Symptoms of a faulty electronic throttle

Like any other part of the car, the throttle control system can also be subject to damage and wear.

There are signs and symptoms to watch out for to protect your vehicle from further damage.

- The car may have jerks and dips during acceleration, and it may jerk when accelerating. Possible misfires. If you notice any of these symptoms or rough shifting, there may be a problem with the electronic throttle.

- Problems with the electronic throttle control can cause problems when shifting gears. This could be a sticky feeling or slow shifting between gears. There may be a problem with getting out of a certain gear, as if it is stuck.

- Another sign of an ED malfunction is problems with displaying power characteristics. This means that the car will display incorrect data or data that is not possible in the current situation.

- The engine may stall for no apparent reason. This could be a sign of a serious problem and could even cause engine damage, so this problem needs to be fixed as soon as possible.

- An additional sign that may indicate you need to have your E-Gas checked is if you experience rapid and unintentional increases in speed while driving. This is a big safety concern because it can happen when you are behind another car or on a turn.

- The Check Engine light may be on on the dashboard. This is a sign of some kind of malfunction detected by the ECU. You can find out the error and the cause of the malfunction using a diagnostic scanner or an ELM327 adapter with the Torque program.

- The final symptom of a faulty electronic throttle control is a sharp increase in fuel consumption. If you realize that you cannot drive as many kilometers on the same amount of fuel as before, this is a clear sign that you need to have your car diagnosed.

Adjusting the gas pedal on a Kia in Belgorod

Adjusting the gas pedal on a Kia in Belgorod is carried out by highly qualified craftsmen of our professional Kia service. You can make an appointment to adjust the gas pedal by calling the receptionist to jointly select the optimal time for the arrival of your car. Also, to adjust the gas pedal, we involve a specialist who has already had experience repairing this unit on a Kia car.

I would like to remind you that in our warehouse we always have spare parts for adjusting the gas pedal on Kia. Also, for adjusting the gas pedal in Belgorod, our service station provides an additional guarantee, because Kia is sometimes a very capricious car.

If a warranty claim occurs after adjusting the gas pedal, you have the right to call our inspection technician and make an appointment for a re-inspection.

Kia service Belgorod is the optimal place to adjust the gas pedal, because when accepting your vehicle, our auto mechanics will first of all do a full inspection of the car and give recommendations for maintenance.

Do not forget that adjusting the gas pedal allows you to avoid major repairs of the entire car in the future and is more likely a preventative measure than a complete repair of the car.

Many people ask: where can you adjust the gas pedal on a Kia car in Belgorod? Sometimes you can listen to friends, advice from colleagues who have encountered adjusting the gas pedal. But you should understand that you have a Kia, and only the specialists of our Kia service center in Belgorod can treat it professionally and properly repair it.

Also, many people want to come with their own spare parts to adjust the gas pedal. This is great, but in this case a number of problems arise; most often the components do not fit on Kia, and we will be forced to install our own or search around Belgorod for stock. We also offer a warranty on our spare parts. For example, you need to adjust the gas pedal on your Kia car and you don't know what to set. In this case, you simply pre-order auto parts and after they arrive at our warehouse, you bring the car to our Kia Service Belgorod. Then, after adjusting the gas pedal, our acceptance technician prints out an order for you, which indicates the Kia car and your data, which states our warranty obligations.

The cost of adjusting the gas pedal may vary, so on the website of our auto repair center we are not ready to provide you with complete information about the price of adjusting the gas pedal on a Kia. In any case, you should contact our specialist.

We may also request your vehicle's VIN number, for example, on a Kia, the Vehicle Identification Number is 17 characters long. Don’t be alarmed by our manager’s request, because he needs to select the optimal components for adjusting the gas pedal on a Kia.

Why did AvtoVAZ need E-gas?

As I already said, environmental standards are becoming stricter every year, in order for the exhaust to comply with the standards, the cable had to be removed. This made it possible to get rid of the driver’s empty gasping, as well as other unnecessary actions that increase the toxicity of exhaust gases. The electronic pedal, as it were, regulates “at its own discretion” how to open the throttle. Even a sharp press on the pedal will be processed in such a way that as little harmful CO2 as possible is released into the atmosphere.

How it works?

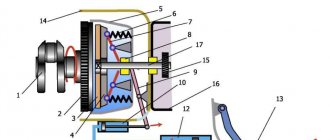

An electronic pedal consists of three main elements: pedal, electric pedal. damper, as well as a sensor located on the pedal itself. The sensor reads the degree of pressure on the pedal, and then sends the data to the electronic unit. It receives the data, analyzes it and sends a signal to the electronic damper, which opens to the required degree.

What advantages does E-gas have for the motorist?

- First of all, the electronic pedal helps reduce fuel consumption.

