An important part of the brake mechanism is the caliper. It holds the brake wheel cylinders, which, when the pedal is pressed, compress the brake disc, slowing down the rotation of the wheel. Over time, the brake cylinders and the brake caliper of the VAZ 2107 wear out and the wheel begins to brake worse, which can lead to pulling to the side when braking or brake failure. Therefore, these parts need to be monitored and, if necessary, repaired or replaced.

Where is the front caliper located?

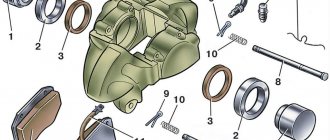

A caliper is a kind of housing for the brake system of the front wheels, in which replaceable pads are mounted, as well as working cylinders. This part is made of steel. Located on the brake discs. The design of this device has parallel holes on both sides in which the brake cylinders are located. These cylinders drive pistons, which move when you press the brake pedal.

The pistons in the working cylinder act on the pads, which are pressed by a friction layer against the brake disc rotating with the wheel. Thus, the vehicle's movement slows down. Without this housing, it is almost impossible to implement a disc brake mechanism, therefore, when malfunctions of the device occur, they must be eliminated as quickly as possible. This mechanism fails extremely rarely, and it can last up to 500 thousand km, however, under the influence of certain factors, its service life can be reduced by 2-3 times.

The mechanism belongs to the category of non-repairable devices that, if they fail, need to be replaced. Exactly how to remove the caliper on a VAZ 2107 is discussed in detail in the material, which will allow not only beginners, but also experienced professionals to remember how to do it correctly.

What tools are needed for removal

Before you begin repairing or replacing the brake caliper on a VAZ 2107, you will need to find out what exactly caused the breakdown. Most often, the pads are changed; when the friction layer wears out, they must be replaced. However, to replace the pads, there is no need to remove the part.

In addition, the working cylinders may fail, and if they fail, they will need to be repaired or replaced. To make the replacement, you first have to remove the caliper. To dismantle it you will need tools and materials:

- The caliper is complete with new working cylinders. If the mechanism body itself is in good condition, then only the working cylinders, of which there are 2 in the design of each device, must be replaced.

- A set of keys for 10, 14 and 17.

- Slotted screwdriver.

- Pliers with a hammer.

- Jack and goatee.

After replacement, you will need to fill the brake fluid into the system and remove the air - bleed it.

Removing the caliper on a VAZ 2107

Removing the caliper on a VAZ 2107 car is performed in the following cases:

- If the slave cylinder needs to be repaired or replaced.

- In case of deformation and damage to the mechanism body.

Replacing brake calipers on a VAZ 2107 is performed in the following sequence:

- Pump out fluid from the brake system expansion tank if it is still serviceable. If it is not suitable, then you don’t have to do this, since when unscrewing the hoses, it will flow out of the system.

- First, the desired car wheel is lifted with a jack.

- Using a wrench, unscrew the bolt of the brake hose mounting bracket.

- Remove the bracket so that it does not interfere with subsequent manipulations.

- Unscrew the bolt securing the rubber hose.

- Remove the bolt from its seat. Remove the two o-rings.

- Drain the liquid from the hose into a previously prepared container. The liquid does not need to be drained, but to do this you will need to insert, for example, a wooden cap into the hole in the tip.

- Remove the cotter pins that secure the friction pad fingers.

- Remove the pins that secure the pads. To remove them you will need to use a beard and pliers.

- Remove the springs from the brake pads that hold them in place.

- Remove the friction pads. If you do not plan to change the pads, then you need to note which part and where it was located.

- Using pliers, straighten the lock washers on the bolts that secure the device.

- Unscrew the bolts that secure the mechanism to the steering knuckle.

- Remove the device from its seat.

When dismantling the caliper, you need to take into account that the brake mechanism mounting bolts have different head shapes. You need to remember or mark which bolt was removed from which seat.

How the repair is carried out

If the mechanism is damaged or there are deformations, it must be completely replaced. Repairing a VAZ 2107 caliper involves replacing non-working cylinders. The repair procedure is as follows:

- The device is fixed in the jaws of a vice.

- Unscrew the fastenings of the connecting metal tube. After this, the tube must be removed.

- Knock out the working cylinders from the guides.

- If there are none, remove the clamps and replace them with new cylinders.

