An oil pressure sensor, or simply DDM, is a signaling device for the driver that displays the level of oil pressure in the engine. It usually turns on when the level drops noticeably. However, this element may also fail.

Replacing the Grant oil pressure sensor is a process that does not require phenomenal knowledge. You need to have a few tools and instructions on hand.

The DDM consists of three elements:

- Protective housing;

- Measuring membrane;

- Transmitting element.

DDM review

The oil pressure gauge is an integral element of any modern engine. To begin with, we suggest you understand what types exist, as well as what the principle of operation of the device is.

Today, automobile DDM can be of two types:

- Electronic oil pressure indicator, which is also often called emergency. This device can operate in several modes - either “yes” or “no” mode. In fact, the emergency oil pressure sensor does not provide accurate indicators of the functioning of the system. Such a device can only inform the driver that the working fluid pressure in the power unit has completely disappeared. The device, which is located in the engine, warns the motorist thanks to a control lamp - if it lights up on the instrument panel, then this element of the circuit must be changed or the system’s functionality must be checked.

- Mechanical oil pressure gauge. Such a device, unlike its electronic counterpart, when connected, allows you to accurately determine the level of liquid pressure. The driver is notified using a warning lamp, as well as a scale located on the dashboard.

Mechanical sensor in dismantled form

Depending on the vehicle, two types of regulators can be used at once. Thanks to this, the driver has the ability to control the exact level of the parameter in the system, as well as immediately respond if a problem occurs.

Operating principle of electronic and mechanical oil pressure sensors

The operating principle of the oil pressure sensor depends on its type, so we will consider each process separately. For example, a remote electronic DDM is simpler in design, in contrast to a mechanical one; accordingly, the likelihood that the digital controller will fail is very low. The main purpose of the digital DDM is to check the pressure, as well as transmit information to the control panel located in the car interior that the pressure has disappeared.

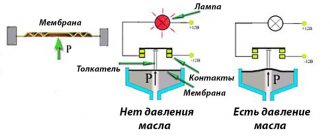

By design, the digital DDM, which is located in the engine, consists of the following components:

- frame;

- membrane;

- contacts;

- as well as a pusher device.

Electronic regulator removed

The digital oil pressure sensor must be connected to the vehicle's on-board network. In particular, we are talking about the section of the circuit where the emergency indicator is also located. When the digital DDM is not working, that is, the engine is turned off, its diaphragm is straightened, the pusher device is pushed into its original position, and the contacts themselves are closed. If in this state you decide to connect a digital DDM, then the emergency pressure indicator located on the circuit section will begin to function - it lights up, flashes and blinks.

Accordingly, when the motor starts working, when starting the unit, the light always lights up at the very beginning. When starting the internal combustion engine, working fluid pressure appears in the system, which, in turn, begins to affect the membrane. This element begins to interact with the pusher device, which opens the contacts. If the parameter begins to decrease, the contacts of the digital DDM will close again - at this moment the emergency lamp on the instrument panel lights up, flashes or blinks. It should be noted that if the device itself breaks down, the lamp flashes, blinks or simply lights up.

As for a two-pin analog mechanical device, such a device has a more complex design. The mechanical oil pressure sensor, in addition to the membrane, housing and pusher device, also has a slider and a nichrome winding in its design. In addition, the two-pin analog mechanical oil pressure sensor also has several components in its design. It must be taken into account that if these components fail or operate incorrectly, the regulator will display incorrect information on the car’s dashboard or will fail altogether.

Frequent causes of malfunction of DDM Grant

Before replacing, you need to make sure that the oil level in the car is normal and the oil filter is not clogged, since these factors become frequent reasons for the operation of the DDM.

In addition, the sensor may give incorrect readings if electrical contact with the terminal block is broken. This is often caused by dirty contacts.

In this case, the oil sensor itself does not need to be changed. You just need to tighten and clean the contacts both on the DDM and on the contact block, and install everything in place.

