Connection diagrams for high-voltage armored wires for Nexia, Matiz, Lanos, Spark, Chance, Chance and other GM cars.

Connection to a 3-cylinder engine with a Matiz distributor

The procedure for connecting spark plug wires to a Daewoo Matiz with an ignition module is not particularly difficult - everything is clear.

The procedure for connecting armored wires to 8-valve 1.5 liter engines with a distributor

In the photo: The first wire is the top one on the distributor. The third wire is in front of the distributor. The second wire is behind the distributor. The fourth wire is from the bottom and is not visible in the photo. The central contact is, as always, from the ignition coil.

Connecting high-voltage wires on 8-valve 1.6 Daewoo Nexia, Chevrolet Lanos, ZAZ Sens and similar engines with an ignition module.

The ignition module is located vertically to the right of the engine. The order of the wires is clearly visible in the photo. In order to optimize the wire route, it is permissible to swap wires within their pair 1-4 or 2-3.

Example: 1 wire can be swapped with 4, but cannot be swapped with 2 or 3.

The upper pair of contacts on the ignition module are 1 and 4. The lower pair of contacts are 2-3. You cannot swap pairs of contacts!

The procedure for connecting spark plug high-voltage wires on 16 valve engines Nexia, Lanos

The principle is the same as in 8-valve engines. You can change 1-4 and 2-3 wires with each other, but you cannot change pairs 1-4 and 2-3 on the module. Pair 2-3 is always in the front half of the ignition module, pair 1-4 is always in the rear half.

Daewoo Matiz is a small, small-capacity car with low weight. The power unit for it was selected according to the weight of the car: the Daewoo Matiz engine has, depending on the model, a volume of 0.8 to 1.2 liters, which is quite enough to give the car good dynamics.

Operating order of Daewoo Matiz cylinders

Connection diagrams for high-voltage armored wires for Nexia, Matiz, Lanos, Spark, Chance, Chance and other GM cars.

Connection to a 3-cylinder engine with a Matiz distributor

The procedure for connecting spark plug wires to a Daewoo Matiz with an ignition module is not particularly difficult - everything is clear.

The procedure for connecting armored wires to 8-valve 1.5 liter engines with a distributor

In the photo: The first wire is the top one on the distributor. The third wire is in front of the distributor. The second wire is behind the distributor. The fourth wire is from the bottom and is not visible in the photo. The central contact is, as always, from the ignition coil.

Connecting high-voltage wires on 8-valve 1.6 Daewoo Nexia, Chevrolet Lanos, ZAZ Sens and similar engines with an ignition module.

The ignition module is located vertically to the right of the engine. The order of the wires is clearly visible in the photo. In order to optimize the wire route, it is permissible to swap wires within their pair 1-4 or 2-3.

Example: 1 wire can be swapped with 4, but cannot be swapped with 2 or 3.

The upper pair of contacts on the ignition module are 1 and 4. The lower pair of contacts are 2-3. You cannot swap pairs of contacts!

The procedure for connecting spark plug high-voltage wires on 16 valve engines Nexia, Lanos

The principle is the same as in 8-valve engines. You can change 1-4 and 2-3 wires with each other, but you cannot change pairs 1-4 and 2-3 on the module. Pair 2-3 is always in the front half of the ignition module, pair 1-4 is always in the rear half.

Daewoo Matiz is a small, small-capacity car with low weight. The power unit for it was selected according to the weight of the car: the Daewoo Matiz engine has, depending on the model, a volume of 0.8 to 1.2 liters, which is quite enough to give the car good dynamics.

Daewoo Nexia engine 8 valves timing device, technical characteristics of Daewoo Nexia 1.5 l.

The Daewoo Nexia engine 8 valves with a volume of 1.5 liters has become one of the most popular in Daewoo Nexia in recent years. Today there are quite a few cars on the secondary market with this engine. 80 hp unit (A15 SMS, the same engine is in the Chevrolet Lanos), this is a naturally aspirated gasoline engine with distributed multipoint fuel injection with an ignition coil, which replaced the 1.5-liter G15 MF series engine developing 75 hp. with an unreliable distributor.