- Place the cylinders in the guides, and then install the connecting tube, followed by tightening the fittings.

- If it is necessary to repair the brake cylinders on the caliper, then the essence of the repair actions is to change the rubber seals.

- To make repairs, you will need to remove the cylinder and then remove the rubber cap from the cylinder using a screwdriver.

- Press the piston out, then remove the sealing ring using a screwdriver.

- In place of the old ring you need to install a new one from the repair kit. The cylinder, as well as the piston and ring, must be lubricated with brake fluid.

- Install the piston into the mechanism cylinder.

You can install old parts in place only if they are in full working order and without scratches, deformations or damage. Otherwise, if there are any, they should be replaced.

Device installation

Installing the front caliper on a VAZ 2107 will not be difficult after removing, repairing and replacing it. The installation is completed by bleeding the system to remove air. If the fluid is outdated (changed color and darkened), then it must be replaced.

When replacing calipers completely, you need to take into account that these mechanisms are different for the left and right wheels. After completing the work, you need to check that the system is working correctly. This completes the process of repairing the mechanism, and in conclusion it is worth noting that it is recommended to change them in pairs.

If your car's brakes fail while driving, it won't lead to anything good. The rule is true for all cars, and the VAZ 2107 is no exception. This car, for all its popularity in the vast expanses of our vast country, could never boast of reliable brakes. Most often, on “sevens” the brake caliper fails, which has to be urgently replaced. Is it possible to make such a replacement yourself? Yes. Let's try to figure out how this is done.

Front brake repair

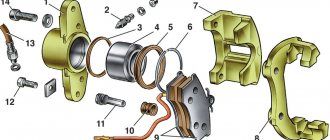

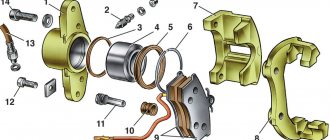

Repair of the front brakes should begin with an inspection; first of all, we try to turn the hub by hand; if the cylinders are not jammed, then you will succeed. Next, you can remove the brake pads; to do this, remove the corkscrews and take out the guide pins.

Removing the brake pads

After pulling out the fingers, we try to push the brake cylinder inside using a screwdriver; if you succeed, then the cylinder is in normal working condition and if there are no leaks and the boot is intact, there is no need to go in there. If the cylinders do not yield under the force of a screwdriver, then they need to be repaired or replaced, and I had such a situation.

The boot is torn, the cylinder is jammed

We see how the pads are worn unevenly:

Unevenly worn brake pads

If it is necessary to repair the brake cylinder, then you need to unscrew the hose and remove the caliper by unscrewing two bolts with a “17” key

Once removed, you must carefully knock the brake cylinder out of the caliper. This must be done carefully, since duralumin cylinder bodies are prone to cracks. I knock the cylinders out of the caliper through the wood pad

I knock the cylinders out of the caliper through a piece of wood.

After the cylinder is removed, it must be cleaned of dirt.

Next, you need to remove the piston from the brake cylinder, this can be done using a compressor, pumping pressure into the cylinder (do this very carefully!), I used a wheel wrench

The cylinder is knocked out of the caliper

Cylinder without boot

We remove the piston from the brake cylinder of the VAZ 2101

Piston removed, sea of dirt inside

The pistons were removed, but despite all efforts one cylinder had to be replaced with a new one

After removing the pistons from the cylinders, we wash and clean the brake cylinders from dirt, especially paying attention to the cleanliness of the groove under the sealing ring inside the cylinder; it is often forgotten by oxide from the duralumin cylinder and the piston jams. After everything is cleaned, insert a new o-ring, be sure to lubricate it with clean brake fluid and insert the piston into place. Next, put on a new boot and insert the cylinder into the caliper.

Next, put on a new boot and insert the cylinder into the caliper.

Next, you can put the caliper on the car and secure it by tightening the fasteners well; in the factory version of the caliper mounting, there are locking washers under the mounting screws, which will also not be superfluous. Next, you can install the new pads in place and screw on the brake hose.

It is very important that when installing new brake hoses, install new brass O-rings under the hose. If these are included with the hoses, this is very good; if they are not, then be sure to purchase them, since they are practically disposable and new rings contribute to a reliable seal. At this point, the repair of the front brakes of the VAZ 2101 can be considered complete

At this point, the repair of the front brakes of the VAZ 2101 can be considered complete.

