Carburetor for VAZ 2105 - device

The carburetor plays a vital role in the fuel system of any car or mechanical system. This part is used to combine fuel with air in the correct proportion for natural combustion and operation of the entire mechanism. The VAZ 2105 carburetor is suitable for uninterrupted use in different modes. For each individual mode it is necessary to provide a separate air-fuel mixture.

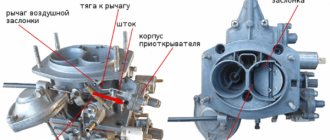

Carburetor models 2105-1107010 and 2107-1107010 from the throttle valve drive side: 1 - air damper; 2 — starting device; 3 — three-arm air damper control lever; 4 — telescopic rod; 5 - microswitch; 6 — throttle valve drive lever; 7 - lever limiting the opening of the throttle valve of the second chamber; 8 — return spring; 9 — pneumatic drive rod; 10 — pneumatic drive of the throttle valve of the second chamber.

With the development of high technologies and mechanical engineering, carburetors are inferior to injection units. They are characterized by greater functionality and improved details. Carburetors still have a number of undeniable advantages. For example, starting the engine the first time in the most severe weather conditions. In addition, thanks to the suction, the heating process of the power apparatus occurs much faster.

Functions of the carburetor on the VAZ 2105

- responsible for starting the engine after idle time;

- regulates the supply of gasoline while the engine is running without connecting to the transmission;

- mixing air and fuel in the correct quantities with further transfer to the power unit;

- guarantees additional fuel supply when the vehicle accelerates.

Structural parts of the carburetor for VAZ 2105

- lid;

- main block;

- throttle body.

In turn, the carburetor cover consists of a semi-automatic starting system, a filter, a float with a valve and an econostat tube.

The main block diagram contains more details:

- air and fuel jets, diffusers, which constitute the main dosing system;

- float chamber;

- pump;

- transition system and idle channels with jets;

- fuel supply channel;

- vacuum drive unit.

At the bottom of the carburetor there are axles with dampers and adjustment screws. The channels of the starting system, idle speed, and crankcase ventilation also end here.

Algorithm for carburetor operation on a VAZ 2105

The principle of operation of the carburetor is quite simple - in the intake manifold, which connects the fuel system with the power unit, a decrease in pressure occurs when the engine is turned on. As a result, a vacuum occurs in the carburetor. The vacuum thereby provokes the simultaneous absorption of air and gasoline. Then these two elements are combined to form a working mixture, which, when ignited, sets the pistons in motion.

Payment methods for goods:

- It is possible to send cargo with a thirty percent (30%) advance payment with blocking and removal of blocking upon full payment.

- It is possible to send cargo without prepayment, provided that the buyer pays for the services of the transport company in both directions at the branch of the transport company.

- Sending by PEC by cash on delivery with the condition of prepayment of delivery in both directions (this way we are safe from fraudsters) - in PEC before payment you can inspect the goods received, PEC charges a commission for this service in the amount of: 1.5% for cash and 3% for non-cash calculation

You can make any changes (tuning/additions) to the standard engine configuration BUT the warranty will be 3000 km or 3 months of operation

You can also make any set of attachments (standard and non-standard) if you have some of the equipment - write what to add/exclude from the set, the manager will write a price change.

Engine manufactured in Togliatti with all warranties. For components, assemblies, engines and gearboxes, the warranty is 15 thousand km or 1 year, whichever comes first. The warranty period is 1 year or 15 thousand kilometers due to the inability to control the operating conditions of the listed products, the replacement interval and the quality of fuels and lubricants.

Methods of payment for goods: It is possible to send cargo with a thirty percent (30%) advance payment with blocking and removal of blocking upon full payment. It is possible to send cargo without prepayment, provided that the buyer pays for the services of the transport company in both directions at the branch of the transport company. You can make any changes (tuning/additions) to the standard engine configuration BUT the warranty will be 3000 km or 3 months of operation. You can also make any set of attachments (standard and non-standard) if you have some of the equipment - write what to add/exclude from the package , the manager will write a price change.

Working volume 1.57 l

Power 74.5 hp

Cylinder diameter 79 mm

Piston stroke 80 mm

Number of valves 8

Power injector system

What does the engine package include: Block, crankshaft, pistons, rings, connecting rods, bearings, half rings, oil seals, cylinder head assembly with camshaft, crankshaft pulley, flywheel, oil pump with oil receiver, iron oil pan (aluminum can be installed - check price with manager), valve cover, gas distribution mechanism with a closed cover, spark plugs. Sensors: oil, temperature, phase sensor (if injector), knock sensor, antifreeze drain plug, dipstick, break-in oil (10v40 semi-synthetic Lukoil, recommended after break-in 1000-1500 km, oil change).

