When servicing calipers or replacing them, experts advise carrying out a procedure for lubricating the parts. This must be done because the caliper is one of the most important parts of the brake system. The safety of the driver and passengers depends on the correct operation of the braking system. Ignoring maintenance leads to blocking of the brakes and breakdown of various system elements. But many drivers do not know how to lubricate caliper guides correctly. Let's consider this issue in the presented material.

How to use it correctly

Before lubricating the caliper, the driver needs to understand the “instructions for use.” Let us list the main secrets of using the substance:

Anti-squeak plates need to be treated with the substance, provided that extraneous squeaks occur during braking.

Any parts that have been replaced or serviced are lubricated with the appropriate composition.

The driver should clean the area of the pressure pads himself from time to time.

As soon as problems appear with the movement of the piston, it is treated with a lubricant. This must be done correctly, without excesses, otherwise everything unnecessary will “jump out” of the anthers.

When working, the main thing is not to overdo it. Excess will fall on the work surface, which is not desirable, since the substances are not intended for this.

SLIPKOTE 220-R DBC

SLIPKOTE 220-R DBC

Quite a high-quality solution for cars. SLIPKOTE 220-R DBC can be used in the following temperature range: from minus forty-six to almost plus three hundred degrees. The basis of this solution is synthetics (oil), and various additives that make this product anti-corrosion. One of the significant disadvantages of this solution is its high cost. One way or another, this product collects a large number of positive reviews among motorists, many note its high efficiency and versatility.

pros

- Wide temperature range.

- Universal application.

- Protective properties.

- Anti-corrosion.

Minuses

- High price.

Lubrication requirements

Even if the car owner knows how to lubricate the caliper guides, he needs, first of all, to select the correct composition. They are subject to special requirements based on the operating conditions of the braking system (TS).

The product must have:

Heat resistance - the elements of the mechanism become very hot (up to +180°C).

Frost resistance - exposure to -15-20°C or more.

No destructive effect on rubber and plastic.

Highly resistant to various automotive fluids and moisture.

Pastes should have a viscous consistency and not wash off at the slightest impact.

All of the above requirements are the most basic. You can also provide additional ones. For example, corrosion protection is an important property that is not found in all lubricants. Experts claim that products from the Litol and Nigrol brands are not suitable for processing elements, since they are not able to “withstand” aggressive working conditions. As a result, piston seizure and brake failure may occur.

Venwell Aluminum Spray

The lubricant works in the widest range from -60 to +1500 degrees. Experts note that when a critically low level is reached, the lubricant does not freeze, does not thicken, and loses its qualities.

- Characteristics

- Average price: 220 rub.

- Country Russia

- Base type: mineral

- Temperature range (C): -60 to +1500

- Specialization: extreme pressure, anti-friction, anti-corrosion

- Properties: waterproof, frost-resistant

It is known that car brakes can heat up to 600 degrees, and even more in case of emergency. The caliper lubricant must withstand such loads, and the higher its temperature spread, the better. Now we have the most stable lubricant, operating from -60 to +1500 degrees, and this is the most impressive result, which, moreover, is confirmed by independent experts. Of course, it is unlikely that such values will be achieved in reality, but it never hurts to have a margin of safety. In addition, the product has high anti-corrosion properties and is able to repel moisture without reacting to brake fluid and chemicals.

Types of lubricants

Lubricants are sold in different formats: as a paste or spray. Which composition to choose? It depends on how the driver operates the car. If we take sports cars as an example, then when driving their calipers heat up to +300°C. Also, do not forget that those who drive a car in winter expose parts to moisture and road reagents.

Drivers who do not understand trains buy budget options. These include the familiar nigrol or lithol. Unfortunately, these products do not meet the quality characteristics. They perform the task assigned to them, but ineffectively. It is best to buy a composition from a well-known brand.

Today, the following varieties are presented on the auto lubricants market:

Mineral (synthetic) pastes containing metals. This species can withstand severe frost and excessive heat. Its operating temperature range is -180°C to +1100°C. The metal component may be in the form of copper powder, magnesium silicate, or a combination of aluminum, graphite and copper.

Classic mineral pastes include fatty acids in combination with metal and bentonite. Withstands from -45°C to +185°C. These characteristics are enough for the brake unit to work smoothly. The lubricant retains its consistency. The paste is used to lubricate bolts, rods, cylinders, etc.

Classic synthetic oils - the main component of the composition is silicone. To make the substance “work” better, additives are added to it. With their help, the components are reliably protected from the aggressive influence of liquids and acids. Operating temperature varies from -40°C to +300°C. The paste has a semi-liquid consistency that can be used to lubricate guides and other elements.

But another important characteristic of the lubricant is the manufacturer. High-quality products are produced by companies specializing specifically in lubricants. Today the Toyota and Slipkote brands have proven themselves well.

