Windshield wiper motor - what is it and how does it work?

Modern cars are equipped with two windshield wipers, which for the front window have a double design (there are two rubber bands on the blade for more efficient operation), and for the rear window - a single version. Most windshield wipers operate in three main modes. These modes are intermittent, slow and fast operation.

A windshield wiper includes in its design an electric motor with a gearbox, a system of levers, brushes and a mechanism that automatically returns the car wipers to their original position. The windshield washer operates simultaneously with the cleaner. When this small but important mechanism stops working, you should not hesitate to fix it, because the weather is rarely predictable.

Technical characteristics of the gearmotor

Shaft rotation speed at supply voltage 14 V,

moment 0.15 kgf.m

and ambient temperature 25±10°С, min –1

Current consumed under these conditions, A, no more than:

at first speed

at second speed

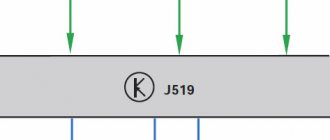

The purifier has three operating modes, they are activated by the right steering column switch.

Intermittent mode is provided by an electronic relay K2 type 524.3747 installed in the mounting block. This relay also turns on the wiper motor at low speed when the windshield washer is turned on.

The relay must ensure that the electric motor is turned on with a frequency of 14±4 cycles per minute at a gearmotor shaft speed of at least 20 min -1, a temperature of 20±5°C and a supply voltage of 14±0.2 V.

When the cleaner operates at low speed in constant mode, the supply voltage is supplied to diametrically opposed brushes.

When the cleaner operates at maximum speed, “+” power is supplied to the brush located on the side.

To relieve the load on the contacts of the ignition switch, the cleaner is connected through an additional relay K6 in the mounting block.

It is recommended to replace a faulty gearmotor with a new one (cleaning the commutator, limit switch contacts and replacing gears is possible).

Windshield wiper motor repair - how to determine the cause of the breakdown?

There may be several reasons why the windshield wiper does not work; we will consider common situations below. First of all, there may be no contact between the commutator and the brushes. If, after disassembling the electric motor and cleaning the contacts, the fault has not been resolved, then in this case, most likely, repair of the windshield wiper motor is necessary, but there are several other options that are worth checking before drastic measures are taken.

If the levers are jammed or the gearbox is stuck, the bimetallic fuse may trip. Then your system will also not respond to attempts to turn it on. Naturally, by adjusting the position of these components and replacing the fuse, this problem can be solved. After correcting the problem, the windshield wiper should work normally.

Sometimes this mechanism begins to function at only one speed. In this case, the switch or resistor is most likely faulty. The brushes may not be installed in the lower position; to do this, it is necessary to adjust the stopping mechanism. There are often situations when, when you turn on the windshield wiper, extraneous sounds appear in the form of creaking or grinding. If this is not due to the dryness of the glass or the presence of sand under the rubber brushes, then, apparently, something is acting up inside, so it’s time to look deeper.

The structure of the windshield wiper is not complicated. The brush levers are attached to the fingers, which may be the first suspected source of extraneous sounds. As a rule, they sour in the bracket bushings due to protection violations when water and dirt get inside. If the device passed this test successfully and the sound remains, then repair or replacement of the windshield wiper motor is necessary.

In order to remove the motor, you need to de-energize the electrical system, and only then can it be dismantled.

Replacing a windshield wiper motor - how to remove the device?

Sometimes the rear wiper motor, just like the front one, simply fails. It is unlikely that this will be a frequent breakdown, but if it catches you, there is nothing you can do, you will have to figure it out. In order to repair the device, it must be removed, and this is a rather labor-intensive process. As an example, classic VAZ models are usually given, which most fully demonstrate the entire technical process. So, removing the motor takes place in several stages:

- The nuts that secure the brush arms are unscrewed, after which they can be removed from the cone splines of the drive. If this is difficult to do, a penetrating lubricant can be applied to the splines.

- The drives of the brush levers are dismantled by unscrewing the fastening nuts, and then the plastic bushings and rubber gaskets are removed.

- The block of wires in the harness is disconnected and removed by lifting the edge of the seal through the slot in the partition of the engine compartment.

