Detonation that occurs during engine operation not only creates vibration that disrupts the operating comfort of the Chevrolet Niva, but also has a destructive effect on the engine. It gradually damages the elements of the cylinder-piston group and brings closer the need for a complete repair of the power plant.

To combat detonation, an electronic control unit is used, which receives information about the operation of the engine with DD. Depending on the data obtained, the ignition timing and the composition of the air-fuel mixture are adjusted.

Where is the knock sensor located and what is it responsible for?

Depending on the make of the car, the location of the sensor may vary, but it is always located on the engine body.

The part itself is very small, about the size of a matchbox. Detonation is one of the main defects of an internal combustion engine; it has considerable force and cannot be neglected. Among a dozen different sensors used to optimize the operation of internal combustion engines, the knock sensor is directly used to prevent detonation combustion of fuel.

The process of fuel detonation can be well controlled thanks to its main feature - the appearance of high-pitched and ringing metallic sounds, which, based on symptoms, are sometimes mistaken for the clicking fingers of the cylinder-piston group.

The force of detonation is enormous; if the detonation prevention systems malfunction, the engine will fail after 5-6 thousand kilometers.

You can check the sensor:

- using a multimeter;

- testing the ECU mode with the engine running;

- equivalent replacement with a working sensor.

The first sign of a malfunctioning knock sensor is an error indication on the dashboard.

The functionality of the sensor or its malfunction is checked by the computer, and if there is no control signal of the required shape and level, the microcomputer switches to the mode of checking the sign of sensor malfunction.

If the adjustment does not help, the ECU increases the level of enrichment of the fuel mixture, while simultaneously reducing the ignition timing. Such an algorithm is dictated by the need to prevent, first of all, timing malfunction and further destruction of parts of the cylinder-piston group.

One of the most popular domestic passenger cars is the Chevrolet Niva. This all-wheel drive vehicle has a gasoline engine and is classified as an SUV. Based on this, the Niva has a tendency to frequently travel over bumps and off-road. The operating conditions of this vehicle are conducive to providing maximum engine protection.

The first sign that can be noticed is the so-called detonation. In other words, a knocking sound in the engine. One of the parts of electronic vehicle control systems is the knock sensor. Despite its small size, it performs the most important functions in a car.

Sensor operation

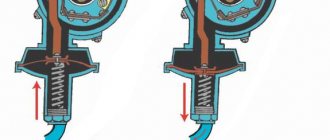

The DD housing contains a piezoelectric element that converts mechanical vibrations into electrical impulses. These signals are sent to the electronic control unit. During normal engine operation, the frequency characteristics have a certain character. If deviations occur in the signal parameters, the ECU makes adjustments to the operating processes of the motor, thereby eliminating the causes of detonation.

Detonation very often occurs when going uphill. In this case, the car is moving slowly, and the speed is increased. But do not worry, since this phenomenon is called glow ignition, and it does not indicate that the engine is not working properly.

Any internal combustion engine works according to the following principles:

- A mixture of gasoline and air is supplied to the combustion chamber of the cylinders, where it is ignited by a spark on the spark plug. Moreover, the piston should be literally a few millimeters from top dead center. As soon as the piston reaches the top position, the greatest pressure is generated in the cylinder. At this moment, the entire air-fuel mixture will completely burn.

- During normal operation of the knock sensor on the Chevrolet Niva, signs of this phenomenon will not appear. This device will help get rid of the manifestation of detonation. And it appears when the mixture begins to ignite much earlier than it should. This usually happens halfway to top dead center. And when the air-fuel mixture burns, a force is exerted on the upper part of the piston, which pushes it in the opposite direction. At the same time, the engine power is reduced, and significantly, and its parts wear out.

There is a "Check" icon on the car's dashboard. In English this translates as check or control. If it is not active, then the knock sensor is working and working as expected.

The operating principle of the knock sensor is based on a piezoelectric mechanism. Inside the sensor there is a plate with a piezo effect. When detonation occurs, voltage is created at the input and output, and the engine vibrates. Otherwise, this is called the creation of a potential difference. If the voltage level at one end is too high, the sensor corrects this process.

