions can be fixed fairly quickly with your own hands; repairing them is much easier than, say, repairing an automatic transmission.

Photo report on the removal and installation of the windshield wiper trapezoid on a VAZ 2110-2112

When all the preparatory steps are done, everything will look something like this. The arrows at the top show the attachment points of the two nuts:

You need to unscrew them, of course.

After this, we disconnect the clamp securing the expansion tank and, lifting it up a little, move it to the side to gain access to the third trapezoid mounting nut.

After this, the nut can be unscrewed; it is located at the very bottom:

After you have dealt with this, you can carefully turn the trapezoid and remove it from the left side, slightly bending the metal frame below the windshield to the side ( the force required is very small - there is no point in talking about any real bending!

)

And lift it almost all the way to take it out:

All that remains is to disconnect the power plug:

And now you can finally remove the entire structure of the trapezoid and the wiper motor from the bore. If you need to disconnect and replace one motor, then in principle there will be no difficulties with this - just unscrew it and replace it.

Installation of all removed parts occurs in the reverse order. It is worth mentioning the prices of these spare parts. The cost of a trapezoid assembly with an engine for a VAZ 2110 is about 2000-3000 rubles from the manufacturer AvtoVAZ. Chinese analogues cost about 2000 rubles.

First of all, it is necessary to de-energize the system. To do this, simply disconnect the negative terminal on the battery.

- set the wiper arms to a vertical position;

- unscrew the nuts and remove them from the rollers;

- remove protective caps;

- twist the nuts (one on each side) securing the brackets at the top;

- dismantle the rubber sealing washers;

- in the engine compartment, remove the wiring harness from the connector;

- unscrew the bolts holding the lower part of the bracket;

- the mechanism rollers are removed from the holes;

- unscrew the nut securing the windshield wiper crank and remove it;

- dismantle the bolts holding the wiper gearbox and the motor in place;

- disconnect the wires from the bimetallic fuse and remove the engine from the bracket.

All that remains is to remove the locking ring and adjusting washers from the gear shaft and install a new motor. Assembly is carried out in reverse order.

The windshield wiper itself must also be moved slightly to the left before removal.

It is better to number the adjusting washers so that they are not confused during assembly.

How to speed up the work of Priora wipers

The problem of slow windshield wipers appears over time. The speed may decrease several times; the windshield wipers begin to move slowly even on wet glass covered in rain. There are three reasons for the malfunction:

- engine malfunction;

- poor performance of wiper hinges;

- problems with the engine power supply.

Motor malfunction may be due to worn brushes or bearings. But the wiper motor is quite reliable, so more often the reason is in the hinges or power supply.

The operation of the hinges can be adjusted using high-quality lubricant. To do this, you need to remove the trapezoid with the motor, wash the hinge joints and apply a lubricant that does not thicken at low temperatures.

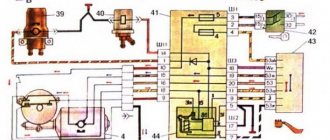

Power supply problems are solved by updating the Priora windshield wiper circuit. The wiper switch circuit contains many electrical connections and contacts that oxidize over time. As a result, there is a drop in the voltage supplied to the wiper motor, and it does not develop the required power.

Modification of Priora wipers by installing a five-pin electromagnetic relay, which minimizes current losses in the power circuit.

For this you will need:

- 5-pin relay - 3 pcs.;

- 5-pin relay motor connector;

- round terminals - 5 pcs.;

- wire with a cross section of 2.5 mm.

The connection diagram involves installing three relays in the wire gap in front of the windshield wiper motor and does not make changes to the standard car wiring (Figure 1). As a result, the voltage supplied to the engine through the contacts and switches of the wipers only controls the activation of the relays, which supply the on-board network voltage to the engine without loss.

Particular attention should be paid to the insulation of the contact wires. The relay unit must be installed in a suitable plastic case and the holes sealed to prevent moisture from entering, which can cause oxidation of the contacts and damage to the relay.

This solves the problem of slow operation of the wiper motor.

When using the Priora windshield washer, the wipers make four passes instead of two, as on most cars. The first two cycles the wipers scrape dirt and water from the glass, and the last couple of cycles the wipers move over dry glass. As a result, accelerated wear of the rubber bands occurs, and scratches appear on the glass. This “bug” can be corrected by modifying the Priora windshield wiper. It consists of modifying the windshield wiper relay, after which the number of strokes will decrease.

Removing the windshield wiper trapezoid assembly with the motor on a Priora

The first step is to remove the wiper arms, as well as the rubber seal on the top of the hood. After this, using a thin knife, we pry off the decorative plugs, under which there are screws securing the frill.

Under these plugs we unscrew the screws securing the frill.

Now, again, on the left side, unscrew several screws securing the insulation to the frill, as shown in the photo below.

After which you can remove one part of the frill:

Also, loosen the clamp bolt on the thin hose of the expansion tank and remove it from the hole in the insulation:

The engine compartment insulation is also attached from below, which is not very clearly visible, but in the photo below this screw is quite clearly visible.

Now you can lift the expander up and move the insulation section to the side, as shown in the photo below.

Now you can begin to unscrew the mounting nuts and bolts of the motor with the trapezoid. Top left:

And top right:

But to get to the trapezoid mounting bolt in the bottom center, you must first unscrew and remove the expansion tank mounting bracket. Two mounting bolts are located on top, as can be seen in the photo:

And two more bolts on the inside of the wing, of course, after first removing the fender liner.

Now the platform can be removed and the last bolt securing the Priora trapezoid can be unscrewed.

Now we carefully remove the entire assembly, finding the desired position so that the trapezoid does not cling to the body and heater housing.

There is still one thing left to do - disconnect the block with the power wiring harness.

Now the entire trapeze assembly with the motor can be removed without any problems.