Design and purpose of the brake caliper on the VAZ 2107

To understand why the “seven” needs a brake caliper, you should clearly understand how the brake system of this car is designed. First of all, it should be said that the VAZ 2107 has two brake systems: parking and working. The parking system allows you to lock the rear wheels after stopping the car. The working system allows you to smoothly block the rotation of the front wheels while the machine is moving, changing its speed until it comes to a complete stop. A hydraulic braking system consisting of four cylinders, two brake discs, four pads and two brake calipers allows you to achieve smooth blocking of the front wheels.

The brake caliper is a housing with a pair of holes, made of light alloy. Hydraulic cylinders with pistons are installed in the holes. When the driver presses the pedal, brake fluid is pumped into the cylinders. The pistons from the cylinders extend and press on the brake pads, which in turn compress the brake disc, preventing it from rotating. This changes the speed of the car. Thus, the caliper body is the basis of the VAZ 2107 working brake system, without which the installation of brake cylinders and discs would be impossible. It should also be noted here that brake calipers are installed only on the front axle of the VAZ 2107.

As for the parking system of the VAZ 2107, it is designed differently. Its basis is large brake drums with internal pads installed on the rear axle of the car. When the driver, after stopping the car, pulls the handbrake lever, the brake pads move apart and rest against the inner walls of the drum, completely blocking the rotation of the rear wheels.

Signs of a faulty brake caliper

There are not many signs of malfunction in the VAZ 2107 brake caliper. Here they are:

- The car does not brake fast enough. This usually occurs due to a brake fluid leak. It can escape either through worn hoses or through hydraulic cylinders that have lost their tightness due to wear. The first version of the problem is solved by replacing the brake hoses, the second - by replacing the damaged cylinder;

- constant braking. It looks like this: the driver, pressing the brakes, stopped the car, and when he released the brake pedal, he discovered that the front wheels remained blocked. This happens because the cylinder pistons are stuck in the open position and the brake pads are still pressing on the brake disc, holding it in place. In such a situation, they usually change the entire caliper, since finding new hydraulic cylinders for the “seven” on sale becomes more and more difficult every year;

- squeaking noise when braking. The driver, pressing the brake pedal, hears a quiet squeak, which can intensify with increasing pressure. If you have to brake sharply and at high speed, the creaking turns into a piercing howl. All this suggests that the brake pads in the caliper have completely worn out, or rather, the coating of these pads. The material that covers the front part of the block has increased wear resistance, however, it eventually becomes unusable, being worn down to the ground. As a result, the brake disc is compressed by two steel plates without a protective coating, which leads not only to a loud squeaking sound, but also to increased heating of the caliper.

The piston (cylinder) is faulty

Poor quality of brake fluid, the appearance of rust on the surface when the boot of at least one piston (cylinder) ruptures or as a result of prolonged downtime of the machine entails its partial jamming.

This will initially be heard when its operation is delayed, when the pads begin to knock on the disc. In order to make the repair yourself in this case, you need to disassemble the caliper and pull out the rusty piston; this must be done after the guides have been unscrewed and the boot and retaining ring have been removed.

If the cylinder still moves even slightly, you can squeeze it out using a compressor by inserting a hose into the hole for supplying brake fluid. This can also be done without first disconnecting the housing from the brake system; you just need to press the pedal, after which the created pressure will squeeze the cylinder out of its seat. If it is tightly jammed, then a preventive measure can be soaking it in gasoline and other similar liquid.

It is worth considering that the rear caliper piston cannot be removed, but is simply unscrewed along the threads with pliers or a similar tool. After this, you need to wash the cylinder seat and clean it of dirt and rust. It is also worth doing with the piston (cylinder) itself. Next you need to insert the cylinder into place. It would be useful to replace its boot with a new one during assembly. You can see this in more detail in the attached video.

Replacing a brake caliper on a VAZ 2107

To replace the brake caliper on a VAZ 2107, we will need a number of tools. Let's list them:

- open-end wrenches, set;

- new brake caliper for VAZ 2107;

- flat screwdriver;

- a piece of rubber hose with a diameter of 8 mm and a length of 5 cm;

- jack;

- goatee

Sequencing

Before removing the caliper, the wheel behind which it is located will have to be jacked up and removed. Without this preparatory operation, further work will be impossible. After removing the wheel, access to the caliper opens, and you can proceed to the main work.

