On the fifth model Zhiguli we are interested in, the main power unit is a four-stroke four-cylinder internal combustion engine with a volume of 1.45, 1.29 and 1.57 liters.

Russian Ozons (DAAZ 2105) of several modifications are used to form the combustible composition for the “five” engine.

The most commonly installed models were 2105-1107010-20 and 2105-1107010-10. Their difference lies in the size of the cross section of the two elements:

- additional pipe;

- fuel main jet located in the primary chamber.

Carburetors of these modifications have five main mechanisms:

- econostat system;

- dosing main chamber;

- system for starting a cold engine and warming it up;

- accelerator pump;

- idle system;

- system responsible for maintaining the required level of gasoline.

The VAZ 2105 carburetor jets are marked as follows:

- 2105-1107010-10. Air jet: main system - 170 for the first and second chambers, idle speed - 170 and 70, respectively. Fuel: main system - 109 and 162, idle - 50 and 60. Accelerator pump: 40 (bypass and fuel).

- 2105-1107010-20. All markings are similar to the previous model, with the exception of the fuel cell of the main system - 107 (in 2105-1107010-10 marking 109).

In general, the “five” carburetor is a rather complex device that ensures stable operation of the car engine in different modes, mixes vehicle fuel and air in a given proportion, and then supplies the resulting combination to the cylinders of the power plant. Its correct setting guarantees economical fuel consumption and stable operation of the “heart” of the car.

Signs of carburetor problems

Dust, contaminants and foreign particles that enter the carburetor with fuel and air settle on the internal walls of the channels, of which there are many in the design of the unit, which leads to malfunction. The carburetor design includes a number of components, the components of which wear out and become damaged over time, which affects its performance. Signs indicating a carburetor malfunction:

- Difficulty starting the engine;

- Decrease in acceleration dynamics;

- Jerks, failures during acceleration;

- Unstable idle speed;

- Unauthorized stop of the engine;

Causes of “triple tripping” of a VAZ car engine

Incorrect timing of ignition installation Air leakage in the vacuum brake booster system Malfunction of the spark plug Breakdown of the high-voltage wire Malfunction of the capacitor Loss of tightness in the area of the intake manifold (intake manifold, carburetor) Burnout of the valve, piston Breakage of the piston rings Incorrect adjustment of the valves Destruction of wear of rockers (valve levers) Breakdown of the gasket Cylinder head Wear, hardening, destruction of oil seals Very low fuel quality Incorrect carburetor adjustment Wear of the distributor shaft, rotary plate bearing Loss of tightness of the membrane of the vacuum ignition advancer Use of spark plugs that are not suitable for the engine and other “faults” I do not take into account

Perhaps not all the reasons, but what I could remember, if you have anything to add, then write in the comments.

Well, now let's talk about each of the reasons in more detail.

Incorrect ignition timing. With this option, I personally know not a tripping, but a seemingly slamming of the engine (missing), which is accompanied by “bouncing” of the entire engine. This is especially noticeable at idle; as the speed increases, the skips disappear. Most likely, your ignition is set too early; this may also be indicated by jerky cranking of the engine by the starter when starting. Quite often, the cause of engine tripping in a VAZ of all models (except for the VAZ 2101, which does not have a vacuum brake booster) is a loss of tightness in the hose, diaphragm, or valve. As a result, excess air appears in the intake manifold, which leads to over-leaning of the mixture and misignition of the mixture in the cylinder, as a result of which the spark plug may become wet and stop igniting the compressed mixture. A faulty spark plug is one of the most common causes of engine misfiring.

There is nothing special to tell here, it is important to remember and replace spark plugs regularly, and the presence of a spark on an inverted spark plug at atmospheric pressure does not indicate its full functionality, because ignition occurs under much more difficult conditions (Za Rulem magazine, dating back to Soviet times). At this point I will combine the breakdown of the high-voltage wire and the capacitor on the contact ignition system. A wire breakdown can be determined by replacing all wires, as well as the capacitor