In addition, frequent reasons for the failure of the Grant DDM are:

- Manufacturing defect

- Mechanical damage

- Short circuit in on-board circuit

- Exhaustion of the operating life of the DDM

The sensor has a non-separable design, so it cannot be repaired. Let's look at how to diagnose the sensor and how to replace it yourself.

DDM Verification Guide

How to properly check the oil pressure sensor? Diagnostic options vary depending on the type of regulator.

Electronic sensor diagnostics

To diagnose an electronic DDM engine, you will need a multimeter, as well as a pump, and it is advisable that the pump be equipped with a pressure gauge. Before proceeding with diagnostics, it is necessary to remove the DDM from the car, and then activate the multimeter in the mode of checking the electrical wiring for open circuits. The motor DDM must be connected to the pump, and a multimeter must also be connected to it. Using a pressure gauge in this case is very important, because with its help you can regulate the pressure parameter and not give too much, otherwise the regulator may simply break (video author - SamodelTV).

So, having connected a pump with a pressure gauge and a multimeter to the regulator, you need to make sure that the arrow on the device scale is at zero. After these steps, you need to apply minimum pressure from the pump itself; as a result, if the engine’s DDM is working, its membrane will bend and begin to move the pusher. Accordingly, as a result, the circuit should open, which will contribute to the deviation of the arrow on the device, namely, towards infinity. In order not to doubt the performance of the regulator, you can try to give the maximum pressure (or rather, as close as possible to this indicator).

Diagnostics of mechanical DDM

As for diagnosing a mechanical regulator, in general this procedure is similar to that described above, but there are some differences. First of all, to get more accurate results, you will need a pump, also equipped with a pressure gauge and a rubber hose (small). To check, the DDM must be removed from the motor along with the dial scale. It is necessary to install and place the pump to the regulator in such a way that the connection point is as tight as possible. If you are sure that as a result of installation the connection of the elements is airtight, you can begin checking (the author of the video is Kirill Zbruenko).

The essence of the diagnosis is to supply air with a pump through the DDM, while the pressure parameter, which should be different, must be monitored using a pressure gauge. When the maximum and minimum parameters are supplied, the resulting indicators must be recorded, while recording the resistance level. After several indicators are recorded, they must be compared with a table that shows the optimal values. These values are indicated in the service manual; we will not write about them, since they differ depending on the vehicle model.

Gas pedal position sensor Lada Granta

Granta's fully electrified engine control implies the presence of an electronic gas pedal, thanks to which the owner of the car can indicate the desired acceleration or deceleration of its speed by pressing this pedal, or by weakening the pressure. Such systems are known as “E-gas”.

This system includes a lever made of plastic and two built-in sensors. By their design essence, they are potentiometers, and the information they transmit helps the ECU track the position of the pedal, with its possible changes, which the system controls using information about changes in the resistance level at the device terminals.

When the electrically conductive tracks and moving contacts wear out, the devices begin to provide incorrect information. Their breakdown will lead to instability in the functioning of the engine and a spontaneous change in the frequency at which the crankshaft rotates at idle.

A breakdown of one of the elements or a malfunction of its circuit will be indicated by the illuminated Check Engine. When the time given by the ECU to restore the signal expires, the system will transfer the engine operation to the reserve operating mode. Activating this mode will lead to a slow increase in speed, which will follow after a sharp press on the gas pedal, which will preserve the vehicle’s ability to move independently. Its operation in this mode can provoke a sharp increase in fuel consumption standards; in addition, other engine performance indicators often change.

If two sensors break down at once, the engine will be put into emergency mode, during which it will begin to function only at speeds slightly higher than its idle speed. This will allow you to maintain the minimum ability of the car to move (since its speed will be quite slow).

Replacing the sensor yourself

Why is the oil pressure sensor replaced?

There may be several reasons for this:

- The regulator is leaking. It doesn’t matter whether it’s idling or while driving, drivers often encounter a problem when the device leaks. It does not matter whether the lamp on the control panel is on or not when the DDM is flowing. In any case, if the regulator leaks, this indicates a bad connection.