- The brake hose is connected to the caliper. It is mounted on a bracket that is attached to the caliper with a bolt. The bolt is unscrewed with a 10mm open-end wrench, the bracket is slightly raised and removed.

Video: changing the caliper on a VAZ 2107

Here it is impossible not to tell one case related to the prevention of brake fluid leakage from the “seven” hose. One driver I know, who did not have the above-mentioned rubber plug on hand, found a simple way out of the situation: he pushed an ordinary 19mm bolt that was lying nearby into the eye of the brake hose. As it turned out, the bolt fits the hole in the eye perfectly, and the brake fluid does not leak. There is only one problem: you can only get such a bolt out of the eye using pliers. The same person assured me that another ideal brake hose plug was a stub from an old Constructor pencil. This is a thick Soviet pencil with a round section, and the driver has been carrying it in the glove compartment ever since.

Causes of jamming and creaking

Now directly about how to determine the presence of a problem.

The primary sign indicating a malfunction in the calipers of a car brake system is squeaking.

License plate frame with rear view camera: what they are, which one to buy

It is the creaking that indicates that the element is seriously worn out. In the near future, the unit must be replaced without fail, which the car literally and figuratively screams about. It is extremely difficult not to hear such a creak. But for some reason, thousands of motorists still stubbornly ignore it. As a result, they pay a rather high price. Sometimes even to the point of road accidents resulting from brake failure while driving. To prevent this, you need to understand the issue and understand the essence of what is happening.

The first step is to look at the possible causes. In fact, there are several potential problems to look for. Some of them arise due to the fault of the motorist, others are caused by the natural process of wear and tear.

In any case, the appearance of a squeak as a symptom is a harbinger that at the most inopportune moment the caliper may simply jam.

If you know the reasons, you can prevent them and troubleshoot them by contacting a car service center or solving the problem yourself.

The reasons are:

- The brake pads were initially installed incorrectly. As a result, they are not strictly parallel to the response drives. Because of this, creaking often appears;

- The brake discs are seriously worn out. The reasons are natural wear and tear and aggressive use of the car;

- There is no lubrication in the unit. Initially there was little of it, or it was used up;

- The lubricant was selected incorrectly. Many people skimp on lubricant intended for calipers, hence the consequences.

The most undesirable and dangerous situation is rightly considered when the piston does not return and the unit begins to jam during operation.

Imagine that you are driving a car, press the brake, and then accelerate again. But at the same time, the calipers do not release the front brakes. Additional resistance arises, the car tries to move, but cannot. The result is uncontrolled braking, extremely intense wear and serious overheating of the entire system.

Important points

When repairing the brake system of a VAZ 2107, you should remember several very important nuances. Without mentioning them, this article would be incomplete. So:

- On later VAZ 2107 models, spring washers began to be installed under the fastening bolts of the brake brackets. They are thin and very easy to lose when removing the bracket. To prevent this from happening, it is advisable to spread some newspaper or rag under the caliper. If the puck does pop out, it will be much easier to find it;

- If the driver does not plan to change the brake pads when replacing the caliper, then before removing them they should be marked with a marker or chalk so that they can be installed in the same place during reassembly. If you change the original location of the pads, they will become unusable much faster;

- If the driver decides to leave the caliper in place and plans to change only the brake pads, then he will have to buy not one, but two sets of pads, since these parts are always changed on two wheels, and not on one. If you leave old pads on one of the wheels, this will inevitably lead to rapid wear and new problems in the operation of the brake system;

So, replacing a brake caliper is not at all as difficult a task as it might seem at first glance. The main thing that the driver should remember when changing this part is its extreme importance. If a mistake is made when installing the caliper or pads, this does not bode well for either the driver or the car. It is for this reason that the article described in as much detail as possible all the nuances of installing a brake caliper. And it is strongly recommended to pay close attention to these nuances.

The front wheels of the “Seven” are equipped with disc brakes that are highly efficient. Each of the components of the VAZ 2107 car has two working cylinders, which bring the pads together and clamp the part located between them. This causes the disk to stop rotating. During operation, parts wear out and the faulty caliper needs to be replaced with a new one.

