The electrical network of any car is powered by a generator, which is driven by the engine using a belt drive. Its revolutions are constantly changing, ranging from 900 to several thousand, causing the rotor to rotate accordingly. For the normal operation of all electrical appliances and charging the battery, the voltage in the on-board network must be stable, which is ensured by the relay regulator. Being the weakest link in the power supply system, the device first of all needs to be checked when problems with battery charging and other breakdowns in the vehicle's electrical network are detected.

Step-by-step replacement of generator brushes

replace worn brushes without removing the generator from your car. However, according to experts, this process will be much simpler if you remove the generator from its permanent place before replacing it. After the generator is removed, the replacement process is performed in the following order:

- using a screwdriver, remove the cover made of plastic to protect the generator in order to be able to get to the brushes;

- the connecting plug with wires is disconnected from the brushes;

- two fixing fasteners, which are located at the edges of the elements being inspected, are carefully unscrewed;

- using a size 13 wrench, unscrew the fixing bolt in the center of the element;

- after all the fasteners have been unscrewed, the brushes should be removed to inspect their external condition and replace them.

Read

What signs will indicate that the generator brushes are faulty?

The following external signs will help you understand that the generator brushes have become unusable on a Priora with power steering or air conditioning:

- length of the element being inspected;

- if upon inspection it is discovered that the length of the brushes is less than 5 mm, they must be replaced;

- Replacement also be required if the appearance of the brushes indicates uneven wear, that is, one element is heavily worn out, and the second is brand new. Uneven wear of these elements will certainly negatively affect the operation of the generator, so experts recommend replacing them without fail.

The cost of new components for the Priora does not exceed 150 rubles; of course, you can also find cheaper brushes for the generator, but it is unlikely that such elements will serve faithfully for a long period of time, and such savings will lead to a repeated procedure for replacing these components.

The car won't start - 5 most common reasons

Imagine getting into your car in the morning to go to work. And suddenly the car won't start. This situation can confuse many drivers. Why did this happen if everything was fine yesterday?

We've collected the 5 most common reasons why a car won't start and told you how to diagnose and fix the problem.

Replacing the ignition relay for a VAZ 2107

relay is used to turn on the power supply for the accounting ignition system on carburetor non-injection modifications of the “Seven”. If this part becomes a cause of machine malfunction, it does not have to be replaced. You can localize the problem without the help of others, without resorting to the services of specialized 100. List of forums autolada.ru - Classic - and where in 2107 is turn signal relay , one on. For this purpose, it will be necessary at the cinema hall level not to know where the relay and how to change it correctly.

READ Renault Simbol Rear Wheel Bearing Replacement

Candles

Another reason is spark plugs filled with gasoline, whose job is to ignite the fuel. If the elements are installed a long time ago, they gradually become dirty. Each automaker specifies the intervals for checking and replacing spark plugs in the maintenance schedule. In addition, the necessary information is indicated in the service book or in the vehicle’s operating manual.

When the driver tries repeatedly and unsuccessfully to start the car, the spark plugs become heavily flooded with gasoline. After that they definitely won't work anymore. To correct the situation, unscrew and dry them.

Candles can also be filled on a carburetor engine. But the described situation is especially relevant for modern cars with electronic injection, when the driver unknowingly begins to repeatedly press the gas pedal, which in this case only causes harm.

Brush mechanism with relay regulator

On older models of generators, the brushes that transmit current to the rotor winding to create an electromagnetic field that generates electricity could be replaced individually. They were installed in a special device - a brush mechanism, from where they could be easily removed. In modern generators, brushes are mounted complete with an electronic device - a relay regulator. The relay regulator is designed to equalize the voltage supplied to the vehicle's electrical system. A transistor with a threshold for turning off the excitation voltage is built into the relay circuit. He is able to change it depending on the engine speed and, accordingly, the generator. The fact is that without a regulator, as the speed increases, the voltage jumps to 16-18 V, which can lead to failure:

- side lighting lamps;

- low and high beam;

- instrument lighting;

- electric motors of various components.

