Every modern car, including the VAZ 2109, is equipped with a variety of sensors and devices, each of which plays its own important role. One such device is the oil pressure sensor. It is located in the engine compartment. Regardless of which engine the car is equipped with, an injector or a carburetor, the sensor is located on top of the cylinder block on the intake manifold side.

A protective cover is installed on top of the oil pressure sensor. To ensure stable operation of the engine and the entire machine as a whole, it is necessary to ensure that the sensor is working properly. An oil filter is located next to the sensor.

Sensor design

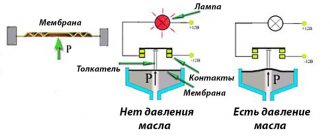

The oil pressure sensor in modern cars is quite simple. It includes an outer casing, a hard elastic membrane and a transfer device. The principle of interaction of the device is the interaction of oil with an elastic partition.

The membrane reacts to the force with which the oil presses on it. The oscillations of the partition, the opening and closing of the contacts of the electrical circuit, communicate with the rheostat. Changes in rheostat indicators are displayed on the dashboard of the VAZ-2109.

A malfunction of the sensor is indicated by a light on the panel. When an alarm icon appears, you must immediately check the serviceability of the sensor. But before doing this, you should make sure that the engine oil level is correct.

Today there are several oil pressure sensors for the VAZ-2109, which any owner of this car can purchase if necessary. The table shows the types of sensors, as well as their article numbers and prices.

| Sensor | vendor code | Cost, in rubles |

| Oil pressure sensor analog MM120D | SOP20101O7 | 80 |

| Oil pressure sensor VAZ Samara | 33000 | 150 |

| Oil pressure sensor (BCG) | OS3518-BCG | 150 |

| Oil pressure sensor ERA | 11260 | 100 |

Location and appearance of the device

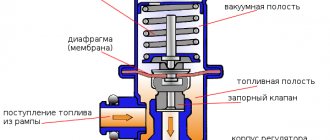

The sensor installed on classic VAZ 2106 models consists of the following parts:

- an element in the form of a round metal barrel with one terminal for connecting a wire (factory name - MM393A);

- the second part is a membrane switch in the form of a nut with a contact at the end (designation MM120);

- a steel tee into which the above parts are screwed;

- sealing bronze washers.

The large “barrel” MM393A is designed to measure pressure, the “nut” with the MM120 terminal fixes its absence, and the tee is a connecting element that is screwed into the engine. The location of the sensor is on the left wall of the cylinder block (if you look in the direction of movement of the car) under spark plug No. 4. Do not confuse the device with the temperature sensor installed higher in the cylinder head. Wires leading inside the cabin, to the dashboard, are connected to both contacts.

In later models of the “classic” VAZ 2107, the indicator arrow on the dashboard is missing, only a warning lamp is left. Therefore, a stripped-down version of the sensor is used without a tee and a large barrel.

Sensor check

In practice, there are several proven methods for checking the oil pressure sensor.

The first method involves removing the device and idling the starter. If, when the device for mechanical engine starting is turned on, oil begins to pour out from the location of the sensor, then the device is in working order.

You need to carefully inspect the sensor, then treat it with a degreasing liquid, for example, gasoline. Then the sensor must be returned to its original place. If in this case the light on the dashboard remains on, it means that the sensor has failed and needs to be replaced.

The second verification method is more thorough. In this case, you should do the following:

- Check oil level.

- Start the engine and warm up the car.

- Unscrew the sensor and connect it to the device for testing. An adapter from a pressure gauge should be installed in place of the sensor.

- Ensure that the pressure gauge is in contact with the ground (ground).

- Connect the positive LED from the battery to the sensor contact.

- Start the engine, press the gas pedal.

- If the pressure gauge shows a value of 1.2-1.6 bar, the LED will turn off; if not, then the sensor has failed.

Often a light comes on on the dashboard of the VAZ-2109, indicating problems with oil volume

The third method involves checking the oil pressure sensor using the crankshaft. To do this, you need to crank the crankshaft without turning on the engine. At the same time, pour oil into the place where the sensor was screwed in. If the light is on, it means the device is unusable and needs to be replaced.

All about oil pressure VAZ 2114

One of the important parameters in a car is oil pressure. It is on its basis that one can judge whether the car’s engine will work for a long time. In the VAZ 2114, oil pressure plays a huge role and often the owners of this car are faced with the problem of a drop in oil pressure, which can seriously damage the engine.