If for any reason the sensor breaks down, the “Check” icon will light up on the dashboard. This will mean only one thing: urgent repair or replacement of the element is required.

How to replace a faulty knock sensor on a Chevrolet Niva

From time to time, malfunctions occur on any car. One of the causes of malfunctions that cause problems may be the occurrence of detonation. This can be seen by the engine running for a long time after the ignition has been turned off. It usually occurs due to explosive ignition of fuel in the cylinders.

There is a general principle of operation of an internal combustion engine:

- The fuel-air mixture enters the cylinder and is ignited by a spark from the glow plugs at the moment when the piston remains a few degrees before reaching top dead center. Complete combustion occurs at the moment when the piston reaches the top point, creating maximum pressure.

- If a detonation effect occurs, then ignition occurs much earlier, when the piston is still in the middle of the compression stroke. Therefore, during combustion, a force acts on it in the opposite direction, reducing engine power and leading to increased wear of parts.

If an indication of errors in engine operation appears on the instrument panel, this does not mean that the problem lies precisely in a faulty sensor. But if corresponding problems also arise when driving, then its urgent replacement is necessary. It should be done in accordance with the table.

· Switch the multimeter to DC voltage measurement mode

Connect the connectors to the sensor output

· tap the sensor with a small hammer. In this case, the voltage should change.

· If the voltage does not change, then the sensor is most likely faulty

The cost of a knock sensor on a Niva is 500-600 rubles, so you shouldn’t delay replacing it so as not to spend much more on engine repairs.

From time to time, malfunctions occur on any car. One of the causes of malfunctions that cause problems may be the occurrence of detonation. This can be seen by the engine running for a long time after the ignition has been turned off.

Also interesting: Chevrolet Niva camshaft sensor

It usually occurs due to explosive ignition of fuel in the cylinders. It appears gradually, you can notice it when going uphill at low speed when the gear is in high gear.

This effect is classified as glow ignition and does not indicate malfunction of the engine.

- The fuel-air mixture enters the cylinder and is ignited by a spark from the glow plugs at the moment when the piston remains a few degrees before reaching top dead center. Complete combustion occurs at the moment when the piston reaches the top point, creating maximum pressure.

- If a detonation effect occurs, then ignition occurs much earlier, when the piston is still in the middle of the compression stroke. Therefore, during combustion, a force acts on it in the opposite direction, reducing engine power and leading to increased wear of parts.

Symptoms of a problem

Visually, it is quite difficult to determine a sensor failure, but if the sensor fails, it entails several standard symptoms that will undoubtedly affect the operation of the engine.

- Loss of dynamics and power. The loss of engine power will be noticeably felt when driving a vehicle with passengers or cargo. When the engine is under load, it will stop developing its former power, and every kilometer will be difficult for the car.

- Increased fuel consumption. Due to incorrect adjustment of the ignition timing, fuel consumption begins to increase.

- Black smoke from the exhaust pipe. This problem occurs due to an excess of fuel in the combustion chamber, which does not have time to burn out completely and burns out in the exhaust manifold, forming black smoke. It should be noted that black smoke can also form for other reasons.

- Increased vibrations of the internal combustion engine. Vibrations occur due to uncontrolled detonations and improper combustion of fuel during engine operation.

If the knock sensor malfunctions, the “CheckEngine” lamp on the instrument panel lights up.

Is it possible to avoid detonation?

- When going uphill at a high incline, select a lower gear or one that will allow the engine to operate between 2500 and 3500 rpm.

- Do not use fuel with an octane rating lower than that recommended by the car manufacturer.

- Check the condition of the spark plugs in a timely manner. During scheduled maintenance, monitor the condition of the spark plug wells and check the compression in the piston.

On a Chevrolet Niva, a knock sensor error can be read using a special diagnostic scanner.

If there is an on-board computer, an error code will be displayed on it:

- 0327 - excessively low signal level from the knock sensor. Most likely, there is a break in the circuits connecting the sensor to the control unit.

- 0328 - signal level too high. The cause of this error may be a malfunction of the device itself.

