In our country, cars are often used for more than fifteen years, sometimes after major repairs for more than twenty or even longer. VAZ kopecks produced in the early seventies of the last century can be found very often on our roads. One of the biggest malfunctions can be called stuck piston rings - signs and solutions that we will describe in this article.

With proper care and timely service, a car of any brand can last for many years, and this does not require the knowledge of a top-class mechanic.

What are piston rings?

Piston rings are open rings located in grooves in the surfaces of power plant pistons.

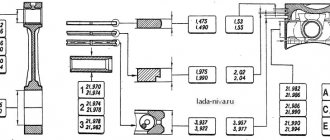

Piston system

When designing a motor, designers constantly have to solve the same problem - the diameter of the bottom of the piston and cylinder must be different sizes. And at the same time, the lubricant should in no way end up in the chamber where fuel combustion occurs. The use of a heavy piston may cause it to jam in the cylinder, even though its diameter will be slightly smaller. But the use of a narrow flexible ring, which has a movable lock, will allow it to move freely. This option is still considered the best.

Rings are divided into two types - compression and oil scraper. The main purpose of the former is to create pressure in the chamber.

Two types of piston rings

The engine design has a small gap between the cylinders and pistons, which makes it impossible to create the required pressure in the chamber. When expanding, the gases would certainly penetrate into the crankcase of the power plant. This problem was solved only by installing additional compression rings, which are thin rings with a cut. The cut is a lock that allows the tight ring to compress and expand within specified limits, while not allowing it to jump off the piston. To allow the rings to compress freely, there are grooves on the outer surface of the cylinder body.

The rings are made of a special grade of steel and are a kind of spring, which is in a slightly compressed state, which allows it to fit tightly to the walls of the cylinder. During operation, they gradually wear off, but the tightness of their fit remains the same until their wear reaches a critical level.

A design feature of modern pistons is 3 rings. Compression - a pair, oil scraper - one.

The use of compression rings does not completely solve the problem of gas breakthrough. It can be solved in a variety of ways, for example, during the installation of the rings, they are positioned in such a way that the locks are not located on top of each other. Their best location is 180 degrees, so that they are in opposite directions. You should definitely pay attention to this during engine overhaul.

Why do the rings lie?

To understand the reasons for the occurrence, you should remember how they work. The piston rings are located in the grooves of the piston. The grooves themselves are wide enough to allow the rings to move fairly freely. The rings placed on the piston do not fit closely to it, but, on the contrary, are pushed apart. Thus, the expanding force forces them to fit tightly against the cylinder walls, providing high pressure inside the combustion chamber at the end of the compression stroke.

This entails all the symptoms indicated at the beginning of the article: difficulty starting the engine, especially in cold weather and a drop in power due to the presence of compression rings, as well as increased oil and fuel consumption and thick blue smoke from the exhaust pipe, for which the oil scraper rings are to blame.

There are several reasons for the appearance of deposits in grooves:

- the car is not used for a very long time, as a result of which the engine oil loses its properties, thickens and begins to play the role of glue;

- The car often takes short trips, during which the engine does not have time to fully warm up. In this case, a large amount of carbon deposits forms in the cylinders, which does not have time to completely burn out due to the engine operating time being too short;

- low-quality motor oil, which burns out much more intensely than high-quality lubricant.

Reasons for occurrence

Most car owners do not even imagine why the problem occurs and how to eliminate this problem at an early stage. In reality, everything is much simpler than it might seem at first glance. The main culprit for the occurrence of rings is the carbon deposits that form in the power plant. Motor lubricant partially burns out in the engine, and the ring grooves become clogged.

Carbon deposits from oil combustion

The result is deterioration of the seal between the pistons and cylinders of the vehicle engine. As a result, carbon deposits form, which leads to sticking of the rings.

Signs and symptoms of rings:

- Reducing engine compression. This can be determined not only by diagnostics, but also by a decrease in engine power. A stuck piston cannot guarantee the required level of mixture compression. This is especially noticeable when starting in the cold season.

- If lubricant consumption has increased.

- There is a burning smell. Blueish smoke comes out of the exhaust pipe.

The occurrence of rings is caused by operating the car without first fully warming up the engine. Short trips of up to five to seven kilometers have a negative effect on the engine. This time is clearly not enough for the engine to warm up to the required operating temperature.

The use of low-quality oil that burns out at high temperatures directly in the engine.

