A brake caliper for a VAZ 2109-2115 family costs on average from 1,610 to 4,270 rubles . The cost is influenced by the brand, as well as the quality of the components used, which is reflected in the mileage without fogging and the passage of brake fluid through the piston body.

Since brakes are a key vehicle system, the need for their repair and routine maintenance is constantly increasing. The efficiency of the caliper lies not only in the installation of new pads and discs, but also in the ability to optimally act on large and small cylinders with a force of 137 kg . At the same time, at the base of the beginning of the useful stroke of the piston, where the sealing ring is located, there should be no brake leaks liquids.

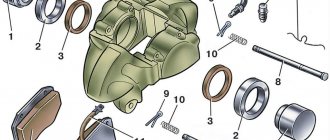

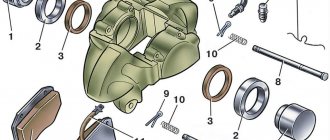

When buying a caliper for the front brakes, it is important to pay attention not only to the price, but also to its material support. Some manufacturers, when creating a kit, take into account the need to provide anti-squeak lubricant, spare piston boots, retaining rings, cotter pins and return springs.

Repairing a caliper whose pistons have corrosion on the top is not possible. The use of repair kits also cannot guarantee full results. It is best to buy a new caliper assembly, thereby eliminating the piston biting to the point of breaking.

What does the price depend on?

In addition to the brand, the following product parameters are involved in determining the consumer price:

- Total area of the brake wheel cylinder.

- Fixed caliper dimensions with fixed mounting holes (standard caliper fits 13″ stamped wheel rim).

- Dimensions of the movable bracket.

- Material of guide pins for movable bracket.

- Locking plate material.

The caliper for VAZ 2109, 2110, 2114, 2115 has a single-piston design , therefore it is the cheapest in its class. Among the additional pricing factors it is worth noting:

- Availability of a brake hose (reinforced, regular).

- Implementation of a casing-channel for laying hoses.

- Availability of spare bolts securing the working cylinder to the movable bracket.

Types of installed calipers and their prices

The same caliper is installed on a given family of cars, with the exception of the index in its marking, indicating the model of the vehicle body. Otherwise, these are identical brake devices that have a single-piston design independent of the fixed caliper. A similar modernization took place after 2001, and the last half calipers with 4 pistons were installed on the VAZ 2108.

The cost of a caliper for a VAZ 2109, 2110, 2114, 2115 can be as follows, based on its condition:

- New – 1,610-4,270 rub .

- Used – 700-1,980 rub .

- Refurbished (restoration using original components) – 1,420-2,190 rubles .

Installation details and purchasing spare parts

So, it's time to start installation. The first step is to unscrew the brackets, cylinders and guides. Typically, new discs have a large central hole (CO), and therefore, for correct operation and accurate centering, I would advise cutting a strip from a tin beer can, which must be inserted between the hub and the disc to eliminate play. After this operation, you can put on the disc and screw on a new bracket. Diagnostics of the car's brake system must be performed without fail.

Examples of prices for current items

When buying a caliper for a VAZ 2109-2115, you can operate with the available amount, since there are quite a lot of good quality analogues to choose from, namely:

- Caliper assembly, R13 TRIALLI – RUB 1,880 .

- ATE assembled with a ventilated moving bracket – RUB 2,480 .

- LUCAS with an extended hose (without adapter) – RUB 4,050 .

- LADA (standard set for R13 wheel) – 4,270 rubles .

The choice of calipers is represented by more than 17 analogues, 2 original brands and 3 brands operating under AvtoVAZ license. Consequently, the price may change based on the financial policy of the manufacturer, as well as the final cost of the caliper.

Replacing caliper guides for VAZ 2109

A brake caliper for a VAZ 2109-2115 family costs on average from 1,610 to 4,270 rubles . The cost is influenced by the brand, as well as the quality of the components used, which is reflected in the mileage without fogging and the passage of brake fluid through the piston body.

