Classic VAZ models should be understood as cars from 2101 to 2107. Owners of such cars with a carburetor often resort to searching for more effective solutions to improve dynamic performance and/or reduce fuel consumption. Both acceleration and efficiency directly depend on the model of carburetor under the hood and on the quality of its adjustment. If the owner decides to install a third-party carburetor, then a number of individual features need to be taken into account when choosing.

Choosing a carburetor for a VAZ classic

Classic VAZ models should be understood as cars from 2101 to 2107. Owners of such cars with a carburetor often resort to searching for more effective solutions to improve dynamic performance and/or reduce fuel consumption. Both acceleration and efficiency directly depend on the model of carburetor under the hood and on the quality of its adjustment. If the owner decides to install a third-party carburetor, then a number of individual features need to be taken into account when choosing.

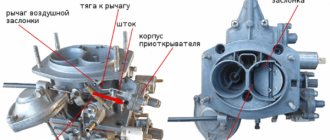

Repair of the throttle valve pneumatic drive.

We check the pneumatic drive in the same way as the starting device and if there is a malfunction, change the diaphragm of the pneumatic drive in the same way as the starting device.

We press on the diaphragm rod and close the inlet channel with our finger.

If the pneumatic actuator is working properly, the rod will return to its original position after opening the inlet channel. The pneumatic drive housing should be disassembled only if necessary, since the rod length will have to be selected experimentally. If the pneumatic drive mechanism of the second damper was disassembled, the length of its thrust should be adjusted:

4. Release the locknut on the rod...

We insert the finger into the rod and secure the connection with a locking ring.

6. Press on the pneumatic actuator rod, recessing the rod into the diaphragm mechanism housing. (When the shutter of the first chamber is closed, the second should remain closed).

In frequent cases, a malfunction of the pneumatic drive is caused by insufficient tightness of the channels through which vacuum is supplied to the diaphragm. In this case, you need to check the lower surface of the carburetor body (see Disassembling and repairing the carburetor body). When tightening the carburetor mounting nuts, the plane can be “moved” under the influence of temperature. In this case, the required vacuum is not created and the damper of the second chamber does not open or does not open completely, with a delay.

Standard carburetor models

Various carburetor models are focused on the environment, reducing consumption or maximizing vehicle dynamics. Carburetors were also created for engines of different sizes. Some models of carburetors from one power unit can be easily installed on another, and in some cases modifications will be required.

Carburetor DAAZ/Weber

DAAZ carburetors (Dmitrov Avtoaggregatny Zavod) 2101, 2103 and 2106 were products that were produced thanks to a license from Weber. For this reason, the models are called both the DAAZ carburetor and the Weber carburetor, but they mean the same device. These carburetor models are characterized by maximum simplicity of design and provide excellent acceleration characteristics.

Carburetor Ozone

VAZ 2105-2107 models received improved DAAZ carburetors.

This carburetor model is also called Ozone. The Ozone carburetor got its name due to its environmental friendliness. A fully serviceable and tuned Ozone carburetor allows you to reduce consumption from 7 to 10 liters of gasoline per hundred kilometers compared to Weber and is capable of providing good dynamics. Among the disadvantages of this model is the design of the carburetor. The process of active operation leads to a number of problems with the secondary camera. The opening of the chamber does not occur mechanically, but thanks to a pneumatic valve.

Solex carburetor

No less popular is the DAAZ 21053 carburetor model, which is a licensed product from Solex. The carburetor has proven itself to be an economical and at the same time dynamic solution when installed on classic engines. The design of this model is very different from previous DAAZ carburetors. The Solex carburetor has a fuel return system (return). Thanks to this solution, excess gasoline goes back into the gas tank. The return route allows you to save about 400-800 grams of gasoline per hundred kilometers traveled.

Some versions of this model may have a range of auxiliary electronic systems. The main solutions include an idle system with regulation by an electric valve, an automatic cold start system, etc. Such innovations were found on export versions of the car. In the CIS, the Solex carburetor with an electric idle control valve has become widespread.

The system turned out to be problematic in operation. In this type of carburetor, the air and fuel passages are narrow and quickly clog. If the carburetor is not serviced in a timely manner, then the idle system was the first to fail. A Solex carburetor consumes from 6 to 10 liters of fuel in quiet mode. As for dynamics, it is second only to the early development of Weber.

How to make repairs for a “classic”

Initially, we will discuss the carburetor repair instructions from 2107. For the work, we will need the following tools:

- screwdrivers;

- spanners;

- pliers;

- ruler.

Also find out about and.

We begin repairing the VAZ 2107 carburetor by dismantling the unit from the car. It is produced in the following sequence.

- First of all, we dismantle the air filter housing together with the filter element by unscrewing the nuts.

- After unscrewing the fasteners, disconnect the throttle cable and the choke cable.

- We disconnect the crankcase gas exhaust hose.

- Loosen the clamp and remove the fuel hose.

- Disconnect the vacuum regulator hose.

- Disconnect the pneumatic valve from the economizer.

- Remove the microswitch from the terminals.

- Using a screwdriver, press the tip away from the damper drive rod, and then remove the return spring.

