As you know, for the VAZ-2114 engine to function normally, there must be normal compression in the cylinders. But not all motorists understand how to measure it and what should be the norm. This article will talk about the compression rate in the engine cylinders, as well as the reasons for the increase in the indicator and the measurement process.

Video about measuring compression on a VAZ-2114 with your own hands:

The video will tell you how to measure compression in a car.

Correct compression (norms) for VAZ-2114

The process of measuring compression in engines

According to the regulatory and technical documentation, a limit value of compression in the cylinders of the VAZ-2114 engine has been established. Thus, an increase or decrease in the indicator is not considered normal, since excessive compression of the air-fuel mixture in the engine can lead to not very good consequences.

Also, it is worth noting that the compression in all cylinders should be relatively equal. Different indicators are not the norm and these are the first signs of a major engine overhaul.

Normal compression in the engine cylinder

As practice and many years of experience of motorists show, the compression in the cylinders should be 14 bar, but the lower limit should not fall below 11 bar .

When measuring, the difference in compression between the cylinders should not exceed 1 bar .

Example of a bad and normal compress

Let's give a clear example: 12-13-12-13 is normal compression for the engine, but 12-11-12-8 is not normal and it is believed that the engine needs diagnostics and major repairs.

Reasons for increasing compression

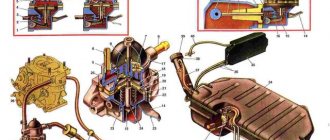

Compression gauge for replacing compression

It becomes clear that a decrease in compression in the engine is associated with wear of key elements, such as pistons and compression rings, main and connecting rod bearings, as well as valves. But what are the reasons for the increased compression?

So, let's look at the main ones:

- When performing repair operations related to the gas distribution mechanism, an error was made in the adjustment work , which changed the order of operation of the unit, and, accordingly, the compression in the cylinders.

- Heat on the valves , as well as the accumulation of carbon deposits on the cylinder walls and throttle assembly, leads to an increase in the compression ratio due to a decrease in space in the nodes.

- Also, the reasons for increased compression in the cylinders include engine overheating.

- The last reason for increased compression is the “occlusion” of the valve stem seals. The malfunction is diagnosed quite simply - the spark plugs are unscrewed and the oil wells are examined. An oil film indicates that there is an excess of oil and the need to replace the valve seals.

Do-it-yourself compression test

Compression in the cylinders must be measured using a special device - a compression meter. There are many types of them, but threaded ones are considered the best and most accurate.

- So, to measure the compression in the cylinder, you need to unscrew the spark plug and screw in the compression gauge fitting.

- Then, turn the ignition key until the engine begins to turn the crankshaft.

- The engine should start and the car enthusiast adds gas so that the engine runs a little.

- So, the compression meter measures the most accurate value.

The compression should not be lower than 11 bar, otherwise it is necessary to understand the causes of the malfunction.

About LADA 2109 engines 1st generation (1987 - 2011)

VAZ 2109 (Lada Samara), popularly known as a nine, is a five-door hatchback, a continuation of the Samara line.

It was developed in 1987 using the three-door hatchback VAZ 2108 as a basis. The nine itself became the basis for the creation of the VAZ 21099. The car became widely popular thanks to its rapid design, good engines for those times, as well as a practical five-door body. All this, coupled with its low cost, as well as a wide selection of spare parts, made the VAZ 2109 very attractive. This attractiveness was passed on to its successor, the VAZ 2114. In contrast to the VAZ, the injector was installed as standard on the 2109 engines (power unit 2111). In addition to the injector, the 2109 was equipped with a carburetor with a displacement of 1.1 l, 1.3 l and 1.5 l. Such engines can be seen if you look under the hood of the 2108.

In the article we will look at the engines themselves for the VAZ 2109, their characteristics and weaknesses.

ENGINE VAZ 2108

The 1.3 engine is the base for the eight, it was developed from scratch, and is structurally similar to the 21011 1.3 liter engine. there is nothing in common. This engine became the basis for the creation of power units for installation on the Samara family with a displacement of 1.1 liters and 1.5 liters. This is an in-line carburetor type engine, has 4 cylinders and an overhead camshaft. The timing drive uses a belt.