- The next step is to directly remove the wiper. Then the washer and spring clamp are unscrewed from it, and the rod is disconnected.

- After unscrewing the three mounting bolts, you can remove the motor.

After a visual inspection, all unusable parts should be replaced. If restoration is not possible, then you should purchase a new motor. Reassembling the entire glass cleaning system is carried out in reverse order.

How to check the rear wiper motor

Hello again everyone.

If you remember, I told you how I went to a disassembly site and bought rear ESPs and a windshield wiper motor there. First I checked it with a multimeter to rule out the possibility of a faulty steering column switch or wiring.

When purchasing, I looked at the differences between the old and the “new” motor. The “new” one has a wire coming out of the relay and is already connected to it, while the old one had the wire connected directly to the relay. Moreover, the plugs themselves are different. Therefore, he also took the other part (dad).

And finally I decided to replace it.

I haven’t had the rear trim for a whole year now) Since Shumka last summer, I still can’t install it. Therefore, I skip the step of removing the trim from the building door.

We remove the wiper, unscrew and remove the motor. We put a “new” one in its place, put on a wiper (I bought a Bosch Eco for 130 rubles, the length is like 45 cm).

Now let's do the wiring. We remove the terminal from the battery and reluctantly cut the 4 wires... put on heat shrink, twist it with the mating part. We heat the heat shrink. All. It turned out quite beautifully and reliably.

We connect and voila, everything works. I was blown away, it was so simple. Almost for the first time)

The windshield cleaning system in your car should always be in working order. After all, no one knows when to turn on the wipers, and the driver’s safety while driving largely depends on them. We will tell you more about how to change the windshield wiper motor yourself and in what cases it is necessary below.

Disassembling the gearbox

If the wiper does not work due to contamination of the gearbox, then it will not be difficult to clean it. But under no circumstances should you unscrew the adjusting screw installed in it - otherwise you will most likely not be able to properly restore the armature clearance later.

The procedure is as follows:

- remove the protective panel from the gearbox;

- remove the gear;

- take out the cage nuts, having first unscrewed two bolts;

- The gear housing is disconnected together with the brush holder from the motor;

- the anchor is removed and cleaned with a compressor.

Removing the rear wiper generally follows the same algorithm, but you will also have to remove the door trim to get to the wires and other elements.

Operating principle and purpose of the motor

The windshield wiper motor is one of the main components of the entire system. Its purpose is to ensure the movement of the brushes along the windshield and rear window (if we are talking about a hatchback or station wagon). The windshield wiper motor itself supports operation in several modes - slow, intermittent, and the fastest.

In general, the design of the wipers includes an electric wiper motor with a gearbox, a unit that returns the blades to their place, as well as levers and the brushes themselves. As a rule, a washer device also functions with the brushes, providing water supply to the glass. The windshield wiper motor itself is considered one of the most unreliable components, which fails quite often.

Applicability

| Brand | Model | Name according to auto catalog | Drawing |

| VAZ | VAZ-2108 | Gearmotor | Body / Window and rear window |

| VAZ | VAZ-2109 | Gearmotor | Body / Window and rear window |

| VAZ | VAZ-2109 | Gearmotor | Body / Window and rear window |

| VAZ | VAZ-21099 | Gearmotor | Body / Window and rear window |

| VAZ | VAZ-21099 | Gearmotor | Body / Window and rear window |

| UAZ | UAZ 3160 | Electric motor with gearbox | Body / Window and rear window |

| UAZ | UAZ 31519 | Electric motor with gearbox | Body / Window and rear window |

| IZH | IZH 2126 | Electric motor | Body / Window and rear window |

| IZH | IZH 2717 | Electric motor | Body / Window and rear window |

| UAZ | UAZ 31512 | Electric motor with gearbox | Body / Window and rear window |

Where else is the spare part used?

The parts data presented on this page is for informational purposes only.

Download price lists

To download price lists, you need to log in. If this is your first time on the site, please fill out the registration form.

Main malfunctions of the mechanism and ways to eliminate them

When is windshield wiper motor repair required?