- We dismantle the entire assembly unit.

Now, to repair a carburetor from a VAZ 2107 with our own hands, we need to disassemble it, replace the defective parts with new spare parts (they are sometimes sold in the form of a special repair kit for repairing VAZ 2105 - 2107), and we may also have to process the filler plane. We will describe how to do all this.

- We dismantle the three-arm lever, spring and rod.

- We remove the cover, as well as the housing from the throttle valves. Replace the gasket if necessary.

- Carefully dismantle the float by pulling out the axle.

- We unscrew the fuel needle valve, as well as the fuel jets from the float chamber. If necessary, we replace parts.

- We unscrew the fuel nozzle of the idle system. If necessary, we replace it.

- After unscrewing the accelerator pump bolt, remove the pump cover, diaphragm and spring. These parts can also be replaced.

- We take out the diffusers that worked above the dampers.

- Unscrew the screw for the amount of mixture.

- We wash all disassembled metal parts in acetone.

- We apply the edge of the ruler to the plane of the upper body, which is connected to another plane of the body for fastening the dampers. Checking the curvature. By the way, if before this it was not possible to properly adjust the stable idle speed, the culprit could be precisely this curvature, which causes air leaks. If necessary, we process the plane with an emery wheel manually, without an electric drive of the wheel, after first removing the adapter tubes from the plane. We perform this operation extremely carefully.

- We assemble it in the reverse order, just like installing it on a car.

Let us add that repairing a carburetor from a VAZ 2106 is done in exactly the same way, since the unit is the same, under the DAAZ 2107 brand. Generally speaking, repairing a VAZ 2105 is done in the same way, because again the brand of the unit is the same.

Differences for front-wheel drive

Now let’s look at the features of the process when it is necessary to repair a VAZ 2109 carburetor.

With the front-wheel drive Lada, a unit called “Solex” was used, somewhat improved compared to the DAAZ 2107. Its removal from the car is carried out according to the already described scenario. Let's see what differences there are from the above manuals when disassembling and repairing a carburetor from a VAZ 2109. The same tools are needed. We move point by point in the same way and look at the differences.

- Removing the lever.

- The cover and housing from the throttle valves are removed in the same way as the previous instructions.

- The float chamber here is arranged in a similar way - let's disassemble it.

- We unscrew the similar fuel jets plus the needle valve.

- The fuel jet of the idle system is definitely replaced here with a solenoid valve; we unscrew the valve with a wrench. We then install a new one instead - this is desirable.

- The accelerator pump is disassembled in a similar way, its parts, especially the diaphragm, are replaced with new ones.

- We remove the diffusers.

- The mixture quantity screw is of a different type here; we also dismantle it.

- We wash parts that are not worn out in acetone.

- If necessary, we process the plane of the upper body according to the above recommendations.

- We do the assembly, moving back step by step, this also applies to installation on the car.

As you can see, the instructions differ little from those given earlier. Here it must be added that when repairing a carburetor, most often it is necessary to replace the jets, since due to their small size, coupled with the strict requirements for their operation, the life of these parts is short.

In addition, it is important to know that on the “nines” they actually installed a carburetor with brand 2108, so repairing a carburetor from a VAZ 2108 is carried out exactly according to the instructions given. In addition, the “eight” and “nine” modifications have the same unit, but modified, with slightly different clearances. Therefore, repairs on 21083 are done in the same way, but when making adjustments they are guided by slightly different gap values. Their values should be taken from the technical documentation. The same goes for repairs on 21099.

Settings must be made after installation.

Something about cost and non-repairability

Of course, not everyone can repair such a complex mechanism as a carburetor. Many car enthusiasts would rather resort to the services of car services. Let's see how much money they have to shell out. Here are the average data for major cities of the Russian Federation.

| City | Price |

| Moscow | 2500 rub. |

| St. Petersburg | 2500 rub. |

| Ekaterinburg | 1800 rub. |

| Samara | 1700 rub. |

| Krasnodar | 1800 rub. |

These prices are indicated approximately for the repair of a carburetor type 2108. The cost is not small, however, it is approximately two times lower than purchasing a new unit. Although sometimes you can’t do without a purchase. After all, there may be cases when repairs and adjustments will not help the carburetor.

For example, the processing of curved planes, which was discussed above, may be useless due to the general so-called “fatigue” of the metal. It is not uncommon for threaded holes for jets to become worn out. In addition, the combination of many minor defects in the unit can persuade the owner to buy a new one.

For decades, the carburetor mechanisms of VAZ 2106/2107 vehicles ensured stable operation of the vehicle’s power units. However, regardless of the year of manufacture and configuration, the carburetor requires special attention to maintenance. In most cases, repairs or adjustments can be made by the driver himself, but it is recommended to be extremely careful.

Installing a custom carburetor

Owners of “classics” in some cases resort to installing non-standard carburetor models on their cars. Such an installation will require certain modifications and subsequent configuration. We are talking about the Solex 21073 and Solex 21083 carburetor models.