Signs of a problem

The position of the rings in the engine is directly related to compression. If we talk about gasoline engines, the normal compression rate will be from 9 to 13 atm. Diesel engines have a slightly different structure. Therefore, a compression of 28-35 atm is considered normal for them. In this case, there should not be a significant run-up between the cylinders.

Remedies

Having discovered the first symptoms with the occurrence of rings, all car enthusiasts deal with them in different ways, but there are three main ways.

- The most common method is to use a mixture of kerosene and acetone (in equal proportions). The spark plugs must be unscrewed and the mixture must be poured into all combustion chambers. Next, the motor needs to be left for 8-12 hours, acidification should occur in the chambers. Then the candles are put back. The engine starts and you need to drive along a flat road at maximum speed for about fifteen kilometers. Typically, this method allows you to solve the problem of rings sticking and without resorting to expensive repairs. Next you need to change the filters and oil.

- The next method is almost identical to the previous one, with the only difference being that regular kerosene is poured. Other conditions, driving on a flat road and changing the lubricant mixture and filter must be met.

Prevention

Now we know why the rings are stuck in the engine and what to do about it. But in order not to encounter such a problem, it is better to know preventive measures. They are quite simple and clear:

- It is necessary to monitor the condition of the valve stem seals. Their malfunction will be indicated by high oil consumption. There is no need to delay replacing these caps.

- Fill only with proven oil. It must also meet all tolerances. A quality product should not burn out in the engine. If the engine begins to eat it up, adding oil with a higher viscosity will not solve the problem.

- Maintain the engine according to the regulations. Moreover, in our conditions it is recommended to reduce the oil change interval to 10 thousand kilometers. Regular replacement will prevent such situations, since the fresh product has persistent additives and does not burn out, leaving carbon deposits.

If the mileage of the car is more than three hundred thousand, the rings may already be worn out. This is a natural process, so in case of oil leaks on older engines, it is recommended to immediately repair the CPG. But, of course, it’s better to start with the valve stem seals (especially if the problem is only oil consumption, but the power and other characteristics remain the same).

Video “Coking rings”

This video shows what to do if the piston rings are stuck. What are the best products to use and how to use them correctly.

Engine malfunctions are some of the most annoying and costly. If, for example, a rusty or rotten body does not affect the speed in any way, then a malfunction in the engine will somehow affect the dynamics and overall operation of the power unit.

One of the most important engine groups is the cylinder-piston group (CPG). This group is directly involved in the combustion of the air-fuel mixture (FA). Working in harsh conditions, the CPG is subjected to serious loads, which in one way or another affect the service life of the working parts.

One of the main failures of the CPG is the occurrence of the piston rings, which are responsible for a lot of processes during the power stroke of the piston. The occurrence is mainly due to the appearance of deposits, which over time turn into hard carbon deposits. Carbon deposits block the mobility of the rings and also clog technological holes in the compression and oil scraper rings. As a result of this phenomenon, compression in the engine decreases, and the supply of lubricant to the cylinders also deteriorates. Working under such conditions, the piston is subjected to even greater stress. since there is no proper lubrication, friction occurs almost “dry”, and due to a drop in compression, power decreases and fuel consumption increases.

What does this threaten?

Most drivers prefer to ignore the first signs of trouble. The car running is the main thing. Not realizing that the problem gets worse with every minute the engine runs:

- Gases that have broken through into the crankcase change the chemical composition of the oil, a reaction occurs and it is saturated with fuel combustion products. The oil gradually loses its lubricating and cooling properties, causing wear of all engine parts lubricated by it to increase.

- In addition, fuel begins to partially enter the oil, diluting it, reducing lubricity.

- Oil burning in the cylinders, which is not collected by the oil scraper rings, produces carbon deposits that cause the remaining rings to stick, damage the pistons and liners (scratches and scuffs appear), their wear increases, and cooling decreases.

- Next comes the piston burning out or jamming, which will be followed by expensive and time-consuming repairs, almost equivalent to replacing the engine. Since most of the parts will no longer be suitable for use. And after the piston jams, as a rule, the connecting rod breaks and the block is destroyed.

The result of ignoring signs of breakdown

Signs of stuck piston rings

- Traction disappears, power drops. The car accelerates poorly and loses power at the slightest load (driving downhill, with a load, etc.).