- Despite the widespread belief that E-gas “presses” the engine, statistics show that electronics, on the contrary, improve dynamics. Although there is indeed a slight “stupidity” at the beginning.

Now about the disadvantages of E-gas

- Most often email. The pedal is criticized for its pause (“stupid”) at the start, when you press the pedal sharply and try to accelerate. According to many, the engine interacts poorly with the pedal, as a result of which approximately one second is lost. Although we have learned to correct this shortcoming.

- E-gas does not allow serious engine tuning, since the pedal negates all efforts. Installing a cable drive solves the problem. I would also like to note that we learned how to customize and customize the pedal for specific needs.

- The electronic pedal causes a lot of trouble during operation.

The main problems of E-gas

In addition to shortcomings with dynamics, other problems are also observed, for example, floating speed, “sticking” pedals, unauthorized throttle application. Main errors of the electronic pedal: (P2122-P2123, P2127-P2128, P2138).

In the office AvtoVAZ reports that when replacing the controller or removing the battery terminal, the electronic pedal requires adaptation.

To adapt E-gas, you must do the following:

- Connect the battery terminal if it was removed;

- Then turn the key in the ignition switch to the “ignition” position. You will see indicator lights on the dashboard. Wait half a minute and start the engine. The air temperature must be at least +7°C;

- After this, we adapt the ignition diagnostic function. We accelerate at second speed, after which we brake the engine from 4000 rpm to 1000 rpm. We perform six such cycles in one run.

Useful video: How to adjust the electronic pedal

Our service center is often visited by GAZelle cars, because this is a commercial vehicle that plows like a workhorse day and night. Every day, many GAZelles hit the roads of our country and sooner or later certain breakdowns arise, which we try to eliminate! Today is no exception. A GAZelle Business with a UMZ engine came to our repair zone! Well, let's help business!

After listening to the client: the car does not pull, the check light is on. After you turn the ignition off and on again, the car sometimes starts to work as it should, but then the problem repeats. The rpms don't rise above 2000.

Here it is, a workhorse!

Fig.1

Where to start repairs? Of course, with computer diagnostics. We connect the diagnostic equipment and read the errors that are registered in the engine control unit.

Fig.2

We are interested in the current error P2138 Throttle/Pedal Position Sensor/Switch “D”/”E” Voltage Correlation. What does it mean? This error literally stands for: P2138 incorrect voltage ratio “D”/”E” of the throttle position sensor or accelerator pedal. Our throttle valve is electronic, as is the gas pedal. That is, both the damper itself and the pedal may be faulty. In order to defect a pedal or throttle valve, you need to understand how they are designed, so first let’s look at their design features, structure and figure out what is the difference between a mechanical throttle valve and an electronic one.

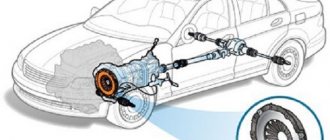

The operating principle of the system with an electronic throttle valve and an electronic gas pedal.

Correct setting

Setting up the electronic gas pedal on different car models is different, since although the same principle is used, the design is different. Therefore, it is better to search for information on the Internet about your model. Let's take an example of how this is done for Lada cars; the differences are small:

- Remove the pedal from the bracket.

- Loosen the screws that hold the cover. One of them fixes the position of the cover; it must be completely unscrewed.

- Turn the cover clockwise until it stops and tighten the screws again.

Read more: Headlights for BMW X5 E53, E70, E46 and others: restyling (glass, LED lights and eyelashes) and repair

This makes the pedal more responsive. Some note that it starts to work almost as quickly as a mechanical one. Engine performance as a whole may improve, and the car starts to move away without jerking. Other improvements are also noted. If, on the contrary, it is necessary to reduce the sensitivity, the cap must be turned counterclockwise.

The value of acceleration

Jed Christensen's research noted that when choosing accelerator programs, startup founders focus on long-term interests and the benefits that participation can bring. Their priority is building relationships with future investors and the reputation of the program, which contributes to additional attention from journalists and users.

Seed funding

Although the amount of seed funding provided by the accelerator is rarely a determining factor, it is important because it allows the team to focus on the project. It also covers the startup’s basic expenses for moving the team to the city where the program is being held and hiring outside specialists to develop the product.

Reputation

Well-known accelerators that have produced multimillion-dollar startups (for example, Reddit, Airbnb, Dropbox, Stripe in the case of Y Combinator) attract special interest from journalists and investors. Participation in such a program helps residents build their own reputation, facilitates communication with the media and attracting early followers (English)Russian..

Feedback

Participation in the accelerator allows a startup to receive expert assessment from experienced entrepreneurs and investors (whether they are the founders of the accelerator, presenters of lectures and seminars, and other guests), invited specialists and other teams.