Model Solex 21073

This model was developed for a 1.7-liter engine and was standardly installed on the power unit of a Niva car. The Solex 21073 carburetor differs from others in its large channels and jets. Installing this model on other VAZ cars with a carburetor allows you to achieve an increase in dynamics, but fuel consumption rises to 9-12 liters per hundred.

Model Solex 21083

Solex 21083 was installed on the VAZ 2108-09. If you install it on “classic” engines, then modifications will be required. The gas distribution systems of engines 01-07 and 08-09 have a number of differences. Installing such a carburetor without modifications will lead to the fact that at speeds of about 4000 the speed of the supplied air can reach the sound speed, and the engine will not be able to spin up further. To install this model of carburetor, it is necessary to drill out the diffusers of the primary and secondary chambers to expand them. You also need to install large jets. The refinement process is labor-intensive, but the result allows you to obtain gasoline consumption lower than model 21053, and dynamics exceed those of 21073.

Checking the pump accelerator and repairing it

You need to start checking by testing the functionality of the system. You need to collect in a beaker the fuel that will be generated during 10 cycles of operation of the throttle lever. From 5.2 to 8.7 cm³ of fuel should accumulate. If this is not the case, you need to clean the VAZ 2101 carburetor jets. To do this, bleed the pump. This will help clear clogged injectors. This procedure is performed about 10 times. Then the fuel is measured again.

If the purging procedure does not give the desired result, the accelerator will need to be completely replaced.

If the engine malfunctions at high speeds, you need to check the pump diaphragm. It could wear out. The fuel pump rod often wears out.

Summarize

Finally, we add that there are single-chamber and two-chamber models of foreign-made carburetors. The disadvantages of this choice include high cost, difficulty in setting up and maintaining, as well as not always better dynamics and efficiency compared to the DAAZ, Solex or Weber carburetor models listed above.

Features of adjusting the Solex carburetor. How to set the fuel level in the float chamber, adjust the idle speed, select jets, remove dips.

Carburetor cleaning: when to clean the metering device, signs and symptoms. Available methods for cleaning the carburetor without disassembling and removing it from the car.

DIY adjustment

Each car owner of a “six” or “seven” has the ability to adjust the carburetor independently. Adjustment work can enhance the dynamic qualities of the car, as well as reduce gasoline consumption. Undoubtedly, these are important indicators for any car owner, so you should be responsible when adjusting the carburetor.

Preparatory stage

Before you start work, you need to prepare thoroughly. This stage is necessary to ensure that nothing distracts the driver during setup and configuration.

First, it is recommended to prepare your work area. The carburetor must be installed on a flat and hard surface; it is better to stock up on rags in advance, as gasoline leaks are possible. In addition, it is necessary to ensure that the room in which the adjustment is planned is well ventilated and has high-quality lighting.

The second point of preparation is the set of necessary tools. You will need to prepare in advance a set of wrenches and two screwdrivers - a Phillips and a flathead with a narrow blade.

Attention! Adjustment work is carried out only after the carburetor has been washed, worn elements have been replaced and the device has been installed on the engine.

How to enrich or lean the mixture

Enriching or depleting the air-fuel mixture must be done at engine idle speed:

- Start the engine and wait until it warms up to its operating temperature.

Tighten the fuel quality and quantity screws until they stop.

Referring to the idle speed data given in the VAZ service book, set the required number of revolutions by adjusting the screws in one direction or another.

That is, the principle of adjusting the mixture is to set the idle speed recommended by the manufacturer by reducing or increasing the enrichment of the mixture (quality screw) and reducing/increasing the amount of mixture (quantity screw).

At the bottom of the tube there is a quality screw, and a little to the right in a tube of smaller diameter there is a quantity screw

How to reduce gasoline consumption

The main element in a carburetor is the float. After you have adjusted the enrichment/leanness of the mixture, the float will invariably return to its axis. However, it may be slightly higher than normal - in this case, fuel consumption will increase. In addition, adjusting the float is also necessary in order to reduce the toxicity of gas emissions, since due to poor-quality sealing of VAZ cars, some gases can enter the cabin.

Adjustment of the float mechanism is carried out on a completely cooled motor. In order to get to it, you will need to remove the air filter box and unscrew the carburetor cap:

- The float tongue needs to be adjusted.

Adjusting the clamps and axle fastenings allows you to set the desired stroke.

Then you need to install the cover on the carburetor and screw the filter box into place.

Adjustment of the float tongue is ensured by screws and clamps

Carburetor VAZ 2107

In the 1970s, it was important for AvtoVAZ designers to create a new, easy-to-use and reliable car. They succeeded - the “Seven” is actively used on the roads today, which indicates its high quality and ease of maintenance.

The plant produced cars with both carburetor and injection systems. However, the classic standard equipment for this model is a two-chamber emulsion carburetor. After all, this was the only way to achieve simplicity and ease of use.

The standard equipment of the VAZ 2107 in the Soviet Union implied the installation of 1.5 or 1.6 liter carburetors. The maximum output power of the unit was 75 horsepower. Like all Soviet cars, the VAZ 2107 was fueled with AI-92 gasoline.