The Chevrolet Niva is a very specific car, as it is designed for driving in conditions where there is practically no road. Therefore, any problems with it can simply be fatal. The risk of stopping in the middle of the forest increases several times.

Pay attention to where the knock sensor is located on the Chevrolet Niva. It is located in the center of the engine block. The distance from the sensor installation location to the 1st and 4th cylinders is the same, thanks to this it allows you to capture all detonation knocks that appear in the internal combustion engine.

And in order to eliminate the possibility of detonation, it is enough to follow a few simple rules:

- When you drive your car uphill or off-road, you need to downshift. It is desirable that the engine operates at a frequency of 2500..3500 rpm.

- Monitor the condition of the spark plugs - the quality of ignition of the mixture depends on them. It is better to occasionally check the compression in each cylinder.

- It is not recommended to use gasoline with a low octane number. It is advisable to fill the tank only with fuel recommended by the car manufacturer.

How does detonation occur in a Chevrolet Niva car?

Like any car equipped with an internal combustion engine, the Chevrolet Niva may experience problems with detonation over time. And considering that it is mainly used to overcome obstacles and drive off-road, the risks increase several times. Therefore, it is important to listen to the operation of the engine under load and, if a metallic clatter appears, visit diagnostics, so as not to develop a number of problems over time:

- destruction of the cylinder head and crank mechanism

- burnout of the cylinder head gasket. This is due to the fact that during detonation the operating temperature of the engine increases significantly.

- piston burnout. occurs as a result of corrosion of the piston day.

Therefore, when moving up at low speeds and in a selected high gear, it is necessary to control the operation of the engine. If you give an increased load and contribute to the occurrence of detonation, you can ultimately damage a large number of car components, which will lead to the need for expensive major repairs.

Problems with engine detonation on a Chevrolet Niva car

The problem of detonation is also familiar to the Chevrolet Niva. Coming from an SUV family, the Niva has the peculiarity of frequent trips not only off-road, but also in hills and mountainous areas. Therefore, when climbing at low speed and in high gear, you sometimes hear the sound of a metallic clatter. This phenomenon can lead to the following types of problems:

- Engine failure resulting from the action of a destructive force on the cylinder head and crank mechanism;

- Burnout of the cylinder head gasket (cylinder head), which occurs when the temperature rises to critical values during detonation. Often the first one to become unusable and requires immediate replacement;

- Piston burnout. Corrosion of the piston crown appears and with frequent exposure to this phenomenon, it leads to burnout.

Therefore, it is necessary to control the operation of the engine when moving up at low speeds and in high gear. Detonation can contribute to the failure of the cylinder block, pistons and crankshaft of a Chevrolet Niva, which can only be corrected by replacing them with new ones, which will be practically very expensive.

The true reasons for the occurrence of this phenomenon on the Chevrolet Niva

All cars are susceptible to this phenomenon. The main reasons that lead to this effect are:

- Circumstances under which the Chevrolet Niva is operated. This is exactly the case when climbing a steep hill at a speed below 40 km/h and in fourth gear;

- Quality of the fuel mixture. If the octane number is low, then detonation is guaranteed. A high number ensures detonation resistance;

- Design characteristics of the motor. These include: the condition of the spark plugs and their location, the shape of the combustion chamber, the compression ratio and the shape of the piston.

What methods of protection are provided in Shnivy against detonation?

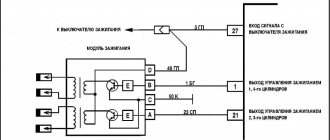

Chevrolet Niva is equipped with a knock sensor. It is designed to protect the motor from this effect, as well as to display the process of its occurrence in the form of a light alarm. The sensor is a sensitive element made of piezoceramic material. On the Chevrolet Niva it is located in the area of the cylinder block. The operating principle of the sensor is as follows:

- When the phenomenon of engine detonation appears, the amplitude of its vibrations increases;

- The built-in controller on the instrument panel corrects the ignition timing, which helps to dampen the phenomenon;

- The signal to the controller is supplied by a sensor, which generates an incoming voltage signal that occurs under certain engine vibration parameters;

- The controller is also capable of displaying a sensor malfunction in the form of a light alarm on the instrument panel. The alarm is represented by the inscription “CHEK ENGINE”, familiar to all drivers, which is highlighted in red.