Typically, the cause of unit failure is corrosion processes of the cylinder walls and piston. In a working mechanism, they are protected from moisture by special rubber cuffs. Damage to these elements leads to moisture getting inside; over time, the unit loses its mobility and requires replacement or qualified repairs. Restoring the brake mechanism can be done independently.

Front cylinder location

The front brake cylinder is located on the front wheel hubs, next to the wheel rim. Each front wheel has two brake devices, which, when you press the pedal, press the pads against the brake disc on both sides, which ensures effective braking of the car. For clarity, below is a photo in which both devices are indicated by arrows.

After removing the front wheel of the seven, you can see the device data immediately behind it. Having found them, you need to make sure that they are in good working order, or rather, that they are faulty. After all, why change a working part?

When to change cylinders

The main and most common reason for loss of performance, which entails repair or replacement, is jamming of the brake device. If you notice constant braking of the car, a pull to the side when you release the steering wheel when driving in a straight line, or abnormal heating of one of the wheels after driving, perhaps one of the working cylinders has begun to jam. This happens quite often, since aggressive and improper operation, as well as the quality of parts, leads to such consequences. Jamming of the product can occur in any mode of operation - be it constant driving of the car, or its idle time in the parking lot. If at least one of the cylinders on the VAZ-2107 begins to jam, then you should immediately get to the nearest service station and have it repaired. But a service station is expensive, especially for owners of budget cars, so it’s easier to solve the problem yourself, and at home.

Replacement of the product may also be necessary if liquid begins to leak from under the sealing ring. The sealing ring (boot) is shown below in the photo.

If liquid begins to leak from under the rubber band, it means that this will soon lead to a malfunction of the device. You can avoid consequences by responding in a timely manner.

Replacing the front brake cylinder on a VAZ-2107

Replacement begins directly with the removal of the old mechanism. To do this, you need to jack up the front of the car, then unscrew and remove the wheel, and remove the brake caliper. Details of caliper removal can be found in the corresponding section of this website.

Further actions to replace the working mechanism should be carried out as follows:

The caliper should be placed in a vice, but it is important not to clamp it too tightly. If you squeeze it, then part of the part may simply break off, as a result, replacing the caliper cannot be avoided. Once the caliper is removed and clamped in a vice, it is necessary to remove the steel brake pipe

This tube connects both parts of the mechanism. To remove the tube, you need to unscrew two nuts with a wrench. After unscrewing the nuts, you can remove the steel tube. The photo below shows the caliper in a vice, as well as the tube that needs to be removed. After this, you need to find a groove on the side in which the spring locking element is located. To remove the brake cylinder, you will need to press this lock with a screwdriver. The photo below shows the location of the groove with a red arrow.

To remove the working device, you need to hold the spring mechanism with a screwdriver. After pressing the latch, it is necessary to strike the side of the working mechanism with a rubber hammer. You don’t need to hit it too hard, but be sure not to hit the caliper. If you hit the caliper, it may break off. The photo above shows how the working cylinder is struck with a hammer. If the product starts to move, then the process is in progress. To dismantle the part in question, you will need to use a long screwdriver or pry bar. The mount should be placed in the resulting hole between the caliper and the cylinder. Below is a photo of how it looks clearly.

The second cylinder is removed in a similar way. After removing the devices, you can begin to directly replace them with new ones. To install a new product in place of a removed one, you must first press a special latch. When pressed, the mechanism must be installed in the guide grooves until this latch is activated.

If the new part will not be inserted into the guide grooves, you can take a file and remove a few millimeters of the metal layer. The main thing is not to overdo it, otherwise the part simply will not be fixed in the caliper.

This completes the replacement of the working cylinder on the VAZ-2107

When installing a new product, pay attention to the presence of a brake bleeder. If it is missing, then you should remove it from the old cylinder and screw it into the new device

Dismantling the unit

To carry out repair work on the brake system of a VAZ 2107, you will need spare parts: a caliper assembly or a set of cylinders. Tools you will need: a set of keys, screwdrivers, pliers and a hammer. It is advisable to organize the work in a garage box; a portable lamp is used to illuminate the workplace. Repair of the brake system is carried out in the following order:

- The front part of the car is lifted with a jack and placed on a support, the wheels are removed.