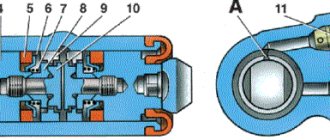

Compositions for treating caliper elements

The scope of application of materials of the second group is static parts of brake mechanisms. This includes bolts of threaded connections, rubber and plastic covers, rods and various bushings. They are made on mineral bases and are not subject to melting (English designation - Rubber Grease). The temperature range in which the lubricant works without problems is from minus 40 to +180 ° C.

Important point! Lubricants of this group are not intended for application to moving parts - guides and cylinders. It is allowed to process the end part of the piston pressing on the block.

The products on the market are represented by the following brands;

- ATE Plastilube (Germany);

- composition Loctite Teroson Plastilube with a thickener based on natural clay;

- Teroson Plastilube from the famous German manufacturer Continental Teves, specializing in brake units.

Application of the listed lubricants creates the effect of surface preservation. Simply put, a few years after processing, the threaded connections unwind and the assembly is easily disassembled. Conventional silicone grease is not suitable for car calipers - the operating temperature is too high.

Recommended Brands

When a car owner is faced with the question of what to lubricate the caliper guides with, many problems arise regarding the choice. The products of the following companies are very popular:

Liqui Moly is a well-known brand that offers a wide range of pastes. Among the manufactured products you can find universal products for calipers and pistons. Pastes cannot be considered budget, but many drivers are delighted with the quality.

TRW is a manufacturer that is very popular among Russian drivers. The products are sold in different versions, but the owners recommend buying 25 g tubes.

PAG is a domestic analogue of TRW products. Lubricants contain calcium and lithium. Sold in 5 gram tubes.

Similar products are not made by many popular brands that produce oils.

Be careful with Liqui Moly Bremsen Anti-Quietsch-Paste

In automobile stores, Liqui Moly Bremsen Anti-Quietsch-Paste is often sold under the guise of a composition for lubricating guides. The characteristic features of the product include a gray-blue color.

At the same time, the manufacturer positions the product as an anti-squeak paste, not advising its use for processing guides and boots.

It is known that the composition contains a ceramic filler, the peculiarity of which is its high temperature resistance up to 1200 degrees Celsius.

But the synthetic base of the product can lose its qualities at a much lower temperature. This means that melting and leakage are possible.

Anti-Quietsch-Paste (art. 7656), distinguished by its red color, is available in the line of this manufacturer. This tool has already been mentioned above.

It does not have a negative effect on rubber and plastic elements, but retains its quality at temperatures up to +250 degrees Celsius.

TOP 5 best lubricants

Among the wide variety of products, there are always those that are most in demand. The current review has collected the five best products in terms of price and quality ratio.

Lavr BRAKE CONTROL is a semi-synthetic paste with frost resistance. It can also withstand high temperatures up to + 1000°C. The average cost is 115 rubles. The main feature of the substance is its versatility. Lubricant can be applied to guides and calipers, as well as to piston cylinders. The only drawback of the product is that there are often manufacturing defects.

ABRO Synthetic Brake & Caliper Grease is a budget lubricant containing molybdenum and Teflon. ABRO is considered a well-known manufacturer producing high-quality products. It is this composition that has the best characteristics. The synthetic substance perfectly protects the brakes from wear.

TRW PFG110 is a high-quality lubricant that interacts well with different surfaces. The composition contains a large set of additives with water-repellent properties. The substance is also resistant to reagents. Before the treatment procedure, the brake system must be degreased. After application, the substance creates a film on the surface of the elements that protects against rust formation. The product is manufactured in America, and therefore has a high cost compared to analogues.

VMPAUTO MS 1600 is a lubricant for calipers that can withstand up to +1000°C. This high temperature substance has anti-corrosion properties. The brand not only produces products under its own brand, but also tests them in the laboratory. Thanks to constant testing, the manufacturer was able to increase the temperature threshold. The advantages of the lubricant include plasticity and affordable price.

RUSEFF is a product that is often included in various reviews and car ratings. This is a Russian brand of synthetic-based lubricants. The composition contains anti-friction components. However, do not apply the composition to the piston cylinder or moving fingers. The advantages of the product include a low freezing threshold and recommendations from experts.

What do disc brake manufacturers recommend?

World-famous companies that produce well-known brake systems for cars and motorcycles (for example, Delphi, Rems America, Cardone and others) recommend silicone compounds.

They are more suitable for disc brake calipers and are resistant to high temperatures.

Therefore, preference should be given to products from group 3, which can be applied to brackets, pistons, bolts, pads and other surfaces with a guarantee of results and without the risk of deterioration in functionality.

How not to buy a fake?