Before removing, checking the motor and replacing it, familiarize yourself with the main faults of the unit:

- The device does not function, the safety element does not work either, but its integrity does not work. In this case, you must first diagnose the integrity of the wiring and contact connections, and if damage is detected during the diagnosis, they must be eliminated. If everything is fine with the wiring, then you need to check the steering column brush switch; it is quite possible that it has failed. Naturally, the problem may also lie in the electric motor, for example, its contacts are burnt or the brushes are acidified; if this is the case, then it will need to be repaired or replaced. It would not be superfluous to diagnose the wiring that goes to it and the block. It is recommended to clean the safety element or replace it if cleaning does not produce results. If after performing all these steps the system still does not work, then you will need to diagnose the integrity of the winding of the so-called motor armature. If the diagnostics show that the circuit is missing, then either the armature or the entire electric motor assembly is replaced.

- The brushes do not work, while the safety element is working, and the fuse in the power circuit regularly fails. In this case, the levers are diagnosed - perhaps they cannot work as a result of deformation or freezing of the brushes to the windshield. It is much worse if the failure of the unit is caused by a short circuit in the armature circuit, then you will have to decide what to change specifically - the armature or the gear unit.

- The device does not operate in intermittent mode. As a rule, such a malfunction is caused by a failure of a relay or switch. In both cases, it is better to replace the failed mechanism.

- The wipers operate intermittently but do not stop. In this case, the problem, as a rule, lies in the inoperability of the relay or limit switch. If the reason is the switch, then most likely the spring plastic is not pressed to the end by the gear, and in this case it will just need to be bent (the author of the video is Igor Ivanov).

Finding Electrical Problems

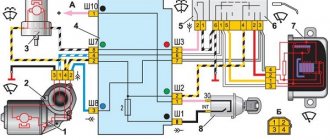

Each owner of a VAZ-2110 involuntarily paid attention to the clicks coming from the left side and the barely audible noise from the gearmotor when the windshield wiper was running. Therefore, at the initial stage of searching for the reasons why the VAZ-2110 wipers do not work, you need to check the performance of this particular product.

If the electric motor does not show any signs of life, you need to check the fuse located on the mounting block, which is located on the left side, under the headlight switch lever. If the fuse is in working order, this indicates a malfunction in the electric drive feeding system.

A multimeter will help determine the problem area in the circuit. You need to check the circuit from the fuse to the gearmotor, from it to the hydraulic corrector.

Naturally, it is necessary to check the fuse itself. If zero is constantly lit on the multimeter screen and a not very pleasant sound signal is heard, then the circuit is working properly. When several numbers appear on the screen, without sound, we move on - we move on to inspecting the terminals and wires.

You can troubleshoot the problem as follows:

- Clean and tighten all terminals that were checked with a multimeter.

- Replace wiring.

- Install a new lever on the steering column that turns on the windshield wiper.

Relay K2 (5243747), located in the mounting block, is responsible for the operation of the windshield wiper. If an intermittent mode is not observed during system operation, then it is time to change the relay. Under these circumstances, the hydraulic corrector also needs to be checked. If the windshield wiper relay has a defect, it will work wonderfully in the third extreme position of the right steering column stalk. A faulty relay does not stop working in all cases. Windshield wipers can function perfectly if they are turned on in position 1, but the fact that there is a defect and the relay is not working correctly will be indicated by pauses between sweeps of the blades. Often the relay simply goes away, and the wipers and heater do not work at the same time. In this case, you usually need to tighten the contacts.

In searching for the reasons why the wipers on the VAZ 2110 stopped working, you also need to check the limit switch located on the cover of the gear motor. It is also advisable to clean the contacts from oxide and bend the contact petals.

Instructions for replacing the windshield wiper motor

If, as a result of diagnostics, you determine that the windshield wiper motor does not work, then the failed unit will need to be replaced. There is nothing difficult about this; even a beginner can cope with this task. But you need to take into account that the replacement procedure may be different for a particular vehicle. Therefore, before changing the unit, familiarize yourself with the technical features of the system and read the service manual for the car. We will describe the procedure using the example of a traditional VAZ.

How to properly change the rear or front wiper motor:

- First, you need to unscrew the nuts that secure the windshield wiper arms; to do this, use a wrench. After this, remove it from the installation site. If you are having trouble dismantling at this stage, try using a penetrating lubricant.