You can also try to determine the breakdown of the wire by looking at them in complete darkness; if there is a breakdown somewhere, you will see flashes. Loss of tightness in the collector area, as a rule, does not occur on its own. More often this happens due to incorrect assembly or bad gaskets. I also had a case where they complained about trimming at idle. The reason was the elimination of the vacuum ignition advancer and the unplugged vacuum tube on the carburetor. As a rule, when a piston or valve burns out, the cylinder stops working altogether or does not work for a long time. It can only be determined by measuring compression and opening the engine. Breakage or sticking of piston rings is also not a very common occurrence, because a number of conditions are necessary for its occurrence. You can check it by measuring the compression; if it turns out to be low, then eliminate cylinder head malfunctions in a simple way - pour a little oil into the cylinder; if the compression increases, then there is a malfunction in the piston system. With incorrect valve adjustment, everything is already clear - any valve may not open or close completely. Proper valve adjustment can cure this problem. Rocker wear can cause a similar problem. The valve stops opening correctly and the cylinder stops working. Well, now let’s briefly go over the problems that may arise with the distributor. Quite often, on not new machines, wear of both the shaft itself and the bushings in which it rotates occurs, as a result of which it becomes impossible to establish an adequate gap between the contacts. The same thing happens if the swing plate bearing is worn out. Also, misfires can occur due to depressurization in the vacuum ignition timing advancer, where the membrane may fail.

Here I have written a few reasons why a VAZ engine may be tripping, if you want to notice or ask something, write below in the comments!

Correct adjustment of the VAZ 2107 carburetor

- At the first stage, a full inspection of all parts is carried out, then they are washed and cleaned of dirt and other elements;

- The mesh filter is removed and the float chamber is washed;

- Then the air jets are cleaned;

- At the last stage, elements such as the float chamber, trigger mechanism and idle system are adjusted.

It is necessary to make a remark that all these operations are performed without removing the carburetor itself.

After setting up the elements, you need to check the mesh filter. It is located in front of the entrance to the float chamber. The strainer is checked at least every 60 thousand kilometers.

When you turn on the heater, the engine temperature drops

As we said above, turning on the interior heater can affect the engine temperature. In short, many cars have a so-called heater radiator. The specified radiator is included in the general circuit of the engine cooling system, that is, the coolant heated from the engine passes through the radiator, giving off heat. The resulting heat then enters the car interior through the air deflectors. The intensity of heat extraction from the radiator is regulated by the speed of the heater fan and the position of the temperature regulator of the air supplied to the cabin.

It is quite obvious that when the outside air temperature drops, drivers prefer to turn the heater on to “maximum” to quickly warm up the interior space and further maintain comfortable conditions. At the same time, in winter, the engine often idles, operates at low speeds when driving, etc. It turns out that the unit burns a minimum of fuel and does not experience any special loads. In such a situation (taking into account the working stove and the “minus” outside), the heat generated by the engine is simply not enough to fully warm up the coolant and bring the engine to operating temperature.

For better heating of the interior and internal combustion engine, as well as complete warming up of the gearbox, it is enough to drive the car for several kilometers at medium speed (about 3-3.5 thousand rpm) in a low gear. Also, many drivers use the method of additional insulation of the engine compartment using felt, installing a cardboard or plastic damper on the radiator, etc.

This decision to insulate the engine for the winter is fully justified in cases where the car is operated in conditions of intense cold for a significant part of the time. With additional insulation of the hood and the engine itself, the engine does not cool down so quickly after stopping and warms up faster at idle and while driving. Consequently, the stove in the cabin also works better.

Finally, we would like to add that the quality operation of the entire cooling system depends on antifreeze/antifreeze and its quantity in the system. For this reason, it is necessary to monitor the condition of the coolant and regularly check the fluid level in the expansion tank. You should also monitor the tightness, avoid the formation of air locks, change antifreeze in a timely manner and flush the engine cooling system when replacing the working fluid.

Adjusting the idle speed on the carburetor VAZ 2105 and 2107

To complete this procedure, you must perform the following steps:

- Preheat the power unit to operating temperature.

- Set the maximum possible number of revolutions - for this, the so-called quality screw is used. Indicators should exceed the norm by one hundred revolutions per minute.

- Using the same screw, the engine is activated and the final speed adjustment occurs.

Naturally, the carburetor must be in its place and be fully connected.

IAC breakdowns

If you have a VAZ 2107 with an injection engine, then pay due attention to the condition of the vehicle systems. If the speed on an injection engine fluctuates, then you need to look first at the idle speed control

The fact is that the breakdown of such a mechanism as the IAC can lead to very sad consequences, including a traffic accident. Here are the main signs by which you can independently determine whether the regulator is broken:

- The engine begins to “live its own life” - the crankshaft rotation speed is constantly changing, sometimes decreasing, sometimes increasing. Consequently, the tachometer needle constantly floats.