The carburetor itself on the “seven” had very modest dimensions and weighed three kilograms:

The standard carburetor on the VAZ 2107 is marked DAAZ 1107010. This two-chamber unit has a falling mixture flow and is equipped with a float chamber.

DAAZ 1107010 carburetor design

The carburetor consists of more than 60 different elements, each of which is designed to perform its own function. However, the main parts of the mechanism that directly affect the operation of the car are the following:

The main function of the carburetor is to create the air-fuel mixture in the required proportions and supply it to the engine cylinders.

Throttle valve adjustment

Adjusting the VAZ-2101 carburetor begins with adjusting the throttle valve. This is a simple procedure. It can be done in three stages. Manually turn the damper control lever counterclockwise. It opens completely.

The distance to the primary chamber is measured. The carburetor design suggests that this figure is 12.5-13.5 mm. If the result is different, you need to bend the rod antennae. Throttle adjustment involves determining the opening value of the throttle valve. It should be 14.5-15.5 mm. Otherwise, you will need to tighten the pneumatic drive rod.

What kind of carburetor can be installed on the “seven”

During the production of the VAZ 2107, AvtoVAZ designers repeatedly changed the carburetor settings so that the car fully complied with the requirements of the new time. At the same time, several tasks were solved at the same time: to obtain a more powerful engine, to reduce gasoline consumption, to ensure ease of maintenance of the device.

Carburetors from another VAZ model

It is noteworthy that the “seven” can be equipped with carburetors from both previous and subsequent VAZ series. In this case, there will be no need for modification or alteration of existing mounts and landing sites: the units are almost identical in size. In some cases, minor connection problems may occur, but these can be easily resolved.

The carburetor of the Dimitrovgrad Automotive Aggregate Plant is the first unit with which the VAZ 2107 was equipped. It must be said that the first carburetors were produced under license from the Italian company Weber, and then they were repeatedly modified to meet the needs of the domestic automobile industry. Structurally, DAAZ products are very simple, so cars with such carburetors were cheaper than analogues with other installations. In addition, the seat for the carburetor in the engine compartment of the “Seven” was originally created specifically for the DAAZ, so any version of this mechanism was ideal for it. On the VAZ 2107 you can install modifications DAAZ 2101–1107010 and DAAZ 2101–1107010–02.

The DAAZ carburetor consists of two chambers and is equipped with a mechanical drive for the damper of the first chamber. It can be installed on any domestic car with rear-wheel drive. Volume - 1, 5 and 1.6 liters. Depending on the year of manufacture, the unit may be equipped with a microswitch and a remote (i.e. external) solenoid valve.

DAAZ carburetors required fairly high gasoline consumption (up to 10 liters per 100 kilometers), but could produce excellent speed characteristics when overtaking and driving on highways.

The Ozone carburetor is a modified and optimized version of the DAAZ. The mechanism had improved environmental characteristics and consumed significantly less fuel (approximately 7–8 liters per 100 kilometers). For the “seven”, the following versions of “Ozone” are considered the best option:

“Ozone” was equipped with a pneumatic valve for efficient operation of the second dosing chamber. When accelerating, the car really had good maneuverability and dynamics, but at the slightest dust on the valve, the second chamber simply stopped working, which immediately affected the speed characteristics of the car.

The Ozone carburetor unit is almost identical to the DAAZ and has the same parameters and elements. The only difference is the modernization of the float chamber and valves.

The Ozon carburetor is no different in size from the DAAZ, and therefore can be installed on a VAZ 2107 of any year of manufacture without any problems.

"Solex"

“Solex” is currently the newest design development of the engineers of the Dimitrovgrad plant. The carburetor of this model is quite complex structurally, and is also equipped with a fuel reverse supply system. It was she who made Solex the most economical carburetor among the entire DAAZ product line.

Carburetor adjustment and tuning

You will need to adjust the VAZ 2107 carburetor and configure its systems just when you begin to notice such defects in the operation of the mechanism. What to do if your car can barely start, even when the frost has not yet arrived and the temperature outside does not drop below zero, and the tachometer needle does not float, but jumps? Or when you press the gas, the engine stalls and stalls.

There are problems such as, for example, the problem of the ignition system, where when a spark is formed, the mixture in the cylinders ignites. In older “classic” models, the ignition coil breaker is responsible for this. In more modern cars, a contactless ignition system is installed, where the ignition switch (distributor) is responsible for the appearance of the spark. But even this seemingly complex problem can be resolved manually. Many carburetor problems can also be adjusted manually. Let's try to figure out some of them...

Adjusting the float system

Any carburetor adjustment begins with adjusting the float chamber. Fuel consumption and engine stability will depend on this part of the mechanism. It is important to follow technology! We start the engine for 3-4 minutes. Then turn off the power. We remove the air filter housing, as it interferes with access to the carburetor unit. Remove the supply pipe from the surface of the carburetor. Then remove the lid from it. We measure from the edge of the float chamber to the level of the remaining fuel. The distance between them should not be more than 25.5 mm. If you find that this is not the case, then it will be necessary to adjust the position of the float. Depending on whether you decrease the distance or, on the contrary, increase it, the bracket on which the float is held will need to be bent to one side. The float axis must be positioned so that it moves freely.

