If you need reliable advice, contact me and my workshop buddies. My guys have many years of experience behind them, and the company’s service center checks the quality of power steering oil changes, as well as the direct implementation of such a service at an affordable price. And today I will tell you how you can do it yourself.

The VAZ 2114 sensor looks like this:

Knowing this will help you when replacing the sensor in your “swallow”.

Fluid replacement: Replace the spare - if it is faulty or has reached its usage limit. Find out useful information about the oil pressure switch.

Sensor repair and replacement

During maintenance and repair, the surface near the sensor mounting hole is cleaned, and consumables, including the liquid gasket, are replaced. Do not use sharp objects when cleaning to avoid damaging components. If the diagnostics showed that the cause of the malfunction was the sensor itself, then the entire component is replaced.

To install a new part, follow these steps:

- Remove the bottom engine cover.

- Disconnect the sensor connector and remove the component.

- Remove the old liquid gasket from the sensor and its mounting hole.

- Apply a small amount of liquid gasket to the threads of the service sensor and install it.

Why doesn't the light go off?

The main advantage that all level sensors have is their low price. Therefore, if the malfunction indicated by a burning indicator occurs in this particular element, then there will be no problems with replacing it. However, in many cases, the light on the dashboard “informs” of more serious problems.

The main reasons why the indicator lights up include the following:

- The signal transmission mechanism from the sensor has failed.

- Damage has occurred in the wires that connect this element to the vehicle’s on-board electronics.

- Low oil level.

- Oil pump malfunction.

- Dirty filter.

The greatest difficulties arise in cases where the indicator signals the last two faults. If a breakdown occurs in the fuel pump, or the filter is clogged, then either not enough lubricant is supplied to the engine, or the material has a lot of harmful impurities. As a result, the engine will fail quite quickly, since the fluid does not reduce the friction of the components of the power unit.

How to replace it with a VAZ 2114

Sensors fail when the sensor light flashes or stays on when the pressure, if acceptable, or when the pressure gauge is at zero.

Remember that the internal combustion engine of any machine, without exception, depends on oil to operate. Pressure is used to create a layer between moving parts. This level of protection prevents moving parts from contacting each other. Without this layer, excess friction and heat occurs between the parts.

Simply put, a lubricant is designed to protect both lubrication and cooling. To provide this oil under pressure, the VAZ 2114 engine has an oil pump that collects the lubricant stored in the oil pan, creates pressure and delivers the now pressurized oil to several places inside the engine through passages built into the engine components.

The ability of such a fluid to perform these functions is reduced for several reasons. The engine heats up when running and cools down when switched off. This thermal cycle causes the oil to lose its ability to lubricate and cool the engine over time. As oil begins to break down, it creates small particles that can clog the oil galleries. This is why the oil filter is tasked with pulling these particles out of the oil and why oil change intervals exist.

To a lesser extent, the sensor/indicator can be used to inform the driver about the status of the lubrication system. As the oil begins to break down, pressure can drop. This pressure difference is detected by the oil pressure sensor and transmitted to the pressure gauge or warning light in the instrument cluster. The old rule of thumb for oil pressure was 5-7 kg per square inch of oil pressure for every 1000 rpm.

Now I’ll tell you how to replace a VAZ 2114 sensor. There are minor differences between different car manufacturers and models, but this article is written in such a way that it can be adapted to perform such work.

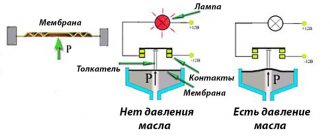

Design and principle of operation of the device

The oil sensor for the VAZ 2114 car has a simple, but quite effective design:

- measuring membrane;

- device body;

- bimetallic plate;

- sealed contact controlled by a magnet (reed switch).

Despite the wide variety of car brands, the operating principle of these devices is almost identical:

- Turning on the ignition - the indicator lights up. The contacts in the electrical circuit are closed because there is no pressure in the system (no oil).

- Starting the engine - the system begins to fill with lubricating fluid, and a gradual rise in pressure occurs. The oil presses on the membrane, it becomes deformed and opens the contacts of the electrical circuit. The indicator goes off.

- A bimetallic plate with a spiral transmits information to the sensor depending on the degree of pressure.

- When the pressure in the system drops to a critical value, the lamp on the dashboard lights up again.

Insufficient oil pressure in the engine system can cause serious damage.

The purpose of the device is to notify about malfunctions in engine units for their timely elimination.

Part 1 of 1: replacing the sensor

- Sensor socket is optional.

- Screwdriver Set.

- Set of towels/rags.

- Thread sealant - if necessary.

- Set of wrenches.

Sensor installed during engine purging.

Step 1: Find the sensor. The sensor is most often installed in the VAZ 2114 engine block or cylinder heads.

There is no real industry standard for position, so sensors can be installed in any number of locations. If you can't find it, you may need to consult your 2114 repair manual or contact a professional repair technician.