Training and mentoring

As part of their training, residents receive knowledge in the fields of law, finance, marketing and sales organization, learn to negotiate, and receive assistance in technical development. Accelerators train residents in the best market practices for business development (for example, lean development, which helps to avoid mistakes in company development.

Reaching investors

Accelerators select promising projects and talented entrepreneurs, and thereby attract investors and business angels

At meetings and events and during the “Demo Day” that concludes the acceleration program, residents present projects and can attract the attention of investment funds or receive recommendations and valuable contacts among venture capitalists

Very hard pedal

The pedal is tight, the stroke is short when pressed... When braking, the car loses directional stability, trying to go to the side. Most often this happens when the caliper cylinders jam in one of the system circuits. If the car does not skid anywhere, and the trouble is expressed only in a sharply increased force when braking, the vacuum brake booster or the vacuum supply hose may be to blame.

Sometimes increased pedal effort is caused by the use of low-quality brake pads, as well as excessive contamination and oiling of both the pads themselves and the surfaces of the discs or drums. But this happens quite rarely.

It is also possible that the brake pads may completely wear out or break. It happens that an ice or salt crust forms on the surface of the disks. It is also possible that the brake pad linings are of poor quality, as well as severe corrosion of the brake disc (often more on the inside).

Signs of malfunction and methods of failure

Like any car part, the sensor is subject to vibration and is susceptible to contamination and oxidation. Therefore, its failure is possible from time to time. To understand the cause of the breakdown and what to do in each specific situation, the following problems should be eliminated:

- broken wiring

- the appearance of oxide on the contacts

- destruction of wire insulation

- mechanical damage to the housing or its internal components

There is a second diagnostic method. This does not require dismantling the sensor. The car is raised with a jack, then a multimeter is connected to the sensor. To appear, you need to rotate the wheel, observing the readings of the device. If the value does not change, the sensor is faulty.

In the Niva Chevrolet, the speedometer needle is driven not by a cable and a magnetic device, as in classic VAZs, but by electronics. The speedometer itself, like the rest of the instruments on the panel, are nothing more than voltmeters or ammeters with different scales.

This is for information, because it is useless to poke into the speedometer itself, it is not repairable and if at least one element fails, you have to buy the entire instrument panel on the circuit board.

The signs of a non-working speedometer are quite clear - the needle either lies shamelessly, showing 160 at a speed of 20 km/h, or twitches, or falls dead to the zero mark.

Since there are not many elements in the electrical circuit of the Chevrolet Niva speedometer, there are only a few reasons for the device not working:

- Mechanical damage to the speedometer itself.

- No contact in any of the terminal connections.

- Broken or shorted wire.

- Failure of the speed sensor.

- ECU malfunction.

Also interesting: Checking control devices and their sensors Niva 2121, Niva 2131

Problems with DS arise from time to time, but not all of them require replacement. Some of them are caused by third-party reasons, such as:

- oxidation of contacts,

- wire break,

- damage to wire insulation,

- damage to gearbox mechanisms.

If a breakdown occurs, it can be indirectly determined by the following signs:

- If your car has a cruise control system, it stops working. The electronic unit forcibly turns it off to ensure safety.

- Forced disabling of the power steering on the car.

- Reduced power and other dynamic characteristics of the car. This is noticeable in poor overclocking and malfunctions when the load increases. Damage is noticeable when towing loads.

- Reduced idle speed or “floating” indicators. A sharp decrease in performance also occurs in the event of braking. Sometimes the engine itself is forced to shut down while driving.

- Increased fuel consumption due to the choice of a less than optimal operating mode.

- Check Engine Light Activation.

- Some cars face forced restrictions on maximum speed or available revolutions.

- Forced disabling of the anti-lock braking system.

- Spontaneous gear shifting in jerks. Such actions are carried out randomly, since the car itself cannot establish optimal performance for the present moment.

- Lack of normal operation of the speedometer - completely or partially.

The sensor itself rarely fails because it is a reliable device. But its operation may be negatively affected by the following factors:

- The sensor is dirty from the inside. Such problems are especially common with sensors with detachable housings.

- Metal shavings get on the device. Sometimes this reason appears in devices supported by permanent magnets.

- Interference from other devices.

- Problems related to fixation. The scheme must take into account the color of each individual part.

- The integrity of the wiring is broken. For example, if it overheated, or some mechanical damage appeared inside. In this case, the contacts are completely cleaned of traces of corrosion, then a special protective lubricant is used for them.

- Oxidation of contacts. The phenomenon is attributed to natural factors, often arising simply from time to time.

- Overheating that occurs during direct operation. This happens even if the pinout is initially correct.

