The VAZ 2107 injector has a number of advantages, but also several significant disadvantages that you should know about in advance. If you have this car model at your disposal, it is worth familiarizing yourself with the maintenance features of its injection system. But first we need to discuss the design of the VAZ fuel system.

Injector purpose

Installing an injector in the VAZ 2107 made it possible to significantly improve engine performance. Changing the type of fuel system increases the amount of energy that is produced during the combustion of gasoline. Compared to a carburetor engine, a fuel injection system is more efficient in the initial stages, but over time its performance decreases. What does this depend on?

VAZ 2107 injector plays the role of the final element in the fuel system of the car. The air mixture, together with a cloud of atomized gasoline, creates a huge amount of energy. Over time, this atomization may become less effective, the fuel jets will become weaker, and all due to low-quality gasoline.

The main cause of injector failure is poor fuel. Car fuel consists of many chemical components; in addition, various impurities are added to it, which should improve the overall performance of the engine. This factor cannot be ignored, since such gasoline leaves sediment on the walls of the fuel system. The thinnest channels are in the injectors, and it is these devices that suffer first. VAZ 21074 injector has the same problem. During operation, deposits from fuel only accumulate. What needs to be done to stop this?

Installation locations

On cars, the injection system is equipped with a separate line for draining excess gasoline, which goes from the fuel rail to the gas tank (fuel recirculation). In such injectors, the regulator is installed directly on the fuel rail (or connected to it), so the unit quickly “reacts” to changes in engine operating conditions and adjusts the pressure in the rail. In this design of the power system, a mechanical type RTD is used.

There is another version of the injector - without gasoline recirculation. In this system there is no “return” at all, and regulation is carried out at the output of their fuel pump. A feature of such a system is the location of the regulator - in the tank or near it. An RTD is already used here, the operation of which is controlled by the ECU - the control unit, through a sensor installed in the ramp, monitors the necessary parameters and corrects them by sending signals to the regulator.

Power systems with electronic regulators are used less frequently than mechanical ones due to their complex design and, accordingly, lower reliability.

Cleaning and preventing plaque in the system

The injector device is very sensitive to large inclusions in gasoline. If you are using a cheap brand of fuel, be prepared to change your injectors soon. So the first thing you should do for your VAZ fuel pump is change the brand of fuel. The power supply system of the VAZ 2107 should become cleaner; the possibility of plaque formation in the system is still not excluded. Since the flammable liquid in the channels occasionally stagnates and sometimes even freezes, an early breakdown can be prevented only in one way - regular cleaning.

Approximately every 35-40 thousand km it is necessary to carry out preventive cleaning work on the fuel system. You need to wash the channels with your own hands. The performance of the engine will depend on the quality of cleaning. If this procedure is carried out irregularly, then soon you can say goodbye to one injector and look for a new one, and then you will have to change the remaining elements of the VAZ fuel pump.

In 4-cylinder types of injection engines, different intensities of injector clogging are observed. The temperature in the area of cylinders 2 and 3 is always elevated, so sediment accumulation occurs there faster.

A special admixture of polyetheramine is considered a prophylactic agent in such cases. It prevents the accumulation of burning for a long time.

Power supply system for the injection engine of a VAZ 2107 car

The idle speed regulator for VAZ is

– 2107 shut-off valve driven by an electric stepper motor. The regulator is installed on the throttle body under the throttle position sensor. Based on an electronic signal from the control unit (ECU), the idle speed controller changes the cross-section of the additional supply air channel, thereby adjusting the idle speed of the crankshaft. Idle control valve VAZ 2107 Gas tank

car 2107 VAZ - steel, leaded inside, welded from stamped two parts.

The gas tank is located in the trunk of the VAZ 2107 car on the right side. The filler neck of the gas tank is closed with a plug and is brought into the niche of the filler neck on the right wing. VAZ gas tank Fuel

2107 is supplied from the gas tank by a gas pump combined with a fuel level sensor.

A mesh filter is installed on the inlet pipe of the fuel pump, which traps large contaminant particles that enter the gas tank along with gasoline. car on the VAZ 2107 fuel pump is turned on by the Serviceable command. The fuel pump ECU should develop a pressure of not 3 bar, less than 2 bar (320 kPa). electric fuel pump VAZ receiving

1 – 2107 mesh filter; 2 – fuel pump; 3 – fuel level sensor indicator; 4 – supply tube; 5 – drain tube; 6 – electrical connector block; 7 – fuel pump float From the sensor, fuel flows through the fuel pipe into the fuel filter for more thorough cleaning.