Daewoo Nexia engine design 8 valves

Engine Nexia 1.5 l. gasoline, four-stroke, four-cylinder, in-line, eight-valve, overhead camshaft. The location in the engine compartment is transverse. The operating order of the cylinders is: 1-3-4-2, counting from the auxiliary drive pulley. The power supply system is phased distributed fuel injection (Euro-3 toxicity standards). The engine has a cast iron cylinder block.

Types of engines for Matiz

Daewoo Matiz is a compact city car, unpretentious, maneuverable and economical. Car enthusiasts appreciated it, among other things, for its financial affordability, while at a relatively low cost it offers an adequate level of comfort for the driver and passengers.

In Russia there are Daewoo Matiz cars with the following engines:

The first produces 51 horsepower, the second – 63. Both engines are naturally aspirated and naturally aspirated. Although the Matiz engine capacity is small, it is sufficient for confident acceleration and movement. You can determine which “heart” is under the hood by looking at the car’s documentation or by its appearance (see pictures below).

Since 1998, three-cylinder 0.8 liter units, combined with a manual gearbox, have been installed on Matiz cars. In 2003, production of cars with a 4-cylinder liter engine began.

Both engines are equipped with distributed injection, which allows them to have good power for their class and good efficiency. The design also uses an exhaust gas recirculation system.

Let's take a closer look at these motors.

As already mentioned, this is a 0.8 liter power unit; Matiz cars have been equipped with it since 1998. The engine has 3 in-line cylinders, the body is made of cast iron, and the cylinder head is made of aluminum. The Matiz engine is powered by gasoline no lower than AI-92.

| Parameter | Meaning |

| Volume | 0.8 l. (796 cc) |

| Power | 52 hp |

| Cylinders | 3 |

| Valves | 6 (2 per cylinder) |

| Compression ratio | 9.2 |

| Fuel type | 92 petrol |

| Fuel supply | Injector |

| Engine cooling system | Liquid |

| How much does it weigh | 80 kg. |

Malfunctions

The engine life of the Daewoo Matiz F8CV is good for its class - with proper maintenance it can travel up to 200 thousand km. But there are also a number of problems characteristic of it.

The first samples of Matiz cars were equipped with a distributor ignition system, which was distinguished by its capriciousness. The engine could stop starting due to a failure of the distribution system, and the distributor had to be completely changed due to its non-repairability. Since 2008, engines began to be equipped with electronic ignition controlled by a control unit, and this problem has disappeared.

If the Daewoo Matiz engine is having trouble, the reasons may be dirty injectors, a faulty ignition system (plugs, coils), a clogged fuel filter, or low-quality fuel in the tank.

Peculiarities

Owners of cars with this engine note an interesting sound - the three-cylinder unit sounds like a motorcycle. Although the developed power seems small, it is quite enough to give the lightweight (less than a ton) car decent dynamics.

The BC in the F8CV is made of cast iron, and the cylinder head, as already mentioned, is aluminum. There are two valves for each of the three cylinders. The camshaft has an overhead placement and is located in the cylinder head bed.

The gas distribution mechanism is driven by a belt.

Important: the belt replacement schedule is after 40 thousand km. mileage If it is not replaced, a break is likely, which will lead to bending of the valves, failure of the cylinder-piston group and expensive overhaul.

The crankshaft rests on four bearings in the cylinder block. It has a tendency to wear out; to restore its characteristics, it can be polished with the installation of repair kits for liners of the appropriate size.

The cylinder liners also wear out and may need to be bored. If this is not possible, the cylinder block is relined or replaced. Worn pistons (or new ones with bored liners) are replaced with new ones of appropriate sizes; repair kits are widely available.

Maintenance and repair

It is imperative to periodically change the oil. For a Daewoo Matiz equipped with this unit, the engine oil volume is 2.7 liters. Synthetic oil with a viscosity of 5W-30 is used. The scheduled replacement interval is 10 thousand km. mileage

As already mentioned, after 40 thousand km. mileage, the timing belt is changed to avoid breakage. This service procedure can be quite expensive, however, it is quite possible to do it yourself.

