A characteristic feature of domestically produced cars is that their repair and maintenance can be carried out on their own. The main thing is to have the necessary knowledge, instructions and the desire to cope with the task on your own. But still, in the case of replacing valve guides, which has a number of its own specific features, it is better to carry it out at a service station. However, many motorists cope well with this task in their own garage.

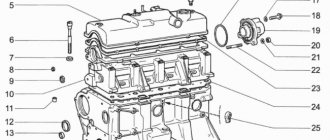

Replacing valve guides on a VAZ-2108 with your own hands

In our article we will talk about how valve guides are replaced on cars with a VAZ-21083 engine. This engine was installed on both “eights” and “nines”, “tens” and similar car models. The special thing about these engines is that you can do maintenance and repairs yourself. The main thing is to have the necessary knowledge and also to have the necessary tools at hand. But if we are talking about valve guides, then it is advisable to entrust this work to an experienced craftsman.

Causes of parts failure and their consequences

A characteristic feature of the guide elements is that they do not fail at once, but wear out gradually. The lifespan of parts on budget cars ranges from 180 to 300 thousand km, and on more expensive foreign cars it can reach 1 million km. The wear process is influenced by several factors that can accelerate it:

- the quality of the motor oil used and the timeliness of its replacement;

- temperature conditions of the power unit, the more often the engine overheats, the faster the rubbing surfaces wear out;

- the quality of the fuel and combustible mixture, whose vapors penetrate into any leaks and contribute to the process of slow destruction of parts.

Carbon deposits on the rod destroy the bushing quite quickly

Note. The working life of all elements of the gas distribution mechanism is also affected by the serviceability of the power supply and ignition system. When, as a result of a malfunction, pops occur in the fuel or exhaust manifold, the lubricant between the valve-bushing pair is washed off with unburned gasoline, which is why the mechanism runs “dry” for several seconds.

A worn part is characterized by a “broken” internal hole, as a result of which the valve stem begins to move too freely in it, and then play appears. The rod warps during operation, and the plate does not fit well with the seat, the tightness of the interface is gradually lost. Gases escape from the combustion chamber into the mechanism, and oil enters from above, resulting in the formation of carbon deposits. It also accelerates wear, quickly rendering the part completely unusable.

Why does deformation occur, its consequences

As the engine operates, the guide bushing wears out, so alignment with the valve stem may be lost. As a result, the element breaks more strongly, the valve “walks” and does not fit very tightly to the seat. This causes the seat chamfer to break. As a result, the valve burns out. To repair it, it is necessary to replace it, as well as change the saddle. And of course, replace the valve guides on the VAZ-21083.

In addition, due to valve instability, oil seals become unusable. They do not retain oil as the angular displacement of the rod increases. As a result, oil enters the combustion chambers and its consumption increases. Consequently, carbon deposits will appear on the valves, and harmful emissions from the exhaust pipe will increase significantly. As a result, you may end up having to replace the lambda probe or catalyst (on injection engines). Moreover, it should be noted that replacing the caps will not help, since even new ones will soon become unusable.

Why do you need a guide bushing?

The guide bushing can quite rightly be considered the main element on which the resource and proper operation of the “seat - valve plate” tandem depends. The material from which the part is made and its design itself are primarily aimed at working under conditions of high speeds of the valve stem fixed in it, constant high-temperature loads and the almost complete absence of lubrication in the valve-bushing pair.

Causes and consequences of deformation

The described conditions lead to the fact that during engine operation, the valve guide bushing also wears out, which is why, over time, its alignment with the valve stem may be disrupted. Subsequently, the part breaks even more and the valve begins to “walk” and does not fit tightly to its seat, and this, in turn, leads to the chamfer of the seat breaking over time. As a consequence, you can get a burnout of the valve and have to replace the seat.

