The injection fuel intake into the VAZ 2114 ensures reliable operation of all components, ease of starting, and so on. For proper operation of the injector, fuel must be supplied at a certain pressure.

The pressure in the fuel system is pumped up by a special fuel pump, and it is regulated by an RTD, which, by the way, is what today’s article is about.

This article talks about the VAZ 2114 RTD, its design, purpose, signs of malfunction and how to replace it yourself.

Purpose of RTD

The fuel pressure regulator (FPR) is designed to regulate fuel to the limits required for proper operation of the internal combustion engine. This part on VAZ cars is completely mechanical and does not contain any electronics.

The main task of the RTD is to keep the fuel at an acceptable pressure and release it when the pressure reaches a peak. When a part fails, interruptions in the operation of the internal combustion engine are observed.

WHAT GASOLINE TO POUR IN THE VAZ-2114?

This topic has become overgrown with various conjectures and speculations, but we will try to put everything in its place.

Another thing is that many car owners, over their long driving experience, have accumulated rational doubts about the existence of any serious differences between 95 and 92 gasoline. Adding fuel to the fire was the recent statement by the chief engineer of the Moscow oil refinery, A. A. Abrosimov, that we do not make 95-grade gasoline in our country, and everything that is sold under its guise is either 92-grade or unknown fuel brought from somewhere.

As evidenced by reviews from VAZ 2114 owners who use exclusively 92-octane gasoline, there were no problems with the car during its service life due to fuel, and they see no point in using a more expensive analogue. However, the final decision about what to pour into the fourteenth is yours.

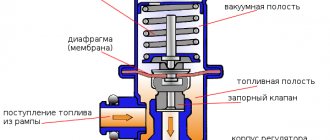

Design

The regulator includes a check valve that opens when exposed to excess pressure. The RDT has two outputs, forward and reverse. The fuel pump pumps fuel into the direct line, since the fuel pump pumps fuel continuously, therefore, when a certain pressure value is reached, the RTD valve opens and excess fuel is discharged into the return line, which is connected to the tank.

What you need to check the pressure in the system

In order to verify the serviceability (malfunction) of the RTD, as well as the entire fuel system, it is necessary to determine the value of the fuel pressure. Naturally, you will need a special tool for this.

- a piece of high pressure hose (internal diameter 8-10 mm);

- several clamps corresponding to the diameter of the hose;

- pliers;

- screwdriver;

- nipple cap;

- fuel collection container;

- dry clean rag.

Types of RTD

The VAZ 2114 uses two types of fuel pressure regulators. They differ in installation location, size and price. The type of RTD depends on the year of manufacture of the vehicle and its fuel supply system.

If the car has a fuel system with a return line (there are two pipes on the fuel rail), an external RTD is installed.

System with return and external RTD

If the car is equipped with a fuel system without return (one tube on the fuel rail), the RTD is installed in the tank on the fuel pump cup.

System without return and internal RTD

Old style RTD

This type of regulator is installed on older VAZ 2114 models with an engine capacity of 1.5 liters and a fuel system with a return line. In this case, the regulator is installed directly on the fuel rail, and a pipe for discharging excess fuel into the return line, which leads to the tank, is connected to it.

RDT s.o. Quite often it fails and has a higher cost than that of RTD no.

New model RTD

This regulator is installed on cars with a volume of 1.6 liters. These cars do not have a return fuel line. Excess fuel generated during the operation of the internal combustion engine is dumped directly into the tank, since the RTD is no. installed in the tank on the fuel pump glass.

A LITTLE ABOUT THE OPERATION OF THE FUEL SENSOR

The latest developments by the designers of the automobile plant in Togliatti have brought the produced models closer to the best European models, but annoying, minor breakdowns can add “a fly in the ointment.” These fully include problems with the gasoline level sensor in the car tank.

It is located in the same block as the fuel pump. It includes a movable lever with a float, a resistor and a contact group, which turns on the signal lamp for the gasoline reserve in the tank. Among the most common malfunctions of this unit, the most common are problems such as resistor breakage, oxidation of the moving contact or output terminals. It is very rare that the float in the fuel level indicator loses its seal.

In any case, to repair or service this unit, it must be removed from the fuel tank. To perform this work, remove the rear seat cushion and upholstery that blocks access to the gas tank cap. When performing this operation, do not forget that you are working with a flammable substance. Fire safety rules must be strictly followed.