Packaging: everything is mounted on a wooden stable pallet, screwed on, the engine itself is made of cardboard on all sides and wrapped with stretch film. The transport company is packed in a wooden box. At the request of the client, we can dismantle any component of the engine or replace it with a non-standard sports or tuned part.

Types and modifications of carburetors for the VAZ 2105

The carburetor for the VAZ 2105 and its modifications - Ozone, Solex - are produced at the Dimitrovograd Automotive Component Plant.

- Ozone - among its other parts there is an idle air control. Suitable for classic VAZ models - 2107, 21043, 21074;

- Solex - in comparison with previous options, it is the most versatile. Used in new front- and all-wheel drive versions.

Carburetors are also distinguished depending on the supply of fuel mixture to the cylinders:

- float - consists of a mixing and float chamber;

- needle;

- bubbler - represented by a fuel tank in which there is a board and two pipes.

Following the direction of fuel flow, carburetors can be:

- horizontal;

- vertical - with upward and downward flow.

For the number of cameras:

- single-chamber;

- multi-chamber.

The Zhiguli 2105 uses four-stroke, four-cylinder Ozone. The most commonly used 2105-1107010-20 and 2105-1107010-10 Ozone models.

The difference between them is the cross-sectional size of the following elements:

- additional pipe;

- the main jet, which is located in the primary chamber.

Expert advice

After completing the procedure for adjusting the VAZ-2105 carburetor device, experienced auto mechanics recommend paying attention to the following critical points:

- Valve location - is in the retracted position, with the idle speed jet touching the seat in the carburetor body.

- Lubricating the rubber seal with special motor oil.

- The location of the air damper intended for cold passage is in a vertical plane, while the suction handle is lowered.

- The condition of the solenoid valve - the presence of damage and malfunctions is checked as follows: turn on the ignition;

If clicks are heard during the inspection process, the part is in full working order.

Adjusting the carburetor VAZ 2105

Adjusting the VAZ 2105 carburetor is a fairly simple task if you have minimal technical knowledge. Otherwise, the best solution would be to contact a professional, since rash intervention can only aggravate the situation, and you will be forced to resort to repairing the 2105 carburetor.

If you are still confident in your capabilities, then such adjustment of the VAZ 2105 carburetor device will significantly improve the functionality of the mechanism, reduce fuel consumption and improve the performance of the power unit. If this procedure is carried out competently and wisely, then it will not harm the 2105 carburetor in any way.

To do this you need to do the following:

- change the crankshaft speed. Screw it until it stops, and then turn it 3 turns in the opposite direction;

- the amount of ozone needs to be adjusted. For this procedure we need a quality screw. It needs to be turned all the way, and then returned back four to five turns. This will increase the fuel fluid level;

- warming up is a necessary and integral part of carburetor tuning;

- the next step will be to adjust the idle speed of the DAAZ 2105 carburetor. To begin with, using the quantity screw, it is important to stabilize the operation of the power unit, while simultaneously turning the quality screw. Such a rotational imbalance will cause unstable engine operation. Now you can begin to gradually unscrew the screw back until the power apparatus is restored;

- In the end, it is important not to forget about adjusting the idle speed. This result can be achieved by using a screw.

After adjusting and tuning the carburetor on the VAZ 2105, it would be appropriate to check its serviceability. Start the car, and then sharply press the gas pedal, releasing it just as sharply. If all steps were performed correctly, the crankshaft will begin to rotate faster. This means that the adjustment of the VAZ carburetor was successful. If you fail to start the car, increase the number of revolutions using the screw.

Features of the operation of the timing belt in VAZ cars

The timing belt is subjected to serious loads during operation - heat, oil ingress, stretching, wear due to constant contact with pulleys, etc. In winter, when the car is stopped, the belt freezes, loses elasticity and suffers even more when starting the engine. In hot summers, on the contrary, the belt heats up significantly, which leads to its intensive aging. Therefore, the timing belt must be changed regularly, otherwise one day it will start to slip or even break, and this will have the most dire consequences for the engine.

