The knock sensor is an important component of the electronic injection system of the VAZ-2109 injection engine. The task of this sensor is to control detonation that appears in the cylinders of the car’s power unit.

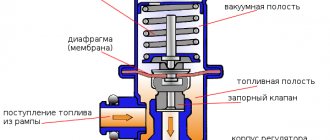

The knock sensor itself is presented in the form of a housing in which a special plate is located - a piezoceramic element. This element has specific properties called the piezoelectric effect. Additionally, a resistor is installed in the housing, and the power supply wiring must be connected to it from the outside.

Knock sensors are available in two types; they differ in their operating principles.

Resonant piezoelectric knock sensor. The ECU controller transmits a constant voltage of 5V to the sensor. The resistor in the sensor reduces this voltage to 2.5V and returns it back. When detonation occurs in the engine cylinders, the sensor begins to transmit alternating voltage with an amplitude and frequency to the control unit, which varies depending on the characteristics of detonation. Having received this signal, the control unit automatically changes the ignition timing, due to which detonation disappears.

Wideband piezoceramic knock sensor. In this case, the sensor sends an alternating voltage to the controller corresponding to the vibration frequency of the engine. When detonation occurs, this signal increases its frequency. Thus, the electronic control unit determines that detonation has occurred. The existing detonation damping mechanism adapts to the operation of the engine, taking into account detonation, thereby maintaining performance at an optimal level.

Knock sensor failure

If the knock sensor installed on the car fails, the control unit controller will begin to work according to a scheme using a backup table for calculating the ignition timing. When the system operates in such an emergency mode, there will be a loss of engine power, engine tripping and an increase in fuel consumption.

A faulty knock sensor cannot be repaired; it can only be replaced with a new part. As we noted above, two types of sensors can be used on VAZ-2109 cars. Each type of DD has its own triggering characteristics.

The wideband piezoceramic sensor captures and transmits to the ECU a wide range of noise that comes from the engine. As a result of this expanded transmission, the electronic control unit can eliminate the causes of each noise.

Resonant knock sensors only operate when detonation occurs.

Considering both sensors from the point of view of efficiency and practicality, we can come to the conclusion that a broadband sensor is a better choice, but its cost is higher than a resonant device. Therefore, the decision of choice remains with the motorist.

Sensor cost

On VAZ 2109 cars with “January 4.1” controllers, DD 211203855010-01 is used. It has a low prevalence. Because of this, its price is extremely high. For an original product you often need to pay 1500-1700 rubles. A good analogue is General Motors 21120-3855010-01. Its cost is 1600-2000 rubles.

On the VAZ 2109 with “January 5.1” controllers, broadband DD 21123855020 is used. Its price is 300-450 rubles. Good analogues of the branded sensor can be found in the table below.

Table - Good analogues of the branded VAZ 2109 knock sensor

| Manufacturer | vendor code | Approximate cost, ruble |

| ZAZ | 183855 | 170-290 |

| Phoenix | SD10100O7 | 230-390 |

| VOLVO | 183855 | 290-410 |

| Bosch | 0 261 231 046 | 370-400 |

| EPA | 550489 | 250-400 |

Replacing the knock sensor

To replace the knock sensor yourself, you need to take a ratchet and a No. 13 socket. After that you need to follow these steps.

1. Lift the hood and remove the negative terminal from the battery. This is done in order to avoid problems such as short circuits.

2. Disconnect the electrical connector that supplies the knock sensor. To do this, you need to press the metal lock of the pad and then gently pull it towards you.

3. Take a prepared ratchet or a simple wrench and unscrew the existing fastening nut. Carrying out this work is quite inconvenient due to the position of the sensor, but it is still quite doable, so with some diligence you can do it without problems.

4. Take out the faulty sensor, wipe it and look at the markings on it.

5. This marking will help you determine the type of sensor you need to install. It is, of course, advisable to replace the sensor with a similar one.

6. After purchasing a new sensor, all you have to do is install it in place. Then you need to reconnect the electrical block and install the terminal on the battery.

Now you can check the operation of the engine; if the symptoms of detonation disappear, then the whole problem was in the sensor.

As you can see, there are no particular difficulties in this operation. Using our instructions, even a novice motorist can replace the knock sensor.

Without exception, all VAZ cars, from model 2101 to modern versions, are equipped with gasoline power plants, which are a higher priority for all automobile manufacturers.

The normal functioning of any gasoline engine is ensured by a number of factors - maintaining the correct proportion of the air-fuel mixture, the quality of gasoline, the appropriate ignition timing, and the condition of the CPG. If at least one of these factors does not correspond, a negative effect such as detonation may occur.