Idle speed adjustment

Adjusting the idle speed of the car is carried out without disassembling the carburetor. However, before making adjustments, you will need to warm up the engine to 90 degrees. Remove the air filter housing. Take a screwdriver and tighten the quality screw until it stops. Then unscrew the screw 4 turns. We start the engine and turn on everything at once to increase energy use. We use the quantity screw to set the optimal speed for the VAZ 2107 - this number does not exceed 800 revolutions. Next, use the quality screw to achieve the maximum value - 900 revolutions. Then we unscrew it in the reverse position until the motor jerks. At this moment we stop twisting and make 1 revolution back. At the end of the work done, turn off the engine.

Adjusting the starting system

We carry out the adjustment on a not warmed up engine. The carburetor is not removed from the engine. First we connect the tachometer. Then pull out the carburetor choke control handle all the way. Let's start the engine. Using a screwdriver, open the edge of the air damper by one third. Rotate the throttle position adjusting screw under the choke control lever with an open-end wrench to 7mm and set the crankshaft speed to 3200-3400 rpm. Release the air damper. We rotate the trigger screw with a slotted screwdriver, loosening its lock nut with an 8 mm wrench. Thus, we reduce the rotation speed to 2800-3000 rpm. Finally, tighten the locknut again.

Setting the “choke” (air damper drive)

To begin setting up the air damper drive, remove the air filter from the carburetor. Open the air damper. On the damper control lever, loosen the locking screw of the drive rod end. Loosen the screw with one key, and use another 8 mm key to hold the screw bushing. We also loosen the tension of the rod sheath clamp screw. The choke handle must be recessed all the way. After making sure of this, turn the air damper control lever all the way by hand. The distance we set between the edge of the rod shell and the angle of the lever should be 10 mm. Turn the air damper control lever back clockwise. Finally, tighten the shell locking screw and the rod locking screw. Don't forget to make sure that the damper opens and closes completely.

If you are clearly confident that you will undertake the repair of your carburetor yourself, then additional information about the problems associated with it will definitely be useful to you. Well-known carburetor expert Nail Poroshin can share advice on this topic on the Internet.

Carburetor filter

The carburetor strainer is responsible for the normal flow of gasoline from the fuel line into the float chamber. Therefore, in order to avoid the problems that its contamination can bring (and this means improper operation of the entire fuel system!), it is recommended to carry out periodic cleaning.

Cleaning the strainer

Using a 13 key, unscrew the filter plug and remove it along with the mesh filter. Then we clean the cells of the mesh filter (a toothbrush will do) and blow them with compressed air. In the same way, we clean the removed filter plug and its seat in the carburetor cover. And be sure to blow everything out with compressed air.

Installing two carburetors

Two carburetors on the VAZ 2107 will give the car additional power. In addition, fuel consumption will be significantly reduced, which is very important for any driver today.

The procedure for installing two carburetors at once is advisable in the following cases:

Self-installation of two carburetors is possible only if you have the tools and knowledge of the design of your car. The procedure itself is not considered complicated, however, if there are errors in connecting the fuel supply hoses, one or another mechanism may fail. Therefore, to install two carburetor units on a VAZ 2107, it is recommended to contact specialists.

Video: two Solex carburetors on a VAZ car

At the moment, VAZ 2107 cars are very actively used in Russia. Models equipped with carburetors have excellent performance characteristics and are quickly and cheaply serviced and repaired. For the convenience of the driver, carburetors of various types and brands can be installed on the “seven”. However, before installation, you need to calculate the feasibility of such work and guarantee the expected result.

Source

How to remove the unit

Indeed, this question may take an inexperienced owner of a “six” or “seven” by surprise. But the dismantling procedure itself is not considered difficult. The main thing is to remember or write down the connection points of different hoses, since the reverse installation may cause difficulties during the first experience.

It is important to disconnect the fuel lines and wires in sequence

The preparatory stage includes removing the air filter box, since the filter will prevent free access to the carburetor. Further work takes no more than 10 minutes:

- First, two thin wires are disconnected from the carburetor body - the first ensures the operation of the air damper, and the second is connected to the throttle.

The return spring and its retainer are immediately disconnected.

The next step is to disconnect the forced idle economizer wire.

Loosen the clamp connection on the wide gasoline supply pipe and remove the hose itself. After this, you can remove the fuel return hose.

The ventilation and vacuum hoses can be disconnected from the fittings at the top of the housing.

During work, it is recommended to close the open hole in the manifold with soft cloths or a special plug, which can be purchased at a car dealership. This will ensure the cleanliness of the engine and prevent dirt from getting inside the power unit.

Carburetor VAZ 2107: carburetor diagram design

The unit that prepares the air-fuel mixture and supplies it to the power unit is the most important component of all cars of the classic series (only export models were equipped with injection devices) and some other models produced at the Volzhsky plant. Despite the fact that modern vehicles are no longer equipped with carburetor engines, a large number of cars with such engines still faithfully serve their owners. Therefore, it is important to know what the VAZ 2107 carburetor is, to have an understanding of its design and maintenance.