- Compression in the cylinders decreases. This parameter, as a rule, manifests itself with signs characteristic of the previous paragraph, however, it is possible to accurately establish that the compression has decreased only by taking appropriate measurements. You can check the compression like this!

- The engine does not start well. As a rule, stuck piston rings affect starting, especially in cold weather, when the temperature drops below -5 C°.

- The engine takes oil. Due to improper lubrication and removal of oil, it burns and naturally its consumption increases and the level drops. The derivatives of this phenomenon are blue smoke from the exhaust and a characteristic smell of burning and oil.

Diagnostics using compression

The above problems with the power unit can be identified through special diagnostics using a compression meter.

This is a device that measures pressure. You can do such diagnostics in your garage. To do this, you will need the help of a friend and the presence of the device itself.

To carry it out correctly, you need to adhere to the following algorithm. First you need to put the car in the garage and warm up its engine to operating temperature.

After this, disconnect the spark plug of the first cylinder and insert a compression gauge there. Using the starter, start the engine for a few seconds (crank the crankshaft), and remember the pressure that the device shows. Next, you need to pour no more than 20 grams of oil into the cylinder chamber and turn the crankshaft again. If the pressure in the first case is low, and in the second case it increases, then the problem is in the piston rings and they definitely need to be changed.

Next, the second and subsequent candles are removed, and similar manipulations are carried out.

As you can see, there is nothing complicated in such a diagnosis, but it helps to identify one of the problems with the appearance of smoke.

It is important to remember that loss of engine power at high speeds or loads also indicates that the piston rings are worn out.

The reason for the appearance of smoke of different colors from the exhaust pipe may indicate several problems in the power unit. If they are diagnosed on time, then large deviations in engine operation will not appear. If you start it, then serious breakdowns may occur, and large costs for their correction may occur.

Oil scraper rings are one of the most important engine components. What kind of parts are these, where they are installed and how to replace them - every car owner must know in order to help his iron friend at any time.

Causes of stuck piston rings

Poor warming up of a cold engine. Although most modern engine manufacturers claim that there is no need to warm up the power unit, practice shows the opposite. Regular driving on a cold engine, especially when the engine receives heavy loads immediately after starting, leads to engine malfunction. A cold motor that has received a load wears out without proper lubrication and with gaps in parts that disappear only after warming up.

Low quality motor oil. Those who like to save on oil for their engine risk completely ruining the engine. Low-quality oil does not have the proper tolerances, detergent components, and also does not have the necessary fluidity, therefore, it cannot create a dense oil film.

Cause of smoke in the exhaust pipe

In order to understand the question of why the engine smokes, you need to have an idea of what happens in it during operation.

A fuel mixture is formed in the combustion chamber, which is compressed by the piston and ignited by a spark from the spark plug. The mixture is supplied through the inlet valves, and the spent mixture is discharged through the outlet valves. The pistons have special oil intake rings; they are needed to collect excess oil on the cylinder walls so that it does not enter the combustion chamber.

The engine valves also have special seals (caps), which serve to ensure that the oil located in the cylinder head does not enter the combustion chamber. In addition, spark plugs also play an important role, and if they have a weak spark, or the gaps between the electrodes are incorrectly set, then the fuel mixture in the engine will not burn completely.

Based on this, we can identify the following causes of engine smoke.

- Spark plug . If the spark plugs are faulty, that is, they produce a weak spark, or the gaps between their electrodes are set incorrectly, then the fuel mixture does not burn completely and is discharged from the combustion chamber with blue smoke. In the most severe cases it may be black.

- Piston oil intake rings. As stated above, oil intake rings perform a function related to cleaning the cylinder walls of excess oil so that it does not enter the combustion chamber. They are subject to a powerful frictional force. If they wear out, the oil enters the combustion chamber and ignites along with the fuel mixture. In this case, black smoke appears. Similar functions are also performed by engine rings, which also remove excess oil from the surface of the cylinders and can wear out over time.

- Valve caps. These are seals that serve to prevent the oil in the cylinder head from entering the combustion chamber, and are made of dense rubber. When it wears out, the lubricant enters the combustion chamber and ignites. This produces white (or bluish) smoke.

The last two reasons for smokiness will be discussed below. If a car owner notices the appearance of blue or blue smoke, he needs to pay close attention to the operation of the power unit’s spark plugs and have them diagnosed or replaced.

You need to remember that sometimes the cause of smoke in the exhaust pipe can be bad gasoline. It may contain various additives or additives that will create black or other colored smoke. This problem usually disappears when refueling with other fuel.