Detonation - what is it?

Detonation is simply improper combustion of the mixture. But if measures are not taken in time, then the detonation of a VAZ engine can have strong negative consequences. The peculiarity of this effect lies in the self-ignition of the combustible mixture due to exposure to high temperatures and pressure in the cylinders.

During normal engine operation, combustion of the combustible mixture occurs in three stages.

- Induction, takes place as the piston approaches top dead center. At this stage, a source of flame begins to appear from a spark, which subsequently forms a flame front, and all this is accompanied by a slight increase in pressure in the combustion chamber.

- The formation and passage of a flame front through the combustion chamber, as a result of which the bulk of the mixture burns, and this is all accompanied by a sharp increase in pressure and temperature.

- Burning out of the mixture residues that remained behind the front, as well as those located near the cylinder walls. It is between the transition from the second stage to the third that detonation may occur. The high temperature and pressure that occurs during the second stage leads to rapid chemical reactions in the unburned mixture, causing it to spontaneously ignite. Such combustion occurs very quickly (up to 1200 m/s) and in the form of an explosion, accompanied by the formation of shock waves that are destructive.

These waves lead to the destruction of the near-wall layers of gases, which ensures an increase in heat transfer, due to which the cylinder walls and other components of the CPG overheat. Also, the blast wave destroys the oil film of the walls, resulting in increased friction between the cylinders and rings. Detonation also has a mechanical effect on the elements of the piston group - a sharp increase in pressure leads to the appearance of shock loads on the piston bottom, valve, and cylinder walls, leading to their damage.

The figure shows how normal and detonation combustion of fuel occurs.

On the left – normal combustion; on the right – detonation combustion

Consequences. Fighting methods

Detonation of a carburetor engine is accompanied by the appearance of a metallic knock, especially under load. Many people perceive it as the “ringing of fingers” of the pistons, but the distinct sound, as if metal is hitting metal, is due to the blast wave.

The consequences of this effect, if no measures are taken, are very serious. Overheating of the component parts can lead to breakdown of the block head. The absence of an oil film, which is destroyed due to the effects of detonation, increases friction and leads to accelerated wear of the CPG elements. And finally, the mechanical impact of the shock wave together with high temperature can cause the piston to burn out, destroy the bridges between the rings, bend the connecting rod, and burn out the valve plates.

Consequences of detonation combustion of the mixture

Features of injection engines There are several ways to effectively combat this effect on carburetor engines. First of all, when detonation occurs, the fuel should be replaced, especially if the fuel was previously refueled at a station with questionable fuel quality. If the fuel does not cause suspicion, then it is worth checking the ignition and setting a later advance angle by turning the distributor.

The causes of detonation in an injection engine are identical to that of a carburetor, but in addition to metallic ringing, such engines have a number of other signs indicating the occurrence of this effect.

And all because the engine with such a power system is more advanced. Its processes of mixture formation and supply of mixture to the cylinders are controlled by an electronic control unit based on the readings of many sensors. Also, depending on the operating mode of the engine, he also independently selects and sets the advance angle. That is, the driver can no longer set the ignition on his own.

The electronic unit is able to track the occurrence of detonation. For this purpose, all injection engines are equipped with a knock sensor (DS).

This sensor is capable of detecting the appearance of detonation combustion, and the ECU will take action based on its data. For example, if the cause of detonation of a VAZ-2109 engine equipped with an injection power system is low-quality fuel, and the sensor detects the effect, the ECU will simply reduce the ignition timing and the detonation will stop.

Causes of detonation

Engine detonation can occur for various reasons, among which are:

- Use of fuel of dubious quality and origin;

- Poor air-fuel mixture entering the cylinders;

- Impaired performance or failed engine cooling system;

- Using spark plugs whose characteristics do not match the engine parameters;

- Formation of carbon deposits inside combustion chambers;

- A timing belt that has jumped for one reason or another, etc.

If measures are not taken in time regarding a failed motor, this threatens to impair the functionality of the motor and more.

What does DD failure lead to?

If the knock sensor or its electrical connections fail, the following will occur:

The controller will switch to working according to the backup table for calculating the ignition timing. The consequences of such operation of the device are loss of power of the power unit, increased fuel consumption and engine tripping.

When the motor or its electrical connections grind, detonation increases, which leads to the appearance of a fault code in the controller. As a result, the Check engine light comes on on the dashboard.

