How to check canister valve

A specific question is how to check the operation of the adsorber valve? This device is found on a huge number of new cars. It is designed to absorb excess carbon gases from the car's gas tank. Thus, this mechanism prevents the release of gases into the atmosphere. It was necessary to use a device of this type after the introduction of new restrictive standards Euro-3 and higher. When working properly, the car has a low level of pollutant gases in the exhaust, and there is also an at least insignificant decrease in fuel consumption. But, like any device, this motor element also tends to break. Failure can occur due to clogging of the adsorbent inside the absorber, also due to a specific mechanical effect on the absorber body. In any case, difficulties begin when the engine operates...

First, a little definition.

The adsorber valve is actually located on a can that has activated carbon inside, it is actually installed in the gas tank (or nearby, maybe in the power system) and absorbs excess gasoline vapors. This “can” absorbs them, condenses them and sends them back to the power system. But for proper and long-term operation it must be ventilated.

Signs of malfunction of the adsorber valve (absorber)

According to the requirements of new environmental standards that limit the content of harmful substances in exhaust gases, vehicles must be equipped with an EVAP system.

This equipment prevents harmful fuel fumes from entering the atmosphere. The main function in the fuel vapor recovery system is performed by the adsorber. Some people underestimate the importance of this element in the operation of a car. However, a malfunction of this seemingly minor component can lead to damage to the fuel pump and affect the operation of the entire engine. Therefore, experts recommend checking the adsorber valve when signs of engine malfunction appear. Purpose and principle of operation of the adsorber purge valve

The EVAP system is installed on gasoline internal combustion engines to prevent fuel vapors from entering the atmosphere. The canister purge solenoid valve is an element of this system. Therefore, to find out what the canister valve is for and how it works, it is important to understand the operating principle of the entire system.

The design of the adsorber is a container filled with an adsorbent, most often activated carbon. The device is connected to the fuel tank and the control valve of the vehicle using special tubes.

The canister valve is installed between the intake manifold and the canister and performs the function of ventilation.

Gasoline vapors formed in the fuel tank penetrate the separator, where they condense and are discharged back into the tank. Some of the vapor does not have time to condense in the separator and enters the adsorber through the steam line. In the filter system, they are absorbed by activated carbon, accumulated and then supplied to the intake manifold when the engine starts.

The process of absorption of fuel vapors takes place only when the engine is turned off. When the car is running, the electronic control unit opens the canister purge solenoid valve, through which air enters and thus ventilation occurs. In this case, the accumulated condensate along with air is sucked out of the adsorber and again enters the engine, where it is burned out. The canister valve provides ventilation to the entire mechanism and directs fuel condensate back to the engine.

Malfunctions of the adsorber valve and their elimination

Almost continuous operation of the fuel vapor absorption system canister can cause damage to the purge valve. A malfunction of the canister valve often leads to damage to the fuel pump. Due to poor ventilation of the adsorber, gasoline accumulates in the intake manifold, the engine loses power, and fuel consumption gradually increases. This may cause the engine to stop completely. The operation of the entire vehicle depends on how the adsorber valve works.

How to check the functionality of the canister purge valve?

In order to notice and correct problems in time, regular checks of the adsorber valve are necessary. In this case, a breakdown can be identified by certain indirect signs.

When the engine is idling or in cold weather, the vapor absorption system makes characteristic sounds, like the canister valve clicking. Some people confuse this sound with a faulty timing belt, rollers or other parts. You can check this by sharply pressing the gas pedal. If the sound has not changed, it means the canister valve is clicking. Experts can explain what to do if the canister valve knocks too loudly. To do this, you need to tighten the adjusting screw, and first it is cleared of epoxy resin.

The absorber valve can be adjusted.

The screw turns approximately half a turn. If you tighten it too much, the controller will generate an error. This adjustment of the adsorber valve will make its operation softer and the knocking noise quieter.

However, how to check the adsorber valve for damage?

Valve failure can be determined using an error diagnostic system or mechanical testing.

Electronic error codes are stored in the controller's memory and indicate electrical damage. To check the valve, it is recommended to pay attention to errors generated by the controller, such as “open circuit of the canister purge valve control circuit.”

Signs by which a malfunction of the adsorber valve can be mechanically determined:

- The appearance of dips at idle speed of the engine.

- Very low engine thrust.

- There is no sound of valve operation when the engine is running.

- A hissing sound when the gas tank cap is opened indicates a vacuum in the system.

- This is a sure sign of a malfunction in the adsorber ventilation.

- The appearance of a fuel smell in the car interior. However, its appearance can also be caused by other reasons.

What's the result?

Considering the above information, it is clear that the canister and the canister valve perform important functions. Moreover, system malfunctions can have a serious impact on engine performance. As a rule, the signs and symptoms of valve problems discussed above often indicate the need for in-depth diagnostics. In this case, the fuel vapor ventilation system is often the culprit.

We also recommend reading the article about what an adsorber is. From this article you will learn about why this device is needed, what functions it will perform, as well as what signs and symptoms indicate that the adsorber is faulty and needs to be checked, serviced or replaced.

For this reason, experienced specialists recommend regularly performing both computer diagnostics of the car and periodically performing mechanical checks (assessing valve performance, engine performance in different modes, etc.). This approach allows you to avoid unexpected breakdowns, as well as significantly increase the overall life of the internal combustion engine, gearbox, and other components, assemblies and systems of the vehicle.