Decarbonization of piston rings

If there are piston rings stuck in the engine, you will one way or another have to find out what piston ring decarbonization is. This procedure can be carried out in different ways, the most popular of which I will describe below.

- Method one . A composition of kerosene and acetone in equal proportions is poured into the combustion chambers through spark plug wells. Next, the motor is given time to oxidize, usually a day or a day, depending on the degree of contamination. After this, the spark plugs are screwed into place, and the engine, after normal warming up, is given a normal load while driving. This could be a highway and good acceleration, during which the engine can “cough up” all the dirt and carbon deposits contained in the cylinders. After completing this procedure, it is necessary to replace the engine oil, oil and fuel filters.

- Method two . In the same way, a special wash is poured into the chambers, which can dissolve carbon deposits and unblock the engine piston rings. There are a lot of different products on the market designed to do this job, so there is no point in naming specific brands. The method of application is approximately the same, but it is still better to follow the instructions for using a particular chemical.

The next day

Well, now unscrew the spark plugs and see what happens. We take a syringe with a tube and pump out the remaining liquid. Perhaps the liquid has gone into the pan, it’s okay, this also happens. Cover the spark plug holes with a rag and turn the starter for 5 seconds to squeeze out any remaining fluid. A rag is needed in order not to spoil the car's paintwork.

We screw in the old spark plugs, add flush to the engine and start it. It may not start right away - this is normal. At first it will smoke a lot, this is also normal. Remains of decoking and deposits in the cylinders burn out. The engine must not be loaded. Leave to work for 5 minutes.

Now drain the old oil, change the filter, spark plugs and fill in new oil. We try to measure the compression and evaluate our results.

Photos taken from the Internet!

How can I prevent this from happening in the future? Prevention is better than cure!

A number of simple rules should be followed to avoid a similar phenomenon in the future.

- First of all, you should warm up the engine for at least a few minutes, and after starting to move, try to move at minimum speed until the engine reaches the desired temperature.

- Do not skimp and fill only high-quality oil into the engine. Good oil is the key to the success of any mechanism. Using good oil, you can avoid engine problems, as well as avoid the appearance of soot, deposits and other troubles.

- Carry out intermediate inspections. If possible, do preventive examinations from specialists, measure compression in the cylinders, check the condition of the spark plugs, monitor the cleanliness of the exhaust, and also conduct comprehensive computer diagnostics of the power unit and all its systems.

Only this approach will allow you to protect yourself and avoid possible problems with piston rings and CPG. However, even if you had to deal with the problem of stuck piston rings, you shouldn’t be too upset, any breakdown can be repaired, and a car is, first of all, hardware that breaks down regardless of brands and prices. The main thing is to have health and the desire to fix it all. Stay safe and thank you for reading to the end.

That’s all I have, I would be grateful if you share this article on social networks using the special buttons located under the article. Bye everyone, good luck!

Decent care contributes to a significant increase in the trouble-free operation of the vehicle. It is also guaranteed by regular maintenance, vigilant monitoring of the condition of consumables and timely replacement of worn or deformed parts that threaten impending failure.

Regardless of the time the power unit is used, mileage of more than 150 thousand km usually affects its performance, causing significant problems. Among them, we can note the unpleasant situation with the occurrence of piston rings.

Timely detection and immediate elimination of such a malfunction can protect the car owner’s wallet from significant costs for unplanned engine overhauls.

Let's sum it up

Any problem is easier to prevent, so the best option is to use additives at the first sign of ring sticking. A completely coked engine can only be saved by a major overhaul. However, there are still ways to reduce the contamination of ring grooves with dirt:

- do not skip oil changes, carry them out strictly according to the regulations prescribed in the car manual;

- warm up the engine, even if you go to the store for bread and back, this burns deposits;

- use only branded high-quality oil, avoid counterfeits;

- use only recommended oils for your engine;

- After the car has been parked for a long time in the garage or on the street (for example, all winter), it is better to change the lubricant before driving it again.

How to decarbonize piston rings, watch the video:

Purpose of piston rings

Among the main key elements that make up the design of power units, pistons are by no means the least important. To maintain their working condition for a long time, it is necessary to maintain high-quality lubrication of the parts. In this case, the combustion chamber must be constantly protected from oil penetration.