- A light is on on the dashboard. At the same time, diagnostics of the power unit showed that it was operating normally.

We figured out why it is necessary to change the DDM, now let’s look at the question of how to replace the oil pressure sensor.

The process is considered using the example of a VAZ 2109 car:

- First of all, the device is dismantled. It is necessary to disconnect the wire leading to it with a protective cover from the DDM.

- After this, using a wrench, you need to completely unscrew the DDM. After unscrewing, the regulator is removed from its seat.

- Now installation. A new DDM is taken and needs to be placed in the mounting socket.

- After installation, the regulator must be tightened as far as possible; a wrench is used for this.

- When you have managed to install and tighten the DDM as much as possible, connect the disconnected cable to it along with the cover.

Recommendations

Comments 12

Priora oil pressure sensor

That's it, guys, the problem is solved. There was condensation in the oil receiver, and this condensate froze. We drained the oil, removed the filler, warmed up the oil receiver, filled in oil, started the engine, heated the engine to 80 and drained the oil, then poured in new oil. Now everything seems to be fine.

Drain the oil, my sump and change the oil receiver, a friend did this on a viburnum and the machine came to life.

I don’t think it’s anything serious, maybe the oil is frozen. Another option is to check the wire that goes to the sensor with a tester; if the light does not light, it means there is an open circuit, this happens in cold weather

I had this happen with a couple of Kalinovodovs as well. Condensation. It appears if you go on short trips in winter. Then it freezes in the car along with the oil in severe frost. I warmed up the pan and changed the oil. I switched to 5v40 Mobile. Before this, the owner supposedly had zero .Thank God this didn’t happen again!

How did this happen? was it running or was the car parked for a long time?

Yesterday I had this, the oil was frozen, I started it 3 times, the light didn’t go out, I dragged it to the garage, I warmed it up with a hairdryer, then I started it right away and it went out... Toyota 5-40 oil drove 1000 km... before that I used Lukoil semi-synthetic at -35 there were no problems. But then it froze

It was -30 outside, probably the oil pickup was frozen.

Unscrew the sensor. and if the oil presses, look for the reason. Possibly with wiring jamb.

I measured the pressure with a pressure gauge - there is no pressure at all. I'll take the pan off and have a look.

oo. this is not ice. at best, the oil pump is a mess.

Is the pan jammed in the area of the oil receiver?

no, it's not jammed. I measured the pressure with a mechanical monometer - pressure 0.

Video “We replace the sensor with our own hands”

How the process of replacing the sensor is carried out - watch the video (video author - Auto_Repair).

The engine is considered to be the “heart” of the car. First of all, drivers care about this unit. For this purpose, special oil is purchased and poured into the engine. It is important to monitor how much lubricant is left in order to provide full protection to the engine, reduce friction and extend the life of the machine.

For monitoring, a special device is used - an oil pressure sensor. I know where this device is located and how to check its operation, but many car owners do not have the slightest idea about it. This review will tell you where to find and how to check the oil sensor.

Is it dangerous or is it safe to drive like this?

Often on some forums, I read: “okay, it’s no big deal, you can drive like that, well, just think, it caught fire, then went out, everything seems to be fine”!

Guys, this is a very erroneous opinion, if only simply because after starting the engine runs almost “dry” for several seconds. At this time, there is simply catastrophic wear of parts. Especially in the winter, cold period, the oil is already cold, plus there is no engine lubrication.

With this approach, the capital of the engine is not far away. And guys, a filter costs a penny, a good one costs from 300 to 500 rubles, well, don’t skimp, overpay 100 - 200 rubles, don’t buy the “crap” option, but you’ll ride calmly, as they say - no problems.

I think my message has reached you, now we are watching the video version of the article.

This is where I end, I think my article was useful to you.

(11 votes, average: 4.82 out of 5)

Why is an oil pressure sensor required?

The device, called the oil level sensor (OLS), is considered the most important element of the system. The device allows the driver to monitor the level of lubricant pressure entering the engine. If there is not enough oil, the red light on the control panel lights up. The driver needs to urgently take action and add lubricant to the required level. The light starts to light immediately after the DDM is triggered.