The key to correct replacement is placing marks on the crankshaft and camshaft. If you make a mistake, the valves will be damaged.

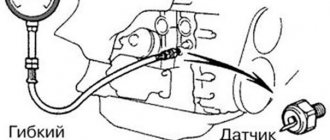

This is what the timing belt looks like:

These operations, as well as routine repairs, can be carried out independently due to the simple design of the internal combustion engine. Current ones include:

Major repairs with overhaul of the unit are carried out in the event of a serious breakdown or after the engine has exhausted its required service life.

Change of oil

To change the oil in a Daewoo Matiz engine you will need:

- oil with the required viscosity;

- new oil filter, part number ADG02110;

- key to 17;

- filter puller;

- rags;

- waste container;

- gloves to protect your skin from burns and hot oil.

Important: all operations must be carried out with a warm, switched off engine.

- the filler neck opens;

- the drain plug is unscrewed and the old oil is drained into the container;

- Then the filter is twisted with a puller. If you don’t have one at hand, you can simply pierce it with a screwdriver and use it as a lever;

- Oil is poured into the new filter and the gasket is lubricated with it;

- when the old fluid has completely drained out, the new filter is installed in place;

- then new oil is poured to the required volume, the level is controlled by a dipstick;

- The neck is closed, the engine is started for a few minutes, after which a control measurement is carried out.

The procedure is relevant for Matiz vehicles with all types of internal combustion engines.

B10S1

This is a more powerful 4-cylinder unit, producing 63 horsepower.

Interesting: the engine is an artificially weakened engine from a Chevrolet Aveo. The deforcing was done by reducing the piston stroke - other pistons, connecting rods and crankshaft were installed.

| Parameter | Meaning |

| Power | 63 hp |

| Volume | 1 l. (995 cc) |

| Number of cylinders | 4 |

| Location | Row |

| Fuel supply | Injector |

| Fuel type | Gasoline AI-92 |

| Valves in the engine | 8 |

| Cooling system | Liquid |

Like its smaller brother, the engine is cast from cast iron, and the cylinder head is made of aluminum. The engine capacity of the Daewoo Matiz B10S1 is higher, it has a different number of cylinders and valves, a different cylinder-piston group and timing, which made it possible to extract power from it, increased to 63-64 horsepower. The installation of this engine made Matiz faster and more dynamic.

The set of typical faults and routine operations is generally similar to the 0.8 liter unit. To change the oil you will need 3.2 liters. synthetic fluid with a viscosity of 5W-30.

Description

Initially developed for the Chevrolet Lanos. Structurally, the engine is built according to an in-line design and has a volume of 1.5 liters. The GDS mechanism diagram uses one camshaft - SOHC. Power supply: MPI distribution injection.

As a rule, the A15SMS engine forms a single power unit along with the gearbox and clutch. Mounted in the engine compartment of the car on 3 elastic rubber-metal supports.

| Manufacturer | Chevrolet |

| Engine brand | A15SMS |

| Years of production | 1997 – 2015 |

| Volume | 1498 cm3 (1.5 l) |

| Power | 59-63 kW (80-86 hp) |

| Torque moment | 123 Nm (at 3200 rpm); 130 Nm (at 3400 rpm) |

| Weight | 117 kg |

| Compression ratio | 9.5 |

| Nutrition | injector |

| Motor type | in-line petrol |

| Ignition | switching, contactless |

| Number of cylinders | 4, bored inside the block without sleeves |

| Location of the first cylinder | TVE |

| Number of valves on each cylinder | 2 |

| Cylinder head material | aluminum alloy |

| Intake manifold | duralumin |

| An exhaust manifold | cast iron |

| Camshaft | 5 supports, casting, cast iron |

| Cylinder block material | cast iron |

| Cylinder diameter | 76.5 mm |

| Pistons | alloy, the pin hole is shifted by 0.7 mm to the rear wall |

| Crankshaft | cast iron, 8 counterweights, 5 supports |

| Piston stroke | 81.5 mm |

| Fuel | AI-92 |

| Environmental standards | Euro-3 |

| Fuel consumption | highway – 5.4 l/100 km; combined cycle 7.6 l/100 km; city – 9.8 l/100 km |