- When you start a cold engine, the crankshaft speed does not increase, it fluctuates within a certain range.

- If you turn on powerful electrical appliances (for example, a car radio, low or high beam), the speed decreases and does not return to the set level.

- When you engage the neutral gear, the engine begins to stall if you do not apply the gas pedal from time to time.

These are the main signs that the regulator is faulty. In fact, any interruptions in the idle level are the first sign of a breakdown or minor defect in the IAC. But the time has come to diagnose it. It won't be difficult to do this.

As part of eliminating illiteracy on the basics of adjusting, tuning and repairing carburetors on the VAZ-2107, we are conducting a series of publications focusing on the main nuances and “secrets”, based on the experience of our colleagues from the forum. So, today we will tell you how to correctly adjust the idle speed on a VAZ-2107 carburetor without having a gas analyzer at hand, but guided only by the tachometer readings. The need for adjustment arises among owners of VAZ classics quite often. Signs - the engine idles unstably, stalls, troits, etc. So, let's go, this procedure is described in simple 6 steps for adjustment.

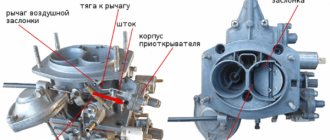

We draw your attention to the location of the quality and quantity screws on the OZONE carburetor for the VAZ-2107

1.

We set the nominal crankshaft rotation speed using the mixture quantity screw on the carburetor (for the “classic” it is 820-900 rpm).

2.

quality

screw , we find its position at which the speed will be

maximum

.

3.

the quantity

screw , we set the speed 15% higher than the nominal (for “classics” this will be 950-1035 revolutions/min).

4.

We check that the position of the quality screw provides the maximum possible speed for a given position of the quantity screw.

If this is not the case, then use the quality screw to achieve the maximum possible speed and use the quantity screw to restore the speed above the nominal speed by 15%. We again check that the position of the quality screw provides the maximum possible speed, and return the speed with the quantity screw to +15% of the nominal value. Etc. until the moment when, at a rotation speed 15% higher than the nominal one, any rotation of the quality screw will only lead to a decrease in speed.

5.

By tightening the quality screw, we reduce the speed to nominal.

6.

We check and make sure that the car’s engine runs smoothly, without “tripping” at idle and does not stall when the throttle is closed abruptly

Briefly, all this can be stated as follows:

1. Find the position of the quality screw at which the speed will be maximum. 2. If necessary, use the quantity screw to set the speed 15% (130.150 rpm) higher than the required XX speed. 3. see point 1 4. see point 2 5. When it is no longer necessary to adjust the speed with the quantity screw, by turning the quality screw we reduce the speed by 15%, i.e. to the required idle speed.

What to pay attention to:

If the adjustment is made correctly, then when you remove the terminal from the solenoid valve or the vacuum hose from the fitting of the “quantity” adjusting screw housing, the engine should immediately stall.

If, when you tighten the “quality” screw all the way, the engine does not stall, then most likely one of the throttle valves is too open - adjust the locking screws.

Pay attention to the return spring and the “gas” drive. The throttle valve should clearly return to its original position when the gas pedal is released.

For the summer season, the idle speed can be set to 800 - 900 rpm, for the winter it is better to 900 - 1000 rpm. This is due to the fact that in winter the load on the vehicle’s on-board network is usually higher.

Carburetor VAZ 2107 idle

is ensured using a forced idle economizer system (EFI).

In order to detect a system malfunction, this article describes methods for checking and replacing all components of the forced idle system of a VAZ 2107 carburetor.

Setup with additional devices

Having obtained a multimeter and a gas analyzer, the adjustment results will be similar to those achieved by car service specialists.

- Adjust the correct ignition angle using a multimeter (connected to the distributor coil) and fix the distributor.

- We insert the gas analyzer into the exhaust pipe and start the car.

- Set the mixture quantity screw (indicated in the figure as number 1) in such a position that the crankshaft rotates within the range of 840-960 rpm.

- We look at the gas analyzer, if the CO value is exceeded, we adjust the quality of the mixture (number 2 in the figure).