Sensor cost

The knock sensor has extremely low maintainability. Usually, when it fails, it requires replacement with a new DD. The original General Motors sensor has part number 21120-3855020-02-0. Its price is 450-550 rubles. If there is a need to change the DD, then you can purchase an analogue. The table below presents the best alternative options for a branded product.

Table - Good analogues of the original Chevrolet Niva knock sensor

| Manufacturer | vendor code | Approximate cost, ruble |

| Bosch | 0 261 231 046 | 850-1000 |

| Fenox | SD10100O7 | 500-850 |

| Lada | 21120-3855020 | 190-250 |

| AvtoVAZ | 211203855020020 | 300-350 |

| EPS | 1.957.001 | 400-500 |

Price and article

Below is a table with prices for knock sensors for Niva from manufacturers that have proven themselves well in the market.

| Manufacturer | vendor code | Price, (rubles) |

| LADA (original) | 21123855020 | 200-400 |

| "Road map" | 21123855020 | 250-360 |

| Fenox | SD10100O7 | 200-400 |

| ERA | 550489 | 300-400 |

| Decaro | 2112-3855020 | 380-500 |

Typical breakdowns

Be sure to listen to how the engine operates as the load increases - if even the slightest metallic clatter appears, be sure to make a diagnosis.

Otherwise, you may experience the following problems:

- Burnout of the gasket under the cylinder head. When detonation occurs, the engine temperature increases.

- Destruction of the pistons, as they all corrode.

- Very often, elements of the crank mechanism and cylinder head are destroyed.

If you are driving your car up a hill and the gear is in high gear, be sure to monitor the engine. If you subject the engine to heavy loads, you will contribute to the appearance of detonation knocks. As a result, many elements of the car will fail, and this is the first step towards a major overhaul.

Failure of the pressure sensor circuit occurs for various reasons. Any of them can cause engine detonation. A thorough examination and diagnosis will help determine which one.

It could be:

- unsuitability of the piezoelectric element itself;

- outgoing cable break;

- sensor short to ground;

- lack of contact in the connector block;

- damage to the shielding braid.

Under no circumstances should you delay troubleshooting. The consequences of detonation can be very serious, namely, they will cause damage to the engine itself.

Fault detection

Even if you don’t have a deep understanding of the internal workings of your car’s mechanisms, you have the power to ensure their smooth operation. Who, if not you, can first of all detect the instability of the functioning of some nodes. Considering that trips with individual malfunctions can have serious consequences, any driver must have at least a minimum knowledge of the principles of operation of the parts of his car, know their service life, and be able to identify and eliminate trivial problems, regardless of the make and model of the car.

What to do if there is a malfunction of the knock sensor on a Niva Chevrolet

A malfunction of the engine is usually indicated by atypical engine behavior.

Main features:

- persistent metallic knocking sound in the engine;

- significant reduction in power;

- strong heating of the fuel combustion chamber;

- exhaust smoke;

- increased gasoline consumption.

The presence of the mentioned signs indicates a potential sensor failure. Its subsequent verification is mandatory. The non-working part should be urgently replaced with a new device.

The failure of the engine is indicated by the illuminated “Check-engine” icon located on the dashboard, as well as by pronounced noise in the engine. Replacing the part will help eliminate the cause. You will need a 13mm wrench and a screwdriver. The sensor seat is located between the second and third cylinders.

Sequencing:

- For ease of access to the exhaust pipe, unscrew the bolt securing the front exhaust pipe strut; move the spacer to the side.

- Disconnect the connector connecting the sensor wire to the cable of the electronic control unit.

- Unscrew the sensor mounting bolt.

- Remove the sensor.

- Check it for serviceability, replace if necessary.

Also interesting: Disassembly and assembly of the Niva 2121, Niva 2131 gearbox

Installation is carried out in reverse order.

If you determine the breakdown yourself, then it’s not far to independently diagnose the sensor, as well as replace it yourself. In principle, this is not difficult, but it requires some understanding of the process.