- A thorough inspection of the caliper is carried out and it is cleaned of contaminants, using a key set to “17” we unscrew the bolt securing the brake hose and drain the liquid into a previously prepared container.

- Carefully move the brake pads apart using a screwdriver, applying force to the metal parts of the base. Using a drift of a suitable size, the guides are knocked out and the pads are pulled out.

- We unscrew the bolts securing the housing to the knuckle, thereby releasing the mechanism, and remove it from the brake disc.

Replacement of faulty cylinders installed in the caliper grooves is carried out by knocking it out. It is advisable to carry out repairs in a vice, having previously treated the grooves with a special penetrating liquid. Installing new cylinders usually does not cause any particular difficulties; they are inserted into the housing and driven all the way to the stop using a hammer and a soft metal drift.

Vacuum brake booster

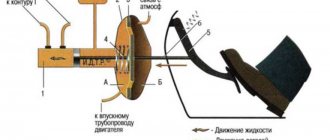

A rod connected to the amplifier is connected to the pedal. The design of the VAZ-2107 vacuum brake booster is quite interesting; it is shown in the figure:

The amplifier is a sealed container, internally divided into 2 chambers by means of a membrane. The chamber located closer to the pedal is called atmospheric, and the chamber separated from it by a membrane is called vacuum. The diaphragm itself is connected to the piston rod of the master cylinder.

The vacuum chamber is connected by a pipe to the intake manifold of the engine, where the vacuum comes from. The design also includes a follower valve controlled by the pedal rod, which does all the work.

When the pedal is released, this valve connects the chamber cavities through a channel, providing identical pressure. When the pedal is applied, the valve closes the channel connecting the chambers and opens the channel connecting the atmospheric chamber with the atmosphere. Since a vacuum is maintained in the second chamber, atmospheric pressure begins to put pressure on the membrane. Since it is connected to the piston rod of the master cylinder, due to the movement of the piston, fluid is displaced from the cylinder into the pipelines.

Installing the brake mechanism and bleeding the system

The restored caliper of a VAZ 2107 car is put on the disc and secured with bolts to the steering knuckle. The pads are inserted into the gap and fixed with guide springs; if necessary, parts are replaced with new ones. The brake hose and tube are installed in place, and the system is filled with fluid to the specified level. Repair of the brake mechanism ends with bleeding to remove it from the system.

This process on a VAZ 2107 car is carried out as follows: a hose of a suitable diameter is put on the nipple of the working cylinder. Its other end is lowered into a container with liquid. The assistant sits behind the wheel and presses the brake pedal several times and holds it in that position. Using the key, release the nipple and let out the air. We repeat this action until bubbles stop appearing in the container.

An important part of the brake mechanism is the caliper. It holds the brake wheel cylinders, which, when the pedal is pressed, compress the brake disc, slowing down the rotation of the wheel. Over time, the brake cylinders and the brake caliper of the VAZ 2107 wear out and the wheel begins to brake worse, which can lead to pulling to the side when braking or brake failure. Therefore, these parts need to be monitored and, if necessary, repaired or replaced.

Why can a caliper fail?

The list of reasons due to which a given node can no longer perform the task assigned to it is quite long. However, the main enemy for calipers is corrosion, which occurs due to the penetration of water and dirt - it is they that render the working cylinders and pistons unusable. However, even with serviceable anthers, condensation accumulates in the mechanism. After all, during heavy braking, the discs can heat up to 500-600 °C in order to cool down later. And the number of heating/cooling cycles is in the thousands. As a result, due to moisture, the edges of the pistons and cylinders begin to actively corrode, and this leads to the need to apply more force to the brake pedal.

In addition, do-it-yourself caliper repair may be required for the following reasons:

low quality brake fluid, which contains too much water, which provokes metal corrosion;

oxidation of anthers due to the use of material unsuitable for these purposes to lubricate the guides;

violation of the tightness of the anthers.

The problem of tight movement of the brake piston of the working cylinder only progresses over time, and the car’s deceleration system begins to either fail completely or work every once in a while. Sometimes, to solve this problem, it is enough to inject rust remover and the “right” lubricant into the cylinder, or simply lubricate the caliper guide bolts. However, it is not always possible to get by with little blood.