How to change the gasket

Over the years, gaskets made from a wide variety of materials were installed on DAAZ: heat-resistant cardboard, paronite, metal. The main function of the gasket is to create the most reliable and tight connection between the carburetor body and the surface of the engine intake manifold. This is the only way to ensure normal operation of the power unit.

After dismantling the carburetor, it is necessary to inspect the gasket for deformations, tears or severe dents. The manufacturer recommends changing the seal after each carburetor removal.

On the left - new, in the center - when dismantling the carburetor for the first time, on the right - after 3 years of operation of the car

The gasket is selected according to the type of the old one. You cannot install a gasket made of a different material or with a change in shape - it will not be able to provide an adequate joint between the parts of the mechanisms.

The gasket replacement procedure is not difficult:

- A new gasket is placed on the carburetor mounting studs.

Before this, you need to clean the planting site from soot and dirt.

It is necessary to install the gasket in the same position as the old one.

Then install the carburetor on it and tighten the fixing nuts until they stop.

Main types of DAAZ carburetors

Of course, carburetor feed mixture supply systems are considered obsolete today. However, according to a number of criteria they are superior to injection designs. A small number of electronic components increases the reliability of the unit and ensures ease of repair work. In addition, carburetor engines do not have high requirements for fuel quality.

Carburetors can be of three types.

What to put?

Sometimes there is a need to completely replace the carburetor. Therefore, you immediately need to decide which model to buy. Today there are two most common families: Solex and Ozone carburetors.

Many car owners don’t even know what kind of device they have. Externally, these devices can be distinguished by the following characteristics.

- In Ozone, the fuel intake fitting has the shape of an oblong tube, in Solex it is a return

- Ozone consists of three parts: the throttle valve axis, the float chamber and the cover. Solex consists of only two parts: the lower part with the float chamber and the upper part - the cover in which the float is held.

- The ozone has a vacuum valve that controls the opening of the throttle valve of the second chamber.

- On a Solex carburetor, the air damper is controlled by such a large lever: On ozone, this lever looks completely different. It is also called a three-arm lever.

In the 90s, a massive hobby began to replace the standard Ozone with Solex. Taxi drivers were especially guilty of this. This was explained by the fact that fuel consumption decreased slightly, and engine dynamics became a little better.

If you install an oxygen sensor and compare its values on different models, you can understand the reason for this phenomenon. With Solex, after adjusting the mixture composition, the range in composition is no more than one. On ozone, after adjusting the mixture at the moments of braking and acceleration, the mixture acquires a very strong spread of values. At the same time, it can increase or decrease by a large value.

This is due to the fact that the jets on the Solex are located in the center of the float chamber. When the position of the car changes during sharp turns or during acceleration and braking, part of the fuel is deflected by inertia towards one of the walls of the float chamber. The central location of the jets reduces the likelihood of changes in the fuel composition at these moments.

On ozone, the device is significantly different. The jets are not in the center. Therefore, fuel moves around the float chamber in different directions, which significantly changes the spread of air proportions in the fuel mixture. In different driving modes, the engine receives a different mixture composition.

So, the Solex carburetor on the VAZ 2106 keeps the mixture more stable while driving. This is its main technical advantage.

Who produces and on what VAZ models it is installed

The Dimitrovgrad Automotive Aggregate Plant (DAAZ) produced carburetors to equip various cars produced in Tolyatti. All of them are of the float type.

Table. Types of DAAZ carburetors for VAZ cars with a 1.5 liter engine.

| Carburetor model | car model |

| 2107–1107010–20 | VAZ 2103, 2106 |

| 2107–1107010 | VAZ 2105, 2107 |

| 2107–1107010–10 | VAZ 2106,2103 |

Modifications of DAAZ carburetors are also used to equip cars.

In addition to these modifications, the Pekar carburetor was assembled in St. Petersburg (then Leningrad), which became an analogue of the DAAZ and OZON models. Its main differences are low cost with excellent operational parameters, unpretentiousness and long service life.

The basic model installed on the VAZ-2017 is the DAAZ 2107–1107010 carburetor. However, the car can also be equipped with all of the listed types of devices.

How to reinstall the carburetor

After the device has been washed and repaired, you will need to reinstall the carburetor. To do this, first a new seal is applied to the installation site, and the carburetor itself is installed on it. Nuts are screwed onto the four mounting studs, ensuring a tight fit of the carburetor body to the engine manifold:

- Then you will need to connect two thin hoses for vacuum and ventilation to two fittings that are located in the upper part of the carburetor.

A fuel supply hose is connected to the inlet valve; it is recommended to replace the clamp with a new product.

The return hose is screwed on the reverse side.

It is better to install the throttle return spring before connecting the throttle and air valves.

Installation and connection of the DAAZ carburetor is considered complete.

Basic operations for removing/reinstalling, flushing and adjusting the carburetor are available to drivers with any level of training and experience. It should be borne in mind that the mechanisms are considered to be quite capricious, so all stages of the procedures you perform will require increased concentration.