Before running to the auto shop, it is better to check the electrical connection circuit. But if the spare part is still faulty, then it is recommended to replace it.

How to Replace a Knock Part

To do this, we need a new sensor, a “13” key and 20 minutes of free time.

Next we perform three simple steps:

- Turn off the ignition. Carefully disconnect the sensor terminal.

- Using a wrench, unscrew the bolt that secures the spare part to the cylinder block.

- We remove the sensor from the hood.

To install a new element, we perform the same algorithm of actions, but in reverse order. A properly functioning sensor ensures power and long service life for your car's engine. A new DD costs around 12-15 dollars. Therefore, sometimes it is better to carry out routine checks of the serviceability of this part, because repairing a car engine is much more expensive.

Next we perform three steps

Knock protection

The engine management system contains a knock sensor - it allows you to determine the presence of knocks, as well as evaluate their strength. If detonation suddenly appears and the sensor is faulty, the electronic engine control unit will generate an error signal. On the contrary, when the sensor is working properly, it will begin to produce a signal.

The design of the device is based on a piezoelectric element, which generates energy under the influence of impacts. And after that, the electronic control unit processes the signal and analyzes its level. After this, it sends a signal to change the ignition timing.

Replacing the sensor

The procedure for replacing the knock sensor on a Chevrolet Niva is quite simple. You need to adhere to the following sequence:

- Find the location of the element on the engine block. And it is located in the middle part of the block; a wire made of a corrugated tube is connected to it.

- Prepare your tools. A 13mm wrench and a screwdriver will be enough.

- For convenience, you need to unscrew the bolt securing the front tube strut in the gun. After carrying out the necessary manipulations, this spacer must be moved to the side.

- Press the latch to disconnect the block from the sensor.

- Using a 13mm wrench, unscrew the bolt that secures the sensor to the engine block.

- Install the new element in reverse order.

It is advisable to check the integrity of the electrical wiring before installing a new sensor to ensure that it is working correctly. Depending on where the knock sensor on the Chevrolet Niva is purchased, its price may vary between 450-650 rubles.

Engine operation is often accompanied by various types of failures. One of these failures is detonation, which involves prolonged engine operation when the ignition is turned off. From the technical side, this occurs as a result of explosive ignition of the combustible mixture in the engine cylinders.

1. When a combustible mixture enters the cylinder, it ignites when the piston does not reach top dead center by several degrees. Complete combustion of the mixture is completed when the piston reaches the top point. This is how the normal operation of any internal combustion engine is carried out. 2. The phenomenon of detonation occurs when the piston reaches the middle of the compression stroke. At this moment, the piston receives a counterforce, resulting in reduced engine power.

Problems with engine detonation on a Chevrolet Niva car

Purpose of the knock sensor

The knock sensor has the shape of a round torus. There is a hole in the middle through which the fastening bolt passes. There is also a connector on the DD. It provides an electrical connection between the meter and the electronic control unit of the power plant. There is a piezoelectric element inside the torus. The vibration that occurs during detonation leads to shaking loads, which the DDs convert into an electrical signal of a certain frequency and amplitude.

The ECU controls the voltage coming from the motor. If the amplitude and frequency do not correspond to the normal range of values, this indicates the occurrence of detonation. To eliminate it, the control unit adjusts engine operation.

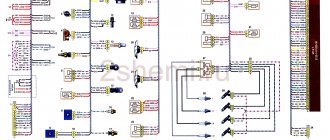

Elimination of excessive vibration and detonation makes it possible to reduce parasitic destructive loads affecting the power unit. Therefore, the main purpose of DD is the task of timely detection of the occurrence of detonation and increasing engine life. The image below shows the DD connection diagram.

This part is equipped with vehicles that run exclusively on gasoline and have an injection type engine. Knock sensors (DS) control the combustion process of liquid fuel, normalizing engine operation. This happens with the help of an electronic control unit (ECU), which, in the event of a sensor malfunction, ceases to see the detonation processes occurring in the cylinders.