Refinement of a new electronic gas pedal

The pedal assembly (11183-1108500-01) does not have oval holes, which does not allow adjustment in the manner described above. Instead, it is proposed to cut off the protrusion (by 2-3 mm), which prevents the pedal from moving completely. This modernization made it possible to increase the pedal travel, which made acceleration with “pedal to the floor” more active. It is also noted that there is no hesitation when pressing the pedal sharply. What I don’t like about the pedal assembly (8450008980), which is installed on Lada Vesta:

- tight gas pedal;

- large free play of the gas pedal (about 8 mm at the tip of the pedal).

What was decided to do:

- remove one of the return springs to make the pedal softer;

- Place a spacer to reduce the free play of the pedal.

How to measure pedal free play:

- Let's start the engine.

- Place a ruler at the tip of the pedal.

- Smoothly press the pedal until the engine begins to gain speed.

- We remember the distance on the ruler.

We remove and disassemble the electronic gas pedal:

- Disconnect the connector (by pressing the inside of the upper part of the latch)

- Unscrew three nuts (head “10”).

- Remove the top cover by unscrewing the fastening screws.

- Remove the rheostat slider by unscrewing the screw.

Refinement process:

- Remove the spring (holding them with a screwdriver from the outside).

- Remove the white support spacers, remembering how they were installed.

- We measure the distance between the support pad of the return spring lever and the support rubber in the body, retracting the pedal to the amount of free play (indicated by an arrow).

- We glue the material of the same thickness (in this example we use 4 mm stickers for furniture legs and doors) using glue or double-sided tape.

We assemble the pedal assembly and install it in the car. The idle motion of the pedal should be minimal, about 1 mm. If the engine idle speed is higher than usual, and there is no free play of the pedal at all, then too much has been added. You will have to repeat the adjustment operation, adjusting the thickness of the lining. The same thing applies if the free play after adjustment remains more than 1-2 mm.

When the throttle assembly of any modern vehicle operates, a lot of contaminants in the form of dust, soot, and oil gradually accumulate on the surface of the throttle. They form a layer of dirt, which makes the air gap between the damper and the car's air duct smaller than the established norm. This gap is important for the normal functioning of the “heart” of the car, since thanks to it the idle speed is maintained at the required level.

When it decreases, the vehicle's electronic control unit (car computer) slightly opens the damper by introducing coefficients that take into account changes in its cross-section. Up to a certain point, the ECU manages to maintain the air gap at a constant level, but sooner or later the throttle valve will still have to be cleaned of dirt.

The need for such an operation, which involves bringing high idle speeds to a standard value, arises not only after flushing the throttle assembly, but also in other cases, in particular in the following:

- after the vehicle battery is completely discharged;

- after replacing or removing the accelerator pedal;

- after replacing or reconnecting the vehicle's electronic control unit.

Undoubted signs indicating that the damper needs to be trained immediately are the following phenomena:

- whistling when revving;

- inadequate behavior of the engine at idle;

- lack of power at idle or failures.

It is advisable to adapt these devices before you teach idle speed. If the cable of the sensor that sends the signal about the accelerator pedal position is disconnected, you must perform the following steps:

- Release the pedal completely.

- Turn the ignition key to “ON” and wait at least two seconds;

- Turn off the ignition, wait 10 seconds;

- Repeat the procedure according to point 2, and then according to point 3.

The described procedure (you must admit, it’s not at all complicated) will teach the damper to open correctly. But to adapt the valve to the “Closed” position, the following operations should be performed:

- Release (fully) the accelerator pedal.

- Place the key in the “ON” position.

- Switch the ignition to “OFF” and wait 10 seconds.

- We make sure that the valve lever moves within 10 seconds (a characteristic sound indicates that there is movement).

The process of setting up the carburetor "VAZ 2106" ("VAZ 2107")

The vast majority of Volzhsky Automobile Plant cars of the sixth and seventh models are equipped with an Ozone emulsion carburetor.

This is a factory option, and therefore this type of carburetor will be considered in the tuning instructions below.

Attention! Before adjusting the VAZ 2107 (VAZ 2106) carburetor, be sure to make several preliminary adjustments:

adjust valve clearances;

set the ignition angle to ensure that the moment of opening the contacts of the breaker-distributor advances the start of movement of the piston of the first cylinder at TDC by 1 0 .

So, let's begin the process of setting up the carburetor, consisting of the following steps (observance of the specified sequence is mandatory!):

Adjusting the throttle valve drive.

Setting up the launcher.

Adjusting the level of the fuel mixture in the float chamber.

Adjusting the “idle” mode using the “quality” and “quantity” screws.

How to Diagnose a Throttle Position Sensor Using a Multimeter

- Find the TPS on your car. Since it monitors the position of the throttle valve, look for the sensor on the throttle body.