- After this, the crankshaft rotation will decrease slightly, repeat step 3. The last steps are repeated until the values are at least a little similar to the factory values. To check, you need to sharply press the gas pedal several times and release it. When configured correctly, the speed increases smoothly and quickly, and is released automatically and without interruption.

How to check the strainer

This is done as follows. Use manual fuel pumping and fill the float chamber with fuel, after which you will be able to see the shut-off valve close. Then move the top filter cover and remove the valve. It must be thoroughly washed in solvent, then dried using compressed air.

When the engine behaves incorrectly during loads, there are dips or loss of power, or the car “reacts poorly to the pedal,” most likely you have a problem with the fuel supply. In addition, often the cause is a faulty strainer.

Important! It is strictly forbidden to wipe the bottom of the float chamber using a fluffy or any other rag, since after such cleaning, invisible fibers may remain on the bottom of the chamber, which will clog your jets during operation.

You might be interested in: Replacing the fuel filter for Lada Kalina. Fuel pump repair: replacing the mesh

The float chamber is cleaned using a rubber bulb and then dried with compressed air.

Checking the tightness of the shut-off needle is carried out using a bulb, since the pressure force that occurs during squeezing is equal to the pressure in the fuel pump. When replacing the carburetor cover, you need to make sure that the floats are in the up position. You should feel strong pressure during installation, after which you need to listen carefully to the carburetor for air leaks. If there is even the slightest leak, the needle and valve body must be replaced.

Main types of carburetors

The Seven engines are equipped with both a carburetor and an injector. The operation of the injector does not depend on weather conditions. But the carburetor is much simpler in its mechanical structure, which makes its repair and tuning more accessible.

Not all carburetors are designed to do the same thing. For example, there are models on the market that reduce fuel consumption or, on the contrary, increase fuel consumption, which in turn allows you to maximize the dynamics of vehicle acceleration. Such different models of carburetors were produced for different engine sizes, so it will not be possible to rearrange them so easily. If you suddenly decide on such an experiment, then you cannot do without alterations. And all this is true when it comes to standard models. But what if the car owner decides to install a non-standard carburetor?

However, first, let's turn our attention to the standard classic models.

Adjustment without additional devices

If you couldn’t find special devices, you can make adjustments without a gas analyzer, but only if you have a tachometer. The procedure is basically the same, only you need to turn the screws a little differently.

- We set the mixture quantity screw to the position of the nominal crankshaft speed (820/900 rpm).

- Using the quality screw we catch the maximum speed.

- We increase the crankshaft speed to 950-1035 rpm (15%), using the quantity screw.

- We check the quality screw; it should be in the position of the maximum possible revolutions for the current location of the quantity screw.

- We repeat steps 3 and 4 until, after completing the third step, adjusting the quality screw will only lead to a decrease in speed.

- We tighten the quality screw to the nominal speed.

Maintenance and Troubleshooting

Routine work on systems that ensure engine operation should begin with a complete inspection. For convenience, the air filter housing is removed from the carburetor and all air tubes are inspected. There should be no cracks on them, and the material should remain elastic. If necessary, the carburetor is dismantled and completely disassembled with defect detection and replacement of faulty parts.

The next stage involves diagnosing, eliminating identified faults and adjusting the ignition system. It is recommended to clean the contacts in the distributor with fine sandpaper, replace the spark plugs and set the timing correctly. This can be done using a tester or a primitive test lamp. It makes sense to proceed directly to regulating the VAZ 2107 engine only if the carburetor and other systems are in order.

Description of models

The first VAZ 2107 was standardly equipped with a DAAZ carburetor In Russia, they were modified to meet the needs of the local automobile industry. DAAZ products had simple assembly, which subsequently affected their price. The given carburetor model was characterized by maximum simplicity and made it possible to provide good acceleration characteristics to the car. Initially, the space in the engine compartment was created specifically for DAAZ.

The VAZ 2107 carburetor is a complex, high-precision device, consisting of two chambers, one of which - the first is equipped with a special mechanical damper drive. It can be installed on any domestic rear-wheel drive car. The volume of the model in question is 1.5 and 1.6 liters.

Gasoline consumption when using DAAZ increases noticeably. But this is consistent with the car’s speed indicators, which are also increasing. And this is especially important when overtaking.