Appearance of bronze guide bushings for VAZ 2108–2109 models

Also, due to the “walking” of the valve in a broken guide, the oil seals can quickly become unusable. They simply will not be able to hold oil with increased angular displacement of the valve stem. The result will be oil getting into the engine, and if you also take into account that more oil will pass through the broken bushing than usual, then the situation will not be pleasant. Carbon deposits on valves and other parts around the combustion chamber will increase, the level of harmful exhaust emissions will increase, and you may end up with a prematurely failed catalytic converter. And simply replacing the valve stem seals is not enough, as the problem will soon return again.

Why you shouldn't neglect checking

When repairing an engine, it is better to pay special attention to its head. Often it is this part of the engine that is to blame for the fact that the level of compression in the cylinders is far from the desired level. When repairing cylinder heads, motorists sometimes limit themselves to only grinding the valves to their seats, believing that there is nothing particularly wearable in all-metal bushings. At the same time, checking how large the gap between the part and its valve is will be completely worthwhile. When the obtained clearance figures go beyond those recommended by the car manufacturer, then no amount of grinding in the valves or replacing the valve stem seals will protect against problems in the future.

Materials used to make bushings

For the manufacture of bushings, materials with good wear resistance and thermal conductivity are used. Among these you can find:

- special cast iron alloys;

- bronze;

- brass;

- metal ceramics.

In terms of thermal conductivity and cost, brass, along with bronze, are among the leaders, so the vast majority of bushings are made from alloys of these metals.

Nuances to consider

Most bushings have a special support collar on the outside, designed to ensure proper fixation of the part vertically in the cylinder head. If the part is smooth, then installation is carried out using a special mandrel.

For intake valves, the guide bushings should not protrude so as not to increase the aerodynamic drag of the intake channel. Exhaust valve bushings are designed to “hide” the valve stem as much as possible to protect the latter from high temperatures and better heat dissipation.

Appearance and location of the valve guide in the cylinder head

The manufacturing precision of the bushings is very high. This is necessary to obtain the most accurate alignment and the best fit of the valve plate and seat during engine operation. The outside of the body of the part that is to be pressed into the cylinder head must be processed as cleanly as possible; there should be no scratches or marks on it. This ensures optimal heat removal from this accessory to the block head.

Video: review of valve guides for VAZ 2108–2109

Diagnosis of the condition

When repairing an engine, special attention must be paid to the condition of the cylinder head. It is this element that is usually the culprit when compression is lost in the cylinders. During repairs, car enthusiasts only grind valves.

Some naively believe that bushings made of solid metal practically do not wear out. But it is still recommended during repairs to measure the gap between the valve stem and the bushing. If it is too large, then grinding the valves and replacing the caps will not help, the machine will start to “eat” oil again.

What materials are used to make bushings?

Let's talk about what materials are used to make high-quality bushings. On sale you can find the following items made from:

- bronze;

- brass;

- special cast iron alloys;

- metal ceramics.

When it comes to thermal conductivity and cost, bronze and brass are ahead of all others. That is why most of the bushings that are found on sale are made from these metals. When replacing valve guides, pay attention to what metal they are made of.

Product added to bookmarks!

APPLICABILITY: VAZ 2101, 2102, 2103, 2104, 2105, 2106, 2107, VAZ 2121, 21213, 21214, 21218, 2129, 2131 (Niva), VAZ 2123 (Niva-Chevrolet).

Increased valve guide wear can be a problem on camshafts with high valve lift. Even if the engine is equipped with a smoother camshaft, wear on the guide bushings may still be a problem. When the valve guide clearance increases, the valves may not sit evenly on the seat and leaks may develop, causing power to “leak” from the combustion chamber. Worn bushings can also allow oil to leak into the cylinders. When oil is mixed with the working mixture, it reduces the octane number of the fuel and the fuel in the combustion chamber will already be lower in octane number; oil contamination will increase the chance of detonation, especially at high compression ratios.