Under high loads on the vehicle (steep climb, off-road), an imbalance occurs in the engine combustion chamber between the moment of fuel injection and its ignition. This affects the appearance of strong mechanical vibrations. DD eliminates such phenomena by sending a specialized electrical signal to the ECU.

The cause of detonation may be low-quality gasoline with a low octane number or design features of the engine. The positive aspect of the sensor’s operation is that it promptly protects the power unit from destruction, produces significant fuel savings and allows the car to develop maximum power. All this is extremely important for an SUV.

What is the Niva Chevrolet knock sensor responsible for?

There are three main functions:

- car speed;

- car power:

- fuel consumption.

This is a so-called monitoring system that displays errors on the dashboard: “high signal level” and “low signal level,” thereby signaling to us that there is a malfunction in the car. The knock sensor on the Chevrolet Niva is located on the front side of the engine cylinder block. For stable operation of the car’s engine, it is necessary that the ignition overtaking angle be within normal limits. If the latter goes beyond the limits, the engine overheats and, as a result, excessive fuel consumption.

A malfunction of this spare part can occur for a variety of reasons:

- signal wires are broken;

- the braid is broken;

- short circuit;

- control unit failure.

There are three main functions

Symptoms of sensor failure

As already noted, damage can be determined visually. If the knock sensor is faulty, it will affect the performance of the entire vehicle.

Among the most common symptoms indicating a breakdown in the knock sensor are:

- Reduced engine power. Compared to ordinary situations, it will be quite noticeable. So, for example, when operating a car when transporting goods or passengers, the movement of the vehicle will be difficult, the engine will practically stop responding to the accelerator pedal.

- Increasing the length of acceleration. Basically, this symptom is considered a consequence of the previous point.

- Increased fuel consumption. This is explained by the fact that the engine control unit ceases to control the ignition angle level.

- Smoky exhaust. A large amount of smoke from the car's exhaust pipe can signal a problem. However, such a symptom may not always be associated with a malfunction of the knock sensor.

- The occurrence of detonation effect in the internal combustion engine. A fairly striking sign that should serve as a signal to the car owner about the necessary replacement.

Also, symptoms of a motor failure include a lighted indicator on the dashboard. The “Check-engine” icon can indicate several types of breakdowns, but it is recommended to check the knock sensor first.

How to check the knock sensor?

Unfortunately, the knock sensor can also fail. In this case, a person without special knowledge will be able to notice this only by the lit indicator. No other obvious signs will be noticed. The car will continue to operate in the same mode and start without any signs of breakdown.

At this point, it is necessary to remember that this device is not mechanical, it is part of an electronic system, and therefore the breakdown is considered electronic.

A knock sensor malfunction can happen for a number of different reasons, including:

- There has been a breakdown inside the sensor itself.

- Closure.

- The signal wire or braided shield is broken.

- Damage to the engine control unit.

Thus, it will not be difficult to identify the breakdown. In order to determine it, it is necessary to conduct a test.

But those who are not looking for easy ways can always carry out this simple process on their own. Self-checking occurs according to the following scheme:

- First, we remove the protection in the garage. You will have to work directly with the engine block.

- Now we rule out a break in the signal wire and shielding braid. If it is torn or the braid is torn, you need to check the fastening of the plug and socket of the sensor. The integrity of the braid must be checked.

- If a break is excluded, the outlet itself is assessed. It is possible that its connection is faulty and requires replacement.

- You can detect faults in the device itself using a voltmeter. In this case, the car must be started and idling.

- You also need to check the condition of the device contacts.

Also interesting: Review of the standard Niva Chevrolet alarm system

You can check it yourself in a slightly different way. For this you need a multimeter. This device is very often found among car enthusiasts.

Checking the knock sensor with a multimeter is carried out only after it is removed from the engine. When checking, they knock on it with something metal. This method is the simplest.

We set the range to 200 mV, connect the positive and negative wires to the sensor terminal and to the metal ring, respectively. Do not confuse ground and signal pin! Now you need to hit it with something metal, but not too hard. The sensor will have to detonate.

You can check the sensor with another device called an oscilloscope. It will allow you to study the signal more qualitatively.