The entry of lubricant into the system leads to the formation of carbon deposits, negatively affecting the functionality of the motors. Gases entering the crankcase from the combustion chamber also have a negative impact on the performance of the engine.

Open rings placed on the piston have two types: compression and oil scraper. Their difference lies in the functions they perform:

- The main purpose of compression rings is to protect the crankcase of the power plant from the penetration of gases from the combustion chamber. By compressing and expanding within the limits provided by the designers, they maintain the required pressure in the system. Engine compression rings are usually used in pairs. In this case, the breaks of open elements are positioned relative to each other at 180 0. This placement method promotes better compaction;

- In the design of modern engines there is one more ring, an oil scraper ring. Its function is to protect the combustion chamber from oil penetration.

Separately, we note that special grooves are provided on the pistons for installing rings. Such a device is included by the manufacturers in the design of the unit, providing fairly reliable fixation of the parts.

What to do if the rings wear out?

In order to choose a way to solve a problem, you need to find out why it arose. The occurrence of the above symptoms may be caused by wear or breakage of the compression and oil rings, or if they are coked and stuck.

In the first case, it will be necessary to disassemble the engine and install new parts instead of damaged ones. In this case, you should carefully inspect all mating parts, since if the rings break, scoring may occur, which can only be eliminated by carrying out a major overhaul.

If there is an assumption that the piston and oil scraper rings are stuck, then you can add a special additive to the oil. But this method is used, as a rule, for preventive purposes.

Malfunctions related to piston rings arise in practice quite often. Therefore, in order to prevent serious consequences and, as a result, high repair costs, it is necessary to recognize their first symptoms in time and take appropriate measures.

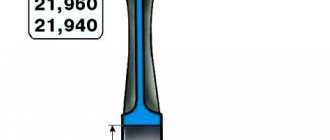

FEATURES OF OIL RING INSTALLATION

I would like to draw your attention to the installation of oil scraper rings. There should be no problems with compression if you follow simple rules, install them with the inscriptions facing up (inscriptions, dot) and use a special tool.

When installing oil scraper valves, difficulties may arise if there are no inscriptions, or if the expander lock is installed correctly. Let's look at this in more detail. If there are no inscriptions, then it does not matter which side you put the ring on and which one will be on top and which one will be on the bottom (inlaid).

Often errors occur when installing the piston into the cylinder, even if a special clamp is used to tighten the rings on the piston. The peculiarity is as follows. When assembling the oil scraper ring, you should pay attention to the expander lock and the correctness of its docking. For clarity, see the image below.

During compression of the rings on the piston, the lock of the oil scraper ring expander can jump out of the correct position and overlap, gathering in a spiral, so the plates fall through the expander and this will lead to scuffing of the cylinder walls and piston grooves. To avoid this, the tightening clamp should be positioned as shown in the image.

Prerequisites for the occurrence of rings

During long-term operation of the engine, a large layer of soot forms on its elements. This is considered to be the main reason causing the occurrence of rings. And the main prerequisites for the formation of excessive amounts of soot are:

- short driving on an insufficiently warmed up engine. Short distances of 5-10 km are considered especially dangerous;

- various damage to valve stem seals, up to complete failure;

- lubricants of insufficient quality poured into the power unit. It should be noted that oil with the proper level of properties does not burn out in the engine, maintaining the specified initial characteristics;

- The last cause of excessive carbon formation is untimely replacement of lubricant. The manufacturer's recommendations should be carefully followed, limiting the period of use of the petroleum product. Also, do not forget to change the oil filter regularly and on time.

Why is oil intensively consumed?

In a working engine, valve stem seals and rings are responsible for removing residual lubricant from the valve stem and cylinder walls, respectively.

At high speeds, the performance of this process decreases, but in general, oil consumption does not exceed the norm prescribed by the manufacturer. For some it is 1 l/10,000 km, for others it is 0.3 l/10,000 km, and still others may not add anything at all between service intervals, since they do not turn the engine above 3,500 rpm. Naturally, when lubricant consumption suddenly increases, say, to 1 l/1,000 km, and even blue smoke comes out of the exhaust, this is a signal of a violation of the oil scraper functions. There are several reasons for this:

- The oil scraper rings are stuck.

- The caps have become stiff.

- The valve guides are worn out.

As a result, it would be nice to determine without disassembly which particular group of parts failed. Whether this is possible is the topic of the next paragraph.