Drawing our attention to the model - “Ozone” - it is worth noting that this is a more modified version of the standard DAAZ. The new optimized mechanism had better environmental performance. Thanks to this, “Ozone” received its environmentally friendly name. In addition, it consumed much less fuel than the previous version, so for such an economical car as the VAZ 2107, the Ozone carburetor was considered the most optimal option of all possible.

Good maneuverability and speed of the car were given by a pneumatic valve located in the new carburetor and ensuring the efficiency of the second chamber. However, there was one “but” - even if the valve was slightly dirty, the second chamber stopped working. The speed of the vehicle immediately decreased. This was noticeable in the acceleration dynamics of the car and when the engine was running at medium speeds.

The Solex 21053 carburetor is no less popular among VAZ 2107 owners. At the moment, it is the latest development. Solex has a rather complex assembly, but at the same time it has a fuel reverse supply system, which makes this carburetor the most economical among the entire DAAZ line.

The carburetor mechanism has a larger volume compared to other models: 1.8 Solex versus 1.5, 1.6 other DAAZs. All these features tell us that this carburetor model is simultaneously designed for economical and fast driving.

Initially, Solex was created for cars with front-wheel drive. And yet, this carburetor can be installed on a VAZ 2107 without special modifications. Solex is picky only about the quality of fuel.

Important! The system may malfunction! In most cases, this is due to the fact that the air and fuel channels are clogged with dust. The solution to this issue will be timely maintenance of the carburetor.

All of the carburetors we list are installed on classic engines. If the size of your engine is not designed for the existing carburetor, then you will need to select and replace the jets. It is also worth adjusting the carburetor.

On the issue of non-standard carburetors, it is worth saying that in some cases, owners of “classics” resort to just such a solution. Without alterations and adjustments there is no question here.

“Solex” 21073 is a model designed for engines with a volume of 1.7 liters. The carburetor differs from previous versions by large channels and jets. Dynamic growth is guaranteed! But so does the subsequent expense.

The following non-standard model is installed on cars of the VAZ 2108 and 2109 series. “Solex” 21083 for installation on version 2107 will require certain modifications. Also, installing it will lead to the fact that at about 4000 rpm the engine will not be able to spin up any further. To install this carburetor model, you need to drill out the chamber diffusers. Then expand them. During the modification process, large jets are also installed. The result of such work can please you: fuel consumption will be lower, and the dynamics will exceed those of other models.

Conclusion

As you yourself have seen, a carburetor is a complicated thing, but you don’t need any special intelligence to adjust the idle speed. Do not try to repeat the procedure if your “Seven” is on gas, the process will be pointless because the carburetor does not work with this type of fuel. You can try to set up the injector, but there is a high probability of only harming the device, since the actions described there are ineffective, so it is better to turn to professionals. All the procedures described and more are clearly demonstrated in the video, where the cheerful specialist easily and simply finds a common language with the carburetor. I wish the same for you, all the best!

Nail Poroshin all about DaAZ carburetors

Good afternoon There have been no major changes to the car. The car drives (tfu x 3). But “warm” summer days don’t give rise to much desire to dig deeper, although there is something to do. Therefore, the entry will be about the purchase of 3/H for the carburetor. Everyone who has a carburetor knows Nail Poroshin. And if earlier it was possible to purchase from him the famous “Nailevsky” wires and a 4-cut cam (and with them a 3/H for the carburetor), then recently, after long discussions and discussions, it became possible to separately buy a “large” set and “mini” set for carburetor (Ozone and Solex). Which is what I took advantage of. I bought the “edited” mini set. A slightly different set, but for the same amount. Plus some little things. The general list (taking into account household supplies) was as follows: Fuel: 95, 97.5, 100, 102, 105, 107, 110, 115, 117, 2 pcs. - 18 pcs. G. Air: 23-140, 23-155, 23-165, ZC-125, ZC-135, 2 pcs. — 8 F. Idling speed: 41, 42, 43, 4 each. — 16 pcs. Sprayer: 35/40, 40/40 - 2 pcs., Nivsky sprayer = 21073-384: No. 45 Needle valve: 4 pcs. Spray valve: 2 pcs. Rubber rings for the idle speed fuel channel. 4 cut cam. 2 pcs. jet EMR 40. 2 pcs. — 2108-1107015 — gasket for carb. lower 1 PC. — 2108-1107017 — gasket to the carburetor flange. 2 pcs. — 2108-1107460 EMR diaphragm (“triangular”).