Now you need to tap the sensor lightly. The device will show detonation.

If the sensor detonates, then it is working, and the breakdown must be looked for elsewhere. But if the knock sensor signal is low or there is no signal, then this is a malfunction.

Element diagnostics

It is quite difficult to clearly identify all the signs of a knock sensor malfunction due to the “sleep” operating mode of the element. If you constantly fill the tank with high-quality fuel and carefully operate the car, then you may not find out about a failed device soon.

The main symptom of a malfunction is the appearance of detonation as such. If, when you sharply press the accelerator, a loud knocking sound of the piston pins is heard from the engine, then the electronic control unit no longer adjusts the ignition. Most likely the problem is with the sensor.

Reference. It often happens that the failure of the detonation meter cannot be determined by service station specialists. The qualifications of the craftsmen play a role here.

The first diagnostic method is carried out “by ear” with a running warm engine in the following sequence:

- Provide access to the element so that it can be touched by hand. If necessary, remove the air filter and pipe.

- Start the engine and leave it running at idle speed of the crankshaft.

- Take a small metal object and gently tap the sensor body while listening to the power unit.

- If knocking on the device causes a change in engine operation, the element is probably working properly. Otherwise, the device must be dismantled to be checked further.

Sometimes a completely working sensor unscrews as a result of vibration and does not fit tightly to the cylinder block, and therefore is unable to detect detonation. Make sure the device is securely fastened before knocking on the case and drawing conclusions.

A more accurate diagnosis is to check the knock sensor with a multimeter. The method is based on the operating principle of the device - the generation of an electrical impulse by a piezoelectric element from the influence of a vibration plate. How to diagnose the problem:

- Disconnect the wiring harness and remove the part from the cylinder block.

- Set the multimeter to measure a maximum voltage of 200 mV and connect the clamps to the sensor terminals.

- Take a small open-end wrench and tap the element body (without fanaticism), observing the display readings.

- Ideally, voltage surges measured in tens of millivolts should be observed. The stronger the impact, the greater the value the working sensor will show. There is no reaction - buy a new spare part.

During the diagnostic process, do not forget about the serviceability of the transmission link - contacts and electrical wiring. If the detonation meter is operational, but you can still hear the sound of your fingers when you press the accelerator, ring the supply cable and clean the oxidized contacts.

Location of the knock sensor on Niva Chevrolet

The location of the sensor is designed in such a way as to obtain the highest sensitivity of the sensor. In order to see where the meter is located, you need to look directly at the cylinder block. The sensor is screwed on with a bolt. You can determine the location of the sensor by following the wires in the corrugated tube running from the ECU to the sensor.

The transmission of an accurate signal from the measuring element to the ECU is very important. You can only get it directly from the cylinder block. Based on this, it becomes clear why the Chevrolet Niva knock sensor is located where the greatest mechanical shock occurs: right at the source.

Fastening is carried out using a bolt. The connection to the ECU is made through a wire protected by a corrugated tube.

Where is it located?

Many people wonder where to find this knock sensor?! The location of the knock sensor is in the engine compartment of the Niva, namely on the cylinder block near the oil filter.

The location of the sensor is determined by the fact that this is the most sensitive area for detecting various engine detonations. This helps to quickly localize the problem in order to avoid engine breakdowns.

in our VKontakte group

DIAGNOSE YOUR CAR YOURSELF!

engine crankshaft speed is more than 1300 rpm; coolant temperature above 60°C; the amplitude of the knock sensor signal is above the threshold. If a permanent malfunction occurs, the “CHECK ENGINE” lamp lights up after 2 drive cycles.

1. The existence of conditions for the occurrence of code P0328 is checked.

2. The serviceability of the screen of wires 2 B and 88 G is checked.

1. Connect the adapter cable to the diagnostic connector. Start the engine and warm up to a coolant temperature of 60°C. Set the engine crankshaft speed to more than 1300 rpm.

Code P0328 is intermittent. If it is currently inactive and there are no other codes, analyze the conditions under which the code occurred. Check by ear the operation of the engine for the presence of extraneous metallic noises and knocking (valves are not adjusted); if found, eliminate them. Make sure that the sensor wiring harness is not routed near high voltage wires. See the “Checking the Knock Control System” card.