Regarding the service life of the engine, it is fair to say that careful and quiet operation, proper and constant maintenance will allow you to exceed the official 120 thousand km and the service life can be 180-200 thousand km.

In terms of disadvantages, the following are most often noted. The parts of the cooling system wear out quite quickly. Frequent oil filter replacement and valve adjustment will be required. Oil leaks often occur due to unreliable seals of the valve cover, fuel pump and distributor sensor. It should be noted that unreliable Solex-type carburetors in general, and EPHH in particular.

If the timing belt breaks, the valves may bend. Also, over time, problems with ignition and engine tripping may occur. In addition, due to ignition problems, the engine may detonate. Another reason for this may be low-octane, low-quality fuel. Detonation is indicated by black smoke coming out of the exhaust pipe and loss of power.

ENGINE VAZ 21081

Engine VAZ 21081 1.1 l. is an analogue of the power unit 2108 1.3. However, it has a crankshaft of less stroke, and as a result, reduced traction. This is an in-line carburetor-type engine with four cylinders, an overhead camshaft, and a timing belt. As for the resource, if you ensure careful operation and quality maintenance, you can count on an official 125 thousand km.

conclusions

It was found that normal compression for a VAZ-2114 engine is 11-14 bar . An increase or decrease in this indicator, as well as a gap of more than 1 bar between the cylinders, is not considered normal and is subject to diagnosis. Engine compression is measured using a compression gauge.

There are several inaccuracies. Firstly, compression is traditionally measured with the engine not running at the starting speed generated by the starter! This is important: the pressure at the end of the compression stroke depends on the crankshaft speed, so if the engine is running, the compression will be much higher than the specified range - up to several times! Secondly, compression is measured on a warm engine (although there are some “former” ones who measure it on a cold engine, but the result is no more than a “funny letter”!). Third, the throttle must be fully open. Otherwise, the required amount of air will not be supplied, so the readings will be underestimated (there is nothing to compress!). On an injection engine, when the throttle valve is fully opened, the fuel supply and sparking stop (so-called cylinder purging). So there is no need to additionally turn off the ignition system (unlike carburetor engines). Fourthly, not only the absolute value of the pressure itself is important, but also how quickly it builds up. This indicator characterizes the condition no less accurately than the pressure itself. Ideally, a fixed value should be achieved in 2-3 “pumps”. And fifthly, the compression level is also affected by the condition of the starter and the flywheel ring gear: if the teeth are worn out and jammed, the compression value will also be underestimated. In general, for a more accurate assessment of the condition, the leak method is now much more often used.

What do we have to do?

First of all, we install the car downhill, in principle, it doesn’t matter what the angle is, ten to fifteen degrees is enough. The most important thing is that the car rolls easily, but there is no need to choose a very steep descent, the test results may be incorrect

How is it checked?

We stopped the car on a descent, engaged second gear, released the clutch and handbrake. Let's note the time. After some time, the compression tightens, the compression is released from the cylinders, but the car, of course, does not start.

We are waiting, after some time there will be such a failure - OP, that’s it, the car started, OP, until the next cylinder, it stopped. We measure the time interval between these dips

. After a while the compression tightened and the car started moving again. And so you need to measure the time four times - unless, of course, you have a four-cylinder engine.

If this distance is equal, plus or minus 10 seconds is allowed, then everything is normal. If some interval turns out to be shorter, then get out of the car, open the hood, open the distributor (if the car is carburetor) and look at where the slider is, on which cylinder the compression is taking place (in the injector you need to look at the timing marks).

Now get into the car and do the same thing, only in ignition order, for example - first and third, fourth and second. As a result, you will know exactly which cylinder has weak compression.

Signs of low compression and how to measure it on a VAZ engine

Compression on a VAZ 2114 should be measured every 30 thousand kilometers. This is usually done in conjunction with adjusting the valves. However, signs of low compression may not only appear with a routine check. As you use your car, signs of poor compression are easy to spot; you just need to keep a close eye on your engine. These are phenomena such as:

- ICE strength drops sharply;

- the engine fires, this can happen when low compression occurs in one cylinder;

- significantly increases oil and gasoline consumption.