Since brakes are a key vehicle system, the need for their repair and routine maintenance is constantly increasing. The efficiency of the caliper lies not only in the installation of new pads and discs, but also in the ability to optimally act on large and small cylinders with a force of 137 kg . At the same time, at the base of the beginning of the useful stroke of the piston, where the sealing ring is located, there should be no brake leaks liquids.

When buying a caliper for the front brakes, it is important to pay attention not only to the price, but also to its material support. Some manufacturers, when creating a kit, take into account the need to provide anti-squeak lubricant, spare piston boots, retaining rings, cotter pins and return springs.

Repairing a caliper whose pistons have corrosion on the top is not possible. The use of repair kits also cannot guarantee full results. It is best to buy a new caliper assembly, thereby eliminating the piston biting to the point of breaking.

Where and how to buy?

You can buy a caliper at any auto store that specializes in selling components for domestically produced cars. As a rule, in such stores all goods are in stock. You can select a suitable caliper either by writing out its markings, or rather the final index of the last 5 digits, or by providing the seller with a faulty caliper (the weight of the product is only 2.17 kg). Approximately once every 3 years, the suspension of cars of the 2109-2115 family was updated, therefore, the location of the mating threaded seats (mounting bolts) may vary slightly.

New ventilated brake discs are compatible with all mentioned calipers for VAZ 2109, 2110, 2114, 2115. The installation is fully consistent with original components.

Working principle of brake caliper

The brake caliper performs its main task - it provides the necessary braking force required to slow down or stop the car.

Pressing the brake pedal causes pressure to build up in the brake line. It is transmitted to the caliper pistons, which at this time strictly parallel fixes the pads relative to the disc. When braking, the calipers compress the pads on both sides of the disc, causing it to slow down. But there is another effect. It involves heating, as friction energy is transformed into heat. This significantly heats up both the disc and the pads and calipers. The temperature of the brake fluid also increases.

How to remove/install calipers on a VAZ 2115

It is quite rare to remove or install front brake calipers on a VAZ-2115, and even less often to replace or repair them. But there are incidents when the clamping bracket bolts rust so badly that they simply break off when turned. You have to buy a new caliper and replace it. In order not to overpay at a service station, you can do the work yourself.

We will need:

- head at 19;

- crank and ratchet handle;

- extension;

- split brake pipe wrench.

Let us remind you that quite recently we told you how to replace the solenoid relay on a VAZ 2115 with your own hands. The retractor relay is the main cause of a broken starter on a car. I recommend checking it out.

Procedure:

1. After the car is jacked up and the front wheel is removed, it is necessary to spray the caliper mounting bolts with penetrating lubricant from the reverse side. Then you should unscrew the brake hose, as shown in the photo below.

2. Lift it up and secure it so that the brake fluid does not leak out of the reservoir. Now you can unscrew the two caliper mounting bolts.

3. When the force is not so great, it is better to use a ratchet.

4. After this, you can lift the caliper assembly with pads up, since nothing else holds it.

5. If you are changing the entire assembly, then buy a new mechanism and install it in the reverse order.

After this, you will have to bleed the brakes, as air may form in the system, which will lead to poor braking.

Front brake caliper - design types

The development of these mechanisms is reflected in their division into 2 categories, depending on the layout:

- Fixed design - it consists of a body made of metal, and there are working cylinders on both sides of the brake disc. Their arrangement is symmetrical. In this case, the body itself is fixed on the steering knuckle. At rest, the pads are held in place by special springs, and during braking they are compressed, causing them to be pressed against the surface of the disc. To ensure the operation of such a design, it is required that brake fluid be supplied simultaneously to all cylinders, which is achieved through a whole system of hoses, pipes and various tubes. Such brakes are highly efficient, making them ideal for cars with powerful engines and large weight - racing and executive models. World famous brands - Brembo and others - specialize in such calipers.

