A modern car has an ECU that controls the main systems of the car, receiving information from various sensors. The article explains where the oil pressure sensor (OPS) and the oil level sensor are located on the VAZ 2109, their purpose, diagnostic features, and provides instructions for replacing these devices.

What you need to know about DDM?

If the indicator lights up indicating low oil pressure, this does not always mean that there is not enough lubrication in the system. It is possible that the DDM is faulty. In order to find the true cause, you need to know what the device is and how it can be checked.

Purpose and location

The DDM consists of a housing, a membrane and a transmitting device. The membrane becomes deformed when oil begins to press on it. Deformation of the membrane is reflected in the rheostat, whose resistance changes. The ECU records changes and reflects them thanks to an indicator on the instrument panel. The controller on the VAZ 2109 is located under the oil filter on the cylinder head on the side where the carburetor is located.

DDM location

Diagnostic features

Before diagnosing the DDM, you should check the oil level in the system using a special dipstick and an oil filter.

One of the simplest diagnostic methods is to check the presence of pressure in the lubrication system. To do this, you need to unscrew the DDM from the socket and manually turn the crankshaft several times. If grease flows or splashes out of the socket and the control light remains on, this means that the pressure is OK and the cause of the malfunction is in the controller.

The process of unscrewing the DDM from the socket

Next, you should visually inspect the device itself. If no mechanical damage is detected, it must be cleaned with gasoline and screwed into the old place. If after this the light does not go out, this indicates that the device is broken and must be replaced.

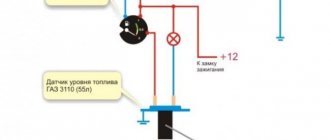

For the second method of checking, a pressure gauge is required. The controller is removed from the warm engine and screwed into the pressure gauge; the adapter from the pressure gauge is screwed into its place. The control LED is connected to the positive terminal of the battery and the controller contacts. Then the running engine should gradually pick up speed until the pressure gauge shows a value of 1.2-1.6 bar. If the controller is working properly, the LED will go out. Otherwise the device is faulty.

On a note

Don’t fall into a premature panic, draw too hasty conclusions, drive to a service station and pay money for faults that might not even exist! An emergency pressure lamp indicates a drop in lubricant pressure in the system, insufficient oil level in the engine, but it is not yet a fact that this is the reason. A fairly common malfunction is when the oil pressure sensor itself has failed and, accordingly, simply “lies.” If you don't notice this right away and don't understand the reason, you can really waste a lot of money or cause yourself more serious problems.

Important information about the oil level sensor

The health of the engine can be judged by various signs. One of them is the oil level. If oil consumption has increased, this means that there are some problems in the system that need to be corrected.

Purpose and location

The main purpose of the oil level regulator is to control the lubricant level so that the mechanisms and components of the engine function normally.

The VAZ 2109 oil level controller is located between the oil filter and the oil pan at the bottom of the engine. It is inserted into the hole intended for it in the power unit housing.

Diagnostic features

A sign of a malfunction of the device is the lighting of the indicator indicating insufficient oil level, despite the fact that in fact it meets the norm. You should regularly measure the oil level using a dipstick. If it is insufficient and the indicator does not light, this is also a sign of a sensor malfunction.

Diagnostics of the device is performed using a multimeter set to ohmmeter mode. One probe is connected to the controller body, the second to the output. By moving the float, we measure the resistance of the device. When the float is in the upper position, the resistance should tend to infinity, in the lower position it should drop to zero. If this is not the case, the sensor is faulty and must be replaced.

Replacement instructions

Replacing the regulator is easy and consists of the following steps:

- First, remove the negative terminal from the battery.

- Next, the plug with wires is disconnected.

- Then the fastening bolt is unscrewed with a “10” key and the controller is carefully removed from the crankcase.

- A new device is installed and the mounting bolt is screwed on.

- Then a block with wires is connected to it and the removed battery terminal is returned to its place.

Photo gallery “Replacing the lubricant level regulator”

Monitoring the health of the sensors ensures the correct operation of the vehicle, since based on their readings the ECU controls its systems.

What to do if the sensor lights up

If the oil pressure light on the dashboard comes on and does not go away for a long time, it can be assumed that there are problems with the engine. Sometimes this may be due to a loose wire.

There are several main reasons why the warning light on your dashboard comes on. These include:

- installation of a low-quality oil filter. Low quality filters are not able to retain oil after the car is stopped. The solution is to replace the oil filter;

- insufficient oil level. In this case, it is necessary to add oil to the required level and find the cause of the leak;

- oil pump damage. It is recommended to have this problem repaired at a service station.

Thus, the oil pressure sensor on the VAZ-2109, despite its small size, plays a rather important role in ensuring the correct and stable operation of the car.

It requires constant monitoring and, if minimal signs of malfunction appear, mandatory replacement. This is the only way to extend the life of the engine of any car and avoid unnecessary financial costs that may arise due to sensor malfunctions.

How to replace the oil level sensor on a VAZ 2108-VAZ 21099?

Removal: 1) First, disconnect the battery by using a wrench to loosen the nut that secures the “-” terminal, and after loosening, remove the “-” terminal from the battery. (How to loosen the nut securing the “-” terminal and then remove this terminal from the battery, see on our website in the article: “Replacing the battery”, point “1”)

2) Next, go to the sensor that measures the oil level, and then disconnect the block with wires from it by hand.

3) After the block is disconnected, use a wrench and use it to completely remove the single bolt that secures the sensor.

4) And to complete the operation, carefully remove the sensor from the hole in the engine crankcase.