We examine the cone of the needle for development (in the form of a rim at the tip). If we do not find any signs of wear, then we wash the valve and seat (first wash the fuel filter) and check the needle tightness again. We replace the faulty and worn needle with a new one. It is possible to restore the valve's functionality by slightly enlarging the hole in the seat, but this operation requires care and plumbing skills and is not always successful.

Carburetor design

The unit installed on the “seven”, despite the abundance of parts, is not complicated. Knowing the structure of the carburetor, you can independently replace failed elements.

Main components of the unit:

Gas tank capacity, autonomous mileage on gasoline

Gas tank of LADA 2107 sedan, autonomous mileage

| Engine | Gas tank | Full filling | Autonomous mileage on gasoline | ||

| In the city | On the road | Mixed | |||

| 1.3MT | 39 l. | ||||

| 1.3MT | 39 l. | ||||

| 1.5 MT | 39 l. | ||||

| 1.6MT | 39 l. | ||||

| 1.6MT | 39 l. | ||||

| 1.7MT | 39 l. | ||||

| Gas tank capacity in liters. Price per liter of gasoline in calculations: AI-92 - 45.00 rubles, AI-95 - 47.00 rubles. | |||||

The principle of operation of the carburetor

The functioning of the power unit is largely determined by the quantity and quality of the incoming fuel mixture.

How the 2107 carburetor works:

Fuel enters the float chamber, the level of which is regulated by a valve or float. After this, the gasoline, divided into droplets, enters the mixing chamber through nozzles, where mixing with the air occurs. The econostat further enriches the mixture when the engine is running at full load. Diffusers optimize the flow of fuel, which is supplied to the manifold through the throttle valves. When the engine runs at high speeds, the accelerator pump turns on.

Basic faults

Solex carburetors are the same technology as other mechanisms in a car, so even with proper operation, it can wear out and eventually fail. Some of the faults can be determined by the way the machine operates. But there may be something hidden from your eyes inside the carburetor body. In this case, diagnosing the breakdown will be much more difficult.

The owner of a VAZ 2107 can judge the incorrect operation of the Solex by the following signs:

- jerks and jolts when the vehicle moves;

- increased fuel consumption;

- problems starting the ignition;

- engine failures;

- decreased acceleration dynamics;

- idle failures.

Faulty operation of the VAZ 2107 carburetor when it wears out has a bad effect on engine power. Some things can still be cleaned, but somewhere else a full replacement of parts will be required. Any problems associated with misalignment of parts or associated with changes in the operation of the power unit are a clear knock on the door of the repair room.

Let's look at the most common problems that arise when a Solex carburetor wears out:

Gasoline is not supplied

The reasons that fuel does not enter the carburetor may be: lack of pressure in the fuel supply system, faulty fuel pump, dirt in the supply hose from the gas tank, or an outdated gas filter. In this case, it is recommended to try to blow out the fuel line or change the fuel filter.

Pouring gasoline

If you find leaks of gasoline (especially in winter they are very easy to notice - small puddles of gasoline in the snow), then be careful! This may cause a fire . Therefore, this problem must be resolved immediately! Most likely the solution lies in the depressurization of the hoses. The operation of the accelerator pump also needs to be checked, since if the problem is related specifically to it, then the cause of gasoline leaks may be excess fuel that is formed during accelerated operation of the pump.

Shoots

“Shooting” in the carburetor can be caused by a severe leanness of the fuel mixture, incorrect connection of high-voltage wires, a timing belt that is displaced by two or three teeth (when you change it completely, the belt must be tensioned well, and over time, tightened when displaced) and incorrectly installed ignition moment. The malfunction is detected when you press the gas pedal. As a result, you see the car jerking jerkily, after which it begins to stall.

The second camera does not work

Often the second chamber on Solex carburetors reminds of itself by breaking down. To eliminate it, we need to establish the cause of its occurrence. There can be as many reasons as with “shooting”. Here are all kinds of malfunctions: flooding of the carburetor chamber, incorrectly set gap, problems with opening the damper, lack of the proper amount of fuel, some components of the chamber have failed. You can determine the cause of the malfunction by unscrewing a couple of spark plugs. If the carbon deposits on the spark plugs are abnormal (black), this may indicate either a mixture that is too rich or too lean. Ideally, it is necessary to check the operation of all elements of the system.

Accelerator pump does not work

This problem can occur if the accelerator pump does not operate correctly. Because of this, the volume of fuel may be too large or too small, since the required pressure in the system is not provided. To solve this problem, you will need to remove the carburetor, disassemble the pump device and diagnose its operation. Most often, the malfunction may be due to wear of the rubber parts of the pump.

The engine stalls when you press the gas

One of the most common problems that VAZ 2107 owners face is the engine’s refusal to start. This can happen even after the car has been started. All this tells us that the fault lies in the float chamber. There may simply be no fuel in it or its level may be extremely low. Most often, engine starting problems occur due to the mixture being rich or lean. To deal with this problem, you will need to disassemble the carburetor and check the functionality of individual elements. (float, jets, dispenser)

If the car is only idling and the same problem occurs, then the malfunction may be hidden in such components as: control unit, solenoid valve mechanism, idle jets.