In this article we will talk about the oil pressure on a VAZ 2114 car, namely its permissible and normal parameters, methods of self-measurement, and the reasons affecting the decrease in pressure.

About oil pressure

Engine oil pressure is necessary to supply it to the top of the engine and lubricate the rubbing parts in the cylinder head, namely camshafts, valves and pistons. The engine is pressurized by a special oil pump, which takes oil from the crankcase and distributes it throughout the engine.

If the oil pressure in the engine has dropped and the warning light comes on, you need to sound the alarm and urgently repair the car. Operating a vehicle with oil pressure below acceptable parameters is prohibited, as this can lead to serious consequences.

Why is the oil pressure light on?

If the oil pressure light on your car comes on, you must stop the car as soon as possible and turn off the engine. You should not immediately sound the alarm, as the lamp may light up due to a malfunction of the sensor itself or simply due to a connector that has come off from it.

What should be the oil pressure in a VAZ 2114

The oil pressure parameters in the VAZ 2114 must always be normal; on a hot engine at idle speed, the oil pressure must be at least 2 bar; at increased speeds of at least 4000 rpm, the oil pressure must be at least 4 bar.

If the pressure is below the permissible parameters, it is necessary to repair the engine, namely the parts that affect the oil pressure.

Checking oil pressure VAZ 2114

Checking the oil pressure can be done either at a service station or independently. Let's look at the procedure for measuring oil pressure using an example of self-testing.

To check, you will need a special pressure gauge with a set of adapters.

- We assemble the structure with the necessary adapter;

- Remove the connector from the oil pressure sensor and unscrew it;

- We screw the device into the place where the pressure sensor is installed and start the motor;

- We look at the readings of the device and compare the results obtained with the acceptable ones. Based on the data obtained, we draw a conclusion about the condition of the engine;

Reasons for the drop in oil pressure in the VAZ 2114

If your car loses oil pressure, the following parts are most often to blame:

- Oil pump. Over time, the pump gears wear out, and it is no longer able to pump up such a high pressure necessary to lubricate all parts. The problem is solved by replacing the pump with a new one.

- The oil receiver mesh is dirty. With high mileage or driving for a long time without changing the oil, the oil receiver mesh becomes clogged, which does not allow the pump to pump the required pressure into the system.

- Oil pickup sealing ring. In the place where the oil receiver connects to the oil pump, an O-ring is installed, which over time, due to high temperatures, dries out and loses its properties, which leads to a loss of oil pressure.

Replacing the sensor

The process of removing and installing the sensor is quite accessible to any car enthusiast. Before screwing in the new sensor, you need to check the markings.

Experts recommend installing a new sensor with the same markings as the old one.

- First you need to disconnect the wire with the protective cover from the sensor.

- Using a wrench, unscrew the bolt and remove the sensor.

- Install the new sensor in place.

- After this, you should tighten it until it stops with a wrench.

Finally, you should start and stop the engine several times to check its operation and absence of malfunctions.

How to check and replace an element

During long-term operation, the internal parts of the sensor wear out and periodically fail. The malfunction manifests itself in the form of false readings on the indicator scale or a constantly burning emergency lamp. Before drawing conclusions about power unit failures, it is highly advisable to check the functionality of the sensor.

If the control light comes on while the engine is running and the indicator drops to zero, your first action is to immediately turn off the engine and do not start it until the problem is discovered.

When the light comes on and goes out in a timely manner, and the needle does not deviate, you should check the serviceability of the oil sensor - the MM393A pressure meter. You will need a 19 mm open-end wrench and a pressure gauge with a scale of up to 10 Bar (1 MPa). A flexible pipe with a threaded tip M14 x 1.5 must be screwed to the pressure gauge.

The verification procedure is as follows:

- Turn off the engine and let it cool to 50-60 °C so you don’t have to burn your hands while working.

- Disconnect the wires from the sensors and unscrew them with a 19 mm wrench along with the tee. Please note that during disassembly a small amount of oil may leak out of the unit.

On the road, it is more difficult to check the VAZ 2106 oil sensor, since there is no pressure gauge at hand. To make sure there is lubricant in the engine channels, unscrew the element, disconnect the main ignition wire and rotate the crankshaft with the starter. If the pump is working properly, oil will splash out of the hole.