When else is this method useful?

Perhaps piston wear in one cylinder is rare, but the valve is pinched - this is a fairly common occurrence. And when the engine heats up, the clamped valve will simply burn out. And if it turns out to be understretched, then strumming sounds will be heard. This is where this method of checking compression without tools comes to the rescue.

Therefore, if you have been adjusting valves, but do not have much experience in this matter, then after adjusting the valves, perform the described operation twice, once on a cold engine, the second time, heat the car to 85-90 degrees and repeat the procedure. When the valves are adjusted incorrectly, but on some cylinder the compression disappears, there will be almost no compression, this means that you have overtightened the valve. We urgently open the lid, adjust the valve and go.

If the information was useful to you, don’t be lazy and hit the THINGS UP! And in order not to lose it, share it with your classmates or another social network.

WHAT THE COMPRESSION SHOULD NOT BE IN AN ENGINE

At first glance, it may seem that the higher the compression parameters of the air-combustible mixture, the better. But actually it is not. Compression has an upper threshold that cannot be crossed, as this will lead to overheating of the engine, and, as a result, deposits of carbon deposits, excessive load on the pistons and rings, as a result of which engine parts may fail.

Low pressure in the engine leads to excessive consumption of fuel and oil. It is not permissible that in individual cylinders it differs sharply from neighboring ones. Different compression in the cylinders indicates serious problems in the engine - wear and defects that have appeared that require replacement or repair of parts.

Thus, bad compression is:

All of these signs of poor compression are a sign that the heart of the car needs repair.

How to get rid of inaccurate compression measurements

The compression meter may show inaccurate values if at least one of the following factors exists:

- VVAZ-2109 battery is practically not charged;

- a starter malfunction has been detected;

- the engine is cold;

- valve clearances do not correspond to normal values;

- gasoline got into the cylinders;

- The measurements were initially taken incorrectly.

In the absence of an assistant, the procedure was carried out without pressing the gas pedal, which in itself is considered a significant violation of pressure measurement.

Experts note that the compression meter gives increased readings when there is excess oil in the cylinders, this is due to wear of the oil scraper caps built to guide the VAZ-2109 or CPG valve bushings.

Regardless of which mechanism is installed in the VAZ-2109 - a carburetor or an injector - the maximum pressure value is calculated based on the product of the compression ratio and a constant coefficient equal to 1.2.

CORRECT COMPRESSION

How much compression should be in the engine for its long-term and trouble-free operation? Long-term practice of operating cars shows that ideally it should be 14 barrels in each cylinder. But a reduction to 11 barrels is allowed, provided that the difference in compression in the cylinders should be no more than 1 barrel. For example, a compression pattern of 11-12-11-12 is considered acceptable, but if the pressure in different cylinders is 11-12-11-9, or another combination of indicators that differs from normal, then the engine already needs repair.

What compression should be on a VAZ 2114 8 valve also depends on how long and under what conditions the car is operated. Ideal pressure, as a rule, occurs with a new engine, or one that has just come out of a major overhaul. During vehicle operation, compression may drop by 1-2 barrels. And this will also be within the normal range.

COMPRESSION – WHAT IS IT AND WHAT SHOULD IT BE?

Compression is a measure of the maximum pressure in the combustion chamber that the piston can create when it reaches TDC during the compression stroke. Measuring this indicator gives an idea of the tightness of the chamber, which in turn depends on the condition of a number of elements - the piston and compression rings, valves with seats, head gasket, and the installed thermal gap in the timing belt. Since the compression measurement technology itself is simple, and the data obtained as a result of its implementation makes it possible to estimate the remaining life of the power plant and identify a number of malfunctions, this diagnostic operation is quite common.

Although car power plants have a common design principle, they are structurally different, which also affects compression indicators. Each engine has its own specific maximum pressure values in the combustion chambers, which must be indicated in the technical specifications. documentation for the car. For example, for a VAZ-2106 a compression of 11 kgf/cm2 is considered normal, but for a VAZ-2110 this figure is already 13 kgf/cm2.