Searched device

What to use

When planning to replace the DD, it is important to think about which sensor will be used in the injection system on your VAZ 2109.

As we have already noted, two types of regulators can be used on nines. But each of them has its own operating characteristics.

- Broadband piezoceramic devices are capable of recording and transmitting a wide range of noise emanating from the engine to the electronic control unit. As a result, the ECU eliminates the causes of each of them.

- Resonance devices are configured only to operate when detonation occurs in the engine.

From the point of view of practicality and efficiency of the knock sensor, the best choice for the VAZ 2109 is broadband. But it's up to you to decide.

Knock sensor, how it works

Structurally, all knock sensors are the same and are based on the piezoelectric effect, that is, the mechanical action is converted into electrical action. And the greater the mechanical impact, the more energy the sensor is able to generate.

The main component of this sensor is a piezoelectric element, which generates electric current from mechanical action. During normal operation, this sensor generates low-power electrical pulses that are not transmitted by the resistor included in the design.

During detonation, shock loads and vibration increase significantly, therefore the impact on the piezoelectric element increases. When a certain current generated by the sensor is reached, a breakdown of the resistor occurs and a pulse is sent to the ECU, which is a signal to it that measures must be taken to eliminate the abnormal combustion that has occurred.

Since the DDs operate on the same principle, the design of the VAZ-2110 knock sensor is the same as on models 2107, 2109 (injection versions), 2114, etc.

DD connection diagram

Speed sensor

With the transition of the nine to an injector, the measurement of vehicle speed began to be carried out not mechanically, using a special sensor that reads readings from the rotation of the gearbox gears, transmitting the readings to the computer. The block processes the readings from the sensor and sends signals to the speedometer.

Location

The VAZ 2109 speed sensor is located on the gearbox housing, you can see it by looking under the thermostat and you can find this sensor next to the gearbox dipstick.

Signs of malfunction:

- The speedometer does not work;

- The speedometer does not show the speed correctly;

- The odometer does not work;

Signs of a malfunctioning knock sensor (DS)

Note that a malfunction of the motor drive can affect the performance of the power plant. The fact is that if the ECU detects that it is not working, it will switch the engine operation to emergency mode, in which the ignition will be delayed in order to completely eliminate the possibility of detonation combustion.

Signs of a malfunction of the VAZ-2110 knock sensor are as follows:

- Unstable engine operation at idle;

- Decrease in engine power performance;

- Increased gasoline consumption;

- Difficulty starting the engine;

In general, everything that is a consequence of late ignition. Signs of a malfunction of the VAZ-2114 knock sensor or any other VAZ injection model are identical.

But such signs can be given not only by the DD, but also by other sensors responsible for the operation of the power system, so it is important to know how to check the knock sensor of the VAZ-2110. Otherwise, you can spend a long time looking for the cause of the motor’s malfunction. Often car owners do not pay attention specifically to the DD, sinning on other elements.

To your attention errors in the knock sensor VAZ 2114

- Error code 0325 - there is a break in the wiring that supplies power to the DD. Most often, the cause of this error is oxidized contacts of the knock sensor; a wiring break occurs extremely rarely. It is necessary to clean the contacts, this will give a positive result, at least it will not get worse. In addition, this error can be caused by the timing belt, so if after cleaning the motor contacts the problem remains, check the timing belt. Most likely he jumped a couple of teeth. Align the belt to the marks and check again if the error appears.

- Error code 0328 - as a rule, indicates faulty high-voltage wires. However, the possibility of the timing belt jumping cannot be ruled out.

- Error code 0326 . and also 0327 - mean an excessively weak (low) signal from the knock sensor. To eliminate errors, it is necessary to clean the VAZ 2114 DD connection contacts. The tightening torque of the sensor is also important; if the tightening is weak, the above errors may appear.

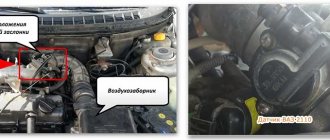

Where to look and how to check the knock sensor

In order to check it, you also need to know where the VAZ-2110 knock sensor is located. Everything is simple here; so that it can effectively capture vibrations, it is placed on the cylinder block. Its location largely depends on the design features of the motor itself.

On 8-valve engines

it is usually located in the line of sight and is usually easy to get to. Therefore, it is not difficult to determine where the knock sensor is located on a VAZ-2107 (injector). It is installed on the exhaust manifold side and consists of a massive washer with wiring going to it and secured to the engine with a bolt.