If the arrow on the instrument scale shows normal pressure (in the range of 1-6 Bar), but the red lamp is on, the small MM120 membrane sensor has clearly failed.

When the light signal does not light up at all, consider 3 options:

- the light bulb burned out;

- broken wiring;

- The small sensor in the form of a hexagon has become unusable.

The first 2 versions can be easily checked by testing them with a tester or multimeter. The serviceability of the membrane element is tested as follows: turn on the ignition, remove the wire from the terminal and short it to vehicle ground. If the lamp lights up, feel free to change the sensor.

Replacement is done by unscrewing the large or small sensor with a wrench. It is important not to lose the bronze sealing washers, since they may not be included with the new part. Remove any leaks of engine lubricant from the hole with a rag.

Both meters cannot be repaired, only replaced. Their metal cases, capable of withstanding the oil pressure of a running engine, are hermetically sealed and cannot be disassembled. The second reason is the low price of VAZ 2106 spare parts, which makes such repairs pointless.

Video: how to check lubricant pressure with a pressure gauge

Video: replacing the VAZ 2106 sensor

What to do if the sensor lights up

If the oil pressure light on the dashboard comes on and does not go away for a long time, it can be assumed that there are problems with the engine. Sometimes this may be due to a loose wire.

There are several main reasons why the warning light on your dashboard comes on. These include:

- installation of a low-quality oil filter. Low quality filters are not able to retain oil after the car is stopped. The solution is to replace the oil filter;

- insufficient oil level. In this case, it is necessary to add oil to the required level and find the cause of the leak;

- oil pump damage. It is recommended to have this problem repaired at a service station.

Thus, the oil pressure sensor on the VAZ-2109, despite its small size, plays a rather important role in ensuring the correct and stable operation of the car.

It requires constant monitoring and, if minimal signs of malfunction appear, mandatory replacement. This is the only way to extend the life of the engine of any car and avoid unnecessary financial costs that may arise due to sensor malfunctions.

Reasons for the indicator light and diagnostic methods

A sufficiently experienced car owner can independently diagnose or repair this system. Otherwise, it is recommended to contact a service center for help.

Sensor malfunction

To check the serviceability of the sensor, it is necessary to perform a number of operations:

- Turn the ignition key to the first position (turn on the ignition).

- Make sure the pressure indicator lights up.

- Open the engine compartment and disconnect the sensor wire.

- Make sure the indicator is not lit.

- Attach the bare end of the wire to ground, for example to the engine housing.

- The indicator on the dashboard should light up. If so, the wire is OK and the cause of the malfunction lies in the sensor.

The manufacturer does not recommend disassembling or repairing the sensor. It needs to be replaced.

Violation of the integrity of electrical wiring

Due to large temperature changes, ingress of fuels and lubricants, natural drying or mechanical damage in the engine compartment, electrical wiring is a vulnerable part of the vehicle's electrical systems.

Checking its integrity can be visual, by inspecting visible parts, or using a multimeter to check the conductivity and resistance of the wire.

This check is carried out strictly in accordance with the electrical diagram of the VAZ 2109 car.

Low engine oil level

During the operation of the vehicle, minor consumption of engine oil is allowed. Checking its level should be done using a special dipstick with the engine cold or not running for more than 10 minutes.

It is necessary to check its level using the dipstick and, if necessary, top up. The indicator is then rechecked with the engine running.

Low oil levels can also be caused by oil leaks.

Engine wear

Engine operation involves constantly rubbing metal surfaces. No matter how well they are lubricated, wear is inevitable.

In internal combustion engine elements such as the piston group and the timing mechanism (gas distribution mechanism), there are special oil channels. Through them, the most inaccessible rubbing surfaces are lubricated. Due to prolonged use of the vehicle and engine wear, the sealing of the channels is lost and the oil pressure drops. To eliminate this problem, you need to completely disassemble the internal combustion engine and overhaul it.

Pump fault

The oil pump is a device located at the bottom of the engine crankcase that is driven by a mechanical connection to the crankshaft gear. Due to its rotation, oil pressure is generated. The higher the engine speed, the higher the pressure level. Lack of maintenance and untimely replacement of technical fluids, as well as a long service life, can affect the quality of the pump.

To check it, a pressure gauge is used, which is screwed into the technical hole of the sensor.

When the engine is running at idle speed, the pressure should be ±1.5 atmospheres (kg/cm2), and when the speed increases - up to 5–6 atmospheres.