In the picture below, the red arrow points to this sensor.

For demonstration purposes, I removed the air supply pipe so you can see how the throttle assembly works. This will help you when checking the sensor.

- In older cars, a mechanical lever is used on the throttle body, which is connected to the gas pedal in the cabin via a cable drive (newer cars use an electronic accelerator pedal).

- The throttle body has a plate (circular disc) installed that acts as a door for air to enter the engine.

- When the throttle is closed (the gas pedal is not pressed), the throttle is in a fully closed state.

When the throttle is wide open (the gas pedal is pressed to the floor), the throttle is fully open, allowing maximum air flow into the engine.

- The next step is to ensure conditions for the correct operation of the TPS. To do this, start by disconnecting the electrical connector from the sensor.

Connect the black lead of the multimeter to the negative terminal of the battery and set the meter to DC mode.

Start measuring on one side of the three-wire plug. Turn the ignition key to the ON position, but do not attempt to start the vehicle. One wire should read about 0 volts. Typically this is the leftmost or rightmost pin in the plug.

Measure the voltage at the middle pin where the signal wire is usually connected. It should also display approximately 0 volts.

Connect to the third pin, which should show about 5 volts. This is our reference voltage. If, when connecting to the third contact, you do not see 5 volts on the multimeter, the throttle position sensor is not receiving the required voltage, and this is a sign of a wiring defect on the way to the sensor. Check it for mechanical damage.

It is important to note that as long as there is 5 volts on one contact and approximately 0 volts on the other two, you do not have to worry about the integrity of the wiring. Remember that the signal pin is usually the middle pin in the connector and remember where 5 volts and ground are located

- Connect the wiring connector to the TPS and connect the multimeter probes to the signal and ground contacts using paper clips (see photo below).

- Connect the multimeter's positive (red) lead to the signal wire (middle pin) and the black lead to the ground wire. Set the multimeter to constant current (DCV) mode

With this connection, the multimeter should read approximately 0.9 volts

Exact numbers may vary depending on the car model. Rotate the throttle body lever and notice the voltage change. If you are not comfortable doing this, you can place the multimeter on the windshield with the screen facing the car's interior, sit behind the wheel and press the gas pedal

The result will be similar. If the throttle position sensor is working correctly, you will see a smooth change from the base voltage (in our situation about 0.9 volts) to the maximum value (about 4.47 volts). Turn the lever or slowly press the gas pedal, try to see the voltage “peaks”. Sudden surges or drops in voltage are what interests us. For example, if you press the gas pedal about halfway and the display shows about 2.5 volts, sharp spikes above 4 volts or drops to 1 volt indicate a faulty TPS.

This occurs due to physical wear and tear on the throttle sensor. If you find an area where the voltage jumps every time you pass it (either on the way up or down), this is a sign that the resistor is worn out. Information about this voltage surge is transmitted to the electronic control unit, causing the computer to think that you suddenly pressed or released the gas pedal.

If the TPS check shows that the sensor is faulty, replacing it will not be difficult. As a rule, it is secured with only two bolts. You just need to disconnect the electrical connector, unscrew the mounting bolts, pull out the sensor and install a new one.

How to adjust the throttle cable of a Lada Priora?

- The adjustment is carried out using a clamping bracket, which we previously removed. This bracket is a tensioner for the casing in which the cable moves.

- Remove the bracket and tighten the throttle cable so that it sags about 1-2 mm near the throttle drive.

- Now you need to install the fixing bracket into place in the casing. Make sure that the cable is tensioned optimally and that the gas pedal is not open at zero position. A cable that is too tight will cause constant high voltage. Squeeze the gas pedal several times and check how everything works.

- Start the engine and make sure the throttle cable is adjusted correctly and the idle speed is normal.

The main “miscalculations” of VAZ

Of course, no matter how much VAZ praises e-gas, this mechanism also has serious drawbacks. For example, if it fails, this device cannot be repaired. A complete replacement will be required, which will be very expensive. Although today there are “traditional craftsmen” who have adapted to repair the device themselves, this is not always effective - driving with such e-gas is even dangerous.

As for the responsiveness of the car, not everything is clear here either. Many motorists claim that the old Kalinas were much easier to pedal and responded better to pressure. E-gas responds to them with a delay, and this can become a critical problem, especially if you need to quickly avoid a collision or simply quickly overtake.

Thus, the famous e-gas Lada Kalina is not a panacea for poor car handling, but rather another unfinished system in the car that engineers will have to improve.

Adjustment

The adjustment process may vary on different car models, since different manufacturers use mechanisms of different designs. But the same principle can be applied for configuration. As for a specific model, it is better to find information on it in advance.