Symptoms of stuck piston rings

First of all, it should be noted that most often the priority occurrence of oil scraper rings is noted, while compression rings are able to maintain mobility much longer without succumbing to coking. The main signs indicating the onset of an undesirable process are:

- unreasonable increase in engine oil consumption by the power plant. The increase in consumption is explained by partial penetration of the lubricant into the combustion chamber, where it is used for waste;

- engine operation is accompanied by the release of blue smoke from the engine compartment. The rationale for this process is the combustion of oil trapped in the chamber. It has been noticed that puffs of bluish smoke become especially noticeable when the crankshaft speed increases under a certain load or after the engine warms up;

- difficulties when starting the power unit when cold;

- the appearance of a noticeable decrease in compression in the cylinders;

- reduction in engine output. The engine is unable to achieve the required power.

Note that the explanation for the last three symptoms is a decrease in the compression ratio of the fuel-air mixture in the cylinders due to insufficient sealing caused by the presence of piston rings. In particularly advanced cases, a burning smell can be clearly felt in the cabin. In such difficult situations, it is impossible to do without replacing the elements in question.

The appearance of any of these signs requires immediate intervention. It is urgent to take measures to decarbonize the rings in order to prevent the occurrence of more significant problems in the power unit.

Valve seals or rings: how to determine what caused the blue smoke

If you've done a quick study of the issue, you've probably noticed that there is a lot of conflicting information. For example, there is a lot of controversy around the same compression: some argue that with normal pressure in the cylinders there is no reason to go into the piston, others insist that this is not an indicator at all in the current situation. And regarding the relationship between the engine temperature, the position of the gas pedal and the time of appearance of bluish smoke, it is not at all clear what’s what.

Let us immediately note that there is no connection between compression and defective oil scraper rings. Firstly, the rings that scrape oil from the cylinders wear out or become stuck first, while the compression rings continue to work as expected. Secondly, even with slightly worn compression rings and damaged oil scraper rings, compression will be normal, since the oil remains on the cylinder walls.

At the same time, unspoken differences exist that make it possible to determine what exactly has failed: caps or oil scraper rings. The difference is that each group of parts produces blue smoke at different intervals.

Symptoms of problems with caps

In the old days, stiff or worn valve seals were indicated by a puff of bluish smoke that burst out of the exhaust pipe immediately after starting the engine. By the way, these observations have not lost their relevance today. Even in this situation, it would be a good idea to ask how much the work costs and what else needs to be changed when replacing the valve stem seals on the engine.

The following test will help you accurately judge the caps for replacement:

- Warm up the engine to operating temperature.

- Let the engine run for 5-7 minutes while warm.

- Sharply depress the gas pedal for 5-10 seconds and watch the exhaust gases at this moment.

If there are problems with the seals, in the first seconds of the “gas to the floor” mode, a cloud of smoke with a bright bluish tint flies out of the muffler. For extra confidence, repeat the attempt to throttle to failure 2-3 more times. Observations are such that in subsequent cycles the puff of smoke will lose saturation, and may even disappear altogether.

For your information. The most reliable diagnosis is considered to be based on the color of the exhaust, in which “gas to the floor” is given after warming up and running the engine at operating temperature for 5-7 minutes. The bluish tint under such conditions turns out to be much more saturated than during the morning start and other gas conditions.

What explains this prioritization? If the cap is worn, oil will flow down the valve stem when the engine is running. Whether it will accumulate on the valve plate or immediately enter the cylinders is determined by the angle of the throttle valve. So, at idle, the speed of the air mass is low, the oil is not removed from the plate, but continues to accumulate. As soon as you sharply (it is important to press this way) press the gas pedal, air or the fuel-air mixture (depending on the type of fuel injection) draws the accumulated oil emulsion into the cylinders and it burns, forming a bluish smoke.

There will be no ominous tint at revs, and, in fact, there shouldn’t be. The oil does not have time to accumulate, but immediately enters the cylinders and burns in small fractions, which is why it does not affect the color of the exhaust gases.

It is worth noting that with a new catalyst, the color of the exhaust may not change at all, since it qualitatively converts CH into water vapor. On a half-dead catalytic converter or installed flame arrester, the picture appears in all its glory: there is smoke.

How to determine whether oil rings are faulty

Worn rings make themselves felt when under load. In reality, it looks like this: the color of the exhaust gases changes when moving uphill with the gas pedal half-pressed. It is worth noting that looking in the rearview mirror, you are unlikely to draw the right conclusion. The puff of smoke usually dissipates quickly. However, the driver of the car behind may well record his appearance.