- Next, the wiper lever drives are removed; to do this, the nuts securing them must be unscrewed. Having done this, you can dismantle the plastic bushings, as well as the rubber seals.

- After performing these steps, you need to disconnect the connector with the wires in the harness and lift one part of the seal through the hole formed in the partition of the engine compartment.

- Now you can remove the wiper itself. Subsequently, the washer is removed from it, as well as the spring fastening. After completing these steps, you will need to disconnect the pull rod. Next, all you have to do is unscrew the three screws that secure the electric motor and remove it. The unit is repaired and put back or replaced with a new one.

Price issue

Micromotor gearbox VAZ 2110

The serial micromotor gearbox of the VAZ 2110 has found its application in the heating system of this car. Such a gear motor for the VAZ 2110 stove, a photo of which is presented on the Internet, is responsible for regulating the air temperature created by the heating system to warm up the cabin, engine, windshield and stern glass. There are several modifications of such products that were installed on the same make of car, so you should study the instructions for the heater gear motor 2110, the drawing for it and visually compare the new part with the old, dismantled one for similarity. Only after this should it be installed to replace the failed one.

Photo of heater gearmotor 2110

The main reason for the failure of this part is the lack of air temperature control by the car's electric heater. Checking the functionality of this micromotor gearbox for the VAZ 2110 damper drive consists of the need to supply electricity from the battery (12 V) to its engine in the middle position of the heater. At the same time, the operation of the controller is checked, failure of which will also indicate a lack of air temperature regulation.

Causes of defects in the heater damper gearmotor of the VAZ 2110

If there is no change in air temperature, the following defects are possible:

- The heater damper motor gearbox of the VAZ 2110 has failed

- The integrity of the electrical circuit is broken, i.e. the supplied voltage does not reach the engine

- The presence of a defect in the autonomous control system of the vehicle heating system

If it is necessary to replace the heater damper gearmotor of a VAZ 2110, we carry out a number of the following operations with our own hands:

1. Prepare metalworking tools. We will need Phillips head screwdrivers, both short and long, as well as a 10mm socket or open-end wrench.

2. Free the windshield wiper contacts from the rubber safety caps

3. Using a 10mm wrench, unscrew the contact nuts.

4. We free the frill from the decorative type plugs (there are 4 of them) and access to the screws appears.

5. Remove 2 nuts from the side planes of the frill; for this it is advisable to use a set of keys - heads with a ratchet - wrench.

6. Remove the rubber seal from the electric motor compartment

7. Unscrew the screws that secure the thermal radiators of the electric motor.

8. We dismantle the frill, having first disconnected the pipeline.

9. The location of the damper motor is the left plane of the heater device, not far from the vacuum brake system booster. It is secured with 3 screws.

How to check the windshield wiper trapezoid motor?

There is a front windshield wiper motor with the code - 85110-21040, what contacts should I connect and what voltage should I give it to to check its functionality? I connected it according to the diagram, it doesn’t spin, I think I don’t understand the diagram correctly. Please advise. Contacts on it (+2, E, +1, B, S).

I forgot to add that he is at home. Home conditions.

if the motor is at home, pick it up, there are usually no more than two contacts, supply 12V DC voltage from a regular car battery (the power supply from some household appliance may not have enough current), polarity does not matter when checking.

There are 5 wires coming from it. (+2, E, +1, B, S)

Take a photo of the connector and post it here

Take a photo of the connector and post it here.

Well, the method of “scientific poking” has not been canceled

Article: ME241, additional articles: 2103-3730000

Order code: 001655

- Buy with this product

- show more

Gearmotor ME 241 Rated voltage – 12 V Rated power – 6 W Maximum current – 2.8 A Rated rotation speed – 60 min -1 Weight – 1.24 kg

Applicability: VAZ-2101. 07, -2121, -1111 Information used: JSC "KZAE"

Buy analogues

Passenger cars / VAZ / VAZ-21021 drawing

» href=»/catalog/vaz-3/legkovye_avtomobili-30/vaz_2102-4/stekloochistitel-16/#part4830″>Geared motorWind and rear window / Windshield wiper

- Passenger cars / VAZ / VAZ-21042 drawings

- » href=»/catalog/vaz-3/legkovye_avtomobili-30/vaz_2104-5/stekloochistitel-15/#part10000820″>Geared motorWind and rear window / Windshield wiper