Damage diagnostics

How to understand that an injector needs to be replaced, checked or repaired? Even without sensors, you can understand that repair of fuel system elements is required if there are 1 of 2 main signs in models 2107, 21074:

- Unstable engine operation. Sometimes it may stall or have difficulty starting.

- A much less obvious sign is loss of power. This effect is noticeable if you mostly drive at medium speeds, but at high speeds it is very noticeable.

- The last sign is recorded only by sensors - the pressure inside the system increases.

The cause of such failures is clogged injectors; even diagnostics are not needed. Cleaning helps restore the engine to its original performance. If the problem has not been resolved after cleaning, it is worth checking the tubes and injectors for damage or breakdowns. In such cases, it is better not to start repairs, but simply replace the damaged parts with new ones.

Sometimes it is impossible to determine on your own where the damage is, and only then will diagnostics at service centers come in handy. A blockage can cause quite serious damage to the VAZ 2107 injector, as well as rupture of channels. The pressure that arises inside the system can easily destroy the most fragile parts. Here you won’t be able to fix the situation with your own hands, even if you have a complete diagram of the car at hand. There is only one conclusion - you need to devote a lot of time and attention to cleaning injectors and do it regularly.

Why do you need a fuel pressure regulator?

As mentioned above, this regulator maintains the required fuel pressure necessary for normal operation of the injectors, taking into account one or another operating mode of the power unit. In other words, the RTD affects the amount and intensity of the fuel supply that enters the engine cylinders through the injectors.

Simply put, the amount of fuel supplied to the engine at the time of injection depends on the pressure that is created inside the fuel rail (rail), as well as on the pulse duration for opening the injector and the vacuum in the intake manifold.

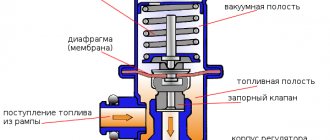

For more accurate dosing and maintaining constant pressure, a diaphragm valve-regulator is used, which experiences fuel pressure on one side, and a spring force on the other. RTD is used in power systems where there is a so-called “return”. The regulator is installed at the fuel rail. Also, this element can be located in the fuel tank, while such systems do not have a return line.

- Let's first look at the common design in which the regulator is located in the fuel rail. The element operates on the following principle: the fuel pump forces fuel from the fuel tank along the line. The resulting fuel pressure acts on the regulator. The device itself has two chambers (a spring chamber and a fuel chamber), which are separated by a membrane. On one side, the membrane is pressed by fuel, which enters the regulator through special inlet holes, and on the other side, there is spring pressure and intake manifold pressure. If the fuel pressure turns out to be stronger than the spring force and the pressure in the inlet, then the regulator opens slightly, resulting in some of the fuel being discharged into the return line. The fuel returns through the return line to the fuel tank.

- In systems without a return line, the regulator is usually located directly in the tank. The advantages include the absence of an additional pipeline. The injectors are supplied with the required amount of fuel directly from the tank, that is, excess fuel does not enter the engine compartment, and there is no need to deliver it back to the tank. This also allows us to talk about less heating of the fuel and provides a number of additional advantages in the form of less intense evaporation.

The fuel pump supplies the injectors with a strictly defined amount of fuel in relation to specific conditions and operating modes of the internal combustion engine. Let us add that in this system there is additionally an excess pressure relief valve, which helps to avoid its increase to a critical level.

Device

The VAZ 2107 injector consists of the following elements:

The injector power system contains the main element - a computer or ECU. Its permanent memory contains a program (algorithm) in accordance with which the control of actuators is implemented, these include:

Each of the above elements performs its own function.

Gasoline pump

Turned on by the ECU output signal through a relay. Has a strainer and fuel level sensor. The gasoline from it passes through the fuel filter. The pump is located in the tank and to remove it, you need to remove the back seat, remove the hatch and unscrew the fastener.

Nozzle

It is a sprayer equipped with a solenoid valve. Triggered by an ECU impulse. Accordingly, the duration of valve opening (the amount of gasoline supplied) depends on the time the pulse is applied. It is installed on a ramp common to all injectors, a constant pressure in which is maintained by a valve. If it is exceeded, the valve opens and gasoline returns back to the tank. The injector enters the intake manifold. The air flow, passing through the intake manifold, carries away a portion of gasoline ejected by the nozzle.