To begin the adjustment, the first step is to remove the pedal from the holding bracket. Next, loosen the screws securing the cover. One screw holds the cover in a certain position - it must be completely unscrewed. The cover is turned to the side clockwise until the end, then the screws are tightened again.

This adjustment will reduce pedal response time. Some car owners note that after such adjustments, the response speed can even be compared with a mechanical pedal. Adjustment allows you to improve engine performance and improve the start of movement from a standstill.

In cases where a pedal with low sensitivity is needed, it is necessary to rotate the cover in the opposite direction - counterclockwise. The machine begins to respond to presses not so quickly.

Sometimes you can come across harmful adjustment tips - drivers advise placing shims under the lever. This is the wrong approach. Sometimes the pads get caught under the contact pads in the potentiometer, and the machine may lose control as a result.

How to adjust the electronic pedal

Like any mechanism, the electronic gas pedal sometimes also needs adjustments. This event is necessary to maintain normal operation of the accelerator if the settings have been reset.

Sometimes it happens that when you press the gas pedal, the car stops responding to changes in the throttle position. This is due to the fact that there was simply no change in the situation. All electronic pedals have a certain free play, during which the voltage supplied to the transistor circuit changes. If the voltage changes, the response to the pedal position also changes, therefore, the car may behave inappropriately when controlling the throttle. Sometimes this problem can be recognized by the corresponding indicator on the dashboard or using electronic diagnostics carried out through the vehicle's on-board computer.

https://youtube.com/watch?v=LdbbOmcLTu0

Adjustment procedure:

- First of all, you need to remove the pedal from its seat. This means that when the pedal is removed, the angle measurement module is also removed along with it. The plug connector must be left in place, since power to the pedal will be needed during the adjustment process.

- Once the pedal is released, unscrew the screw located on the pedal cover. Thus, you need to release the cover relative to the pedal, allowing it to rotate freely. Next, you will need the reference literature that came with the pedal.

- Connect a voltmeter between the connectors and set it to the appropriate measuring range. Turn on the ignition. The manual for the pedal contains voltage standards that will be different for a diesel and injection engine. By turning the pedal cover, you can change the supplied voltage. Set this parameter according to the documentation and tighten the fastening screw.

- Place the pedal in place and try it out. If the car's behavior has changed for the better, it means that the electronic gas pedal has been adjusted correctly.

In addition, the voltage value may vary depending on the environment. That is, during seasonal maintenance of the car, it is strongly recommended to also adjust the gas pedal, since this value can change in inverse proportion to the changing resistance.

How to check serviceability

An electronic potentiometric gas pedal (without a built-in digital converter) can be checked using a conventional multimeter in resistance measurement mode. Using the VW GOLF as an example, the check is carried out according to the table given above in this article.

In order not to dismantle the gas pedal, you can control the resistance from the engine control unit, as shown in the figure:

Similarly, for other car models, you need to know the pinout of the engine control unit and the resistance table when moving the potentiometer. You can use the AUTODATA 3.45 program.

In the case of digital electronic pedals, fault monitoring is only possible using computer diagnostics.

If the electronic gas pedal malfunctions, you can replace it completely or replace only the sensor unit.

Lada Granta electronic gas pedal malfunction

Features of the Lada Granta throttle assembly

The throttle valve is turned by an electric motor through a gearbox. Both are built into the throttle body. When starting and warming up the engine, as well as during idling, the flow of air into the cylinders is regulated by opening the throttle valve. The throttle position is controlled by two sensors built into the throttle body.

The throttle valve opening angle is set by the electronic control unit (ECU) depending on the estimated amount of air that should enter the engine cylinders. This takes into account the operating mode of the engine (starting, warming up, idling, and so on), the temperature of the ambient air and the engine, and the position of the gas pedal.

Control commands are sent to the throttle assembly to the electric motor. At the same time, the ECU monitors the opening angle of the damper and, if necessary, sends appropriate commands to adjust its position. As a result of the fact that the ECU simultaneously regulates the amount of injected fuel and incoming air, the optimal composition of the combustible mixture is maintained in any engine operating mode.

The electric throttle body is sensitive to deposits that may accumulate on its inner surface. The resulting layer of deposits can interfere with the smooth movement of the throttle valve, jamming it (especially at low opening angles). As a result, the engine will operate unstably and even stall at idle, start poorly, and failures may also appear during transient conditions. To avoid this, as a preventive measure, deposits should be removed with special detergent compounds during regular vehicle maintenance. A large layer of deposits can completely block the movement of the damper. If flushing fails to restore the throttle assembly to operability, it must be replaced.