The best way to prevent wear on the guide bushings is to install bronze guide bushings. If this is done correctly, they will “outlast” cast iron bushings for a long time. While bronze bushings are only slightly more expensive, installing them is a smart investment because... In addition to reducing valve-bushing clearances, they withstand lack of lubrication. And if you want to achieve high engine performance, then use bronze bushings.

These bushings are not recommended for installation on high-speed engines of VAZ cars.

What nuances need to be taken into account

Almost all bushings have a special thrust collar, which is located on the outside. It allows you to fix the element as accurately as possible in a vertical plane on the cylinder head. If the bushing is smooth, then installation must be carried out using a mandrel. As for the intake valves, the guides should not protrude on them. Otherwise, their aerodynamic drag will increase.

The bushings installed on the exhaust valves hide the stem as much as possible in order to protect it from high temperatures. It also allows for very good heat dissipation.

guides from VAZ 2108

I wanted to install valve guide bushings from the eight, but yesterday in the store I saw long German ones and our clumsy and short ones. Which one is better to install? please advise

Put long ones, find cermets. Just give it to a turner, let him grind the sill for you lower for the retaining ring - to what length - don’t be a fool, try it yourself.. Or clamp it into a drill yourself, and use improvised means such as a hacksaw - but this is already a jamb, you understand. Here.

Also take a set of springs and plates from eight. Before pressing the guides, use a drill to chamfer the mounting hole on the side where the springs are, so that the retaining ring goes flush with the plane where the plate sits, then it will sit evenly, and the ring will have nowhere to go. Just make sure that the top plate does not hit the guide when opening the valve - for this you need to ensure that the guide sticks out (IMHO Dnepr - 20 mm) and you can file the top plate where the crackers sit. Take the Dnieper crackers, they hold up fine, just be sure to put in the spots.

In my experience, the valves turn out to be simply eternal - due to stiffer springs, the camshaft smoothly lowers them onto the seats, rather than inertia wobbling them with all its might. Again, the revs will increase.

and I hammered it in without retaining rings, just roughly look at how and why

u menia byla remontirovana odna golova, tak vazovskije (cugunyje) napravliajusce neviderzali i 10 000km vileteli vmeste s klapanomv cilindr. lucse iz spec splava ,kak originalnyje, libo metalokeramiceskije. a ot cego byvajut metalokeramiceskije?

for ziurke

: You're fucking, you're fucking. How did they fly into your combustion chamber? What about the retaining ring? How about the crackers? In the sense of the springs, on the contrary, they should not have been allowed into the combustion chamber.

Metal ceramics seem to be similar to classics. Personally, I took it at the store - they said that they were from eight.

But if I install a vase from a classic, can I immediately install a set of springs from it without modifications?

How to determine wear

The rod in the bushing works constantly, so excessive wear of the elements occurs inside. It will be especially noticeable if the car has an impressive mileage. In addition, if you use low quality lubricant, it will speed up the wear of the bushings. Before replacing, it is necessary to determine how badly the elements are worn.

You can use one of these methods:

- Nutrometer and micrometer. These tools allow you to measure the minimum diameter value on bushings. It is also necessary to measure the maximum diameter of the valve stem stroke area. The difference between the values will be the gap. Note that the wear on the rod is tapered and barrel shaped. Also, the diameter of the bushing changes with height. Before taking measurements, it is necessary to completely clean the surface of dirt and dust.

- Using a dial indicator on the stand. If the gap is larger than necessary, you need to take a new valve and repeat the measurements. If even when installing a new valve the gap is too large, it is necessary to install new guides.

Installing new guides

First you need to measure the diameter of the sleeve and seat in the head. The difference should be no more than 0.05 mm. Minimum value 0.03 mm. If the socket is larger, then you need to look for the appropriate bushings. If the diameter is too small, you will have to drill holes. It is recommended to warm up the head before pressing in new elements. But the bushings are best cooled using liquid nitrogen. And if there is none, then you can simply put them in the freezer for a day or more.