Note that when measuring, it is not necessary that the device should show values that correspond to the norm. As engine components wear, compression readings will drop. Moreover, if they drop below a certain value, this will be a signal of extreme wear of the power plant’s CPG, and the need for major repairs. Some variation in readings between cylinders is also allowed. However, it should not exceed 1 kgf/cm. sq. That is, if measurements on a VAZ-2115 showed that the compression in the cylinders was 12 kgf in the 1st, 11 kgf in the 2nd, 12 kgf in the 3rd, 12 kgf in the 4th, then the power plant of the car will be considered to be in working order.

REASONS FOR COMPRESSION FALL IN ONE CYLINDER

It also happens that a pressure drop occurs in one of the cylinders, and significantly (in some cases, compression can drop to 3-4 kgf/cm2). And such diagnostic results are a reason to worry, because there are malfunctions in the power plant.

The reasons for a drop in compression in one of the cylinders above normal may be:

COMPRESSION RINGS. These elements play one of the most important roles, since their task is to ensure tightness in the piston-cylinder pair. If the rings are damaged (burst) or stuck, they will begin to leak working gases into the sub-piston space, which is why a significant drop in compression occurs;

VALVES. Through these elements, the components of the combustible mixture are admitted and exhaust gases are removed. But during the compression stroke, the valves are closed, which seals the combustion chamber. But if, due to a violation of the combustion processes, the edge of the valve plate and seat are burnt, or the thermal gap is broken, and it turns out to be slightly pressed, then the tightness of the chamber is not maintained, which affects the compression;

PISTON. This element is rarely to blame for a drop in pressure in the cylinder, but there are still situations when the reason lies precisely in it. As a result of the same process changes, the piston crown may burn out. This usually happens due to a violation of the ignition angle. And if the piston burns out, then there will be no tightness;

BLOCK HEAD. Although rare, it does happen that cracks and other defects appear in the combustion chamber, affecting the loss of compression. Also, the head can cause a loss of pressure in some cylinder if it fails due to overheating. Due to changes in geometry, the head in some places simply does not fit tightly to the gasket. Even a simple insufficient tightening of the cylinder head bolts can affect compression;

cylinder head gasket. Due to internal defects or overheating, a breakdown of this gasket may occur. As a result, one of the cylinders is connected to a channel of the cooling or lubrication system, another cylinder (in this case, a strong drop in compression is observed in two cylinders), and the breakdown can also lead out of the engine.

REASONS FOR INCREASED COMPRESSION IN THE ENGINE

Let's look at the main reasons:

- Incorrect adjustment of the timing belt leads not only to increased compression, but also to decreased compression, depending on the direction of regulation.

- The appearance of scale on the valves, which appears due to the use of low-quality gasoline, oil or other automotive chemicals. Carbon deposits on the throttle assemblies and in the combustion chamber also appear due to engine overheating. Thus, overheating of the internal combustion engine is not only a consequence, but also a cause of high pressure of the air-combustible mixture. The operating temperature of the VAZ 2114 8 valve engine should not exceed 85-90 o C.

- High compression can be caused by stuck oil seals. This reason is not difficult to detect. You just need to unscrew the spark plugs and inspect the cylinders. The appearance of an oil film on their walls will indicate an excess of oil in them, and the need to change the caps.

Compression is also affected by the level of oil pressure in the engine. If it is too high, then this leads to increased pressure of the air-combustible mixture.

Low pressure occurs if the rings are worn out or the valves are burnt out. The operating temperature of the engine also affects. If it is below normal, this will also affect the pressure of the air-combustible mixture.

The reasons for the lack of compression in the engine lie in improper operation and untimely preventive repairs. Sometimes air breaks through from several sides at once - for example, through valves, and at the same time through pistons with rings. Then the pressure disappears completely. It's simply not acceptable to let the car get into this state.

How often should I check my blood pressure?

For preventive purposes, diagnostics should be carried out along with replacing the spark plugs of a gasoline engine. Depending on the brand of car, technical condition and quality of products, such an operation is carried out at intervals of 25–50 thousand km.

The following symptoms are the reason for an emergency compression check:

- the power unit began to “eat” oil in the amount of 150 ml per 1 thousand km or more;

- blue smoke from the exhaust tract is noticeable;

- the car became bad;

- At idle the engine stalls and shakes.