But on 16-valve engines

The installation location is slightly different than the location of the knock sensor on the VAZ-2107 (injector). Due to the fact that the block head is much more massive, the sensor is located lower - under the exhaust manifold, so access to it is limited, and often it can only be reached from under the car on an overpass or inspection hole.

And although the location of the motor may differ slightly due to the design of the motor, its connection is always identical. Thus, the connection diagram for the VAZ-2109 knock sensor with an injection engine is the same as on the 2114 model.

Checking the VAZ-2110 knock sensor can be done in two ways.

The first one

implies the presence of a tester converted to resistance measurement (measurement level - up to 2 kOhm).

To check, you just need to disconnect the wiring block from the sensor and connect a tester to the sensor contacts. Then you should apply light blows with a wrench to the DD fastening bolt and monitor the readings on the tester display.

After connection, the display will show a certain resistance value of the sensor. At the moment of impact on the bolt, the resistance will increase sharply, but then return to the old value. If this does not happen (the resistance does not rise or does not return), the sensor is faulty and requires replacement.

Second way

does not require any equipment and is more efficient. To carry it out, you need to start the engine and set the speed to 2000 rpm. Then take an open-end wrench, you can use a small hammer with a metal attachment (if access to the DD is limited) and strike the fastening bolt. If the DD is in good working order, after the impact, the engine speed should drop, since such an impact will be regarded by the sensor as detonation and the ECU, based on its signals, will reduce the ignition angle. After the impact on the bolt stops, the speed should be restored. If this does not happen, the DD is faulty.

Throttle position sensor

This sensor is necessary to determine the opening angle of the throttle valve. These readings are necessary to correctly determine the air supply to the engine. TPS works in tandem with IAC and mass air flow sensor. Since the sensor is made of a rheostatic type, that is, it changes its resistance with each opening of the throttle, it quite often fails.

Location

The TPS is located on the throttle valve of the VAZ 2109.

Signs of malfunction:

- The speed ranges from 500 to 2500 rpm;

- The engine starts poorly;

- No idle;

Replacing the sensor

We figured out how to check the knock sensor of a VAZ-2114 or any other model. Please note that this sensor cannot be repaired and if it is faulty, it must be replaced.

Replacing the VAZ-2114 knock sensor is a simple operation, but it can be difficult due to poor access to it (16-valve engines). To change, you just need a new element and an open-end wrench of the appropriate size.

Before unscrewing the mounting bolt, you must first disconnect the block with wires. Then the bolt is unscrewed, the old sensor is removed, and a new one is installed in its place and securely fixed with the same fastener. And only after that the block with wires is connected.

Replacement

If the DD fails, the only correct solution is to replace the broken device with a new, working regulator. To do this, you must perform the following steps.

- Arm yourself with a 13mm socket and ratchet.

- Remove the negative terminal from the battery and place it aside for a while. It is necessary to deprive the car of power, otherwise problems cannot be avoided.

- Disconnect the block with wires that powers our sensor. To do this, first press the metal latch and then pull the plug.

- Next, use a simple wrench or ratchet to unscrew the fastening nut. It is quite inconvenient to work in the area where the knock sensor is located, but it is quite possible to unscrew it without unnecessary problems.

- Remove the regulator from the pin and look at the markings on it.

- Determining the markings will allow you to find out which version of the sensor is used on your car. It is advisable to replace it with the same one. Or, following the data from the instruction manual for your nine, purchase an analogue that matches the parameters of your power unit on the VAZ 2109.

- Having purchased a new sensor, you can install it in place of the failed regulator. Return the negative terminal to the battery and check the operation of your motor. If the problem really was in the sensor, all signs of detonation will disappear.

Unscrew and remove

Buying a DD today is not a problem. But it’s better to choose proven, good auto parts stores. The approximate cost of the regulator is 300 rubles. Perhaps this is the only financial cost when doing a DIY repair.

There are no particular difficulties in replacing such an important device for proper engine operation. Follow the instructions and use only high-quality gasoline. Then the new DD will not bother you soon.

Video - causes and consequences of detonation

Among all devices, the VAZ 2109 knock sensor occupies a special place; it is responsible for the correct regulation of the fuel mixture and setting the ignition angle. On modern cars you can find two types of sensors - resonant and broadband. Which type to install on your machine is up to you. But you need to know the characteristics of each. The operating principle of the devices is generally the same.

The operation is based on the piezoelectric effect. When subjected to mechanical action (in particular, impact), an electrical charge is generated. And its value is higher, the stronger the blow. From here you can understand the whole meaning of the device. Resonant knock sensors consist of:

- Piezo element.