Features of diagnostics

Before carrying out diagnostics, it is recommended to conduct a visual inspection of the device for damage to the controller housing, stains from fluid leaking from the motor and other changes. If oil traces are detected, you need to make sure that the malfunction is in the sensor; inspecting the power unit will help make sure of this. When consumables leak from the regulator, the cause of the problem is related to wear on the seal. And if oil dripping occurs from the terminal connectors, you cannot do without replacing the controller.

To more accurately determine malfunctions during the operation of the device, diagnostics using a voltmeter will help:

To do this, you will need a pit or overpass and follow the following instructions:

- unscrew the bolts securing the protective coating of the unit;

- dismantle the protection;

- if DDM is detected, start the engine;

- disconnect the power cord from the device;

- use a tester to diagnose the voltage (voltage norm is 12 volts).

If the voltage is low, the cause of the malfunction is the display unit or the contacts of the electrical circuit, as well as its break.

Mechanic disconnects sensor

Step 2: Disconnect the sensor electrical connector. Release the locking tab on the electrical connector and carefully pull the connector out.

As the sensor is exposed to operating elements under the hood, contaminants can build up around the plug over time. It may be necessary to push and pull the plug several times to release it when removing the latch.

Note. In some situations, a small amount of lubricant may help disconnect the electrical connector. You can also use a small screwdriver to carefully pry the connector out. Be careful not to damage the electrical connector when removing it.

How to jam a sensor

Sometimes unscrupulous sellers deliberately suppress the readings of this element on the car. The buyer thinks that everything is in order and the pump is working fully. In fact, the car simply has a soldered light bulb in the instrument panel.

It is very easy to recognize this: when you turn on the ignition, the red “oiler” should light up. If it is not there, it means the sensor has been muted.

Removing the sensor using a connector

Step 3: Remove the sensor. Use a suitable wrench or socket to loosen it. Once released, it should be possible to unscrew it completely by hand.

Step 4: Compare the replacement device with the removed one. This is determined by the internal design, but the physical dimensions must be the same. Also, make sure that the area being threaded has the same diameter and thread pitch.

Warning: Since the sensor is installed in an area where oil will be under pressure, it is usually necessary to have some type of thread sealant. There are several different types of sealants, as well as a number of liquids, pastes and tapes that can be used. Just be sure to use one that is compatible for use with petroleum-based products.

Step 5: Install a replacement sensor. Screw the replacement into place by hand until you can no longer turn it by hand.

Step 6: Reinstall the electrical connector. Make sure the connector is fully seated and that the latch is engaged.

Step 7: Check for proper operation. Start the engine and make sure there is pressure on the pressure gauge or the oil pressure warning light goes out.

Warning: It may take 5-10 seconds for pressure to return. This is due to the fact that when removing the sensor, a small amount of air enters the system, which must be purged. If no oil pressure is observed during this time or the indicator does not go off, turn off the engine immediately. Also, if any strange noises occur during this time, turn off the engine and contact a professional.

Self-test of the sensor

Even in garage conditions it is possible to check the specified element. When the engine starts, the red lamp lights up for a certain time and then turns off. If the warning light continues to work, it is worth checking the lubricant level in the motor. If the level is normal, you should check the element.

Useful : How much oil is poured into the VAZ 2114 engine?

There are several options for conducting diagnostics in a garage:

- Check the condition of the oil filter. A filter element clogged with dirt prevents the lubricant from flowing normally into the engine. Replacing the filter along with the oil is the best option to correct the problem;

- Visual inspection of the mounting location of the part. The presence of smudges indicates the need to change the rubber sealing ring;

- Use a pressure gauge to check the system pressure. With the part unscrewed, install the pressure gauge and start the machine. An indicator of 0.65 atmospheres indicates normal operation of the motor and a malfunction of the sensor;

- Check the power cord connection. When driving over uneven surfaces, the terminals come off from many sensors in the “four”.

Also, if you have second-generation Samara cars, you can install a known working element. The part cannot be repaired, so if there are problems, it is replaced with a new one. Because It is located in an open and convenient place - it can be replaced in a matter of minutes.

At sub-zero temperatures, the first start of the engine may be accompanied by a situation where the pressure light is on for a few seconds longer than usual. This is normal, because... In cold weather, the oil pump needs more time to pump the system with thickened lubricant.

Thermal sensors

It is the thermal level gauge that is most often found in the design of modern car engines. At the heart of the sensor is a heating element. The control unit alternates heating phases, briefly warming up the element to a temperature higher than the actual temperature of the oil in the engine, and cooling. It is the duration of the period of reduction in the temperature of the heating element to the temperature of the engine oil in which it is immersed that allows us to calculate the actual level.

The operating principle of this type of level gauge is determined by the presence of an oil temperature sensor. This is exactly the design and operating principle of the G266 sensor, which is installed on many Volkswagen, Skoda, and Audi cars. Both elements are combined in the level sensor housing, which is located in the engine oil pan.

Electrothermal level gauges

Electrothermal oil level sensors can be called a subtype of thermal level gauges. The sensor is based on a heating element (wire) with a high temperature coefficient of resistance. The total resistance of the heating element depends on the heating temperature. Accordingly, the deeper the sensor is immersed in the cooling lubricant, the better the heat removal from the heating element and the lower its resistance. The oil level is calculated by the control unit based on the actual voltage value at the sensor terminals.