Garage

I had a wonderful motorcycle Zizer 400 -98. And one day this happened: after riding, I drove to a gas station and filled the tank full. It’s already dark outside, I go to the motorcycle, look at it, my eyes are happy, my emotions are overwhelming. I sit down, press the starter and figs - there’s some kind of crackling noise, the starter doesn’t turn. I called my friend, explained the situation, he said he would come. I'm waiting, sir, I arrived in about 10 minutes. We didn’t think long about it, it was too late to get to the garage 1-2 km away, so we decided to try to start it with a pushrod. It started up with a bang from the pushrod, but the headlight does not light up. I drove without a headlight, fortunately my comrade was driving ahead and had his headlight on.

Video for those interested. (you don't have to watch it :))

It was night outside, I didn’t bother to rack my brains, I stomped home with heavy thoughts. The morning is wiser than the evening. The next day I went to the garage to solve the problem. I started dancing from something simple. We diagnose fuses. I checked. They turned out to be all intact.

I took a photo of the fuse box in the garage.

I decided to start the horse again, and oh mystic horror... the starter spun, then silence. Then a neighbor in the garage came, we don’t leave our own people in trouble. The neighbor came not empty-handed, but with a multimeter. I measured the voltage on the battery and it read 10V. Dead acc, such a bastard.

Then a neighbor in the garage came, we don’t leave our own people in trouble. The neighbor came not empty-handed, but with a multimeter. I measured the voltage on the battery and it read 10V. Dead acc, such a bastard.

I took this parasite home and put it on charge. It took three hours to charge. brought it to the garage. I installed the acc, and yay - the engine started up BUT the headlight does not light up

It took three hours to charge. brought it to the garage. I installed the acc, and yay - the engine started up BUT the headlight does not light up

Okay, I think I got burned. In general, the battery charge was enough for three engine starts. I put it in the garage to charge, the voltage is low, charging will take a long time. In order not to waste time, I went to inspect the connectors and terminals for melting/oxidation. Everything is clean everywhere - makes me happy!

I flew to the store, bought a new light bulb, inserted it into the socket without putting on the muzzle - it lights up, hurray, hurray, hurray. And then my natural curiosity takes over, let me think, I’ll put the old one on, check for lice, so to speak... /drumroll/, the same thing - it’s burning O_o Profuse sweating and mental circulation began. I asked my neighbor to measure the voltage with the engine running at 4000 rpm, it showed 14V, which means the generator is working and I’m happy. “Perhaps there is a short circuit, a short circuit somewhere? “, I say to my neighbor. He advises checking using the old-fashioned method - we remove one terminal from the aka. We put a light bulb between the terminal and the cable, turn the key to the ON position and the light comes on. “It’s not short,” says the neighbor.

I decided to buy a new battery since there was such a binge. As in the song: walk, walk. Bought. Now it starts normally and the horror of mysticism continues to repeat itself, now the headlight is on, now it is not. Started it - it lights up. Turned it off. Turned it on again and it no longer lights up. After several tests it stopped starting again, rattling noise, sweating, mental disturbances (I already have the last one).

Video to break up so much text:

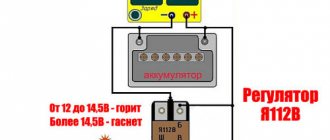

Now it’s the turn of my dear relay regulator (RR)

The manual has several ways to check PP:

Method 1: The lamp should not light on more than one terminal. It lit up happily at terminal Y3. My sadness knew no bounds

Go ahead. Method 2:

Here, too, the lamp should not be lit. Again on Y3 it lit up for me. There is no point in continuing further. RR is dead. It is a thankless task to revive, because it is difficult to disassemble and after tearing apart this rubber casing, it is stupid to change the burnt out parts, it is easier to buy a new one.