Regardless of what the problem is, you will need to inspect all parts of the idle system, adjust their quality and quantity with screws, tighten them, blow them and wash them.

VAZ2107 carburetor: how to clean the unit from dirt, step by step

Often, malfunctions of the device are associated with its contamination.

Signs that can help diagnose the problem:

You can clean the carburetor from blockages on your own. This requires washing the strainer located at the inlet of the float chamber. In addition, cleaning the chamber itself, as well as other components, especially the jets, will help solve the problem.

It is important to remove plaque on the internal walls of the unit, which forms during the operation of the crankcase ventilation system. The walls of the neck, dampers, and diffusers do not need to be cleaned, although if the unit is being serviced, it is better to remove dirt everywhere.

Work technology:

Important! The condition of the strainer must be checked every 50...80 thousand km. mileage

Important! Gaskets with significant wear are recommended to be replaced.

After cleaning the parts from dirt, the carburetor is assembled.

Starter battery correction

At the second stage, you will need to adjust the operation of the starting device. The throttle lever on the secondary chamber is manually turned counterclockwise. It will close. The tip of the thrust lever should fit snugly against the axis of the primary chamber throttle valve.

At the very end there should be a starter rod. Otherwise, you will need to adjust its position. To do this, the rod is bent. This device in carburetor engines is fragile. If you apply too much force to it, the rod will break off.

Cleaning the carburetor without disassembling

In some cases, it is possible to clean the unit without dismantling it. Typically, this need arises when traveling, when it is not possible to get to a service station or remove the VAZ carburetor at home.

To carry out the work, you need to stock up on carburetor cleaning spray.

Important! It is not recommended to use gasoline, diesel fuel or kerosene for these purposes.

How to clean:

It should be noted that subsequently you will still have to disassemble the carburetor on the VAZ 2107, since the dirt accumulated in the float chamber remains there. It will soon clog the jets again.

Washing DAAZ without disassembling

The traditional method of washing carburetors is to completely disassemble them into individual components, which is not always possible for an inexperienced VAZ owner to do. To simplify the procedure, a technique was created for washing and cleaning the carburetor without disassembling it into components. This technique is based on the use of special aerosols in cans.

The most affordable carburetor cleaners are considered to be aerosols produced by ABRO and Mannol - they can be bought at any auto store for 100–150 rubles.

The cans are equipped with a thin tube for access to all parts of the carburetor

These cleaners do an excellent job of cleaning carburetor mechanisms, and they are also very easy to use. To flush the carburetor, it is recommended to turn off the engine, let it cool and begin the procedure:

- Remove the air filter box from the car and place it to the side.

Unscrew the solenoid valve from the carburetor body.

Place a special narrow nozzle on the aerosol can and treat the nozzle channels, first and second chambers, dampers and all visible elements of the carburetor assembly with liquid.

After this, spray the aerosol on the external parts of the mechanism.

If during one procedure the carburetor did not have time to be properly cleaned, then you can treat it again with the same aerosol.

After such cleaning, the VAZ 2108/2109 will significantly increase its dynamic characteristics, since the accumulation of dirt will not interfere with the normal operation of all parts of the carburetor.

Carburetor Solex 21083 DAAZ for VAZ 2108-2109-21099 (21083-1107010)

Today Nail Poroshin will tell and show the main nuances of installing the 53rd Carburetor

to the Classics! Everyone.

This is not much more difficult to restore under standard conditions. What cannot be said about the difficulty of working with the injector in this case. When the plant in Togliatti began producing the VAZ 2109 carburetor

, he chose a proven and fairly loaded one. As for the settings, everything is clear with these carburetors.

Our readers often ask which carburetor is better to install on the VAZ 2109? It is difficult to answer this question unambiguously. But let's think about it. Of what the market offers, the most famous are Solex, Weber and DAAZ. The first is perhaps the most common. The second one is difficult to install, but it is of excellent quality.

And with the third one, how lucky. On the VAZ 21093, most often the carburetors are Weber 40 DCOE 151. Among the owners of Lada Samara of this model, they believe that the Weber model is better.

It is difficult to judge how right certain VAZ owners are, because any carburetors break. And, as practice shows, successful webpers sometimes do not find spare parts, while less complex Solexes compare favorably in this regard. As mechanics say, the life of a simple mechanic is both complex and uncomplicated. The carburetors are far from the best. Especially when it comes to repairing domestic automotive equipment.

Disassembling, cleaning and washing the carburetor from nine. this is another headache. Especially when you have to carry out these procedures in the field, and not in a cozy and hot box. It's hard to blame VAZ, it's the prices for spare parts.

Here they are much more profitable than most competitors. Take at least such a moment as the price of a VAZ 2109 carburetor. This spare part for a VAZ 2109 car is much less than in the case of most foreign cars.

The retail price of a VAZ 2109 carburetor ranges from 3 to 5 thousand rubles. Some car owners choose a service such as VAZ 2109 carburetor tuning. It is difficult to say how much this service is in demand now. But people put a sports carburetor. Of course, to increase the power of the VAZ 2109 engine, the sports type of carburetor influences. But how justified this is in urban conditions, especially in Russia, is difficult to say.