Unscrew all the screws securing the cover, move it slightly forward and remove it from the fuel tank. Before removing the fuel block, it is necessary to relieve the pressure in the fuel line. There are several ways to do this, and the simplest of them is to leave the car idle for about 4 hours.

Disconnect the wires and fuel line from the module, being careful not to spill any remaining gasoline in the hoses. You need to pull out the fuel pump carefully so as not to damage the float. Replacement of the fuel sensor is carried out using a screwdriver with a thin blade.

How does this happen:

- Use a screwdriver to move the locking ring and make it possible to remove the cover from the fuel module;

- Remove all the wires, release the latches on the cover and remove the sensor itself along the grooves;

- The next step is to remove the meter from the block.

To install a new fuel sensor, everything must be done in reverse order.

Symptoms of a problem

Since the RTD is part of the fuel system, its failure can be confused with other parts. One of the main reasons for RTD failure is the valve jamming in the open position. In this case, when the fuel pump pressurizes, the return line remains open, and the resulting pressure is not enough for the internal combustion engine to operate properly. As a result, engine interruptions occur, which significantly affect the technical characteristics of the car.

If the RTD in your car is faulty, the following signs of malfunction appear:

- Loss of engine power;

- Loss of acceleration dynamics;

- The internal combustion engine does not start well;

- When you press the gas, the engine stalls;

- Jerks when the car moves;

If these signs of malfunction are present on your car, it is necessary to check the RTD for operability.

Checking the RTD

The check is carried out using a special fuel pressure gauge, which is connected to the fuel rail.

We connect the device to the fuel rail and start the car engine. We look at the readings on the device, the pressure at idle should be:

- On an internal combustion engine 1.5 liters with return: 2.8-3.4 kgf/cm2;

- On an internal combustion engine 1.6 liters without return: 3.7-4.1 kgf/cm2;

If the pressure is less than the specified parameters, the RTD is faulty and requires replacement.

When the engine is stopped, the pressure in the system should drop gradually over 2 hours; if the pressure drops immediately, this means that the check valve on the RTD or fuel pump does not hold.

Check valve functions

The fuel pumps of modern cars have high performance and, with proper care, provide a continuous supply of fuel, regardless of the load being generated. It is impossible for the engine to operate at idle speed without a fuel system check valve.

The main purpose of this valve is to prevent the build-up of too high pressure in the fuel system, which could result in the fuel hoses breaking. In principle, the purpose of any valve is to allow the movement of different fluids in one main direction. Located in the fuel system, this valve prevents a number of problems that can arise in the system as a result of broken hoses.

For example, if you are driving a car with a diesel engine, then a breakdown of the check valve along the way can cause the fuel system to begin to fill with air. The presence of air is also unacceptable in injection power systems (read also what an injector is).

Additionally, we recommend reading our specialist’s article on how the car’s fuel system works.

What are the features of the diesel engine power system? You can learn about this from the detailed material of our author.

We also advise you to carefully study our expert’s article, which describes in detail how the fuel level sensor works.

If the driver stops the engine, while fuel flows into the tank along the working line, then the vacated space is quickly filled with air. In such situations, you will have to turn the engine with the starter for at least fifty seconds.

Replacement

Replacement is carried out according to the instructions and is not a complicated process if everything is done step by step.

- We relieve pressure from the fuel line by pressing the spool located in the ramp;

- Unscrew the return line fitting from the RTD;

- Remove the vacuum tube;

- Unscrew the bolts securing the RTD on the ramp;

- We remove the RTD from the ramp;

- We install the new one in the reverse order and start the internal combustion engine.

Self-diagnosis

The pressure level that the pump produces is 6 atmospheres

Therefore, it is important to achieve tight connections

To seal, you will need fum tape and a pipe with a diameter of 9 millimeters. So, how to check the fuel pump pressure yourself? Open the hood and look for a ramp with injectors. It is usually covered with a plastic casing. We remove it and see the cap in the form of a wheel nipple. Unscrew part of the ramp. Be careful - gasoline may spill out under high pressure. How to relieve pressure? To do this, remove the fuse for the fuel pump and start the engine. After a few seconds of operation it will stall. There will be no more fuel in the system from the pump to the injectors. You can safely unscrew the ramp that goes to the fuel pump. How to check further? We put on the hose with our pressure gauge, seal it with fum tape and secure it with a metal clamp for reliability.

Next, the assistant turns on the ignition. At this moment you are looking at the pressure gauge readings. If the obtained values are below five atmospheres, it means that the element is not able to generate the required pressure.