Installation: 1) First install the new sensor into the hole in the engine crankcase, and then tighten one single bolt that secures it.

2) Then connect the wire block to this sensor.

3) And at the end of the operation, install the “-” terminal on your battery, using the same article that describes “Replacing the battery”.

Replacement

Replacing the DUM is not some difficult or complicated task. Any novice driver is quite capable of carrying out the replacement, and to make this work easier, we have prepared instructions. So let's get started:

- First, we place the car on an overpass or inspection hole.

- Turn off the ignition and remove the wire from the negative terminal of the battery.

- We dismantle the engine protection.

- Remove the wire tip from the DUM block (it is located near the oil filter).

- Using a rag, clean the upper part of the measuring device from dust and dirt.

- Take a 10mm socket wrench and unscrew the fastener.

- Gently rocking from side to side, we remove the part from its seat, trying not to damage the float.

- We take a new DUM and carry out the work in reverse order.

The structure of alerting the driver about the operation of the lubrication system also includes an emergency oil pressure sensor.

It also sometimes breaks down and requires replacement. It consists of a housing in which the measuring membrane is located, as well as a transmission mechanism. This membrane can bend and take one or another position. At the same time, it closes or opens the contacts. The easiest way to check the functionality of this device is to replace it with a spare one. If there is no spare, then check by connecting a pressure gauge. It is installed in place of the sensor and the engine is started. At idle, its readings should be at least 0.65 kg/cm2. If this is the case, then the pressure in the engine is normal, and the removed device is out of order and must be replaced.

This device cannot be repaired, since it is unprofitable, and the price of a new one is not so high.

Sometimes this trouble, when the red light with an oil can blinks, can happen on the road when there are no instruments at hand. In this case, you can use the so-called traditional method of checking DADM. To do this, you need to remove it and crank the starter (without starting the engine!). Oil should squirt out of the mounting hole. If this happens, then there is pressure in the engine and, at least, you can get to the garage, where in a calm atmosphere you can find out the cause of what happened.

Does the VAZ-2109 oil pressure sensor work?

To determine if it is correct, you need to check the engine oil level. To do this, you need to open the hood and pull out the dipstick. In order to check more accurately, you need to do this:

- drive into a pit and remove the protection;

- get close to the sensor;

- turn on the ignition;

- disconnect the power cord;

- Use a voltmeter to measure the voltage between the block and ground. It should show 12 volts.

If there is no voltage, then there may be a problem in the contact or a broken wire.

Device DDM VAZ2109

Main components of DDM:

- Frame

- Measuring membrane

- Transmission mechanism

Operating principle of DDM

Depending on the pressure in the oil system, the membrane bends and at the same time closes or opens electrical contacts. Before checking the pressure sensor (controller), be sure to check that the engine oil level and oil filter are in order. Visually check for any lubricant leaks on the motor housing. If everything is in order, we can move on to checking the controller himself.

VAZ-2109 owners check the sensor in different ways:

First.

Remove the DDM located above the oil filter, turn the starter, the engine cannot be started during such a check. If all is well, oil should flow out. Then visually check the condition of the sensor. If there is no damage, then wash it with gasoline. They are installed in place. The light will go off. If it continues to burn, then it needs to be changed. Second. Check the oil level. If it’s low, add lubricant, then check again whether the light is on or not. Next, warm up the engine and then turn it off. Then connect to a pressure gauge. This adapter from the pressure gauge is screwed into place of the sensor and grounded through the ground of the car. Connect the signal LED to the battery positive and the sensor, start the engine and step on the gas. When the pressure gauge reads 1.2-1.6 bar, the LED goes out. If it lights up, then the DDM is broken.

The car owner must always monitor the condition of the DDM. After all, he also has problems. And these problems can affect the technical condition of the machine. You should not allow breakdowns, because if the engine jams, this will lead to large financial expenses.

Checking the pressure controller using a pressure gauge

The second method is more accurate and involves the use of special devices. Note that this method can also test the bypass valve at the same time. The preheated engine, into which the required volume of oil is poured, is turned off. The sensor removed from the engine is screwed into the pressure gauge. In place of the sensor, screw the adapter of the monitoring pressure gauge.

As a result of these connections, the pressure gauge and sensor should form a single circuit that records the impulse from the lubrication system to the indicator. Next, start the engine, its speed is gradually increased until the pressure gauge shows a value of 1.2-1.6 bar. If the sensor is working properly, the LED goes out. If it continues to light, it means the controller has failed.

Checking the oil receiver

As a rule, the oil receiver tube is equipped with a screen, at the end of which there is a mesh to prevent the penetration of large debris. Through this element, oil is sucked into the pump from the crankcase. Pump wear can occur due to carbon, contaminants, or other microscopic particles. To check the oil pickup you need:

- remove the oil pan from the engine;

- The element is replaced when it becomes clogged or broken;

- It is quite difficult to clean the oil receiver, since small debris may not be noticed.

Design

Today there are three types of pumps:

- 2-gear pumps, in which one gear is connected to a shaft, which starts working from the intermediate or camshaft of the VAZ. This pump is installed inside a sump located in the lower area of the cylinder block. Typically, the rotation speed of the element is ½ the rotation speed of the motor.

- A gerotor pump has a rotating small gear inside an outer gear. This pump is located in the lower area of the motor in the sump.

Old style oil pump

- The internal pump is often installed on the front cover of the engine. It begins to function from the crankshaft. Structurally, such a mechanism is similar to a gerotor mechanism, but in this situation it replaces the front damper of the engine. As a result, it is possible to generate higher oil flow with higher pressure.