The structure of the VAZ 2107 fuel system

Idle speed control

The fuel system maintains engine idle speed using a regulator. It is a stepper motor connected to a conical shaped control body. Its approach reduces the air flow entering the intake manifold; its removal, on the contrary, increases it.

Canister valve

It is needed to turn on the ventilation of the adsorber, which accumulates gasoline vapors and releases them into the intake manifold at the right moment.

The injector power system contains sensors for measuring, converting and transmitting the signal to the computer.

The following sensors are installed on the VAZ 2107:

Crankshaft position

This parameter is needed by the ECU to open the injectors in a timely manner. If this sensor malfunctions, the VAZ 2107 will not drive.

Air flow

Allows you to supply fuel in the right quantity. The signal from this sensor is sometimes incorrect. The reason for this may be its malfunction caused by high humidity or low temperature. An air filter with condensation inside or dirty will adversely affect this sensor.

Throttle position

This signal is analog, i.e. continuous. It transmits precise data about the throttle position.

Coolant temperature

The parameter is needed so that the ECU understands whether the engine is warmed up. This is necessary for the correct operation of a cold motor. The mixture is enriched due to temperature correction.

Speed sensor

Measures and transmits a signal in the form of a sequence of pulses to the ECU.

Oxygen concentration

The oxygen content in the exhaust gases must be measured to adjust the composition of the fuel mixture. It doesn't work when it warms up. This is advisable because the mixture is enriched.

Fuel pressure regulator malfunctions

Problems in the engine power system can vary. For this reason, during diagnosis it is necessary to look for certain signs of a malfunctioning fuel pressure regulator. Most often, the main symptoms are considered to be when the engine does not pick up speed and does not develop full power, and also stalls in different operating modes. In the list of main signs, experts note:

- unstable operation at idle, the unit stalls at idle;

- loss of power, noticeable increase in fuel consumption;

- slow reactions to pressing the gas pedal;

- jerks and dips during acceleration, at the moment of throttling;

- the car does not accelerate, does not gain momentum;

Note that the malfunction of the RTD on gasoline cars is similar in symptoms to common problems with the fuel pump or its strainer. For this reason, when determining faults in the power system, a mandatory check of the fuel pressure regulator is necessary.

How to check the fuel rail? Checking the RTD yourself

Checking the fuel pressure regulator is carried out to identify malfunctions or for prevention.

Such checks are carried out based on the recommendations of the car manufacturer. But still, how to check the pressure in the fuel rail? Basically, the check consists of inspecting and checking the pressure of the fuel system at various engine speeds. Then comparisons are made with indicators that correspond to the norm. It is necessary to carefully inspect the tightness of the connections, the condition of the vacuum hose, as well as the regulator itself. If no damage or defects are found, then the regulator is dismantled by completely disassembling it. If a blockage is detected in this unit, it is washed.

Important: the pressure in the fuel rail should be diagnosed using a pressure gauge. It is connected to a special diagnostic fitting.

How to check the fuel pressure regulator. Fuel pressure regulator diagnostics

You can also check the regulator yourself. To do this, you do not need to use any special tools or have any special auto mechanic skills. You will need to pinch or disconnect the valve and observe the force of the jet. Or for a better check, use a pressure gauge.

To measure the RTD pressure in the engine when turning on idle speed, it is worth connecting a pressure gauge, installing it between the fuel hose and the fitting. Don't forget to disconnect the vacuum hose. Below we will look at what pressure should be in the fuel rail of a VAZ 2110.

When measuring the pressure in the fuel rail with your own hands, the pressure should begin to increase from

0.3 to as much as 0.7 Bar.

If the pressure remains in place, repeat the procedure. It happens that after a number of necessary procedures, the pressure remains the same. This means that the regulator is faulty and cannot be repaired. It needs to be replaced.

How do malfunctions of the fuel pressure regulator affect engine performance?

A faulty regulator valve affects not only operation, but also the very start of the engine.

If the device is working properly, the pressure in the fuel rail does not drop after the engine stops. If the valve has a malfunction, then the pressure in the fuel rail drops when the engine stops. The engine will not start until the sediment has completely filled the system. And only after reaching the desired level, the first engine start signals may appear. Here everything will depend on the power of the battery. Otherwise, the engine will not be able to start. Therefore, if the pressure in the fuel rail does not hold, this indicates a malfunction! In addition to the above, gas failures may occur during acceleration of the car, unstable idling, and a general weakening of engine power will begin to appear.