But we save money and fight for reliability by not following simple paths. It was decided to solder the relays on our own. There is only one BUT - I can solder two wires together, and anyone who sees my “work” will cry. I started looking for friends who could do this. And such a person was found, we agreed on 2000 rubles

While the relay was being manufactured, it was boring and I decided to check the operation of the generator not in an indirect way (at the speed of the operating engine), but according to science. The alternating current was measured on a connector suitable for the RR. On all pairs of contacts (the chip that plugs into the RR) 42-44 volts were knocked out... The great manual assures that ideally it should be 45... people claim that 44 is also cool, and I believe it. We attribute it to the error of the device and the age of the motor . The result: the generator is alive, it’s proven!

The alternating current was measured on a connector suitable for the RR. On all pairs of contacts (the chip that plugs into the RR) 42-44 volts were knocked out... The great manual assures that ideally it should be 45... people claim that 44 is also cool, and I believe it. We attribute it to the error of the device and the age of the motor . The result: the generator is alive, it’s proven!

RR scheme

Details:

1) Radiator, the bigger the better 2) 36MT120, 3-phase bridge 36A 1200V - 1 piece 3) ULN2003A PBF DIP16 - 1 piece 4) BZX55C13, zener diode 13V, 0.5W - 1 piece (I will solder 14V for myself) 5) BTA26-600B PBF TO218 - 3 pcs 6) K10-17Bimp. 1000pF NPO, 5% -1 piece 7) S2-23 0.5 W, 5%, 300 Ohm -4 pieces

2) 36MT120, 3-phase bridge 36A 1200V - 1 piece 3) ULN2003A PBF DIP16 - 1 piece 4) BZX55C13, zener diode 13V, 0.5W - 1 piece (I will solder 14V for myself) 5) BTA26-600B PBF TO218 - 3 pcs 6) K10-17Bimp. 1000pF NPO, 5% -1 piece 7) S2-23 0.5 W, 5%, 300 Ohm -4 pieces

THE DETAILS ARE JUST LIKE THIS. NO ANALOGUES, SUBSTITUTES, ETC.!!!

In terms of color we are talking about zzr 400 - 1998. On other motorcycles to which this PP will also fit, the color may and most likely will be different!

WHITE wire on the motorcycle “+” BLACK WITH YELLOW STRIPED wire on the motorcycle “-” THREE YELLOW - “phase”. The BROWN wire on the motorcycle is the “key” and can be insulated.

This means there will be five wires from the RR, the positive one naturally connects to the positive one on the motorcycle. Negative from a negative relay on a motorcycle. Three phases from a relay with phases on a motorcycle, the order of connecting the phases does not matter, there is alternating current. Therefore, the phases do not matter which wire is connected to which. It seems like everything is wired...

Materials on RR taken from the site

A week later, the RR is ready, the only thing is that they did not fill this structure with silicone, first check for functionality.

We installed a zener diode at 13v. Now check. At 4000 rpm, the battery charge was 13.3-13.5. Charging is, in theory, normal and not worth worrying about. But I still decided to solder a 14V zener diode so that the charging would be about 13.8-14.2V. The manual echoes everyone who reads it: charging must come

The RR heats up quite strongly, after 4 minutes on the choke (4000 rpm) the hand cannot hold it. After soldering in a 14V zener diode, it will clearly heat up more, and this despite the fact that the size of the radiator is clearly larger than the original. I don’t want to take risks, I’ll do the cooling, take care, as they say...)

Soldered in a 14V zener diode. The lamp is on, everything works. I don’t like the collective farm, I like it to be all right. Usually, when making RRs, people solder wires directly into the device, bypassing the chip (remember the connector on which I measured the voltage from the 42-44V generator). I asked the person to install a connector from the old RR. No sooner said than done.

The person who dismantled the old RR said that there were burnt parts in the 3rd phase (at that time the lamp still came on when checking the RR). It turns out that the discharged battery killed RR, sad thing.