For your information. There is an opinion that the initial stage of wear should be determined during gear shifting. If bluish smoke appears at this moment, the rings will need to be replaced soon.

When the rings are worn critically, smoke comes out constantly while driving and regardless of the terrain under the wheels. In addition, an increase in smoke is observed with increasing speed.

What else could cause a bluish-colored exhaust?

A defective turbine and faulty crankcase ventilation can also cause smoke. What distinguishes these failures from current caps or oil rings is the nature of the smoke: there is a lot of smoke + it can appear and disappear at any time. For example, the engine runs smoothly at idle and suddenly starts smoking, and after 3-4 minutes it stops.

A few tips will help you figure out what's going on:

- The turbine “drives” oil into the exhaust pipe. Smoke appears only after the exhaust tract has warmed up. There may be an oil leak at the joints of the exhaust system parts.

- Crankcase ventilation does not separate the oil from the air mixture. The oil separator is clogged as a result of using low-quality engine lubricant. The intake manifold is covered in streaks of oil emulsion, and clearly behind the ventilation hole.

Decarbonization of rings

So, having recognized the above symptoms, you have discovered that there are compression or oil rings stuck in the engine and you are wondering what should be done first. How can the situation be resolved with the least damage to the affected unit? Let's try to figure it out together!

If the rings are stuck, it is not at all necessary to rush to the nearest workshop or urgently call a specialist, whose services will not be cheap. The problem can easily be fixed on your own.

To do this, it will be necessary to carry out the so-called decoking of the rings, based on the removal of various deposits, such as coke and soot, from the internal space of the combustion chamber. It is the formation of these substances that causes the piston seals to stick, limiting the necessary mobility.

Let's consider the most accessible way to decarbonize the rings yourself, without removing the engine. It involves cleaning the combustion chamber with special compounds. So that you don’t have to rack your brains about how to replace the piston rings later, we recommend using this method.

There is a fairly wide range of such products available on the automotive market. Among the variety of products offered to caring owners of personal vehicles by the chemical industry, a composition called Lavr is in high demand.

However, domestic car enthusiasts are not accustomed to using ready-made products, preferring, in order to save money, to do everything with their own hands from scrap materials.

Tips and tricks

To protect the piston rings and prevent coking of the combustion chamber, it is necessary:

You can also use engine additives (discussed using the example of a diesel internal combustion engine):

These solutions are presented by various manufacturers and are recommended for use for preventive purposes, since they are not capable of effectively removing thick layers of deposits.

Use of anti-wear, anti-smoke and other additives to reduce oil consumption. Pros and cons after applying the additive to the engine.

What does the color of carbon deposits on a spark plug indicate, and why does carbon deposits of one color or another form? How to clean spark plugs from carbon deposits with your own hands, tips.

Should the engine consume oil and what oil consumption is normal for the engine. Increased lubricant consumption, main causes, frequent malfunctions.

Carbon formation and consequences of engine coking. The occurrence of piston rings, the appearance of deposits and varnish on parts. How to remove carbon deposits yourself.

Low compression in engine cylinders: the main reasons. How to increase engine compression without engine repair, available methods. Tips and tricks.

Gradual or sudden increase in diesel engine oil consumption. Potential faults, diagnostics and solutions.

Source

Recommendations for eliminating problems with stuck piston rings yourself

Enterprising Russian owners of personal vehicles have come up with their own cleaning product to remove deposits from the internal space of the cylinders. The following provides step-by-step instructions for cleaning the combustion chamber with a mixture of acetone and kerosene:

- before freeing the rings from plaque and deposits, without disassembling the entire power unit, you must first disconnect all the wires and remove the spark plugs;

- It should be taken into account that proper cleaning of the chamber is only possible if there is a complete absence of oil in the system. Therefore, before starting decoking of the piston rings, the lubricating oil product is drained from the engine;

- then, simultaneously, the working space of all cylinders is filled with a mixture of kerosene and acetone prepared in advance;

- after this, the candles are screwed into place and the cleaning agent is allowed to perform its intended functions. Usually the process lasts for 10-12 hours. It is recommended to diversify the waiting period by regularly cranking the crankshaft a few degrees;

- then the spark plugs are removed again and the cleaning liquid is drained. In order to completely free the engine from the mixture, the engine is cranked with a starter;

- return the drained lubricant to its place. This is necessary to carry out a preliminary check of the quality of cleaning the engine from deposits in the combustion chamber. If after some time of operation of the power unit the symptoms of the occurrence do not appear, the goal is considered achieved;

- At the final stage, all that remains is to change the oil. At the same time, you should not ignore the manufacturer’s recommendations and fill in lubricant that does not correspond to this engine model. The seasonality of the petroleum product should also be taken into account. When updating the lubricant, be sure to install replaced oil filters.

