Actually, replacing the crosspiece (it is precisely the cardan transmission) is intended to relieve the shaft from vibration. But it often happens that this procedure does not help at all, and even the vibration even increases with a new cross. There is only one reason for this - unprofessional repairs.

Important! Repairing any part of the car, carried out by a non-professional, risks causing even greater problems, so the car owner will also have to pay for the consequences of the services of a would-be specialist. Especially when it comes to such an important car part as the driveshaft.

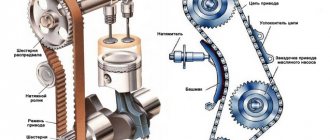

In fact, the smooth movement of the machine depends on the operation of this mechanism, which is responsible for transmitting torque from the engine to the drive axle. When vibration occurs in the cardan, the car becomes unstable, difficult to control, and its transmission begins to wear out at an amazing rate. There can be several reasons for the occurrence of vibration in the cardan drive, and not all of them are associated with wear or breakage of the spider:

- imbalance of driveshaft elements caused by either deformation, mechanical damage, or corrosion;

- wear of certain elements;

- breakage of the outboard bearings or loosening of its fastening;

- vehicle overload;

- wear or breakage of the crosspiece.

As you can see, vibration can occur in different elements of the driveshaft, and most of the reasons that cause it are associated with play in certain moving joints. Therefore, before rushing to change the crosspiece, you should conduct a thorough diagnosis of this entire mechanism. Otherwise, you can spend money on spare parts, pay for the work of a technician - and still the problem will not go away.

Cardan shaft diagnostics

The process of diagnosing these elements occurs as follows. If it was not possible to identify the cause of the malfunction during a visual inspection (in case of serious breakdowns, the malfunction can be determined with the naked eye), then the element is disassembled and completely removed from the car. Its rotating components are placed on a balancing stand, while the static ones are cleaned of dirt and scrupulously inspected for mechanical damage. The suspension bearing is also checked for play. Only after the cause of the vibration has been accurately determined can we proceed to repairing the cardan.

Intermittent or constant squeaking

Periodic squeaking occurs when you press the gas pedal, and disappears when coasting. In some cases, the appearance of a squeak depends on the temperature outside, as well as the angle of operation of the hinge - cross or CV joint.

- The driveshaft crosspiece is jammed. As a rule, it is accompanied by the presence of rusty smudges on the crosspiece. Syringing won't help. Jamming means that the cup bearing has become deformed. The next stage will be its destruction. It is necessary to replace the hinge as soon as possible.

- The CV joint of the cardan wedges in the operating range. Go through, carefully inspect for wear and tear and lubricate, if that doesn’t help, replace.

Cardan vibration after replacing crosspieces

It often happens that the vibration of the cardan after replacing the crosspieces again manifests itself in a seemingly already repaired part. This is due to its incorrect assembly. Experienced craftsmen know how important it is during the process of replacing the crosspiece and subsequent assembly of the driveshaft to maintain the original factory position of the parts relative to each other. Therefore, before disassembling, marks are placed on its parts, with the help of which the “polarity” of the sliding forks will subsequently be maintained. If this is not done, the repair will lead to dire consequences: vibration due to imbalance of the driveshaft will not only not disappear, but, on the contrary, will intensify.

The curious thing about the current situation is that if marks were not placed on the components of the cardan before disassembling it, it will not be possible to determine whether the assembly was carried out correctly. The only thing that can be recommended in this case is to disassemble the crosspiece and reassemble the shaft. Of course, without forgetting to mark the location of its components relative to each other.

Worn or warped brake discs

These elements are installed on the hub and are clamped by pads when the speed decreases. There is practically no gap between the disc and pads. Therefore, the surface of the assembly must be perfectly flat. The slightest distortion of the disc causes the steering wheel to vibrate at speeds of 90-100 km/h. Warping of brake elements most often occurs due to frequent and intense braking, as well as when driving through deep puddles. The heated disk bends due to sudden cooling. This element cannot be repaired - only replaced.

Why does the vibration not disappear and the rear universal joint is faulty?

It often happens that when vibration occurs, the rear universal joint spider became the cause of the malfunction because it was worn out. But even after replacing it, the problem did not disappear. In such cases, it makes sense to once again check the balancing of each of the shaft components. With the new parts, the alignment has changed, and most likely the reason now lies in its imbalance.

Important! Before performing additional balancing of the shaft, you can try to change the location of the crosspiece elements - otherwise the master will in vain cut off a layer of metal from the element.

Incorrect installation of retaining rings

Retaining rings in a newly installed spider rarely fit completely into the existing driveshaft. Therefore, during installation, gaps may form, leading to vibration, or the elements may fit too tightly. In the second case, rotation will be difficult, so craftsmen resort to grinding off metal on opposite rings. This process requires the gradual removal of a small layer of metal, so emery stone is most often used. The ideal position of the flange is when it lowers freely with slight pressure.

When installing a new crosspiece, you can use old rings. However, they must first be cleaned, as well as the recesses in which they are installed.

Replacing the outboard bearing

In many cases, the cause of vibration of the cardan is the suspension bearing: either the play formed as a result of its wear, or loose fasteners with the help of which it is rigidly fixed to the bottom of the car. If the vibration is accompanied by a hum, then most likely this is the problem. Suspended bearings can be dismountable or non-separable. If the former can be repaired by replacing failed elements, then the latter have to be replaced completely.