Any damage to the timing belt is accompanied by a mismatch in the operation of the timing belt and timing belt, which at best simply requires a new engine adjustment, and at worst - serious repairs to the piston group, timing belt, cylinder head and other parts. In particular, a timing belt rupture leads to an almost instantaneous stop of the camshaft, which means that the intake and exhaust valves are locked in the position they occupied before the breakdown. However, in this case the pistons continue to move in the cylinders, so when they rise to TDC they bend the valves, and in the worst case, they are simply broken by the valves. As a result, the engine stops and requires expensive repairs.

It should be noted here that not all VAZ engines break down when the timing belt breaks. In the line of VAZ engines there are models (for example, the 1.5-liter in the VAZ-2109), the pistons of which have recesses for the intake and exhaust valves - they are not afraid of camshaft stopping. But for most VAZ car engines, timing belt rupture poses a serious threat.

In the vast majority of cases, rupture or cutting of teeth (which can also cause serious damage to the engine) occurs after the belt has reached the end of its life; a new timing belt cannot simply break. Today, most manufacturers set the service life of the belt within 50-60 thousand km of vehicle mileage. After this period, the timing belt must be replaced, regardless of its condition. That is, even if the belt looks good outwardly and has no visible damage or serious wear, it still needs to be changed no later than after 60 thousand km.

Replacing the timing belt in VAZ cars is accessible to the average car owner and generally does not present any difficulties.

Transitional system, GDS

When the driver presses the gas pedal, the throttle valve opens slightly. The engine receives fuel due to vacuum through the small diffuser of the first chamber and the jets of the main metering system. At the same time, the GDS is not yet fully operational, but the idle system is still working.

If you press the gas sharply, the accelerator pump will start. It injects a portion of gasoline through its spout directly into the manifold. The pump is designed to eliminate failures when starting and accelerating the car.

A further increase in speed entails an increase in vacuum. The force begins to retract the membrane, and it opens the draft of the secondary chamber. The diffuser and jets of the second chamber come into operation.

To prevent failures when the second chamber is fully opened, the DAAZ-2105 1107010 carburetor is equipped with a transition system. It is designed similarly to the idle system. But the hole for supplying the combustible mixture is located higher than the closed throttle of the second chamber.

Dampers

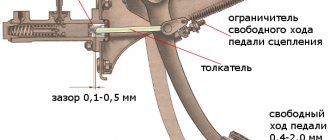

Primary adjustment comes down to adjusting the cable on the trigger mechanism and adjusting the accelerator pedal traction. It is easy to adjust the thrust - the plastic tip is placed approximately opposite the hinge, twisting it along the thread. To secure, tighten the nut 10 mm.

The choke drive cable is adjusted as follows. The choke lever in the cabin is pushed in all the way, and the air damper must be fully open. The cable is threaded through the eyes, and the end is inserted into the corresponding hole in the clamp. While holding the latch, tighten the bolt with a wrench. When pulling and retracting the choke, you need to make sure that the damper opens and closes completely.

Next, check how the throttle of the second chamber opens. The membrane and rod must be in such a state that their stroke is sufficient to fully open the damper. If the stroke is not enough, then unscrew the nut that is on the rod and adjust the length.

Cold start system

The DAAZ-2105 carburetor starts working from the starting system. Using the choke lever, the channel is closed, and the throttle valve is slightly opened to a certain clearance.

At the same time, the engine receives the richest possible mixture - it is supplied from the float chamber through the jets of the main metering system and the small diffuser. Then the engine starts. To prevent a large amount of liquid fuel from entering the cylinders, the vacuum actuates the starting device membrane and the air damper opens slightly.

In what cases is it necessary to replace the heater radiator?

The radiator itself is a simple device from a technical point of view. It consists of a system of tubes through which the coolant moves, equipped with thin lamellas. It would seem that there is nothing to break here. However, radiators fail very often. There are only two reasons here:

- leakage due to drying out, corrosion or mechanical damage;

- obstruction resulting from sedimentation of oxidation products on the tubes or “clogging” with various debris or the same products of oxidative processes.

If you can try to combat the latter reason by flushing the radiator with chemical reagents, which does not always help, and not for long, then if a leak occurs, the only correct solution is to replace the radiator with a new one.

You can, of course, try to correct the situation by soldering the leak, but this option is only suitable for copper-brass radiator models. And no one will give you a guarantee that symptoms will not appear in the near future.

Do you need to bother with repairing the heater radiator if it is not that expensive, and you don’t have to go to a service station to replace it?