The last sign may indicate a malfunction of the ignition system or failure of 1-2 spark plugs. Before measuring pressure, it is advisable to eliminate such problems. On diesel engines, wear of the piston group and valves manifests itself in similar symptoms; cold starts are especially difficult - if there is insufficient pressure, the diesel fuel simply does not flare up.

Since there are many reasons for the appearance of such symptoms, it is first recommended to carry out computer diagnostics of the car. The easiest way to do this without visiting a service station is to use an inexpensive scanner, for example Rokodil ScanX Pro.

If a malfunction is detected, the scanner will accurately indicate the cause of their occurrence, and in the case of malfunctions of the ignition system or failure of the spark plugs, it will indicate a specific cylinder. This car scanner is universal and is suitable for almost all cars with an OBD2 connector.

PREPARATION FOR MEASUREMENTS

Engine compression is measured with a fully charged battery. After charging and installing the power source in place, check the starter. It shouldn't create any problems either. Then warm up the engine. Its temperature during measurements should be 70-90 O C.

It is necessary to unscrew all spark plugs from all holes. Also unscrew the fuel hose to stop the fuel supply. Prepare the compression gauge for use.

Compressometer

BG products used for compression restoration

One example of the use of BG products as a preventative measure to keep the cylinder-piston group (combustion chambers, piston, oil rings, valves, etc.) clean is the so-called “great three” BG:

- Compression restorer working with the oil system - BG 109;

- Engine oil conditioner BG 110 (BG 115), the task of which is to give the oil thermal and antioxidant stability, protect the required additive package provided by the engine oil manufacturer, and also reduce friction in the engine, thereby increasing the service life;

BG 208 is a highly effective fuel system cleaner for gasoline engines, poured into the fuel tank. Its advantages are that its combustion temperature is much higher than the combustion temperature of the fuel (it does not burn in the combustion chamber). Thanks to this, it cleans the entire fuel system, combustion chamber and exhaust system elements (oxygen sensor, catalyst).

And in conclusion, I would like to remind you that preventing a problem is much easier than solving it. Timely and regular use of auto chemicals when servicing vehicle systems will help you save significantly on its repairs, increase the service life of its components and assemblies, increase engine efficiency, and issues with piston rings will arise only if you communicate with those who neglect these recommendations.

Prevention is cheaper than repair!

COMPRESSION MEASUREMENTS IN THE ENGINE. COMPRESSOMETER

A device consisting of a pressure gauge and a rubberized tube that measures compression in the engine is called a compression gauge. The following devices are used:

Experts believe that of all types of compression gauges, it is better to use threaded ones. They provide more accurate information. It is necessary to measure the compression in the engine in each cylinder separately. The measuring instrument hose is inserted into the spark plug socket.

Now that everything is ready for measurements, start the engine and squeeze the gas all the way, let the engine run for a while. Check the pressure gauge readings and record them. Move the compression tester hose to the next spark plug hole, and take measurements in the second and subsequent cylinders in the same way. Write down all the results and compare them.

Downward change

There are 2 types of deterioration in performance: a decrease in pressure in all 4 cylinders or only in one, less often in two. The limit at which immediate repair is required is considered to be 11 bar. When the compression is low at all 4 measurements, then you need to look for one of the following faults in the engine:

- The piston rings have expired. The pressure drops gradually as it wears out. It is considered a completely natural process.

- The same, the entire piston group. Due to the operation of the crankshaft, the cross-section of the cylinders becomes ellipsoidal rather than round. Gaps form between the walls and the pistons that even new rings cannot cover.

- The valves were covered with soot on the inside (in jargon: burnt) and lost their tightness. Carbon deposits prevent the valve from completely seating and closing.

- The rules for adjusting the thermal clearances of the valves were grossly violated. When there are no gaps, after the engine warms up, the valves are constantly slightly open. This most harmless malfunction can be eliminated by adjustment, after which the compression must be re-measured.

The first 3 malfunctions, as a rule, come together and definitely lead to disassembly of the power unit. It rarely happens that after removing the cylinder head, only ring wear is discovered. Typically, valves and seats also need to be cleaned and wiped, and there is an ellipse-shaped development inside.