What is an adsorber, what is it used for and how does it work? Replacing the VAZ 2110 adsorber with your own hands

According to the Euro-3 European environmental standard, the release into the atmosphere of hydrocarbon vapors that arise during the evaporation of gasoline is prohibited. Taking this into account, scientists have come up with a device that allows them to capture and neutralize the vapors described above.

This “saving” device was the so-called adsorber or, as some call it, “absorber” (from the word absorbent - capable of absorbing, in part, this name can also be considered correct), it is installed in the fuel system of a car in order to eliminate harmful vapors that result from the evaporation of gasoline.

Today, we will try to answer the most popular questions related to the adsorber, so that you can find out what it is, what it is for, and how the fuel system adsorber works. As an example, we will take the VAZ 2110.

The absorbent that absorbs hydrocarbon vapors is coal, which is used to fill the adsorber tank. Where do the pairs come from? Vapors, as mentioned above, are released by gasoline due to heating of the fuel and constant agitation during movement; the vapors rise upward, then through the hole in the neck of the tank they enter the separator. In the separator, the vapors condense and flow back into the tank, and part of the gases that did not have time to go from a gaseous state to a liquid state or, simply put, to become a condensate, flows through the steam line into the gravity valve and directly into the adsorber, which it neutralizes with activated carbon. This process occurs when the motor is not running.

If the engine is running, the control system purges the adsorber by opening the solenoid valve, after which harmful vapors along with air are emitted into the intake pipe, where they are burned.

The benefit of such a system is double, because first of all, there is no pollution of the atmosphere with harmful fumes, in addition, fuel savings occur, since gasoline does not evaporate, but is returned through the separator to the tank.

Removal Features

The VAZ absorber is sometimes removed completely. To do this, you need:

- replace the gas tank cap with a leaky one;

- plug the supply and discharge pipes;

- often change the ECU firmware.

As mentioned above, you should not approach the adsorber as an unnecessary thing, and if you decide to remove it, remove it correctly so that the gas tank remains ventilated and not tightly sealed, as if there is an adsorber. Those who convert a carburetor engine to an injection engine have an advantage. If they do not touch the tank pipes, they do not disturb the carburetor ventilation system of the tank, so they do not need an adsorber.

Where is the adsorber located on the VAZ 2110?

In order to find the adsorber, you need to lift the hood and look in the near left corner, there you will see a small black cylindrical jar.

Replacing the VAZ 2110 adsorber is a simple procedure; it consists of buying a new adsorber, removing the old one and connecting all the hoses in accordance with how they were connected.

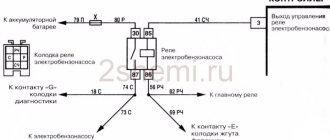

VAZ 2110 adsorber diagram

In a car, the adsorber absorbs fuel vapor from the gas tank ventilation system and supplies it to the intake, because according to environmental standards, the gas tank must be isolated from the atmosphere.

From Wikipedia ;

Adsorber (from Latin ad - on, with and sorbeo - absorb) is a device for absorbing (thickening) a surface layer of a solid, called an adsorbent (absorber), of dissolved or gaseous substances, not accompanied by a chemical reaction. The adsorber is used in chemical, oil refining and other industries. The process occurring inside this apparatus is called adsorption.

Now the first question is - why filter gasoline vapors if they still go into the intake? The answer is simple - adjusting the internal combustion engine control program by adding the nth number of clean air at the inlet is much easier than making adjustments based on the fuel-air mixture (gasoline vapor from the tank) of an unknown proportion.

And now the answer to the main question - why delete it? So, although some manufacturers claim that this device will have enough resources for the entire life of the car, we know that they are lying)

In general, over time, the adsorber becomes clogged and stops passing air. As a result, we get excess pressure in the tank, which interferes with the normal operation of the fuel pump. In the cabin (sometimes under the hood) we get a periodic smell of gasoline, the vapors of which are squeezed out of the ventilation tube. And the engine starts running on a rich mixture due to lack of air.

Now guess how our country solves this problem? That's right, most people simply throw out the adsorber and turn off the system as shown in the diagram:

A fuel filter from a carburetor classic is usually placed on the tube from the gas tank, and the solenoid valve, through which clean air should flow into the engine, is simply shut off with a bolt.

In the picture I already wrote that this is wrong and here’s why. This method of removing the adsorber only partially solves the problem. Yes, the smell of gasoline disappears, the tank is ventilated, but no air is supplied to the intake and the engine continues to run on a rich mixture.

And now the following diagram:

Well, now a couple of visual photos of what it all really looks like:

Everything is clear here, one tube goes to the gas tank, the second through the valve to the engine.

Dear friends, today we will find out why an adsorber is installed on a VAZ, what an adsorber valve is, how this whole system works and why it is needed in general. Let's start with the fact that the adsorber is primarily needed not only so that your car complies with Euro 2, 3, etc. standards. but also so that your cabin does not smell of gasoline and there is no excess pressure in the tank. Many owners of cars of the tenth family are confused by the size of the adsorber on the VAZ, they say it takes up too much space and why is it needed at all. And he is needed. If you want to free up space, install an adsorber from Priora on a VAZ-2110 and sleep peacefully, install signals from KamAZ trucks, additional washer reservoirs in the freed-up space, or just admire it