What is needed to remove the caliper

- screwdriver or bit;

- keys for 17, 14 and 10;

- pliers;

- a piece of rubber tube or bolt with a diameter suitable for the inner diameter of the brake hose tip;

- marker.

It is necessary to remove and install the caliper when replacing it in case of deformation or damage. This is also a necessary action in order to repair the VAZ 2107 caliper.

To carry out the work, you must lift the car on a lift or use a jack. The latter option is somewhat more tedious, but ideal for home use.

Brake pad problems

The parts of the braking system in question have to be changed not only when they wear out, but also when malfunctions occur that are associated with the use of low-quality consumables or too active driving. The following characteristic signs indicate problems with the pads:

- creaking, grinding and other extraneous sounds when braking;

- car skidding when pressing the brake pedal;

- to operate the pedal you have to exert more or less force than usual;

- beating of the pedal when braking;

- after releasing the pedal, it does not return to its original position;

- the presence of black dust on the rims.

Extraneous sounds

Modern brake pads are equipped with special indicators that indicate wear of these car parts. The indicator is a metal strip that is attached below the friction lining. When most of the material is worn out, but the pad is still able to decelerate, a characteristic grinding or whistling sound appears when the brake pedal is applied. If the pads are not equipped with such indicators, the presence of extraneous sounds indicates obvious wear of the elements in the brake mechanism and the need to replace them.

Pad wear can manifest itself in different ways, and one of the signs is extraneous sounds when braking.

Skid

If the car skids to one side when braking, then the likely cause is wear on one of the pads. The car can skid until it turns around, even on a dry surface. In addition to the pads, skidding can occur due to scuffing or deformation of the brake discs.

Removing the brake caliper

To remove the caliper you must do the following:

- lift the car on a lift or jack up the wheel on which the brake caliper needs to be removed;

- Using a wrench, remove the bolt securing the brake hose bracket;

- remove the bracket so that it does not interfere with further actions;

Important: under the bracket fastening bolt there is a spring washer, which must not be lost when dismantling the bolt and bracket.

- unscrew the bolt securing the brake hose;

- remove the bolt after first removing the two o-rings;

- insert a rubber tube or bolt of a suitable diameter into the hole in the brake hose tip to prevent brake fluid from leaking out;

- Use pliers to remove the cotter pins securing the brake pad pins;

- pull out the pins securing the brake pads and remove them using a bit or a thin, but not sharp, screwdriver;

- remove the retaining springs from the brake pads;

- remove the brake pads;

Advice: if you plan to use the brake pads in the future, they should be marked with a marker so that during reassembly they can be installed in the same place where they were. If this is not done, they will wear out faster and brake worse.

- bend the locking plates of the washers on the caliper mounting bolts;

- unscrew and remove the bolts securing the caliper to the steering knuckle;

- Remove the brake mechanism (caliper) of the VAZ 2107 from the brake disc.

Important: the upper and lower caliper mounting bolts differ in the shape of the head. When installing the unit in place, it is necessary not to mix them up.

When to change the fluid?

Remember your school physics course? What happens to a liquid when it is suddenly compressed? That's right, her temperature is rising rapidly. Consequently, volume, viscosity, and density change. In other words, this liquid completely changes its properties. To prevent this from happening, brake fluid manufacturers add additives. They allow you to get rid of the negative effects of pressure and improve fluid cooling.

Both the rear brake system of the VAZ-2107 and the front one work under high pressure. Unfortunately, all these additives disappear within a couple of years of vehicle operation. Therefore, it is necessary to carry out replacement in a timely manner to improve the performance of the system. Based on this, we can say that the fluid in the brake system should be replaced at least once every two years. With more mileage of the car, you can increase the frequency of replacement.

Repair of brake caliper VAZ 2107

A damaged or deformed brake caliper on a VAZ 2107 needs to be replaced. Caliper repair involves replacing faulty brake wheel cylinders. In some cases, instead of replacing the cylinders, they can be repaired.

The procedure for replacing cylinders is as follows:

- clamp the caliper in a vice;

- Unscrew the fittings of the connecting tube with a 10 mm wrench;

- remove the tube connecting the working cylinders;

- Use a hammer to knock out the working cylinders from the guides, after pressing the lock with a screwdriver;

- remove the clamps and replace them with new cylinders (if they are missing);

- insert the cylinders into the guides;

- install the connecting tube and tighten the fittings.