Important! The suspension bearing, just like the driveshaft itself, requires balancing. If this procedure is not performed, the problem may occur again.

Wheels do not comply with factory recommendations

A car rim has its own parameters - width, tire mounting diameter, offset, as well as the diameter of the drill, i.e. the circle on which holes are drilled for mounting bolts or studs. For each wheel model, the number of these holes and their diameter are indicated. If the disk parameters are incorrectly selected, the mount will not screw in completely and will not press the wheel tightly to the hub. As a result, the disk has play. If the diameter of the holes drilled does not match, the wheel will also not sit in its place. Of course, it can be planted using physical force. However, the plane of the disk will not coincide with the parameters of the hub. This is not good for the car.

Engine and gearbox vibration

If even after this the vibration does not go away, the crosspiece may have nothing to do with it. There are cases when such a problem in the driveshaft does not appear as a result of breakdowns of any of its components, but is transmitted to it from the engine or gearbox. The probability of such malfunctions is small, but it cannot be reduced to zero either.

If the cause of the vibration of the cardan is the gearbox, then this malfunction will make itself felt by other signs - for example, jumping out or slipping of the gear (if we are talking about a manual gearbox) or a grinding and knocking sound that appears in the gearbox when changing from one gear to another.

As you can see, there are many reasons why vibration occurs when a car is moving, and not all of them are directly related to the driveshaft. Only high-quality diagnostics of the car’s chassis, performed by car service professionals, can accurately determine its cause.

Painfully banal

If the body vibrates when accelerating, you should not be upset and immediately count out a large amount for repairs. Below are some common and not so common cases that can cause discomfort when driving:

- Dirt or ice block stuck to the inner rim of the wheel rim. Diagnosing the adhesion of dirt is not difficult, since noticeable beating will occur only after off-road driving. In winter, every driver should be prepared for such troubles;

- Incorrect installation of brake and wheel discs. If the mating plane has not been cleared of contaminants or is deformed, this will cause an increase in vibration load during movement;

- discrepancy between the landing dimensions of the wheel rims. Each disk has its own installation parameters, violation of which can lead to imbalance. This mainly concerns disc bolt patterns;

- loose disk fastenings. This is the first thing to check when you notice runout in the steering wheel. The consequences of neglecting this advice can be very dire.

What to do with a faulty clutch

If you notice vibration of the clutch pedal when pressed, you need to contact a service center as soon as possible, because if you ignore the first signs of a malfunction of the mechanism, then in the near future you will face serious problems and expensive repairs.

Vibration and unit failure may be caused by a malfunction of the driven disk

To solve the problem, it is necessary to remove the mechanism and inspect it, paying attention to existing damage, deformations and defects. If present, the unit needs to be replaced

If the vibration is caused by a malfunction of the clutch hydraulic system, a thorough check of the pipelines, master and slave cylinders is necessary. The reason may also be air trapped in the hydraulics. In this case, it is enough to remove it, and the pedal will work flawlessly when pressed.

Please note that you can save time and avoid unnecessary disassembly of the clutch mechanism by first making sure that the pedal travel is sufficiently free. This is done by measuring the free play of the pedal thrust pad (in domestic cars it should vary between 20-30 mm).

You can get acquainted with information about the free travel of the pedal when pressing it in the car’s service book or on the website of the automaker.

If the free play is within normal limits, but the clutch pedal continues to vibrate when pressed, you should contact a car service center as soon as possible. You should not disassemble and reassemble the clutch mechanism yourself, especially if you have no experience in this area, since the consequences for the car can be disastrous.

We recommend

If you nevertheless decide to independently cope with the vibration of the pedal when pressed, carefully disassemble the “basket” of the mechanism, carefully inspect the discs, check how worn the parts are, what condition the springs are in, whether there is lubrication in the unit.

In addition, vibration of the pedal when pressed can be caused by problems with the release bearing, which also needs to be inspected.

Engine vibrates when starting

A fairly common situation is when vibration occurs when starting the engine, and it is the cold internal combustion engine that starts. However, after the engine warms up, vibrations may not be observed during subsequent starts. These signs and symptoms usually indicate the following problems:

- Problems with spark plugs. A normal candle should be light or light brown. If there is carbon deposits on the spark plug and the electrodes are covered with deposits, then it loses its ability to promptly ignite the working mixture of fuel and air in the engine cylinder. In simple words, when starting, the engine begins to rev, the speed may fluctuate, and strong vibrations are felt in the cabin.

- Contaminated or malfunctioning injectors, clogged fuel filters, unstable operation of the fuel pump, airing of the power system, the use of low-quality gasoline or diesel fuel, as well as problems in electrical circuits can also cause the engine to oscillate and vibrate after a cold start.

As mentioned above, engine mounts and mounts can be damaged. In this case, a cold engine vibrates most strongly, that is, when the temperature in the engine compartment has not yet risen. Often, as the rubber in the support structure warms up, it softens somewhat, after which the intensity of the vibrations decreases. For an accurate determination, you need to check the engine mounts using one of the available methods.

Problems with idle speed, ECM sensors, or actuators often cause the engine speed to float or jump when the engine is cold. During speed surges, the crankshaft speed can drop to such low values that the engine almost stalls. At this moment the vibrations are especially strong. It is necessary to check the injectors, IAC, mass flow sensor and other elements.

https://youtube.com/watch?v=fPrVIlGMM7U