- » href=»/catalog/vaz-3/legkovye_avtomobili-30/vaz_2104-5/osveshenie_zadnee-153/#part15377″>Geared motorElectrical equipment / Rear lighting

- Passenger cars / VAZ / VAZ-21061 drawing

- » href=»/catalog/vaz-3/legkovye_avtomobili-30/vaz_2106-7/stekloochistitel-12/#part18837″>Geared motorWind and rear window / Windshield wiper

- Passenger cars / VAZ / VAZ-21211 drawing

- » href=»/catalog/vaz-3/legkovye_avtomobili-30/vaz_2121-13/stekloochistitel-11/#part57725″>Geared motorWind and rear window / Windshield wiper

- Passenger cars / VAZ / VAZ-212131 drawing

- » href=»/catalog/vaz-3/legkovye_avtomobili-30/vaz_21213-731/stekloochistitel_peredniiy-14/#part2008327″>Geared motorWind and rear window / Front windshield wiper

- Passenger cars / VAZ / VAZ-21011 drawing

- » href=»/catalog/vaz-3/legkovye_avtomobili-30/vaz_2101-3/stekloochistitel-16/#part346″>Geared motorWind and rear window / Windshield wiper

- Passenger cars / VAZ / VAZ-21031 drawing

- » href=»/catalog/vaz-3/legkovye_avtomobili-30/vaz_2103-106/stekloochistitel-12/#part9166″>Geared motorWind and rear window / Windshield wiper

- Passenger cars / VAZ / VAZ-21052 drawings

- » href=»/catalog/vaz-3/legkovye_avtomobili-30/vaz_2105-6/stekloochistitel-15/#part10000821″>Geared motorWind and rear window / Windshield wiper

- » href=»/catalog/vaz-3/legkovye_avtomobili-30/vaz_2105-6/osveshenie_zadnee-153/#part18483″>Geared motorElectrical equipment / Rear lighting

- Passenger cars / VAZ / VAZ-21071 drawing

- » href=»/catalog/vaz-3/legkovye_avtomobili-30/vaz_2107-8/stekloochistitel-14/#part22209″>Geared motorWind and rear window / Windshield wiper

- Passenger cars / VAZ / VAZ-21311 drawing

- » href=»/catalog/vaz-3/legkovye_avtomobili-30/vaz_2131-73/stekloochistitel_peredniiy-14/#part61074″>Geared motorWind and rear window / Front windshield wiper

- Passenger cars / VAZ / VAZ-21213-214i1 drawing

- » href=»/catalog/vaz-3/legkovye_avtomobili-30/vaz_21213_214i-1240/stekloochistiteli-276/#part2991590″>Geared motorElectrical equipment / Windshield wipers There are no reviews for this product yet.

Today, the next article in the series “Crystal VAZs or typical breakdowns of domestic cars” is dedicated to the “classics”: VAZ-2101, 2103, 2104, 2104, 2105, 2106 and 2107. These cars have been driving along our roads for decades and, despite Despite all the shortcomings that we will talk about, their popularity is still high.

At the request of workers

“E” is “minus”, “+1” “+2” is respectively “plus” And why are there no electricians on the forum? tell

That's how I connected it. I think there’s just not enough current in any 12-volt units

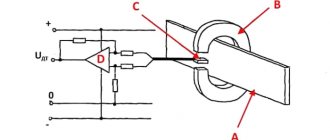

There is a circuit - what is the problem with supplying voltage through it? E - minus. +1 - winding of the first speed of operation, +2 - winding of the second speed. one of them is supplied with a plus. but to determine the initial position of the brushes there is a built-in breaker contact, which operates through terminals B and S. through B the plus is switched, while the position is not zero, there is a plus at the output of S. those. for intermittent mode, through the steering column, plus is constantly supplied to terminal B and plus is supplied once to terminal +1 (to start the motor). then the plus that comes with S still continues to be supplied to +1 through the steering column switch. after a full revolution, the breaker in the motor is triggered and the S plus disappears at the output.