When working, it is best to use a tool for replacing valve guides. It is much more convenient than a hammer and a simple mandrel. Rubbing surfaces must be lubricated with engine oil. Pressing in occurs in the same way as pressing out. All work is done using a hammer and sending.

How to remove guides

Before carrying out work, you need to warm up the entire block head to 100 degrees. The aluminum from which the head is made has a very high expansion coefficient, much less than that of the bushing. When heated, the tension of the connection between the head and the bushing decreases. In this case, you can press out the old bushings practically without damaging the seats. This is done using a sledgehammer or hammer.

Also, sometimes special mandrels are used to remove elements. With this tool you can remove the guide exactly along the axis. Many experienced craftsmen use pneumatic hammers or special drifts when replacing valve guides on a VAZ-2108.

If you can’t knock out the bushing, you’ll have to drill it out. It is best to use a machine rather than a drill. If you use a drill, the likelihood of damaging the socket increases. After dismantling, pay attention to the inner surface of the mounting sockets. They should not contain roughness, scratches, or other defects. If they are present, then you will have to additionally treat the surfaces.

The procedure for replacing guide valves on a VAZ 2106

The whole procedure is divided into several stages:

- Preparation of tools.

- Partial disassembly of the engine, namely, removal of the cylinder head.

- Selection and purchase of new parts.

- Dismantling worn elements and pressing in new ones.

- Reassembling and starting the engine.

The first step is to disconnect the battery from the on-board network

Advice. It is worth following exactly this sequence of actions - first disassembling the engine, and then purchasing spare parts. The dissection will show you exactly what parts you need. If you recently changed the valves (5-10 thousand km ago), then you need to pull them out to try them on with the new bushings in the store. The old valve group will have to be replaced.

Preparing the necessary tools

To disassemble and replace the guides, you will need:

- standard set of open-end and ring wrenches;

- a set of sockets with a powerful wrench and ratchet;

- a torque wrench for tightening the cylinder head bolts and camshaft nuts during assembly;

- screwdrivers, pliers;

- 36 mm wrench for manual rotation of the crankshaft;

- mount;

- puller for unlocking valves;

- heavy hammer;

- mandrel for knocking out and pressing in bushings;

- 8.025 mm reamer with knob;

- container and hose for emptying the cooling system;

- rags.

You can’t do without a ratchet wrench and sockets when removing the cylinder head.

The mandrel for working with guides is a steel rod, the end of which is machined to fit the inner diameter of the bushing. The second part of the mandrel is a nozzle for pressing, the size of which is adjusted to the wide outer part of the part (the so-called cap), since it is impossible to hit the end. The kit can be ordered from a turner or purchased ready-made; it is inexpensive.

The mandrel for knocking out and seating bushings can be machined according to the drawing

Advice. In the process of replacing the guides, you will have to re-grind the valves, or even trim the seats. This work requires a special tool and appropriate skills, so it is better to entrust the operation to a master. In addition, the purchase of devices for cutting and lapping will reduce to zero all the benefits of repairing the cylinder head with your own hands.

This is a scan used on the cylinder head of VAZ 2101-07 cars

A reamer is a bench tool designed for precise adjustment of the internal diameters of holes. In this case, it is necessary to rotate the inner part of the bushing under the valve stem with minimal clearance.

Removing the cylinder head and old bushings

This stage is the most labor-intensive and time-consuming; it begins with disconnecting the battery and emptying the water jacket of the engine (there is no need to drain the liquid from the radiator). Perform further operations in this order:

- Disconnect the starter cable, gasoline hose and accelerator drive, then remove the air filter housing and carburetor.

- Unscrew the valve cover and align the notch on the crankshaft pulley with the long notch on the block. Disconnect the wires from the spark plugs and remove the distributor, remembering the position of the slider. Remove the wire from the temperature sensor.

- Loosen the chain by unscrewing the tensioner, then unlock the camshaft gear nut and unscrew it. Remove the gear and secure the chain so that it does not fall inside the block. Unscrew the nuts securing the camshaft bed and remove it from the studs.