| Oil consumption | maximum 0.6 l/1000 km |

| What kind of oil to pour into the engine by viscosity | 5W30, 5W40, 0W30, 0W40 |

| Which engine oil is best by manufacturer | Liqui Moly, LukOil, Rosneft |

| Oil for A15SMS by composition | synthetic in winter, semi-synthetic in summer |

| Engine oil volume | 4.5 l |

| Operating temperature | 95° |

| ICE resource | stated 250,000 km; real 350000 km |

| Adjustment of valves | hydraulic compensators |

| Cooling system | forced, antifreeze |

| Coolant volume | 10.7 l |

| water pump | with plastic impeller |

| Spark plugs for A15SMS | BCPR6ES from NGK or domestic AU17DVRM |

| Spark plug gap | 1.1 mm |

| Timing belt | Gates, width 22 mm, service life 200,000 km |

| Cylinder operating order | 1-3-4-2 |

| Air filter | Nitto, Knecht, Fram, WIX, Hengst |

| Oil filter | with check valve |

| Flywheel | with clutch landing diameter 200 mm or 215 mm |

| Flywheel mounting bolts | M12x1.25 mm, length 26 mm |

| Valve stem seals | manufacturer Goetze, light intake |

| graduation dark | |

| Compression | from 13 bar, difference in adjacent cylinders maximum 1 bar |

| XX speed | 750 – 800 min-1 |

| Tightening force of threaded connections | spark plug – 31 – 39 Nm; flywheel – 62 – 87 Nm; clutch bolt – 19 – 30 Nm; bearing cap – 68 – 84 Nm (main) and 43 – 53 (connecting rod); cylinder head – three stages 20 Nm, 69 – 85 Nm + 90° + 90° |

Matiz engine tuning

The 1.0 liter engine lends itself well to tuning. It is important to understand what the Daewoo Matiz B10S1 engine consists of: it is, in fact, a derated unit from the Chevrolet Aveo, in its original configuration it has a volume of 1.2 liters. If desired, the engine can be boosted back by simply installing a piston group from Aveo, thereby returning the characteristics of the engine.

Other options for improvements:

All this allows you to “squeeze” engine power up to 85 hp, which is impressive for a Daewoo Matiz. This will require the installation of a new reinforced clutch, because the original one can no longer handle the torque.

Published August 30, 2016

Did you decide to make this video yourself or did my request push you?

Standard. The four-cylinder engine runs 1-3-4-2. there are 3 cylinders. We throw out the 4th one. Based on the movement of the slider we get – 1-3-2

the valves are loud. The gaps are large. Or the exhaust gasket is shot somewhere. I'm thinking about the valves.

Source

Types of engines for Matiz

Daewoo Matiz is a compact city car, unpretentious, maneuverable and economical. Car enthusiasts appreciated it, among other things, for its financial affordability, while at a relatively low cost it offers an adequate level of comfort for the driver and passengers.

In Russia there are Daewoo Matiz cars with the following engines:

The first produces 51 horsepower, the second – 63. Both engines are naturally aspirated and naturally aspirated. Although the Matiz engine capacity is small, it is sufficient for confident acceleration and movement. You can determine which “heart” is under the hood by looking at the car’s documentation or by its appearance (see pictures below).

Since 1998, three-cylinder 0.8 liter units, combined with a manual gearbox, have been installed on Matiz cars. In 2003, production of cars with a 4-cylinder liter engine began.

What problems and frequent breakdowns on Daewoo Matiz do buyers talk about?

Weaknesses of the Daewoo Matiz engine

The peculiarity of the motor is a slight “chirping”, but this is not a defect and does not in any way affect the functional characteristics.

Frequent breakdowns in electrical equipment

The “vulnerable part” of electrics is the generator (a typical malfunction is a breakdown of the diode bridge). True, repairs will cost 50-60 dollars.