It should be noted that instead of the mixture mentioned above, kerosene is quite suitable as a cleaner. Is that the time of its influence on deposits in the chamber is somewhat extended.

Methods for cleaning an engine from carbon deposits

The main signs of engine problems may include symptoms such as:

- Change in exhaust color;

- Reducing engine power;

- Increased volume of fuel or oil consumed.

Most of the mechanics at the service station will insist on a complete overhaul. In addition to car services, you can get rid of the problem of engine coking in a simpler way. It is quite possible to clean off a layer of carbon deposits from an engine at home.

First of all, you need to figure out what specific operations you will need to carry out, and how best to do it. Previously, “hard” decarbonization was popular. This method of cleaning carbon deposits is quite simple; a special cleaning mixture is poured into the cylinders and drained after a certain time. At the moment, there are a large number of other cleaning methods, even without disassembling the power unit.

Partial cleaning of engine rings from carbon deposits

The essence of this method is that a special cleaning liquid is added to the engine oil. With such a mixture, you need to drive from 100 to 200 kilometers. In this case, a large load on the engine during partial cleaning is not allowed.

The disadvantage of this method is that carbon deposits are cleaned only from the oil scraper rings, which is why the cleaning is called partial. But despite this, this method is quite simple and accessible. Most often, this procedure is recommended to be carried out before changing the oil for preventive purposes.

It is important to understand the fact that the resulting mixture of oil and cleaning fluid is thinner in consistency compared to pure oil. Therefore, driving at high speeds will negatively affect the condition of the engine.

Complete cleaning of the power unit

To carry out complete decarbonization, you will have to make great efforts and spend much more time. But only after this operation will the carbon deposits be completely removed. First you need to warm up the car to the optimal operating temperature. Next you need to unscrew all the spark plugs or remove the injectors. Then turn the crankshaft using a screwdriver to set all pistons to the middle position. This is necessary so that the liquid can seep into all the cracks, since it is in the middle position that all the necessary gaps open - this will save us from unnecessary consumption of cleaning fluid. In order to pour the special mixture, it is best to use a syringe. After introducing the mixture into the cylinder block, put the spark plugs in place and wait the time specified in the instructions.

Often you have to wait no longer than a day. But there are also unique decarbonizing preparations that should be poured in for a period of time, from several days to a couple of weeks. When carrying out a quick cleaning that does not exceed a couple of hours, it is strongly recommended to periodically rotate the crankshaft in both directions by 5–10 degrees. This is required so that the cleaning liquid is evenly distributed inside the cylinder.

After the time written in the instructions has passed, we close the candle wells with a rag or special plugs so as not to stain them. Next, you need to rotate the crankshaft until the cleaning fluid is completely removed. We put the spark plugs in their places and start the car. The car should be idled for the first hour after cleaning.

Thus, they got rid of carbon deposits on the engine back in the Soviet Union. But then, due to the lack of special cleaning products, car enthusiasts mixed kerosene and acetone, after which the oil was completely washed out from the cylinders, and the first engine start after decarbonization had to be done “dry”. Which often led to rapid wear of the piston rings and the appearance of scoring.

Fuel additives

It is also worth mentioning another fairly popular method of cleaning rings in an engine. Compared to the previous two, this method is the simplest, but also the longest. All you need is a special product that is poured directly into the fuel tank, where it is mixed and subsequently enters the combustion chamber.

Once in the engine cylinders along with the fuel mixture, the cleaning agent penetrates into the soot layer and gradually burns out, exiting along with the exhaust gases. The advantages of this method are very obvious:

- There is no need to dismantle the engine for cleaning, and there is no need to leave it inoperative for long periods of time.

- In this case, increased engine speeds will benefit it and will only speed up the process of decoking of the piston rings.

- There is also no need to change the oil after cleaning, since the product does not get into the oil when compared to the previous method.