Don’t even think about applying voltage only through terminals +1 and +2! and then there are craftsmen. there is very little resistance, the current is crazy, the motor runs at a very high speed and burns out very quickly.

There is a circuit - what is the problem with supplying voltage through it? E - minus. +1 - winding of the first speed of operation, +2 - winding of the second speed. one of them is supplied with a plus. but to determine the initial position of the brushes there is a built-in breaker contact, which operates through terminals B and S. through B the plus is switched, while the position is not zero, there is a plus at the output of S. those. for intermittent mode, through the steering column, plus is constantly supplied to terminal B and plus is supplied once to terminal +1 (to start the motor). then the plus that comes with S still continues to be supplied to +1 through the steering column switch. after a full revolution, the breaker in the motor is triggered and the S plus disappears at the output.

Connection diagram

If you encounter any difficulties, this diagram will help you figure out what you are doing wrong.

- wiper gearbox (1);

- thermobimetallic fuse (2);

- motor (3);

- washer valve (3);

- mounting block (4);

- ignition switch (5) and relay (6);

- switch (7);

- K3 front wiper relay (8);

- “A” – the contacts of the wiper pads are marked;

- “B” – output to pin 30 of the generator terminal;

- a – second speed;

- b – first;

- c – switch spring;

- d and e – his contacts;

- noise filtering capacitors – C1, C2;

- chokes – L1, L2.

How to check the wiper motor

Hi all. In this topic we will talk about solving the problem that I wrote about in the previous post. I would like to immediately thank ottostolz GodYato mihail-vazsport for your help

And so, where it all began

I drive up to the house, all the indicators on the dashboard go out (tachometer, temperature, fuel level, etc.) I immediately realized that fuse F16, responsible for:

— Direction indicators and relay-interrupter for direction indicators and hazard warning lights (in turn indication mode). Turn signal indicator lamp. — Rear lights (reversing lamps). — Gearmotor and windshield wiper activation relay. Generator excitation winding (when starting the engine). Brake fluid level warning lamp. — Oil pressure warning lamp. — Carburetor air damper warning lamp. Parking brake warning lamp. — “STOP” light display lamp. — Coolant temperature gauge. — Fuel level indicator with reserve warning lamp. Voltmeter

For a long time I thought about what was the matter. I came to the conclusion that the motor winding breaks through to ground and damages

.

There was another motor lying around at home, with oxidized wires. I took it, disassembled both and put another anchor in my little motor.

________________ Now all that remains is to solve the wiring problems so that all 3 wiper modes work. So as soon as it gets warmer, we’ll get around to it. But that's a completely different story.

The device has found its application not only in passenger cars, but also in all other types of vehicles. Even large submarines, helicopters and airplanes are equipped with windshield wipers, which perform an irreplaceable role and at the same time have a very simple operating principle. When the wipers operate, excess water, dirt and other foreign objects on the windshield begin to be removed.

Car models have several operating modes: with a given period of time; constant; single. The auxiliary mechanism supplies water to remove large amounts of dust or dirt from the windshield.

Features of the electric motor design

The windshield wiper base consists of several individual elements. Among them are the following:

- lever axis;

- electric motor (device that drives the windshield wiper);

- brush lever;

- brushes;

- brush holder;

- mounting block;

- frame;

- gearmotor.

Regardless of the model and manufacturer, such parts are irreplaceable. Variations are explained only by model characteristics. For example, the latest innovations in the automotive industry include upgraded versions with a wide variety of functions.

Some of them have a heating function, some work automatically, reacting to any contact with water or dirt on the windshield. In general, these are all the existing parts of the device, so the next step in learning how it works is to review the basic concepts.

It's no secret that all glass cleaners are very fragile and vulnerable devices that require a lot of care and can break . Such a structural element is forced to cope with all the work of cleaning the windshield, therefore, with prolonged use, a problem such as rapid wear is noticed.

The trouble is associated with constant contact of the rubber brush with the surface of the glass and heavy loads. As a result, a good model should have impressive flexibility and rigidity.

How to check the windshield wiper motor? When checking the wiper motor for serviceability, it is enough to pay attention to a number of key subtleties and predetermining factors. One of them is weather conditions. It is no secret that prolonged exposure to low temperatures, heat and rain do not have the best effect on the condition and operation of parts.