The main purpose of the device is to prevent negative consequences due to a lack of lubricants in the system. The sensor is extremely sensitive, so even the slightest fluctuations in the direction of decreasing oil volume can cause the light to light up. In some vehicles, a signal is given to the driver not only audibly, but also visually. A sharp squeaking sound appears in the cabin. Sometimes, instrument readings are displayed in a separate instrument on the control panel.

Mass air flow sensor

This element is located near the air filter; its main task is to estimate the amount of air entering the engine. Based on the information received from the mass air flow sensor, the ECU determines the fuel volume that is necessary to maintain the stoichiometric ratio between fuel and air for the engine to operate within the specified parameters.

It is located next to the air filter, right between it and the air-fall sleeve. It should also be noted that this sensor is no longer installed on modern VAZ engines. The catalog number of the described element on Grants is 11180-1130010-00.

If the mass air flow sensor breaks down, the system stores the error code in its memory, after which the “Check Engine” lights up. Then the controller replaces the readings of the broken device with fixed temperature values. Signs of failure of this element are different, the most common include:

- increased fuel consumption;

- problems when starting the engine;

- disappearance of cravings;

- instability of speed.

What types of oil sensors are there?

Modern automakers prefer to use two main types of sensors. Each of the devices works only with a certain type of engine, so it is unlikely that it will be possible to determine which device is better and which is worse. Let's consider the most popular types of DDM.

Mechanical sensor

A device of this type determines the level of lubricant pressure in the system and transmits the data to the control panel. The mechanical sensor has a complex structure. A membrane, a pusher and a slider are placed in the housing cup. The winding is made of nichrome wire. Since different elements are used to create such devices, the cost of mechanical-type DDM is very high. The product is large in size, which is not very convenient when assembling passenger cars.

Electronic sensor

This type of device is used more often. Manufacturers note a simple device, but also indicate that the sensor cannot transmit all changes in the lubrication system to the control panel. The device can show only two parameters: normal and critical pressure.

The only purpose is to send the driver information that there is no pressure in the system and it’s time to add lubricant. The signal enters the cabin instantly, so the driver can quickly take action.

Some cars are equipped with two types of sensors at once. This expands the driver’s ability to control the condition of the engine and the pressure in it. Even if one sensor fails, it is quite possible to navigate based on the readings of the second.

Crankshaft position sensor Lada Granta

DPKV is responsible for providing the control system with information about the frequency with which the crankshaft rotates and its angular position. Based on this data, the ECU calculates the phase and duration of the pulses responsible for controlling the injectors and controlling the ignition coil. When reading information, the element sends the received data to the controller, whose task is to process it and issue the necessary pulses to the injectors.

The crankshaft position sensor on the Grant is located near the oil filter.

The unit is highly reliable in operation and durable, and therefore its breakdowns occur infrequently. This is also due to the fact that the DPKV contains no mechanical moving parts.

The most common cause of its malfunction is corroded wiring. Failure of a part entails significant problems for the normal functioning of the engine; if repairs cannot be made, the unit will need to be replaced.

A breakdown of the crankshaft position sensor prevents the engine from starting. We list the main signs of its malfunction:

- problems starting the engine;

- unstable operation of the engine;

- loss of power, etc.

Where is the DDM located in different cars?

Motorists often ask questions regarding where the oil pressure sensor is located in the vehicle. In this matter, you need to focus on the make and model of the car. This is necessary because automakers independently combine the engine compartment. The standard location of the DDM is near the cylinder head and oil filter. IN

In certain cases, to get to the device, you just need to open the hood and look. The advantage of this arrangement is that the driver does not have to dismantle other parts to remove the device.

In special situations, in order to dismantle the DDM, you will need to crawl under the bottom of the car. If you don't know where the sensor is located, you should carefully study the table. Here are options for placing the device in different vehicle models.

