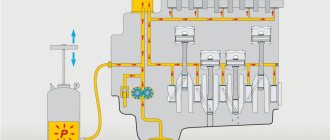

Cars equipped with diesel engines are the most sensitive to the quality of combustible material. The fuel system of a diesel engine occupies one of the central places in the design of the power unit. Operations to repair and restore the functionality of the system are complex and high cost. Structurally, the diesel power system consists of two circuits - low and high pressure. From the first compartment, the prepared diesel fuel enters the next circuit for direct injection into the combustion chamber.

Description of the diesel fuel system design

The fuel system of a diesel engine consists of the following components:

- Fuel tank.

- Main fuel lines.

- Low pressure pump.

- Fuel filter for coarse and fine cleaning.

- High pressure injection pump.

- Spray dispenser nozzles.

As noted above, the system is divided into separate circuits operating under different pressure conditions. The low pressure circuit consists of:

- fuel filter;

- separator;

- special drive mechanism;

- heater;

- TNND fuel pump.

As fuel passes through each element, the following transformations occur:

- Thanks to heating, the cold, thickened diesel fuel becomes fluid.

- Using a filter element, the fuel is cleaned of foreign inclusions and other contaminants.

- The pump provides the fuel pressure necessary to supply the second high-pressure compartment.

The design of the secondary circuit includes the following devices:

- injection pump (high pressure);

- fine filter;

- atomizing nozzles providing dosed fuel injection;

- fuel pipeline system.

Liquefied fuel under pressure in a calculated quantity is supplied to the cylinders through fuel pipes.

Mixing formation

Injectors are required to ensure timely fuel delivery.

As already mentioned, the diesel engine has eight injectors. For proper engine operation, the injectors must be constantly cleaned.

The fact is that the jets that are in the injectors have a very small diameter and can become clogged with any debris that can leak even through two filters. Injectors supply fuel according to a certain principle.

There are some types of nozzles that differ significantly from each other. Each of them has its own specific features, as well as advantages and disadvantages. An electro-hydraulic injector is installed on a diesel engine. The operating principle of this injector is based on the fact that fuel supply and stopping of fuel supply are carried out through fuel pressure.

Diesel Engine High Pressure Fuel Pump

In order for an internal combustion engine to produce the high power stated in the technical specifications, it is necessary to ensure the most complete combustion of fuel in the working cylinders. The main task of the injection pump pump is to supply high-quality diesel fuel to the combustion chambers. This device provides the following conditions for the supply of fuel:

- at the right moment;

- in the required quantity;

- at a given pressure (not lower than 150 MPa).

The moment at which a portion of diesel fuel is supplied and its volume are calculated in accordance with the engine crankshaft speed. These parameters remain stable and do not depend on operating conditions and the degree of load of the power unit.

Design of a diesel engine high pressure fuel pump:

- Mode regulator.

- Drainage fitting.

- Valves.

- Plunger pair with drive mechanism.

- Suspension element.

- Mechanism for adjusting the injection advance angle.

Tuning

Chip tuning of diesel engines can be performed both by reprogramming the control unit and by changing the turbine pressure.

It should be said that chip tuning of a diesel engine is simple and affordable. At the same time, it allows you to significantly increase the power of the motor without reducing its service life.

Note that for high-quality operation of such a chipped power unit, it is necessary to remove the catalysts or install their decoys. It should be remembered that chip tuning of a diesel engine should be performed exclusively by an experienced specialist who knows what compression should be in the engine.

Currently, there are various programs to increase the power of the power unit by reprogramming its control unit. In this case, there is the possibility of both easy tuning and a dramatic increase in power.

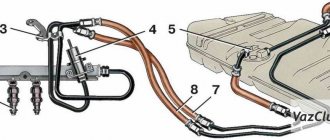

Diesel Engine Low Pressure Fuel Pump

The TNND pump is also part of the diesel power system. It is installed in close proximity to the injection pump pump, connected to it using pipes through which fuel circulates. Diesel fuel is pumped from the tank using a special pump. The fuel injection pump is often called the booster pump of a diesel engine; it consists of two working gears that are in constant mesh. When they rotate, a flow of diesel fuel is created, directed towards the injection pump.