Before purchasing a lubricant, you must visually inspect the product packaging. On fakes, as a rule, not all inscriptions and signs of the brand are applied. Also, the tube is made of low-quality material, which is noticeable even to the touch.

Counterfeits are found “at every step” today. Trying to save money, drivers buy them without receiving a positive effect in return. In addition, low-grade pastes can render calipers, guides and discs unusable. Ultimately, the owner has to pay a lot of money to repair the brake system.

MS-1600

A good solution from a domestic manufacturer, it is universal. The paste can be used in the following temperature range: from -50 to +1000 degrees. The lubricant is resistant to the negative effects of moisture, reagents, alkali, etc. Also, this solution will not harm elastomers, which is also a big plus. The manufacturer recommends lubricating various pad surfaces using this solution. This product will not react with various types of brake fluids.

pros

- Wide temperature range.

- Universal application.

- Protective properties.

- Does not cause deformation.

Minuses

- Not detected.

What shouldn't be lubricated?

Many drivers do not know how to lubricate brake calipers, since the range of lubricants is quite wide. The previous paragraph discussed products that can be used for processing. In order not to get confused in the choice, you also need to know what substances should not be used to lubricate the caliper guides.

It is prohibited to use ceramic and copper pastes for lubrication. They can only process the pad inserts into the caliper.

It is not recommended to use copper and graphite compounds. Otherwise, the lubricant will dry out and the finger will jam.

Lithol is never used for finger strokes, since the substance becomes liquid when heated strongly. It spreads and corrodes the anther.

All of the above prohibitions must be taken into account if there is a need to lubricate the caliper. There is no need to rely on the advice of strangers. An incorrect lubrication process can lead to irreparable consequences.

TRW PFG110

This solution is one of the most popular among domestic motorists, who give their preference to this particular product. The product is universal; it has already proven itself on the positive side, as evidenced by the large number of positive reviews from motorists. The product is sold in tubes of twenty-five grams. Can be used in all mechanical components, including hydraulic ones made of rubber, that are in contact with brake fluid. It is not recommended to use this solution for aluminum elements that are under high dynamic load. This solution has excellent wear protection and resistance to high loads. You can also note the high adhesive characteristics of the product and its water resistance. In reviews, many motorists speak positively about the properties of the lubricant. In general, this solution has shown its highly effective properties, as evidenced by the large number of positive reviews from car owners.

pros

- Protective properties.

- Doesn't coke.

- Adequate cost.

Minuses

- Difficult to find on sale.

Frequency and correctness of the procedure

How to lubricate calipers correctly? This question worries everyone who is going to replace and service parts. First you need to understand which element requires processing. These could be anti-squeak plates, pad pressure springs, etc.

To carry out the procedure, you will need a tube of the substance. The paste is orange in color. By the way, it is also often included in repair kits. If you cannot find a substance with a thick consistency, you can purchase high-temperature paste in bags.

First you need to remove the caliper guides and clean them of dust. It is advisable to change the anthers at the same time. But if this is not possible, then it is also better to remove them, wash and dry them. Lubricant is applied to the finger and under the anthers. The main thing is that the layer is not too thick. It won't do any good. If there are defects on any parts, you need to eliminate them or replace the parts with new ones.

What is better - lubricate or replace?

When deciding to lubricate the guide calipers, the question may arise as to what is better to do - lubricate the product or buy a new repair kit. The latter includes anthers, pins and fasteners.

Repair kit UAZ

The downside is that the guides are made by an unknown manufacturer, are often made from a “raw” metal base and do not always have the correct dimensions.

Some “masters” do not change the fingers, but simply break them with a hammer, which can cause the guides to jam.

Some car owners are faced with a situation where noise from the calipers appears during the warranty period. In such a situation, the only way out is to contact the dealer to replace the components.

But even here there is not always confidence in the quality of spare parts. So, for VAZ and a number of foreign cars, brackets, cylinders and “palms” have to be purchased separately. Moreover, all of them must be manufactured at an official factory.

In other words, when deciding to replace / lubricate, you need to take into account the consequences and the availability of suitable parts.

There is no single answer, because in simple cases it is enough to apply one of the lubricants listed above to the caliper guides, but if it breaks, a complete replacement of the part may be required.

Recommendations for selection

The main requirement for caliper lubricants is that it must be high-temperature and intended for cars. To lubricate components in hard-to-reach places, it is convenient to use sticky pastes in aerosol packaging. For example, Wurth HHS 2000. It is sticky and easily held in places where liquid oils flow out, thick oils separate from the surface under vibration and dynamic loads.

ATE paste is good for pad guide plates, but it should not be used to lubricate seals, rubber parts and caliper guides.

For normal operation of the brake system, it is necessary to select the correct lubricant, following all manufacturers' recommendations.