- A constant resistance that suppresses the 5V supply voltage to an operating value of 2.5V.

During normal operation of the engine, shocks occur, but their amplitude is the same and is not registered by the sensor due to the built-in resistance. Only when mechanical stress increases does some of the signals begin to pass through to the input of the electronic control unit.

More advanced broadband ones - they record all, even small, vibrations of the engine block. There are vibrations when the motor is running, but the sensor sends a signal of equal amplitude. As soon as detonation knocks begin, the frequency of the generated signal increases. And the electronic control unit understands that the detonation phenomenon has begun.

The ECU begins to analyze the fuel map to bring the engine to normal operation. In addition, thanks to this symbiosis of electronic means, it is possible to ensure that the engine functions normally on low-octane gasoline without consequences. But this does not mean that you can drive on such fuel all the time. It is necessary to note other causes of detonation knocks:

- Incorrectly installed timing belt.

- Malfunctions in the cooling system.

- The presence of a large amount of carbon deposits in the combustion chambers.

- Poor quality spark plugs.

- Lean air-fuel mixture.

- Using low-grade gasoline.

Device and location

The knock sensor is enclosed in a housing, inside of which there is a plate - a piezoceramic element. This element is characterized by certain properties called the piezoelectric effect. Plus there is a resistor in the case. The power supply is connected to the sensor externally.

The device is located in the front part of the cylinder block of the VAZ 2109 power unit. It can be broadband or resonant. The first is located on a stud, secured with a nut size 22. The resonant type of sensor is screwed into the hole located under the stud.

Location

Signs of a broken knock sensor

On VAZ 2109 cars, as well as on similar models, when a malfunction of the knock sensor occurs, the control system is configured to operate in emergency mode. In this case, the ignition is delayed. This way you can completely eliminate the possibility of detonation. The main symptoms by which you can determine a device failure:

- At idle the number of revolutions is not constant.

- Power is lost (and noticeably).

- Gasoline consumption increases significantly.

- Starting the engine even in warm weather turns out to be problematic.

In other words, these are all signs of installing a late OZ on a car. On all cars with injection engines, starting with the VAZ 2109, the symptoms are the same. But you will have to carry out diagnostics to finally make sure that this particular device is broken. Similar symptoms appear when the mass air flow sensor, pressure sensor, etc. break down. If it is possible to carry out computer diagnostics, do it.

Self-replacement of the resonant sensor on a VAZ 2109

Replacing the DD on a VAZ 2109 with your own hands is done according to the instructions below.

- Disconnect the connector.

Connector

- Unscrew the sensor.

Turning away DD

- Take out the DD.

Removing the knock sensor

- Install everything in reverse order.

Removing the knock sensor

Do-it-yourself diagnostics and replacement of the knock sensor

Don’t know where the knock sensor of the VAZ 2109 is located? Open the hood and look at the engine block. Find the second and third cylinders. A black sensor with one wire is attached between them using a bolt. This is what he is. The reason for the location in this place is that this is where the geometric center of the motor is. Therefore, knocks of the same amplitude in the first and fourth cylinders will cause the generation of signals of equal magnitude.

You can digress from the topic a little and talk about 16-valve engines. In them, the knock sensor is located on the exhaust manifold side. Access to it is difficult, so replacement is problematic without a pit or overpass. But such engines were not installed on the VAZ 2109, so there will be no problems. But let's get back to how to test the device. And you can do this in two ways:

- An ohmmeter (tester) with a measurement scale of 2 kOhm is required. Disconnect the wire from the sensor and connect the tester between its output and ground. The resistance should be fixed at the same level. But when hitting the body, the resistance should increase sharply and return to its original value. If the readings do not increase, or do not return to the original value, or there is no resistance at all, we can judge that the sensor is broken.

- The second method will be much simpler and, oddly enough, more effective. To check the VAZ 2109 knock sensor, it is necessary (without dismantling or disconnecting the device) to start the engine and set the crankshaft speed to 2000 rpm. Next, strike the VAZ 2109 knock sensor mounting bolt of varying strength. If it is working properly, the crankshaft rotation speed will change (in particular, drop). The reason is a decrease in SOP, since the electronic control unit “sees” the presence of detonation. As soon as the impacts on the bolt stop, the speed returns to normal. But if none of the above happens, then we can judge that the device is broken.

Look at the design of the device. As you can understand, it cannot be repaired. Therefore, you take the faulty one in your hand, swing it well and throw it in a landfill. Buy a new one and forget about your problems. On VAZ 2109 cars it is very easy to replace it.