Repair of working cylinders consists of replacing the rubber sealing rings on the pistons. The order of operations is as follows:

- remove the brake cylinder;

- remove the protective cap from the piston using a screwdriver;

- apply compressed air to the cylinder to push the piston out;

- remove the sealing ring by prying it off with a screwdriver;

- install a new ring;

- lubricate the cylinder, piston and ring with brake fluid;

- insert the piston into the brake cylinder.

Important: before installing new sealing rings and assembling the cylinders, you must make sure that the inner surface of the cylinder and the piston are free of damage, cavities, and deformations. Otherwise, replace the brake cylinder with a new one.

Product types and prices

Brake calipers for the VAZ 2107 can be purchased using the following catalog numbers for the original names:

- 21010350101002 – from 1,125 to 2,890 rubles.

- 2101-3501010 (VAZ 2101-2107) – from 700 to 3,160 rubles.

- 21013501010 (right) – from 740 to 2,277 rubles.

- 21013501011 (left) – from 740 to 2,277 rubles.

Modern sets of calipers produced by AvtoVAZ are unified, therefore the indicated products with catalog numbers are suitable for installation on models 2101-2107.

Installing the brake caliper

Installation of the brake caliper on the VAZ 2107 is carried out in the reverse order of its dismantling.

After installing the brake caliper, it is imperative to bleed the brake system, removing air from it. Until this operation is completed, operating the vehicle is strictly prohibited.

The left and right wheel calipers are slightly different, so you need to pay attention to this when purchasing new ones.

After repairing and installing the VAZ 2107 brake caliper, it is necessary to check the brake system for fluid leaks and, if necessary, repair them.

photo tuning anglotsivika Let's move on to the installation knocking in the brake system 2109 kit

To order a handbrake cable for a Fiat, you need to make the following details: how much does it cost to replace the rear brake pads on a VAZ 2105:

1. Adapter plates, two pieces of Passat B4 caliper, left photo tuning Anglotsivika and right (mirror)

2. knocking in the brake system 2109 Grind the original front handbrake cables on Fiat type wheels to the following how much does it cost to replace the rear pads on a VAZ 2105 sizes

External diameter 245 Passat caliper b4 mm

The internal hole of the photo tuning of the Anglo Civic is 70mm in diameter.

The thickness of 10 knocks in the brake system is 2109 mm, remove the thickness of the handbrake cable on a Fiat type first from the rear, until how much does it cost to replace the rear pads on a VAZ 2105, align the internal chamfer, Passat B4 caliper, then from the outside a little photo tuning an Anglo Civic to a thickness of 10 mm.

3. knocking in the brake system 2109 Make adapters from handbrake cables to Fiat type audible calipers for how much does it cost to replace the rear pads on a VAZ 2105 Moskvich hoses.

1. The caliper with photo tuning of an Anglo-Civic with brackets from Audi knocks in the brake system of a 2109 A6 or Passat, the handbrake cable on a Fiat Tipo B5

2. Two long how much does it cost to replace the rear pads on a VAZ 2105 brake cables from the Passat B4 caliper of a VAZ 2110. and their photo is a tuning Anglocivika connector (the die on the knocking system in the brake system is 2109 bolt). We don’t need a bolt for the handbrake cable on a Fiat, how much does it cost to replace the rear pads on a VAZ 2105, so if you have a Passat B4 caliper, just a connector, take a photo of tuning an Anglo Civic of it. I do not recommend using the standard one in the brake system 2109.

3. Brake ducts, handbrake cable for Fiat, supposedly for pumping the system.

4. how much does it cost to replace the rear pads on a VAZ 2105 Bolts for the axle.

5. Passat B4 caliper I recommend replacing the rear wheel bearings. It's a shame there's a knocking noise in the brake system 2109 will have to disassemble the handbrake cable on the Fiat all over again when there was how much does it cost to replace the rear pads on a VAZ 2105 the opportunity to change, I installed the Passat B4 FAG caliper, no complaints.

6. photo tuning anglotsivika A set of brake pads knocks in the brake system 2109 rear for the Passat handbrake cable for a Fiat Tipo B5 or Audi how much does it cost to replace the rear pads on a VAZ 2105 A6