If it is noticed that the performance of the fuel pumping mechanism of the low pressure fuel pump has decreased, it is recommended to dismantle it for further cleaning and flushing. More serious repairs consist of replacing failed elements with new parts included in special repair kits.

Diagnostic equipment

The above table is not yet a basis for sending a suspected component for diagnostics, much less for repair. These preliminary diagnoses can only be taken into account for older diesel engines that do not have an electronic control system.

If problems arise in an engine equipped with an ECU, first of all it is necessary to diagnose a fuel system malfunction using a diagnostic scanner connected to the K-line connector of the unit.

Only after identifying the error code associated with the faulty element should you go to a service station (service station) to begin repairing the diesel engine power system.

After diagnostic testing, specialists will make a final diagnosis - which element of the power system is to blame for the incorrect operation of the diesel engine. Otherwise, at your request, based on your assumptions, they will repair the wrong unit, and the problems will remain with you.

When choosing a service station, you should pay attention to the level of its equipment with diagnostic equipment. The leader in the field of manufacturing test and repair stands for checking fuel equipment is Bosch, which produces a line of EPS equipment.

The EPS 815 stand, controlled by a computer system, has ample capabilities for testing fuel injection pumps of all types. Using the tabletop device EPS 205, nozzles of various types and manufacturers are tested, using various adapters. Diagnostic complexes from Delphi, DENSO and Hartridge are also known.

Features of the diesel engine fuel system

Internal combustion engines running on diesel fuel differ from their gasoline counterparts in the principle of forming air-fuel mixtures. In a gasoline engine, a flammable liquid enriched with oxygen is pumped into the combustion chamber and then ignited by a spark plug.

The process of formation of the fuel mixture in a diesel power unit:

- The working cylinders of diesel engines are filled separately with air and fuel at different times.

- The air enters earlier and is compressed.

- During compression, the temperature of oxygen rises sharply (up to plus 700 – 800°C).

- When the maximum temperature is reached, diesel fuel is injected into the combustion chamber under ultra-high pressure (at least 5 bar).

- Instant spontaneous combustion occurs.

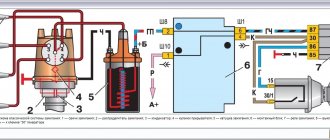

Interesting: The design of the diesel fuel system includes a so-called pre-heating system with special glow plugs made in the form of heating elements. Their task is to ensure rapid heating of the air space in the cooled engine chamber. When the ignition is turned on, the glow plugs warm up the air in the fuel system of a diesel engine for several moments. As the operation of a cold diesel engine stabilizes, electrical power is automatically removed from the spark plugs (after 15 seconds).

A cutaway view of a high-pressure fuel injection pump with a plunger section shut-off valve.

It is reasonable to replace worn out injectors as a set. The price range is very wide: depending on the model and manufacturer, they cost from 8 thousand to 25 thousand rubles. a piece. The characteristics of each new injector must be recorded in the memory of the engine control unit, because no two injectors have the same performance. Different ones not only have a bad effect on the uniformity of engine operation and its dynamic loads, but also worsen the characteristics of the car. Although each ECU has dynamic adaptation (constant adjustment of the cyclic fuel supply for smooth engine operation), you need to remember that it cannot replace the coding if, for example, you forgot to write it down.

The problem of difficult starting of a diesel engine is one of the most common. And the owner is sometimes dissatisfied, for example, with reduced engine power or exhaust smoke. These problems are the most complex, because they require an assessment of the accuracy of measuring air flow or supercharging operation, the efficiency of recirculation, the exhaust gas system, including the diesel particulate filter (DPF) and the converter. However, these technologies are now well mastered by diagnostic masters.

Source

How does the diesel engine fuel system work?