Buy a carburetor from Nail

Hi all! The other day I picked up a parcel delivered from Dimitrovgrad from Nail Poroshin. Why delivery from Russia? After searching here in Almaty, the prices for this carb were disappointing. And ordering from the Russian Federation turned out to be much cheaper.

Delivery was carried out by TC "ZhelDorExpedition". We were pleased with the timing and cost.

The box contained: 1. the carburetor itself 21053 2. installation kit (3 gaskets, return hoses, return tee, extended accelerator rod, choke cable 08, check valve) 3. BB wires of zero resistance (actually 0, I measured it myself ) 4. cut 4 cams

Welcome to the online store of car carburetors Carburetor.ru! You can order carburetors made by DAAZ and PEKAR from us with delivery by Russian Post. Payment for the order upon receipt. We ship to any location in Russia, including regions with air delivery. PEKAR carburetor catalog is here.

DAAZ carburetors

3 types of carburetors are produced - “Ozone”, “Solex” and “Oka”: - “Ozone” carburetors are installed on rear-wheel drive VAZ cars; — Solex-type carburetors are installed on front-wheel drive VAZ cars, classic cars and all-wheel drive VAZ cars, IZH and ZAZ cars; — Oka carburetors are installed on Oka, Gas and UAZ cars. The life of carburetors is equal to the life of the engine. The period of the factory warranty when installed in a specialized car service is 18 months of operation (with an operating time of no more than 30 thousand km). Each carburetor coming off the assembly line is adjusted on a stand until the required characteristics are obtained, which ensures high quality of the output product. Answers to questions about the design and operation of DAAZ carburetors from the manufacturer can be read here. Adjustments for OZONE type carburetors are here. Adjustments for SOLEX type carburetors here.

Do-it-yourself dismantling of the unit

To remove the DAAZ 2107 carburetor, auto mechanics recommend proceeding in the following sequence:

- The hood of the car is opened, the clamp on the warm air intake hose is loosened using a flat screwdriver, after which the hose is disconnected from the thermostat tube.

The air intake hose is disconnected from the thermostat - The air filter cover is removed manually. Under it there is a mounting plate, which is held on by four bolts. They are unscrewed with an 8-mm open-end wrench, after which the plate is easily removed.

The mounting plate of the DAAZ 2107 carburetor is removed manually - Now the air filter itself of the VAZ 2107 is removed.

The air filter from the VAZ 2107 is removed after removing the mounting plate - Using the same 8 key, loosen the nut on the carburetor choke cable. Then the screw securing this cable is held with a flat screwdriver, the nut 8 is unscrewed completely and the cable is disconnected from the carburetor.

The choke cable of the DAAZ 2107 carburetor is disconnected using a screwdriver - The hose through which crankcase gases are discharged is removed from the fitting of the DAAZ 2107 carburetor manually.

The hose for removing crankcase gases from the DAAZ 2107 carburetor is removed manually - Next, the wires of the microswitches of the idle economizer control system (IAC) are manually removed.

The wires of the economizer control system are disconnected from the DAAZ 2107 carburetor without much effort - The vacuum ignition timing regulator has a fitting with a vacuum hose. This hose is also removed from the DAAZ 2107 carburetor manually.

The hose of the vacuum ignition timing regulator is removed from the DAAZ 2107 carburetor by unscrewing the screws - Now you need to find the hose for the solenoid valve. It is connected to the economizer through a fitting. This hose must also be removed.

The solenoid valve control hose is manually removed from the DAAZ 2107 carburetor - After disconnecting this hose, the return spring of the solenoid valve of the DAAZ 2107 carburetor is removed from the socket.

The return spring of the solenoid valve of the DAAZ 2107 carburetor is manually removed from the socket - Use a flathead screwdriver to loosen the clamps on the fuel hoses. These hoses are then removed.

Fuel hoses from the DAAZ 2107 carburetor are removed manually after loosening the clamps - Using a 14mm wrench, unscrew the four nuts that hold the carburetor to the manifold body.

The DAAZ 2107 carburetor mounting nuts are unscrewed with a 14-mm open-end wrench - The DAAZ 2107 carburetor is removed from its original place.

After unscrewing the fasteners, the DAAZ 2107 carburetor is removed manually