A malfunction or incorrect operation of the throttle assembly may be caused by a broken contact in its electrical circuit (oxidized terminals in the wiring harness connection block). In this case, it will be possible to restore operation by treating the terminals with a special compound for cleaning and protecting electrical contacts. There are other possible causes of the malfunction:

— no supply voltage is supplied to the throttle assembly;

— signals are not received from both throttle position sensors;

— The computer cannot recognize signals from the throttle position sensors.

In these cases, the engine control system goes into emergency mode. At the same time, the car retains the ability to independently move a short distance at a slow speed, which, in extreme cases, will allow it to be moved to a safe place

(move to the side of the road, leave the intersection, etc.).

The fact that the throttle assembly is operating in emergency mode may be indicated by a burning indicator lamp for a malfunction of the engine management system and an increased speed of the crankshaft at idle (about 1500 rpm, despite the fact that the engine is warmed up to operating temperature), the engine at this will not respond to pressing the gas pedal.

Each of the throttle position sensors is a potentiometer. During operation, gradual wear of conductive paths and moving contacts occurs. Over time, wear can reach such an extent that the sensor cannot function correctly. The presence of two sensors increases the reliability of the entire unit.

If only one sensor fails, the warning lamp will light up, but the engine management system will switch to backup mode. In this case, the engine will respond adequately to pressing the gas pedal, but with worse performance parameters

The reserve mode allows you to drive your car to the repair site under your own power.

Electronic gas pedal Lada Granta

On modern cars, instead of the usual cable drive for throttle control, a so-called “electronic gas pedal” is installed. In such cars, the throttle position is controlled electronically. When you press or release the gas pedal, information about this goes to the control unit (ECU) and only after processing and adjustment is a command given to the throttle module. The pros and cons of such a system, as well as signs of malfunctions, will be discussed in this article.

Design and principle of operation

To understand how the electronic gas pedal works, you need to know the general principle of the accelerator. The fact is that their functions are extremely similar, but the simplest mechanism is a mechanical drive.

The accelerator pedal, or as it is commonly called, “gas”, is a means of controlling the position of the throttle valve.

The throttle valve, in turn, is responsible for the amount of air supplied to the engine intake manifold. The more oxygen enters the combustion chamber, the higher the crankshaft speed. The pedal is a lever that acts on the damper drive. The drive can be cable or lever. All this, one way or another, makes it easier to press the gas pedal.

The operating principle of the electronic pedal is a little complicated, but it makes it much easier to control engine speed. This pedal is used only on fuel-injected cars, as it is entirely based on the operation of electronic devices. The accelerator includes: a pedal module, a signal conversion module and a throttle position control unit.

When you press the pedal, the module transmits information about the angle of deflection of the lever to the signal conversion module. The transistor system transmits an amplified signal to the throttle control unit. After matching the received signal with the electronic control unit, the throttle valve module determines its opening angle. This provides an electronic way to open the throttle valve.

It is worth noting that the operation of the damper module cannot begin until permission is received from the ECU. The fact is that this system must know exactly how much air and fuel the engine needs in a given operating mode. Therefore, the position of the damper can change regardless of how much the accelerator pedal is depressed.

The advantage of such a pedal is its efficiency and ease of use. This is due to the fact that the force required to press is noticeably reduced, which makes driving easier.

Operating principle of the electronic gas pedal

The EPG is based on a rheostat, and all work is based on contact tracks and embedded sensors. The latter analyze the speed and percentage of pedal change, as well as other important parameters. The computer, based on this data, issues a command to activate the throttle valve in a certain mode.

Even when the E-gas pedal is in one position, numerous elements control the fuel supply. They adapt to the slightest change in the speed of the car and environmental conditions.

Without going into details, the operating principle of E-gas can be represented as follows:

- the driver presses the EPG, its position changes;

- sensors read the accelerator shift angle from the initial position;

- the calculated pulse is sent to the ECU;

- the block responds with a command to the throttle;

- the air valve opens to the required angle.

This is how the new E-gas technology works. The principle of its operation is much more complex than the usual tension and loosening of a mechanical cable. There are many possible errors related to sensors and other components.

Popular brands:

Nissan Almera

How Electronic Throttle Control Works

Compared to the cable throttle, two parts were added to the E-gas:

- damper rotation motor;

- second (control) throttle position sensor (TPS No. 2).

TPS No. 2 operates in “antiphase” with the first one - its signal increases or decreases by the same amount as the signal from the main TPS No. 1.

Electronic throttle valves may differ in the percentage of opening in the de-energized state and the type of TPS.

- Fully closed in a de-energized state - one spring for full closure.

- Slightly opened by 5-7% - two springs, the balance point is in the slightly opened zone. This allows the engine to operate at low speeds in the event of a complete failure of the throttle electronics. Such dampers are more modern than completely closed ones, with which, if they break, the engine will not work at all.

- With contact TPS - inside slider variable resistors.