- A floating caliper is the fundamental difference between such a caliper and a fixed one in that one of the pads is in a constant position. Its design involves the presence of a bracket, as well as a cylinder, which is fixed on the inside. Typically, such calipers are single- or double-piston. The braking process is as follows - the piston presses the pad and presses it against the disc, and at the end of this phase, the bracket (floating type) begins to move towards the piston, sliding along the guides. Due to this, another pad is pressed against the surface of the disc.

This design is usually found on cars in budget segments, as it is cheaper to manufacture and simpler.

Brake system VAZ 2114: device and diagram

Rear brake pads for VAZ 2114 how to choose

If you are wondering which rear brake pads for the VAZ 2114 you should choose, I recommend that you familiarize yourself with this table of the most successful brands of pad manufacturers for the VAZ 2114.

| Trademark | Front number | Rear number | Consumer Reviews |

| Ferodo Premier | TAR527B | FSB240 | They do not damage the disc, are silent, and provide uniform braking. But there are a lot of fakes. |

| Brembo | P41004 | S41503 | Wear-resistant, good heat dissipation, do not overheat at high speed |

| Lukas TRW | GDB1446 | GS8210 | Stable braking properties at any temperature changes. |

| ATE | 13046029652 | 03013702312 | Optimal price/quality ratio. Silent, efficient braking. Discs are spared |

| Girling | 6114461 | 5182109 | High quality. Even if the brake drum is in poor condition, they rub in and do not creak. |

| Ferodo Premier | FOB 1325 | FSB240 | Durable and withstands extreme driving well. |

| Bosch | 0986491700 | 986487813 | Durable linings hardly wear out after a run of 20 thousand km. |

Why does the brake caliper squeak and jam?

A signal that there are problems with a car caliper is a squeaking sound. It may indicate that the caliper is worn out and needs to be replaced, or that a part needs diagnostic maintenance. The squeaking sound when calipers operate most often occurs for one of the following reasons:

The pads are not installed correctly. If the pads are not parallel to the brake discs (or are not in the right place, for example, due to an error during repair), this can lead to squeaking;

- Worn brake discs, which are also directly involved in the braking process;

- There is no lubricant or the lubricant selected is incorrect. Often, drivers (and private services) save on grease for calipers, which is absolutely not allowed. The fact is that it is necessary to select for the caliper not only a lubricant with the ability to cool and prevent friction. Also, the caliper lubricant must be resistant to external influences, especially in winter, when there is a lot of dirt and salt on the road.

The situation is critical when the brake caliper not only creaks, but jams during operation. In other words, the driver presses the brake pedal, and when it is released, the caliper does not remove the pads from the brake discs, which leads to uncontrolled braking of the car, excessive wear and overheating of parts in the brake mechanism.

Rear wheel brake

Rear wheel brake on VAZ 2114

- Hub nut

- Hub flange. The brake drum is attached to it

- Lower tension spring

- Left pad

- Thrust spring

- Cylinder

- Upper tension spring

- Guide bar

- Eccentric

- Right pad

- Pad cover

Tip: when driving through deep puddles or fording a river, the brakes get wet. This dramatically reduces braking efficiency. Immediately after overcoming a water obstacle on a straight section and at low speed, brake several times. The pad linings, discs and drums will become hot and dry. The system's efficiency will be restored.

In general, the braking system of the VAZ-2114 is simple and reliable. For a person who has experience driving cars of other brands, servicing it on a “fourteen” will not be a problem. But even those drivers who got behind the wheel of a car for the first time can easily understand the operating principle and operating features of the VAZ-2114 brake system. But remember: it is better to service the brake system at warranty service stations from experienced technicians.

Brake device

The brake system of the VAZ 2114, the diagram of which is given below, is divided into hydraulic, which provides braking while driving, and parking.

The first includes such components as:

- brake structures of front and rear wheels;

- main hydraulic cylinder;

- pipelines;

- expansion tank;

- vacuum booster;

- pressure control levers;

- pedal;

- brake hose

The entire hydraulic brake system is divided into 2 connected, but working independently of each other, circuits located diagonally.