Typical Transmission and Accessory Problems

Motorists do not complain about either automatic transmission or manual transmission. The clutch basket and discs are miniature, but with proper use they can easily survive 60,000 km. True, the gears are not always engaged clearly (but this is individual; it depends on the driving style).

Weak spots in the interior, body and paintwork

The main problem is the Daewoo Matiz crickets. Corrosion “devours” the hood, fenders, bottoms of doors, wheel arches, and sills. Anti-corrosion treatment of a car does not always cope. The problem often occurs on cars assembled in Uzbekistan (they receive the most complaints). If the mufflers and resonators are rusty, welding is useless.

Frequent malfunctions of the chassis and suspension

They cannot withstand the conditions of our roads. As a rule, levers bend, shock absorbers and stabilizer bushings break.

During interruptions, the engine idles unevenly, does not develop sufficient power, and consumes gasoline increased. Interruptions, as a rule, are explained by a malfunction of the injectors or electric fuel pump (for more details, see “Engine Management System”), a malfunction of the spark plug of one of the cylinders, or air leaks into one of the cylinders. It is necessary to find the fault and, if possible, eliminate it.

| 1. Start the engine and let it idle. Go to the exhaust pipe and listen to the sound of the exhaust. You can bring your hand to the cut of the exhaust pipe - this way the interruptions are felt better. The sound should be even, “soft”, of the same tone. Popping noises from the exhaust pipe at regular intervals indicate that one cylinder is not working due to a failed spark plug, lack of a spark, an injector failure, a strong air leak into one cylinder or a significant decrease in compression in it. Popping noises occur at irregular intervals due to dirty injector nozzles, severe wear or dirty spark plugs. If popping noises occur at irregular intervals, you can try to replace the entire set of spark plugs yourself, regardless of mileage and appearance, but it is better to do this after contacting a car service center to diagnose and repair the engine management system. | 2. If the popping sounds are regular, stop the engine and open the hood . Check the condition of the ignition system wires. High-voltage wires must not have insulation damage, and their tips must not be oxidized. If there is damage to the wires, replace the faulty wire. |

Carefully inspect the candles and compare their appearance with the photographs given at the end of the subsection. The gap between the spark plug electrodes should be 0.8–0.9 mm. If the candle is black and wet, you can throw it away.

Reliable contact of the body or threaded part of the spark plug with the “ground” is optional, but desirable. Connect the high-voltage wire from cylinder 1 to the spare spark plug. Start the engine. If engine interruptions do not worsen, replace the spark plug in cylinder 1 with a known good one. Attach the high voltage wire and start the engine. If the interruptions intensify, repeat procedure step 6 sequentially with all cylinders to identify the faulty spark plug.

Diagnosis of error P0300

What can we do with our own hands and without leaving home, so to speak? The first thing you need to think about is when did this error appear? Maybe it appeared after falling into a “good” hole or appears exclusively in wet weather? Or after refueling? After visiting a tire shop? After an oil change? Etc. All these little things can really help in choosing the direction of your search.

A visual inspection can also bring positive results. Cracked insulation on electrical wiring wires, the presence of moisture in connectors, oil or coolant getting on electrical equipment elements and other troubles can be easily detected by the human eye. It is also worth looking at the explosive wires and ignition coils in complete darkness with the engine running. After all, checking explosive wires and coils for resistance with a multimeter gives only a small picture of what is happening. Most often, these elements of the ignition system fail not due to a break or short circuit in the electrical part, but due to an insulation breakdown. And in the dark you can see a neon glow in the places where the ignition coils are attached or on the explosive wire near the valve cover mounting bolts. The check should be carried out not only at idle, but also in revving mode, because when the throttle valve is opened sharply, the breakdown voltage on the spark plug increases quite noticeably due to the increased pressure in the cylinder.

Cracks and dark marks on the ignition coil housing may also indicate a breakdown of the coil. Although when checked with a multimeter it may seem absolutely fine.

Oil in spark plug wells due to an ever leaking valve cover gasket is also a fertile area for misfires, which can be detected by the same visual inspection

In general, attention and a meticulous visual inspection can quickly identify the culprit of a misfire.