I'm starting to put RR. It will not be possible to stick it in its original place; the radiator dimensions are larger than the stock one. We remove the seat, fortunately we only need to unscrew two bolts. We take a couple of clamps (silicon, it seems) and attach them to the tail. RR must be circuit-based - a mandatory requirement for me.

Now we install cooling. I bought a fan 80 from Zalman. It's a bit big in size, but it cools very quickly. “+” of the fan goes to the brown wire, “-” to the black and yellow one. To prevent the fan from becoming clogged from a sudden power surge, we install a stabilizer “KREN-5” or 8, I don’t remember exactly. It turns out that it was possible to buy a stabilizer immediately in an insulated housing, which I found out about after finishing the work.

That's how it is, guys.

PS: This RR is suitable for different motorcycles. It absolutely fits the Susa RF400, and many other models, I can’t say for sure, but it seems even 600 cc.

Malfunctions of the relay regulator

Most often, the malfunction of the brush mechanism with a built-in regulator is the failure of the semiconductor transistor, a break or a short circuit to the housing. It is also possible for the graphite brushes themselves to wear out or break. This is characterized by a drop or complete disappearance of the charge current. On the Priora this can be seen not only by the battery indicator lamp, but also on the mini display of the instrument panel. It has a charging voltage monitoring function.

The brush mechanism of the generator on the Priora cannot be repaired. In case of any breakdown, you only need to replace the brush assembly.

Multimeter - what is it

A multimeter is a measuring device used to measure resistance, current or voltage. Also, using such a device you can check the wiring for breaks. Each of these measurements involves the use of separate measuring instruments, such as a voltmeter, ammeter or ohmmeter. Therefore, a multimeter is considered a universal tool (mulmeter = voltmeter + ammeter + ohmmeter). In practice, analog and digital multimeters are used.

What is a multimeter

Analog

This multimeter is equipped with a special hand, like on a watch, by the movement of which the measurements are read. The analog multimeter is also equipped with a measuring scale with resistance, current and voltage values. The device is inexpensive, so it is very popular. The disadvantages of an analog multimeter include measurement errors (this mainly applies to products made in China).

Analog multimeter

Digital

Unlike an analog multimeter, a digital multimeter has an LCD or LED screen that displays data. These devices are easier to use and also have high accuracy, which cannot be said about cheaper analogues.

Digital multimeter

How to replace brushes on a Priora generator without removing it

All dynamos installed on Russian Priors are convenient in that the brush mechanism can be replaced without removing the unit itself from the car. This is not a very complicated operation, accessible to almost any car owner who knows how to hold tools in his hands. The replacement is carried out in several stages.

- Battery disconnection.

- Removing the power wire with a 10mm wrench from the generator.

- Disconnecting the test lamp input from the connector.

- Removing the rear plastic cover with snaps.

- Using a screwdriver or wrench, unscrew the 2 bolts or nuts securing the brushes.

- Replace the brush mechanism with a new one, connecting the wires.

- Reassemble in reverse order.

After replacing the generator brushes, be sure to measure the flow of charging current to the battery with a voltmeter and compare it with the readings on the Priora instrument panel. We need to make sure that its work is objective.

In the video you can watch a repair involving the replacement of a relay with brushes on a Priora generator:

>

General recommendations and nuances

It often happens that the generator stops functioning only when the engine is warm. This phenomenon is due to the natural expansion of the metal with increasing temperature or a change in the properties of semiconductors (diodes) for the same reason. In this case, you should first check the functionality of the generator on a warm car, and if this does not bring results, then dismantle the device and check it after heating it with a hair dryer. In conclusion, it is worth noting that independent replacement of generator components such as stator or rotor windings and bearings in domestic conditions is advisable only if you have the appropriate equipment, tools, and experience. If it is not there, then if the battery is not charging, limit yourself to trying to replace the relay-regulator combined with the brush assembly. To do this, you don’t have to buy a new device: you can install a known good one and evaluate the result.