Another option is when compression has disappeared in one place: just yesterday it was there, but today the car is already “sneezing” on 3 cylinders. The reasons are as follows:

- became covered with soot and 1 valve or 2 adjacent ones stopped closing;

- due to overheating, one piston expanded more than the others and stripped the cylinder walls;

- error when adjusting the valves, one of them is very “clamped”.

As in the previous case, the final diagnosis is made after disassembling the motor, examining and measuring the size of the ellipse. Scratches on the inner walls will be immediately visible and will lead to the replacement of all pistons along with rings and repair of the cylinders.

INJECTION ENGINE PRESSURE

Below you will learn how to correctly measure compression in a VAZ 2114 engine with injection type power.

If in at least one cylinder the pressure gauge shows a pressure below 10 barrels, then we need to look for the reason for such a low indicator. Otherwise, very soon it will fall in other cylinders.

Fill a medical syringe with about 10 milligrams of oil and spray it into the cylinder. Take the measurement again. If the pressure gauge readings increase, it means the piston rings are worn out and require replacement. If it remains at the same low level, then it is necessary to adjust the clamped valves or replace the burnt valves.

Boosting with additives: salvation is real, probably confirmed

These additives seem to build up a thin layer on the worn areas of the metal, the thickness of which, however, is sufficient to “replenish” the worn rubbing surfaces of the engine with a certain material, which, moreover, is capable of retaining motor oil. This allows you to further increase the compression in the engine. These additives are available on the consumer market in a fairly wide range, and car enthusiasts can only choose, trusting advertising and the recommendations of friends (if they decide to increase the pressure in the cylinders of their car on their own).

WHAT TO DO IF YOU DO NOT HAVE A COMPRESSOMETER AT HAND?

Is it possible to measure compression without a device? Practice shows that yes, it is possible. But this method will give relative and approximate readings. To measure the compression indicator without instruments, remove the spark plugs from all cylinders except the one being tested. Manually rotate the crankshaft until the compression stroke ends (watch the marks - they should match). Perform this operation on all cylinders one by one. Where the pressure is low, it will take less effort to turn the crankshaft. In this way, of course, you will not get accurate compression readings in the engine. But it is possible to understand the presence of problems.

It is recommended to measure compression every 20-30 thousand kilometers, so every car enthusiast is recommended to have his own compression gauge. Its price is not so high that it is worth saving on it.

The approximate price of a device for measuring engine compression in online stores in the capital is from 600 rubles to 2 thousand. Branded models from Western manufacturers are more expensive – up to 8 thousand. In the regions, a device for measuring compression costs no more than in the capital. Its price varies depending on the manufacturer.

Taking a measurement

Measurements of the compression value are carried out in each cylinder separately, and the power unit must be in a warm state. In a cold engine, the readings will be lower than actual ones, although in the presence of a glaring malfunction they will also be able to reflect the picture. To measure you will need the following tools and devices:

- spark plug key;

- a pressure gauge (otherwise known as a compression gauge) of a threaded or clamping type;

- rags.

A pressure compression gauge is a steel tube with a handle, at one end of which a rubber cone and valve are installed, and a pressure gauge is screwed to the other. The device is inserted with a rubber cone into the threaded part of the cylinder and pressed using the handle. In this case, you cannot do without the services of an assistant who turns on the starter. A pressure gauge with a hose and a thread at the end will have to be screwed into each hole one by one, but you can check it yourself. The procedure for performing measurements is as follows:

- Remove the high-voltage wires from the spark plugs and move them as far away as possible to avoid electric shock.

- Unscrew all spark plugs and wipe their seats with a rag. It is advisable to arrange them in the order of unscrewing, so that during diagnostics you can determine which cylinder the spark plug was removed from.

- Insert or screw the end of the device into the hole of cylinder 1 and turn on the starter for 3-6 seconds.

- Record the readings and move on to the next cylinder.

If for some reason the measurement did not work or you held the compression meter askew, the procedure must be repeated. Take your time to clean the spark plugs; their condition can tell a lot during the test analysis.