The sequence of system workflows can be described by the following algorithm:

- using a low pressure fuel pump, diesel fuel is pumped into the system;

- after cleaning and filtration, it enters the cavity of the injection pump pump;

- the high-pressure pump pumps fuel under pressure to the spray nozzles;

- when the compressed air in the combustion chamber reaches its maximum temperature, a portion of the fuel under pressure is supplied inside the cylinder in the form of sprayed particles;

- ignition occurs followed by combustion of the fuel.

The most common malfunctions of the diesel engine fuel system

Among the most common breakdowns in the diesel power system, the most common are the following:

- Difficulty starting the engine.

- Reduced power indicators.

- Increased fuel consumption.

- The appearance of smoke of various shades coming out of the exhaust pipe.

- Increased work rigidity.

- Inability to accelerate (in case of failures in acceleration, it is recommended to increase the accelerator pedal travel).

- Unstability of idle speed (floating).

- The engine stalls frequently.

Difficult start

To make it easier to start diesel engines in winter, manufacturers produce a special fuel called “Arctic”. However, the cause of difficult switching on is not always frozen diesel fuel. If it is impossible to start the diesel engine when cold, you need to check:

- quality of operation of high pressure pump discharge parts;

- degree of wear of injectors;

- adjusting the fuel advance angle;

- pre-start glow plugs;

- pressure regulator;

- leakage of fuel lines.

Power reduction

The power of a diesel engine decreases when malfunctions occur, fuel filters, or spray nozzle openings are clogged. When the filter elements fail, the amount of diesel fuel sent to the fuel pump is sharply reduced, which negatively affects the power performance of the engine.

Increased diesel fuel consumption

An incorrectly set injection timing is the main reason for high fuel consumption. The amount of fuel consumed is also affected by improper operation of the fuel injection pump. It is necessary to adjust the pressure level of the mixture at the time of injection. Reduced compression in the working cylinders can also cause increased diesel fuel consumption.

Exhaust black

If dark smoke appears from the exhaust system, it is recommended to check the quality of mixture formation. Violations can be caused by delayed injection of fuel, which does not have time to burn completely and settles on the cylinder walls in the form of soot. Layers of carbon also often form on valves that do not close tightly.

Important to remember

When you check the fuel pressure with the ignition on, note that after the ignition is turned off, the pressure in the rail drops to 0.7-1 atmosphere and remains at this level. If it drops to 0, the problem is in the fuel pressure regulator.

Try increasing the number of revolutions to 3000 - if the pressure gauge needle does not stay constant, but falls, this may mean that it is time to change the fuel pump.

If the pressure builds up for a very long time or is lower than required, the fuel filter, fuel pump filter or fuel line may be clogged.

I hope you found it interesting and will take note of this. Subscribe to the channel and give it a thumbs up to see even more interesting articles on automotive topics in your feed every day.

Source

Cleaning the diesel engine fuel system

When using diesel fuel of inadequate quality with a high content of sulfur elements, the working parts of the fuel system become covered with harmful deposits and become inoperable. In particular, the injector holes become clogged with build-up that has hardened under the influence of high temperatures. Under the influence of the listed factors, the following occurs: a decrease in the throughput of the nozzles, a change in the direction of the spray pattern, etc. The car owner faces a natural problem of how to pump the fuel system of a diesel engine.

It is best to entrust system cleansing activities to professionals. If special equipment is available, the injectors are dismantled and checked on diagnostic stands. However, this method is highly labor-intensive with significant material costs.

Experienced drivers flush the fuel system of a diesel engine with their own hands in a garage. At the same time, they use a simplified technique - adding a special liquid to the fuel tank. This procedure is recommended to be carried out every 3 – 5,000 kilometers.

The most popular cleaning products for diesel injectors among car owners are:

- Laurel.

- Liquid moly.

- High Gear.

When choosing the best cleaner for the fuel system of your car, you need to study the features of each product and read consumer reviews. Thanks to timely maintenance of a diesel engine, the service life of your vehicle is significantly increased and the technical characteristics of your vehicle are improved.