Ultrasonic meters

The operating principle is based on the use of ultrasound - sound vibrations, the frequency of which exceeds the frequency range accessible to human organs of perception. The degree of reflection of sound waves depends on the density of the material towards which the source of sound vibrations is directed. Since the densities of the air and engine oil differ, sound waves are reflected at the boundary of the oil level in the pan. The reflected vibrations are picked up by the receiver, and the time interval between the transmitted and reflected signal is used to calculate the engine oil level.

G266 sensor device used in the design of VAG-Group cars.

A PTC resistor is also included in the housing, which allows you to measure the oil temperature. In addition to the measuring element, the device includes an electronic measuring unit that processes ultrasonic signals and signals from a PTC resistor. From the digital logic module, signals converted into a language understandable for control units - a PWM signal - are sent through the engine ECU to the dashboard.

Advantages over thermal elements

- Low current consumption.

- Speed of signal transmission.

- Possibility of implementing a graphical indication of the actual oil level in the engine.

Measurement algorithms

Static control. The engine has been stopped for more than 60 seconds and the vehicle is stationary (the parking brake must be applied)

To level out the measurement error, the possible inclined position of the car body is taken into account. So that the owner does not wait for data after turning on the ignition, the level is measured immediately after opening the driver's door. Dynamic level control

Activated when the vehicle is in motion. This takes into account: crankshaft speed, longitudinal and lateral acceleration, engine temperature, and the position of the hood limit switch. In this case, the movement cycle since the last activation of the hood must be more than 50 km.

The role of the hood switch

VAG in VW, Audi, Seat, Skoda cars uses a rather interesting scheme for connecting the engine oil level sensor. If the low level indicator lights up, then 2 conditions must be met for it to go out:

- activation of the hood switch (it is logical that without opening the hood it is impossible to add oil);

- level replenished.

If, after the low level light came on, you opened the hood but did not make up for the deficiency, the indication will go out and light up again only after 100 km. If the amount of coolant reaches a critical level, the low oil pressure light on the instrument panel will light up.

Sensor operating system

Lubrication in a car is used not only in the engine, but in many other units, but it is in the engine that even a short-term disruption in the system can cause irreversible consequences. Experienced motorists call this “engine knocking.” Therefore, it is very important to find out the reason for the alarm even with a short-term alarm, otherwise there is a possibility of facing expensive repairs. The operating principle of the oil level sensor is to measure current resistance in time. In working condition, the measuring part of the device is immersed in a liquid, in our case, oil. When the lubricant level decreases, the measuring part becomes dry and, therefore, all current resistance is lost. While being immersed in a liquid medium, it gives greater resistance at the exit.

It should be recalled that in addition to the oil level sensor (OLS), there is also an emergency oil pressure sensor (DAPM), but still these are completely different devices.

Triggering of the DUM may indicate the following:

- Insufficient lubrication in the engine. Check visually (with a probe).

- The measuring device itself does not function. Perhaps the DUM itself burned out, or the contacts oxidized.

Before replacing the oil level sensor on a VAZ 2114, it would be advisable to check its functionality.

What to do if the light comes on after replacing the DDM

It must be taken into account that when the engine starts, the oil pump pumps fluid from the crankcase to the main line. At the time of pumping, all liquid is forced to pass through a special filter, whose task is to remove contaminants.

Sometimes it happens that dirt remains on the crankcase, which clogs the filter. Due to this problem, the pump will not be able to fully operate and supply the required amount of liquid. If you encounter this situation, then you will need to drain all the existing oil from the crankcase and replace it with new one. Don’t forget about the filter itself; it will have to be replaced with a new one or simply cleaned.

Good day everyone, such a disaster happened. I went with my girlfriend to IKEA, got there, bought groceries, everything was fine. We were already heading back, we got stuck in a traffic jam, the temperature was rising, and then out of the corner of my eye it seemed like something, but the light on the oil pressure gauge blinked. ok, screw it, let's go. and then I notice that it regularly begins to blink, and then lights up completely. I’m in a panic, I brake, I smoke, the engine cools down, I start it, it doesn’t light up.

I'm moving on. only the temperature reaches 90C and it begins to burn. and it only has to do with it at idle, when you give it gas it stops.

In general, having arrived home, I started using the Internet and was already completely upset, who wrote what and at least it was necessary to remove the oil pan, and I just changed the oil (

what I tried to do:

- added oil. - tightened the filter - revved it up to 3500 thousand when cold (they wrote that debris can get into the valve and with such manipulation of the oil flow it is washed out because the oil is thicker when it’s cold.)

nothing helped.

the next day I decide to start small, go to the store and buy DDM.

I open the hood, look at the old one and see a drop of oil under the rubber cover. and in the hope that it is the problem, and not the liners, oil pump, etc.

Photo gallery

1. Schematic principle of operation of the DDM on Chetyrka

2. DDM with a dial indicator for displaying into the car interior

3. Scheme of operation of the device on Chetyrka

Loading...

Video on the topic

Source

|