Instructions

Please note: on VAZ cars, access to the knock sensor is made difficult by the intake module. As a result, remove the knock sensor by touch. To make the process easier, remove the engine splash guard and dismantle the sensor by approaching it from below the car (on an inspection hole or overpass).

To remove the knock sensor, unscrew the sensor mounting bolt from the cylinder block with a socket wrench. Remove the sensor from the mounting pin and remove it from under the intake module. Disconnect the wire connector from the sensor by pressing the latch.

To check the sensor, connect to its terminals a multimeter turned on in voltmeter mode with a measurement limit of up to 200 mV. To correctly connect a single-contact sensor to the device, connect the negative wire (black) of the device to the ground of the sensor (installation location of the mounting bolt). Connect the positive wire (red) to the signal wire located in the sensor connector. Two-pin sensors are connected with both terminals to the tester wires, observing polarity.

Then use a screwdriver to lightly tap the sensor body, simulating detonation. In this case, the tester should show voltage surges of 40-200 mV, depending on the strength of the shock. If there is any malfunction of the sensor, there will be no reaction to impacts. The sensor should be replaced. Remember that in some cases the devices are not able to detect a weak signal and the voltmeter will indicate a sensor malfunction.

Switch the tester to resistance measurement mode and connect it to the sensor terminals. In this case, it is desirable that the device be able to measure infinitely large resistances. A working knock sensor on VAZ cars should have a very high resistance, tending to infinity.

More accurate checks of the knock sensor are only possible on a special stand. Install the tested sensor in reverse order. Tighten the mounting bolt to a torque of 20-25 Nm.

Sources:

- how to check overheating

- Removing and replacing the speed sensor on VAZ 2112, 2111, 2110

- Replacing the knock sensor on a VAZ

A knock sensor in a car is a device that is designed to determine the time of detonation in an internal combustion engine. The engine knock sensor is one of the devices in the electronic engine management system of a fuel injected car. To replace a broken device with a new one, you need to do a few simple operations.

Instructions

Make sure the engine is completely cool before starting this procedure. Disconnect the negative cable from the battery. If the audio system in your car is equipped with a security code, before disconnecting the battery, check that you have the correct combination to put it back into operation.

In foreign cars, the knock sensor is usually screwed into the engine cooling passage, so its disconnection usually involves some loss of coolant. To avoid this, drain the antifreeze from the cooling system in advance. Now disconnect the electrical connector and then remove the sensor from the engine.

Modern sensors are usually supplied with a threaded part that is coated with an anti-seize sealant. Screw the replacement sensor into the standard place. Please note that over-tightening the sensor may cause it to fail.

Connect the electrical wiring to the sensor and fill the cooling system. Check the engine for signs of coolant leaks.

The knock sensor on VAZ cars changes as follows. To remove the single-pin sensor, which is located at the top of the cylinder block, disconnect the electrical connector and unscrew the sensor using a 22mm wrench. Then remove the sensor.

To change the two-pin sensor on the stud, turn on the ignition and disconnect the wire from the negative terminal of the battery, then disconnect the sensor from the block with wires. Now, using a size 13 wrench, unscrew the nut that secures the sensor. Remove the washer and disconnect the device from the stud. Install the new sensor in reverse order.

Helpful advice

If you are not confident in your abilities, leave this work to the car service employees. This procedure is carried out in any center and costs about 200 rubles.

Sources:

- how to change the fuel sensor in 2017

A modern injection engine is controlled by many sensors. But the electronic motor control system may not always be the cause of its breakdown. Therefore, before checking the serviceability of the sensors, make sure that the remaining parts and components of the power unit are working properly. The only fact that directly indicates a malfunction of any sensor is the Check Engine lamp that lights up on the instrument panel.

You will need

- — a tool for dismantling interfering parts; - ohmmeter (multimeter).

Instructions

The throttle position sensor (TPS) is a variable resistor. To check it, measure the resistance between its terminals. Compare the readings obtained with the factory values specified in the operating instructions (different machines have different sensors). Consider a discrepancy of 20% normal. Also, a malfunction of the TPS may be indicated by instability in idle speed, jumps when the speed increases.

It is impossible to check the knock sensor without specialized equipment. An indirect sign of its breakdown is increased detonation during engine operation. For diagnostics and replacement of the sensor, contact a specialist. The same applies to the timing sensor. It is only installed on engines with four valves per cylinder. It is checked using special diagnostic instruments.

If the engine refuses to start, this is a sign of a faulty crankshaft position sensor. This sensor is the only one that, if it fails, the engine refuses to start. To further check it, measure the resistance between the terminals, having previously disconnected the connector. Normally, this figure should be 550-750 Ohms.