- Disconnect all cooling system pipes and exhaust pipe “pants” from the cylinder head.

- Loosen the 11 cylinder head bolts in random order and remove them. Using both hands, lift the cylinder head and remove it along with the manifolds.

Removing the filter housing

Advice. Immediately after dismantling the head, clean the block of the old gasket and cover it with a clean cloth so that dirt does not accidentally get inside the cylinders.

Place the removed cylinder head conveniently on the table and remove the springs with the rocker arms (it is advisable not to mix them up), then use a puller to unlock the valves and pull them out. At the same time, do not lose the “crackers” - small half-cylinders inserted into the slot of the rod. Then turn the head over with the combustion chambers facing up, place wooden blocks along the edges and knock out all the bushings with a mandrel. Strike with medium force, clearly and accurately. At the end, clean and thoroughly wipe the entire cylinder head from carbon deposits and deposits.

The carburetor must be removed from the manifold so that it does not interfere

Recommendation. Take this opportunity to inspect the disassembled engine for other faults in order to eliminate them immediately. Involve a mechanic - a motor mechanic with a device - a bore gauge, so that he can check the output in the cylinders and advise you on all issues. This is important if you are disassembling the VAZ 2106 power unit for the first time.

It is important to align the marks before disassembling

Photo instructions for removing the cylinder head

How to dismantle the cylinder head of a VAZ 2106 - video

Selection of new parts

Guide bushings for the "six" engine can be purchased in two versions - cast iron or bronze. When choosing, you should adhere to the following recommendations:

- If you have a normal driving style and are not into car tuning, there is no point in installing bronze products. Buy inexpensive cast iron guides and they will last quite a long time.

- It is better to install bronze parts together with lightweight chrome-plated valves (for example, from the AMP brand).

- Considering the price of cast iron products and your first experience of replacing them, it is recommended to purchase 2 sets of parts. The reason is the fragility of the material, which can accidentally crack if handled improperly.

- Select the bushings in such a way that the valves are inserted into them with difficulty or do not fit at all. Do not take products with incorrect holes where the rod fits freely.

- If after disassembly you find that one or more bushings are spinning or dangling in the cylinder head sockets, you need to select repair products. Their outer diameter is 0.05-0.1 mm larger than the standard one, which will allow such parts to fit into broken holes in the cylinder head. Here it is worth using measuring instruments - a micrometer and a bore gauge.

Advice. Do not listen to assurances that bronze bushings resist wear better than cast iron ones, this is not true. Cast iron is much harder than most metals, including bronze, it just transfers heat less well. Hence the conclusion: both parts are good, but they must be used for their intended purpose.

It is also worth purchasing a new valve group (if it has not been changed recently), gaskets for the cylinder head and various pipes, and 1-2 liters of antifreeze for topping up. Buy the rest of the parts based on the results of the previous troubleshooting.

Scan

Sometimes it happens that the valves do not fit into the new bushings. This is due to the fact that when pressed in, the guides change their diameter slightly. To get rid of this problem, you need to use a sweep. It allows you to bore the element to the desired diameter. It is recommended to use diamond reamers as they will last longer than steel ones. Replacing valve guides with your own hands can be done quickly if you have experience. If you don’t have it, you need to see how an experienced craftsman performs this work.

Source

Bronze valve guide bushings VAZ 2101-2107, Niva, Chevrolet NIVA (8 pieces)

- We guarantee fast processing of your order during business hours (we work from 11-00 to 20-00, Saturday and Sunday are days off).

- We guarantee reliable packaging of your order (when sending it by Russian Post or transport company).

- We guarantee the fastest possible dispatch of your paid order (within 2-4 business days after receipt of payment).

- We guarantee a refund or exchange for another product (with recalculation) within 14 days from the date of receipt of the order (the product must be in good condition, without traces of installation, delivery costs are not reimbursed).

- We guarantee a free exchange of goods (transportation costs at our expense) if the purchased goods turn out to be defective.