As already mentioned, the most common option is the location near the BC head, but sometimes, car manufacturers try to make the most of the area under the hood and come up with another option for locating the sensor. In such a situation, the driver will have to do some serious digging before gaining access to the control device.

Camshaft position sensor (phase sensor)

This element is responsible for generating a signal, based on which the ECU is able to determine the angular position of the camshaft at any time period. On eight-valve AvtoVAZ engines, these devices are located at the cylinder head on the left, on sixteen-valve engines - in front and on the right of the engine.

If they break down, the system switches to operating in backup mode, which affects the stability of the engine. Repair of this sensor is impossible; any failure will require replacing the sensor with a new one.

The most common signs of DPRV failure include:

- unstable operation of the motor;

- problems starting the engine;

- the engine often stalls when the gas pedal is released;

- exceeding fuel consumption standards.

When diagnosing the device, the following errors are detected:

- P0340 – element is faulty;

- P0342 – low signal level;

- P0343 – the signal level supplied by the element is too high.

Absolute pressure and air temperature sensors

These sensors are combined into one housing and installed on the receivers of the intake module; the most modern AvtoVAZ engines are equipped with them.

DBP differs in the output signal voltage in the range of 0.15..4.6 V, this voltage depends on the pressure level inside the intake pipe. The information it sends helps the ECU calculate the amount of air received by the intake pipe during one cycle.

A breakdown of the device circuit leads to an error code being entered into the system memory, and then the alarm turns on. After this, the control system calculates the air received based on the crankshaft speed, as well as based on the throttle valve opening angle.

The sensitive component of the DTV is the inlet pipe thermistor. The output signal voltage of the device connected to the computer will be approximately 0.3..4.9 V, it depends on the temperature of the air passing through the specified element. When a DTV failure is detected, the control system performs actions similar to its actions in the event of a DBP failure, replacing the readings of the described device with fixed temperature values.

Purpose of the sensor

The oil pressure sensor is designed to promptly and accurately inform the driver about low lubricant pressure inside the internal combustion engine. So, as soon as the rapid detection of such a malfunction will allow you to avoid unnecessary problems and even greater engine breakdowns in the shortest possible time. It's no secret that dry engine operation can cause very serious damage to the engine. But on the other hand, you shouldn’t immediately panic and draw conclusions; it’s enough to first check the sensor itself.

Mistakes in hasty conclusions

When the oil pressure light comes on, many car owners sound the alarm and begin to fix this problem in all but not the most important ways, and these include:

- Oil change and fuel filter replacement.

- It is washed.

- The pressure is measured.

But after this, the result does not happen! Therefore, always check the oil pressure sensor first, as this is the most common and common cause.

Sensor check

It is necessary to check the functionality of the sensor in the following order:

- We remove the wire from the sensor and lean it against ground, possibly on the motor housing.

- Check to see if the light on the instrument panel lights up again.

- If the lamp stops burning, then the wiring is working properly and you can move on to the next stage of dismantling the faulty sensor.

- And if it continues to burn, then it is necessary to “ring” the wires at the entire stage from the sensor to the instrument panel to detect a breakdown or short circuit in the circuit.

Advice for car enthusiasts without car repair experience

Oil pressure sensor

What to do if trouble happens on the road? The most logical course of action is to check the main causes of low oil pressure as they become more expensive.

Lack of oil in the engine sump

Where can it go? Worn out engines consume oil during operation, loose gaskets cause oil to leak onto the ground, a faulty turbine or damaged housing will lead to the release of oil under pressure. Having opened the hood, inspect the engine compartment and the ground under the car - the oil leaves greasy traces, and it is impossible not to notice them.

Each internal combustion engine has a special dipstick that is used to check the oil level.

The dipstick ring is painted in a bright color

The oil level should be within the marks on the dipstick

If the oil level is low, be sure to top it up. Top up in small portions, monitoring the level.

The place where you need to fill the oil is indicated by the already familiar “oil can” symbol.