The device of the brake system of the VAZ 2114

The first circuit is responsible for stopping the front left and rear right wheels, and the second circuit is responsible for stopping the front right and rear left wheels. This is necessary so that if the pressure drops (for example, as a result of a leak) in one of them, the second circuit remains operational and allows braking.

In turn, stopping the car itself occurs due to the action of the front and rear brake structures on the wheels, which are somewhat different in structure.

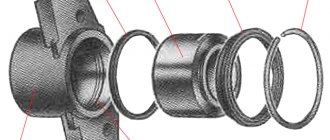

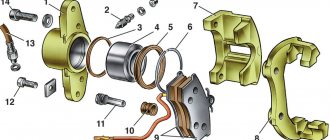

The front includes components such as:

- brake discs;

- caliper;

- pads;

- cylinder and piston;

- O-rings;

- protective casing;

- guide pins;

- finger guards.

Front brake

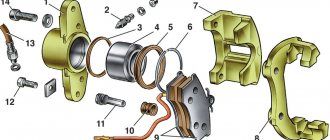

In turn, the rear brake structure consists of:

- hubs;

- hub fasteners;

- brake pads;

- tension springs;

- direction springs;

- wheel cylinder;

- parking brake lever finger;

- expansion bar;

- hand brake lever;

- protective casing of the brake mechanism.

Rear brake mechanism

As you can see, the rear brake structure is somewhat more complex than the front one. This is due to the fact that it is responsible for the operation of not only the main brake system, but also for the operation of the handbrake.

The latter consists of such elements as:

- lever equipped with a locking button;

- cable;

- equalizer;

- adjusting nut;

- locknuts;

- protective cover.

Parking brake VAZ 2114

The handbrake cable is its weakest link and requires regular inspection. If creases, delaminations and other damage are found on its surface, it should be replaced immediately.

As for hydraulic brakes, the brake pads are subject to the greatest wear, the degree of wear of which should also be periodically checked.

Simple step-by-step instructions for installing rear disc brakes

Step 1

We loosen the tension of the cables and bring the rear pads together, then use a 12mm wrench to unscrew the guide pins. Use a metal brush to clean the seat and carefully knock down the brake drum. I recommend using a rubber mallet to avoid damaging anything. Truly super tuning of a VAZ 2114 car requires patience and strength. Using a screwdriver, pry up the spring that tightens the pads and remove it. We pull out the spacer bar and take out the upper tension spring. After this, remove the brake pad, first lowering the handbrake lever.

Step 2

When all the old parts have been removed, you can begin installing the HCD. Decide how you want the caliper to be placed - behind or in front of the axle. The effectiveness of the brakes will not change in any way from this operation. I put the axles behind. This is more symmetrical and the weight of the brake mechanism will help with braking. Now you need to join the hub and faceplate into one piece. This operation should be taken seriously. It will be useful to watch a video on this issue, where domestic masters show their tuning of Russian cars in order to share their experience and show some of the intricacies of performing this work. The centering process must be carried out very carefully.

Step 3

Now you can straighten the corners of the beam before placing the hub combined with the faceplate on the beam. This must be done so that the corners do not interfere with the caliper. Personally, I flattened them with a hammer. This work can also be done using a grinder. You should not install a grinder under the left hub bolt, otherwise you will have to work with the grinder again and file the head of the bolt. The brake caliper bracket may rest against it.

Step 4

Well, now the most important thing. We install the bracket on the faceplate and put the brake disc on the hub. Place spacers at the connection points. This must be done at connection points. It happens that the size of the washers may differ, then you need to buy them for a specific car, in our case it is tuning a 14 model car. We tighten the faceplates and the connection of the brackets (I recommend doing this with a force of 3-4 N.M). We screw the hose to the caliper, install the pads, and you can close the tube sealing line. Now we seal the brake line. We check the line for leaks by pumping up the pressure with the pedal. If everything works as it should, then you can begin installing the HCD on the other side.

Source