Checking the windshield wiper motor is not difficult at all. If there are any defects, scratches or streaks . It is also possible that incorrect noise may occur from the operation of the brushes. In addition, the brushes can move very slowly, out of step, or very quickly. In this case, you should pay attention to the motor.

When inspecting, consider the condition of the relay or lever. If one of the important elements fails, this will be accompanied by movement of the brushes in different directions . If the windshield wiper blades begin to fly off during active operation, you will have to use a new wiper blade holder.

Principle of operation

Modern cars and many other vehicles may be equipped with two windshield wipers.

A similar solution has a double design for the front glass. It does not include rubber bands placed on the blade, which provide more efficient and productive work , as well as for the rear window (here we are talking about a single version).

Most existing models are capable of operating in three different modes:

- Slow mode.

- Intermittent operation.

- Fast work.

At the heart of each glass cleaner is a corresponding motor , which is equipped with a gearbox, brushes, a lever system and an automated mechanism that allows you to return the wipers to their original position.

In addition, together with the device there is a device for supplying water to the entire area of the windshield. If it fails, the motorist should seriously think about upcoming repairs.

Windshield wiper motor repair

There are several factors and reasons that can cause such an important device to fail.

In most cases, this occurs when there is no contact between the commutators and the brushes. If after inspecting the motor and thoroughly cleaning the contacts the problem does not disappear, you will most likely have to disassemble it and replace it. However, before taking such drastic action, there are a few more ways to take decisive action to consider. If the gearbox is jammed and the levers are jammed, most likely a certain fuse in the system has tripped , which is called a bimetallic fuse. As a result, the system will not be able to cope with its responsibilities and will cause additional problems for the driver.

Dismantling the device

In rare cases, the front or rear windshield wiper motor stops working due to some manufacturing defect.

The problem is extremely rare, however, if you become a victim of it, there is nothing left to do but start special repairs. To complete the procedure successfully, perform a complete dismantling . It is no secret that such a process is quite troublesome and time-consuming. Especially if you have to repair a part from old cars, such as Tavria, KAMAZ, Priora, and so on. In this case, you will have to use several separate steps, including unscrewing the nuts that act as fasteners for the levers.

In the future, you can begin to remove the levers themselves from the tapered splines of the drive. If you have any difficulties at this stage, the splines can be treated with penetrating lubricant . Next, the lever drives are dismantled by unscrewing the nuts, as well as removing the rubber gaskets and plastic bushings.

In the harness, the wiring block is disconnected and pulled out using the raised edge of the seal, through a special slot in the partition of the engine compartment. The next step is to remove the windshield wiper .

Now you will have to unscrew the washer from the removed device and remove the spring retainer . And also you can’t do without disconnecting the rod. As a result, all you have to do is dismantle three bolts and remove the engine. After a full visual inspection, begin replacing any faulty parts.

If this does not give any results, the only way out of the situation is to buy a new motor . If the problem is resolved, the glass cleaning system must be reassembled in the reverse order.

Replacement features and diagram

If, after a thorough diagnosis, you were able to determine that the motor is faulty, think about replacing the failed unit.

At this stage there are no special difficulties, so even an inexperienced beginner can easily solve the problem. True, you must understand that the features of the procedure vary depending on the model of a particular vehicle.

Therefore, before performing a series of any actions, pay attention to the technical features of the system , read the service manual for the car.

- First of all, you must unscrew the nuts securing the brush arm. The help of a wrench will come in handy here. Then remove them from their installation location. If difficulties arise, use a penetrating lubricant.

- Then you need to remove the lever drives by unscrewing the nuts that secure them.

- The next step is to disconnect the connector with the wires in the harness and lift one part of the seal through the hole formed.

- As a result, all that remains is to dismantle the wiper itself. Then remove the washer and spring mount. After successfully achieving such goals, all that remains is to disconnect the pull rod, unscrew the three screws and remove the motor. Unit repair is characterized by particular simplicity and speed of execution.

The windshield wiper motor is located in a waterproof housing under the windshield, and the rear wiper motor is located in the tailgate. The corresponding cladding must be removed for inspection. In the future, the front wiper motor will be considered, and the rear wiper will be dealt with accordingly.