Sensor or wiring fault

Over time, the connectors oxidize, and during repairs, the wires get caught and come off. You need to remove the connectors and inspect them for oxidation. The oxide on the connectors is usually green or dark brown. This deposit should be thoroughly cleaned with a file or sandpaper.

A coating of dirt and oxides prevents the passage of electric current

Very often, troubles are hidden in the sensors, but without checking the oil pressure with a pressure gauge, this will not be clear. You can visually assess the condition of the sensor - whether there is any damage, whether the connectors are loose, whether the wire is attached to it at all.

The oil pressure sensor is usually located next to the oil filter or on the cylinder head. Depending on the car model, the sensor can be located in completely different places. To determine exactly where it is located, you need to study the car’s operation and repair manual, or ask a car mechanic.

The only way to check the functionality of the sensor is to replace it with a known good one.

Wrong oil

If too thin oil is poured into a worn engine, the pump will not be able to create the required pressure. Therefore, it is better to use oils prescribed by the manufacturer. Contact specialized oil change services. Employees of these institutions have catalogs of oils recommended for various brands of cars.

In worn-out engines, condensation collects in the oil or coolant gets into the oil. This leads to the appearance of an air-oil emulsion, which reduces the pressure in the oil lines (air is compressed, unlike oil). The emulsion is clearly visible if you open the oil filler neck.

Yellow-brown foam on the oil filler neck is a sign of foreign liquids getting into the oil

If there is a lot of emulsion, you need to change the oil and eliminate the cause of liquid getting into the oil. If it is condensation, you should periodically “walk” the car over long distances. If it is coolant, replace the cylinder head gasket and test the engine parts for leaks.

Clogged or faulty oil filter

If you changed the oil a long time ago and added oil from different manufacturers, sediments and resins can tightly clog the surface of the filter element. If a problem occurs after changing the oil, most likely you were given a filter that does not fit this car model. Car filters are equipped with a special valve that retains some of the oil in the filter. An incorrect valve design will “lock” the oil in the filter and prevent it from moving through the channels. Changing the oil and filters should eliminate these causes.

Other reasons require special tools for diagnosis, and troubleshooting requires a garage and repair skills. Therefore, it is best to entrust repairs to specialists from a service station.

A clogged or faulty oil filter can cause scuffing and engine damage.

It is important to know that the indicator lamp will not light up just like that, there is a malfunction here, so it is worth fixing them as soon as possible. There may be several reasons for the signal, and all are not covered in this article. Do not delay in identifying breakdowns, because they can lead to much more complex consequences. Remember that motor oil plays a very important role in the implementation of motor processes that occur inside a car engine

Monitoring the oil level is the primary task of every driver.

https://youtube.com/watch?v=WR3iI17gLtI

Replacing the oil pressure sensor

To work, we only need a “21” wrench.

We make the replacement as follows:

- When the sensor is detected, we clean its surface and around it from dirt and deposits so that some of the dirt does not get into the engine.

- Then disconnect the power supply from it.

When dismantling, we inspect it for defects and damage.

It's easy enough to rip off the nut and then just unscrew it by hand.

Pay attention to the quality of the connection.

In this simple way, the work on replacing the sensor can be considered completed.

Decoding: Lada Granta errors

The list of possible faults is long. So we've broken it down into three parts based on the original issues. These are the error codes that it produces:

- Electronic control unit (ECU);

- If equipped - automatic transmission (automatic transmission);

- Problem with EEPROM data transfer.

Grant ECU: error codes

The largest group of faults. This includes data on internal combustion engine sensors. Code numbering from P0030 to P2501.

P0030-P0172

P0200-P0363

P0422-P0660

P0661-P1388

Р1389-Р1689

R2070-R2501

Complete list of Grant automatic transmission errors

The complete table of faults with the VAZ2190 automatic transmission is much smaller than the previous one. The whole list is below:

All automatic transmission error codes fit into one block

VAZ 2190 data transmission error codes

The smallest group of codes. There are only six of them, all starting with U - automatic transmission and internal combustion engine faults are indicated by the letter P.

All known data transfer errors on Grant