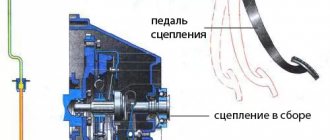

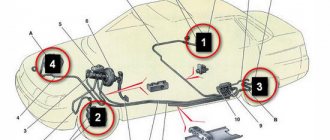

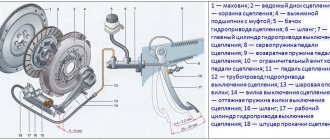

Bleeding the clutch, as well as the brakes, on the UAZ “Loaf” is not a very common procedure. Although it does not require any special tools or skills, car enthusiasts often ignore this procedure during regular inspection of their van. But in vain. After all, removing air from the hydraulic system, which necessarily gets there after replacing the working fluid or reinstalling components, is necessary for the proper operation of the mechanism.

Bleeding the clutch after replacing the master cylinder of a UAZ loaf

I have the following problem: I replaced both clutch cylinders on the tablet and installed new ones.

started pumping and air came out. Already 3 days - air, air. and there is no end to it. I've already drained a bucket of liquid and no results. there are no drops or leaks anywhere. Bleeding hose is new and transparent. I've had this operation done more than once before and there were no problems. what could be the reason? where do tons of air come from? Boo ga ga. A familiar picture. Air bubbles that come out of the drain tube appear due to air leaks through the threads of the bleeder fitting. So you can skip a tank of brake fluid or two and there will still be bubbles. It may partially help if you generously lubricate the threads of the fitting with grease. It seals the thread a little. But it's better not to bother. Check pedal travel and clutch operation. I am 100% sure that they are working great for you now. So stop downloading and start riding. :D

Threat. There is no need to pump the clutch at all. The line there is short and the air is removed simply by gravity. Well, if you really want to pump it, then it’s better to do it with the control center removed from the mount. Because the basket spring is very strong and it manages to push the RCS rod at the same time or a little earlier than the GCS piston returns to its original state. Those. when the RCS is stationary, it is impossible to pump up pressure with the pedal.

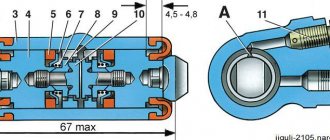

What lubricant is best to use to seal threads? As I understand it, it should be very viscous and dense. Nothing comes to mind. I would like it to become friends with the seals if something happens. And one more question. GCS 2101 Ate, the fitting is screwed in, in addition to the copper washer, with some kind of sealing grease - very hard (probably hardens over time), apparently for additional use. seals and against loosening. It smells neither of ascorbic acid or aspirin, nor of vitamin C))) What can I use? I plan to grind a new fitting for the UAZ standing tank.

I never really thought about it. I coated the threads of the fitting with simple lithol. There's no need to download. And for gravity flow, sealing with lithol was quite enough. And then I didn’t smear anything else at all. It’s just that when the air is forced out of the cylinders and the circuit, there is no brake fluid in the transparent hose at all. And as soon as the brakes go, that means everything. Well, I’ll let the brakes flow a little longer to clear my conscience. At the same time, I don’t pay attention to small bubbles. 10 milliliters. I tighten the fitting and try to press the clutch pedal. It always worked out great after that. I used to bleed the brakes, but recently I stopped doing the same. I fill it with gravity, then I spread the pads all the way on all wheels and try the pedal. If it sticks, it means there is no air in the system. There was always a stake. That's why I don't pump anymore.

I can’t tell you about the sealant for the fitting on the tank. Some kind of special sealant that is resistant to brake wear. IMHO if there is a copper sealing washer, then you can do without it. And then you decide for yourself.

I have the following problem: I replaced both clutch cylinders on the tablet and installed new ones. started pumping and air came out. Already 3 days - air, air. and there is no end to it. I've already drained a bucket of liquid and no results. there are no drops or leaks anywhere. Bleeding hose is new and transparent. I've had this operation done more than once before and there were no problems. what could be the reason? where do tons of air come from?

They showed me a good way. Use a fork to move the working cylinder rod inward as far as it will go, with the bulk of the air going into the tank, then pump the remainder as usual.

I always bleed it by removing the rod from the clutch slave cylinder. Then the piston of the clutch slave cylinder rests against the inner ring and can be pumped like brakes, that is, by pumping the pedal all the way.

If the clutch master cylinder is from a classic Lada, then it’s even easier. Just unscrew the bleeder fitting and wait until the air comes out and the brakes start to flow.

It looks like you have a paw basket. If so then:

You need to check the travel of the fork. The fact is that when squeezing, the fork can rest against the flywheel housing, then it will break. The second thing is to check the adjustment of the paws. If the paws are not at maximum reach, it may turn out that the paws do not have enough travel. That is, the movement of the legs has already ended, and the fork is still pressing on them. In this case, the plug will also break.

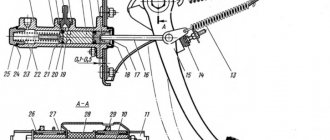

What needs to be done: 1 Completely loosen the fork: remove the clutch slave cylinder with the adjusting rod. In this case, the fork with release under the action of the spring should go as far as possible to the gearbox. (If the release spring is weak and does not tighten the fork, then it must be tightened) 2 Bring the basket legs as close as possible to the release spring, and after approaching, release the adjusting bolts (nuts) by about 1/8 of a turn. (In other words, the release will serve as a measuring plane to align the paws equally.)

After operations No. 1 and No. 2 have been completed, we have normal conditions for the operation of the mechanism.

3 Install the clutch slave cylinder and make sure that the adjusting rod is not too long. If necessary, shorten the rod to the required size. (the rod should be of such length as not to interfere with the fork returning to the zero position as close as possible to the gearbox) But the rod, of course, should preferably be adjustable in length. That's basically all. If this is all done correctly, then everything should work fine.

The thing is that my tank is plastic. We need to come up with a seal between it and the cylinder. I'll try one made from oil- and petrol-resistant rubber first. And the thread is so that the tank does not suddenly unscrew. I'll also try lithol at the RCS. Well, with pumping, for self-soothing)

I bought a GCS from DM Gas - I sucked it in through the fastening of a plastic cup. She refused to change the receipt. I had to apply sealant. I coated the tube fitting with graphite - it was tight and worked out well. A little got into the system and didn’t do much to tint the brakes - but it’s even better, you can see the level right through the white glass =)

Check the pedal for free play and bleed with an assistant.

The issue has been resolved, pumping with an assistant solved all the problems.

Tell me, my engine is a 402 petal basket, the RCS rod is not adjustable. There is a spring on the RCS. Should she stand? When engaging 1st gear it sometimes growls. I turn on the 2nd one first, then the 1st one.

Sometimes it growls because of a dead bearing on the flywheel hub, the basket is pressed out, and the input shaft rotates due to the bearing being wedged.

In the winter, I replaced the gearbox bearing in the K/V, changed the mileage after repair, 4t.km with the old bearing, it also growled

Tell me, my engine is a 402 petal basket, the RCS rod is not adjustable. There is a spring on the RCS. Should she stand? When engaging 1st gear it sometimes growls. I turn on the 2nd one first, then the 1st one.

No spring needed. The whole point of this clutch is that there is no gap between the basket and the release, therefore no adjustment is required.

I have a question about the hose and slave cylinder seal. How is compaction achieved? Just because of the copper washer? I just looked inside the hose and cylinder and there is a cone here and there, but they are in one direction, that is, there is no seal due to them. Maybe I got the wrong cylinder or hose? Or is this how it should be?

Well, the cone stretches towards each other