Also, the cause of a malfunction of the crankshaft position sensor may be the controller installed on the crankshaft pulley master disk. The rubber damper mounted on the controller gear can rotate relative to the pulley. To check this, locate the marks on the camshaft and flywheel. By the way, the mark on the flywheel duplicates the mark on the crankshaft. If the roller is positioned correctly, the indicated marks coincide, and between the two missing teeth between the master disk and the axis of the crankshaft sensor, 19-20 teeth of the master disk fit.

To check the mass air flow sensor, disconnect the block of wires suitable for it. Then measure the resistance between the terminal indicated on the ECM diagram and ground. As a rule, it should be 4-6 kOhm. Or remove the sensor from a running engine. In this case, the engine will not lower the speed below 1500. Also, a sign of a malfunction of the air flow sensor is unstable operation of the power unit, difficulty starting it, delays, jumps, dips during movement, insufficient power and traction of the car.

To check if the speed sensor is working properly, shift to neutral while the vehicle is idling. If the sensor is working properly, the speed will increase slightly. On VAZ-2110/2111/2112 cars, if the speed sensor is faulty, the speedometer stops working.

To check the coolant temperature sensor, find a special table in the repair documentation. A change in temperature in the cooling system must be accompanied by a change in the resistance of this sensor according to the data in the table.

Check the oxygen sensor by measuring the resistance of the heater, having first disconnected the connector from it. The result obtained should be from 0.5 to 10 Ohms, depending on the sensor model. Look for exact data in the repair instructions. Also, to check it, remove the connector from the sensor, turn on the ignition and measure the reference voltage of the crankshaft position sensor controller, which should be 0.45 V.

To prevent mechanical damage to the engine as a result of an incorrect ignition angle, there is a knock sensor. When a mechanical impact occurs on the piezoelectric element, which is the basis of the sensor, a pulse occurs, notifying the control unit about the occurrence of detonation.

Quite often, drivers cannot immediately find this element and ask the question of where the knock sensor is located. To find it, you need to open the hood and look between the second and third cylinders. There are two main types:

- single-contact or resonant;

- two-pin or broadband.

The resonant device is quite rare because it was installed on early car models. Therefore, now it is quite problematic to find it, and the cost can be impressive. The operating principle is based on capturing the detonation frequency. The wideband knock sensor works on a different principle. It picks up all the available noise and then determines the desired one among them.

Due to different operating principles, these elements are not interchangeable. Another difference is their price. A two-pin device costs up to 10 times less than a single-pin device, moreover, it is more common and is not difficult to find. If you want to replace one VAZ knock sensor with another, then along with it you will have to change both the wiring and the electronic control unit. If you weigh all the pros and cons, then installing a new unit and broadband device is completely worth it.

How does he work

Depending on the type of knock sensor used, the operating principle of the device is slightly different.

Principle of operation

The control unit controller supplies voltage to the knock sensor. It is constant and amounts to 5V. A resistor built into the regulator lowers this voltage to a reading of 2.5V, and then returns it back. When detonation occurs in the cylinders of the power unit, the knock sensor transmits an alternating current voltage to the controller, the frequency and amplitude of which changes depending on the detonation indicators. Due to this signal, the electronic control unit changes the ignition timing, as a result of which detonation disappears

When the power unit is operating, the regulator sends a signal to the controller in the form of alternating current, which corresponds to the vibration frequency of the motor. If detonation occurs, the signal is converted to a higher frequency. This is how the electronic control unit determines that detonation has occurred. The extinguishing mechanism adapts to the current operation of the engine and allows you to maintain characteristics at an optimal level, adapt to work with fuel, the quality and octane number of which leaves much to be desired.

The best way to avoid all sorts of problems with the engine's fuel injection system is to refuel with high-quality gasoline.

Troubleshooting

In order to promptly determine the failure of a device, you need to know some characteristic signs:

- a “Check Engine” alert sounds in the cabin;

- You can hear knocking fingers when you press the accelerometer pedal sharply;

- there is a lack of power, the car accelerates poorly;

- The engine overheats very much due to setting the wrong ignition timing.

The knock sensor, the symptoms of which are described above, most often fails as a result of running on low-quality gasoline. Another reason is excessive engine overheating, which may be the result of problems in the functioning of the cooling system. If the reason is contamination and rust, then you can try to clean the element and check its functionality. If the problem is more serious, then the best option would be replacement, especially if we are talking about a two-pin device.