2. Check the serviceability of the screen and the connection between the screen and engine ground. Check the tightening torque of the knock sensor mounting nut.

If comments are found, the sensor or controller is faulty.

If there are no comments, fix the problem.

After repair, start the engine, reset the codes and make sure there is no signal from the “CHECK ENGINE” lamp.

We only find out where the knock sensor is located when we encounter problems with it. And before we talk about its location, it is worth understanding what this element is and what it is needed for. Let's start with this!

Methods for checking a knock sensor

If the first signs of a malfunction of the meter appear, then before making a decision to replace it, it is necessary to check the performance of the meter. First of all, you should pay attention to whether there is an error on the on-board computer screen. If the DD produces too high or low a signal level, this is detected electronically and the driver receives an alert.

You can accurately check the serviceability of the DD only on a stand. All other methods only indirectly indicate the performance of the device.

First of all, it is important to check the resistance between the contacts. In normal condition it should be about 5 MOhm. Any significant deviation indicates a malfunction of the meter.

Another test method is to measure voltage. To do this you should:

- Remove the sensor.

- Connect a multimeter or voltmeter to the terminals.

- Using a small metal object, such as pliers or a bolt, tap the working torus of the meter.

- Check the information on the device. If there are no voltage surges, then the sensor is unsuitable for further use. It is important to take into account that even if there are voltage surges, this is not a reason to consider the DD to be fully operational. The ECU operates in a narrow range of amplitudes and frequencies, the correspondence of which cannot be detected with a multimeter or voltmeter.

In order to independently change the knock sensor on a Chevrolet Niva, you must follow the instructions below.

- Disconnect the terminal block.

- Move the connector to the side so that it does not interfere with further dismantling.

- Using a 13mm wrench, unscrew the DD fastening bolt.

- Remove the sensor.

- Install a new sensor.

- Connect the connector.

It is easy to check the inoperability of the DD yourself without dismantling it by conducting preliminary testing.

How to do it:

- put the engine at idle speed (about 2000 rpm);

- lightly tap with a hammer near the sensor.

A drop in engine speed (which will be audible) will indicate the serviceability of the part. If the speed remains unchanged, then the piezoelectric element is tested additionally. To do this, the DD will need to be removed by unscrewing the mounting bolt and disconnecting the block.

Then use a voltmeter or multimeter.

The procedure is as follows:

- connect the tester to the DD contacts;

- set constant voltage mode;

- Using light taps on the sensor, monitor the meter readings.

Voltage fluctuations of up to 0.2 volts are a sign of the operating condition of the DD. If there are no voltage surges, it means it is damaged and must be replaced.

Removing the sensor and checking

It’s not a lot of work, you just need to use a 20 or 13 key. It depends on which sensor is installed on your car. Unscrew the mount, having first disconnected the wires from the device. That's all, now you just need to check the serviceability. For this purpose you need to use a voltmeter. Moreover, the measurement limit should be 0.2 V. If the sensor has one output, then the voltmeter is connected with a plus to it, and a minus to the metal part of the case.

If the sensor has two contacts, then you need to connect a measuring device to them. Now we need to remember what function this sensor has. That's right, it measures the level of detonation, which means that you need to apply several sharp blows to its body. The voltmeter needle should deflect (if you are using a digital one, the voltage value will appear on the display). The stronger the impact, the more the arrow deviates from the zero value. If this does not happen, then you need to purchase a new knock sensor and install it.

The Chevrolet Niva SUV, produced by VAZ, is popular among car enthusiasts due to its good cross-country ability. To overcome muddy roads, steep climbs, and various obstacles, it needs impeccable engine coordination. One of the negative factors that negatively affects the performance of a car’s heart is detonation. Its increased level creates strong vibration of the vehicle, leading to increased wear and breakdown of internal engine parts. To avoid this, a knock sensor is used on a Chevrolet Niva car, which monitors and normalizes the fuel combustion process in the engine, eliminating potential malfunctions.