- With contactless TPS - there are no rubbing moving contacts inside, the output signal is generated electronically.

Working principle of E-gas:

- The driver presses the accelerator pedal. The degree of pressure is converted through sensors into an electrical signal and transmitted via wires to the computer.

- The ECU controls the closing/opening of the damper using PWM power through a motor. Both the duty cycle of the PWM and the polarity change.

- Based on signals from the TPS, the position of the damper is analyzed and the control signal is changed if necessary.

- Errors in the operation of the throttle valve are monitored.

Model features

The US Department of Commerce has designated business accelerators

as incubator support institutes and incubation programs for investment-ready companies. The main focus of accelerators is technology, in particular software startups: the cost of launching and developing these companies has decreased significantly. The role of accelerators in venture financing is to select promising startups for funds and prepare teams to attract investment rounds.

In the absence of a generally accepted definition, the characteristic features of business accelerators allow us to draw a line between them and traditional incubators. Summarizing thesis from Jed Christensen's MBA thesis, "Copying Y Combinator"

(2009), research from The Startup Factories

authored by Paul Miller and Kirsten Bound (2011) and published by Susan Cohen in the journal

Innovations: Technology, Governance, Globalization

of the Massachusetts Institute of Technology (December 2013), key features of the model can be noted.

- The composition of accelerators is formed on a competitive basis. Teams go through a rigorous selection process, interviews, and interviews. The number of applications to well-known accelerators (such as Y Combinator) reaches thousands, but only a few dozen teams are accepted into one set.

- Qualifying teams are trained simultaneously as part of a stream (also called a roster, set, or cohort). Constant communication promotes the exchange of experiences and mutual support.

- Most accelerators provide seed funding to residents and receive income from the growth in the value of their shares in the capital of invested startups.

- Acceleration programs are limited to several months, during which teams undergo training in areas close to entrepreneurship, communicate with well-known entrepreneurs, investors and niche specialists, and work with mentors. The development of a business model plays a major role in the learning process. Upon completion of acceleration, teams present their projects to investors and have the opportunity to attract the next round of funding.

Large pedal free play

As a rule, increased free play is accompanied by an increase in braking distance. Most often this happens when the brake system “grabs” air; at the same time, after several presses, the pedal seems to pump up, becoming tighter. Why this happened is a separate question - in any case, the system will have to be pumped, at the same time identifying possible brake fluid leaks.

Sometimes the pedal becomes loose due to swelling of the brake hoses. Broken hose cords have the same effect. But this happens only with left components. Sometimes brake fluid can boil, but this also happens either with a frankly poor-quality product, or with a very old brake fluid that has never been changed at all.

Another possible cause is very large runout of one or more brake discs. In addition, the automatic clearance maintenance device in the drum brake mechanisms may not work.

History of the approach

The business accelerator model was formed based on the experience gained by entrepreneurs and investors during the dot-com boom. Market practice at that time implied large investments in individual companies - and it was on this principle that startup incubators for information technology companies that existed in the late 1990s worked. The crisis of technology companies demonstrated the inadequacy of this model, and the financial losses of incubators earned them the sarcastic name “incinerators” (play on words: incubator and incinerator, lit. waste oven

).

With the renewed interest of venture capitalists in the Internet market, a model has emerged that takes into account the growth characteristics of startups from this industry. The pioneer among accelerators was Y Combinator, opened by Paul Graham, Trevor Blackwell, Robert Morris and Jessica Livingston in Boston in 2005. Instead of lengthy “incubation” of projects, Y Combinator offered three-month group training programs and small seed investments. The second Y Combinator intake took place in Silicon Valley. Following him, other well-known accelerators opened - Plug and Play and Techstars (English) Russian. The first European accelerator - London-based Seedcamp - began work in 2007, and by 2013 their number reached 50. A study of the startup support industry in Europe, conducted in 2014, demonstrated activity commensurate with the American startup ecosystem. According to various estimates, by 2014 there were from 300 to 400 accelerators operating in the world.

Among the first to use the Y Combinator model in Russia was the AddVenture accelerator, which opened in the technopark of Troitsk near Moscow in 2008. Two years later, the Bricolage accelerator, created by people from KupiVIP and its holding company Fast Lane Ventures, owned by the management company of the Bright Venture fund, opened by the founder of Price.ru Arkady Moreinis, Glavstart, Techdrive and Yandex.Factory, began recruiting for their programs. According to a joint study conducted by Firrma.ru and the Russian Venture Company in 2013, Fastlane Ventures, like Farminers, which opened a year later, remained among the most active Russian accelerators. In addition to them, the list includes the Internet Initiatives Development Fund, GenerationS, Pulsar Ventures, API Moscow, Global TechInnovations, iDealMachine, MetaBeta.