Next, you need to unscrew the spark plugs and compare them with each other. As a rule, this is the most informative process. The difference between one spark plug and the rest clearly indicates problems in a particular cylinder, which will significantly narrow the search range. Next, let's get creative. We move the problematic spark plug to another cylinder and drive for a while. We are re-inspecting. If the same candle is different again, then it’s the problem. And if the spark plug from the same cylinder is different again, it means either the high voltage wire or the injector of this cylinder. Or maybe the iron of this cylinder.

If two spark plugs have differences - 1 and 4 from 2 and 3, then with a high degree of probability you can suspect the ignition coil if the car has a DIS ignition system, like the Lacetti. Since here one coil works on two cylinders.

If the problem is chaotic, then it makes sense to check the connectors on the injectors and ring the wires to them

Also check the ECU connector and main grounds.

The best option is to treat all connectors with a contact protectant.

If, along with error p0300, the dynamics of a warm engine have deteriorated, then measuring the fuel pressure is necessary. At low pressure, fuel can simply boil in the ramp on a warm engine and lead to misfires.

Temporarily turn off the EGR valve. If the problem goes away, it means the valve did not close hermetically and exhaust gases entered the intake manifold uncontrollably.

We monitor the coolant level. If it changes constantly, then there may be problems with the cylinder head gasket. The same goes for the oil level.

Disabling the crankshaft position sensor

If the engine does not start, the camshaft position sensor is faulty.

And vice versa, turn off the camshaft sensor

If the engine does not start, the crankshaft sensor is faulty. If one of these sensors fails, misfires may also occur.

We wash the valves and combustion chamber. If this gives even a slight positive effect, then it’s worth thinking about changing the gas station and changing the oil to another manufacturer.

We buy an inexpensive diagnostic adapter and look at the diagnostics section. Sometimes it is possible to determine the search direction on computer diagnostic graphs

Peculiarities

Owners of cars with this engine note an interesting sound - the three-cylinder unit sounds like a motorcycle. Although the developed power seems small, it is quite enough to give the lightweight (less than a ton) car decent dynamics.

The BC in the F8CV is made of cast iron, and the cylinder head, as already mentioned, is aluminum. There are two valves for each of the three cylinders. The camshaft has an overhead placement and is located in the cylinder head bed.

The gas distribution mechanism is driven by a belt.

Important: the belt replacement schedule is after 40 thousand km. mileage If it is not replaced, a break is likely, which will lead to bending of the valves, failure of the cylinder-piston group and expensive overhaul.

The crankshaft rests on four bearings in the cylinder block. It has a tendency to wear out; to restore its characteristics, it can be polished with the installation of repair kits for liners of the appropriate size.

The cylinder liners also wear out and may need to be bored. If this is not possible, the cylinder block is relined or replaced. Worn pistons (or new ones with bored liners) are replaced with new ones of appropriate sizes; repair kits are widely available.

Reasons for retightening cylinder head bolts

Tightening the cylinder head bolts.

Before we begin to consider the tightening torque of the cylinder head itself, it is necessary to understand for what reasons the cylinder head can be removed . So, let's look at the main ones:

- Engine repair , both major and “throwing up” oil scraper rings. To do this, you need to remove the cylinder head, and then tighten the bolts correctly.

- One of the diseases of Lanos can be called a head gasket failure . At the same time, to replace it, it is necessary to remove the cylinder head itself. It is worth noting that the new gasket must maintain a tight seal, so the tightening torque plays a big role.

- Burnout of valves is a good reason to remove the “head”, so after repair you will need to tighten the bolted connections.

- Replacement of connecting elements , which requires dismantling the block head.

Trying on the cylinder head gasket.

Tightening process and tightening torque on a Chevrolet Lanos

Tightening sequence for cylinder head bolts.

The reasons why it is necessary to remove the cylinder head have been established and further it is worth considering the process itself and the tightening torque of the cylinder head. After installing the new gasket between the head and the block, we begin to tighten the bolts. The bolts must be tightened in a certain sequence so that the cylinder head is pressed tightly against the block through the gasket.

Five stages of tightening

In the process of tightening the cylinder head on Lanos.