Malfunctions of the knock sensor are most easily determined using a special device. Computer diagnostics allows you to find out the true cause as accurately as possible. If there is a break in the device circuit, then this may indicate several options. Firstly, sometimes the part itself is the problem. Secondly, the case may rust, which will cause a failure. Third, lack of power or control signal. Many motorists, when trying to clean rust, come to the conclusion that it is much easier and faster to replace it.

Knock sensor for injection engines of VAZ 2108, 2109, 21099 cars

The knock sensor (DS) is one of the elements of the electronic injection engine control system on VAZ 2108, 2109, 21099 vehicles.

Purpose of the knock sensor

The knock sensor is designed to monitor knock in engine cylinders.

Inside the sensor body there is a piezoceramic element (plate) with certain properties (piezoelectric effect) and a resistor. Outside connection block.

Location by car

The knock sensor on VAZ 2108, 2109, 21099 vehicles is installed on the front part of the engine cylinder block. The broadband is on a stud and is secured with a 22 nut; the resonant one is screwed into the hole under the stud.

Operating principle of the knock sensor

Resonant piezoelectric sensor.

The ECM (control unit) supplies the DD with a constant voltage of 5V. The resistor built into the sensor lowers the voltage to 2.5V and returns it back (the voltage at the sensor output). When detonation occurs in the engine cylinders, the DD begins to output an alternating current voltage to the controller with an amplitude and frequency that varies depending on the magnitude of the detonation. Based on this signal from the sensor, the controller adjusts the ignition timing to dampen detonation.

Wideband piezoceramic sensor.

While the engine is running, the sensor sends an AC signal to the controller corresponding to the engine vibration frequency. When detonation occurs, the sensor produces a signal with an increased frequency. The ECU detects the occurrence of detonation.

The detonation damping mechanism is adjusted to the operation of the engine and allows it to maintain its power characteristics at a normal level, and also allows it to adapt to operation on fuel with a lower octane number.

Detonation occurs due to increased temperature in the engine cylinders. Its reasons: the use of low-quality fuel, a lean fuel mixture, a faulty cooling system, the use of spark plugs that do not correspond to this type of engine, carbon deposits in the combustion chambers, a skipped timing belt, etc.

DD malfunctions

If the knock sensor fails or its electrical connections malfunction, the controller switches to backup tables for calculating the ignition timing. As a result, engine power decreases, fuel consumption increases, and the engine “troubles.”

A sensor malfunction or exceeding the operating limits of the detonation damping system (detonation is too large) leads to a fault code being written into the controller’s memory and the “Check Engine” lamp in the instrument panel coming on.

Applicability of the knock sensor on VAZ 2108, 2109, 21099 cars

VAZ 2108, 2109, 21099 vehicles use both resonant and broadband piezoceramic knock sensors. Broadband detects and transmits the entire spectrum of engine noise to the ECU. And that, in turn, detects detonation noise. The resonant sensor is configured to operate only when engine detonation occurs.

For VAZ 2108, 2109, 21099 with controllers January 4.1 (2111-1411020-22), GM ISFI-2S (2111-1411020-10 (20, 21)), BOSH M1.5.4 (2111-1411020) – knock sensor 2112- 38550102112-3855010-01 (resonant).

For VAZ 2108, 2109, 21099 with controllers January 5.1, VS 5.1 (2111-1411020-72), BOSH MP7.0N (2111-1411020-40), BOSH M1.5.4N (2111-1411020-60) – sensor 2112- 3855010-01 (broadband).

Notes and additions

Piezoelectric effect - a mechanical effect on a piezoelectric element causes its electrification and the occurrence of an electric current. When engine vibrations occur, the piezoceramic plate inside the sensor is subjected to mechanical stress (compressed), a potential difference arises at its ends, and an electrical signal is sent to the controller. In this case, the sensor is axial, i.e. it converts axial movement (shocks from the engine).

More articles on the injector of VAZ cars

How to perform a sensor test

You need to understand that even highly accurate modern scanners cannot always reliably identify a malfunction. For a control check, you will need a digital voltmeter or ohmmeter. It is necessary to measure the voltage between the contacts. If the device is working properly, the resistance will be enormous. Low values or zero ohmmeter readings indicate the need for replacement.

Another way is to connect the contacts of a voltmeter and set the measurement limit to 200 millivolts. When hitting the sensor body, the device should show an increase of up to 40 mV. This parameter will directly depend on the force of the impact. The knock sensor prevents mechanical damage to the engine, so it is important to replace this element in a timely manner.