Malfunctions and replacement of the VAZ 2110 throttle position sensor The VAZ 2110 throttle position sensor (TPS) is an automobile potentiometer that transmits data to the regulator about how the throttle is positioned. The latter can change its location depending on the intensity of pressure on the gas pedal. There is a voltage regulator at the base of this device.

Its readings are recorded by the controller and, taking into account the available information, it supplies gasoline in portions. If it breaks down, the controller will receive distorted information. This can lead to suspension of its operation and excessive fuel consumption.

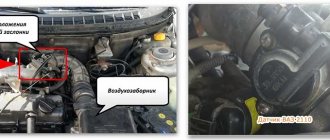

As a result of the signal pulse from the TPS, the controlling sensor evaluates the current throttle position, and the intensity of the signal change analyzes the degree of pressure on the accelerator pedal. This becomes a decisive circumstance for activating the necessary modes, as well as directing the air flow past the throttle through the idle shut-off and control mechanism. The TPS in a VAZ car is located in the engine compartment on the throttle fitting. It connects to the damper shaft.

Symptoms of sensor malfunction

The main control unit contains a program: if one of the important meters stops working, the air-fuel mixture is prepared and supplied according to average indicators, and the Check Engine warning sign turns on on the dashboard. Emergency operation with increased fuel consumption is a clear sign of a breakdown of any sensor.

The insidiousness of the TPS is that it does not break in the usual sense. When the resistive film begins to wear away, the resistance of the device changes unpredictably. The controller either “sees” a working sensor in the circuit, or notes incorrect voltage surges and tries to switch to emergency mode. From here, the main sign of a malfunctioning throttle valve is determined - a periodically flashing Check Engine display.

The problem is accompanied by a change in the behavior of the engine, or more precisely:

- “shaking” and spontaneous stops of the engine idling;

- there is no acceleration dynamics; after pressing the gas pedal, jerks and dips are observed;

- increased idle speed of the power unit (1500–2500 rpm);

- the car “does not pull” due to loss of power;

- jerks are also felt while driving;

- Fuel consumption increases by 10–25%!

The listed symptoms can be caused by a dozen reasons, ranging from malfunctions of the ignition system to wear and tear of engine parts. That is why it is important to weed out problems that lie on the surface, including incorrect operation of the throttle position sensor.

Evidence of pollution

Don't forget that the throttle valve can become dirty. Signs of this are the following criteria: the engine begins to stall, lose speed, the engine starts with difficulty, at the minimum speed of the car, jerking begins. Always check the throttle assembly for causes of problems. Damper contamination occurs in many cases. Settlement occurs on the walls of the mechanism, entering the assembly due to ventilation of gases. Another reason is poor filter performance.

The VAZ 2114 starter does not turn - the main reasons

Malfunctions

There are several telltale signs of trouble that may indicate that there is a problem with the throttle valve control.

- High idle speed;

- When the gear is switched off, the engine may stall;

- When the car picks up speed, the car jerks and jerks are felt;

- Acceleration dynamics deteriorate significantly;

- Floating speed occurs at idle.

It should be noted that similar symptoms may also be characteristic of the failure of other components - the idle speed control or the ignition module, for example. Therefore, you first need to check the TPS.

Checking the status of the regulator

Next, let's talk about how you can check this throttle valve sensor. The event is necessary because it allows you to understand whether all the troubles are really due to it, or whether the problems arose due to the failure of other elements of your car.

We recommend: Changing the VAZ 2110 crankshaft oil seal yourself

It’s not uncommon for novice car owners to make hasty conclusions based on the primary signs of a breakdown. This results in unnecessary repair work and costs.

To check the current status of the throttle position sensor you need to:

- Measure the voltage at the output of the slider, turning on the ignition and opening the idle contacts;

- If the test shows that the voltage is more than 0.7 volts, then the sensor has indeed failed;

- Open the damper completely. In normal condition, voltage readings should be no more than 4 volts;

- Measure the variable resistor for resistance;

- To do this, connect an ohmmeter or a multimeter in ohmmeter mode to the power supply and output;

- Slowly begin to turn the throttle;

- At the same time, monitor the readings on the device;

- If, as the damper opens, the resistance also changes slowly, then the unit is working properly.

If you find during the test that the sensor is faulty, you only need to replace it. It cannot be repaired.

The resistive layer along which the slider moves wears off over time due to friction. Because of this, the regulator begins to produce incorrect data, the characteristics of the supplied mixture change, and engine performance deteriorates.

Disabling the regulator

Examination

In addition to checking the sensor itself, pay attention to the condition of the throttle valve. Sometimes it becomes coked, and as a result its mobility is lost. In this case, symptoms similar to sensor failure will also be observed.

The simplest check of the sensor’s functionality can be done even without removing it from the car:

- To do this, turn on the ignition and measure the voltage at the TPS terminals, it should not exceed 0.7 V;

- Next, use the plastic sector to fully open the throttle. Then the voltage is measured again. The normal value is at least 4B;

- Then check the correct operation of the sensor. To do this, you need to measure the voltage at the TPS terminals when the damper moves.

- It should not jump sharply, all changes should occur smoothly. Abrupt changes indicate a malfunction of the device;

- The final check is to check the resistance between any of the terminals and the slider contact. To do this, turn off the ignition and pull out the connector. When turning the damper, this indicator should change evenly.

If you find out that the sensor is faulty, you should replace it. It is important to choose this design element correctly. The VAZ 2110 is equipped with 2 types of TPS. One of them is film resistive. This type is installed by the manufacturer, the sensor is designed for 55,000 kilometers. The other type is called non-contact. It uses a Hall sensor. This device has no restrictions on its service life. But it costs a little more.

Conclusion

. The “ten” is equipped with a familiar sensor. The same version of the device is installed on this entire family. In this regard, all signs of a malfunction of the throttle sensor on the VAZ 2110, with the exception of minor nuances, are similar on all cars with this sensor model. Timely repairs will save you from the hassle of having a poorly functioning machine.

The throttle unit (DU) is responsible for supplying air to the engine of the VAZ 2110 car. The enrichment of the fuel mixture with fresh air depends on its operation. And if the throttle assembly is damaged, then the functioning of the power plant is disrupted. If it breaks down, the remote control is replaced with a new one, but sometimes the result of a malfunction can be contamination of the unit or a broken TPS - throttle position sensor of the VAZ 2110. You can do both cleaning and replacement yourself.

Helpful advice: cleaning and changing the gasket is necessary every 50-60 thousand kilometers. This figure is suitable for almost all VAZ models. Then repairs and replacements will not be required. Cleaning will cost only 150-200 rubles.

TPS problems and their diagnosis

As you know, eternal parts for cars have not yet been invented. And the breakdown of the TPS can be foreseen; for this you need to inquire about the possible reasons for the failure of this part. Here are the main ones:

- Abrasion of the sprayed base layer, which serves to move the slider (the result is incorrect TPS readings).

- Failure of the movable type core (the result is deterioration of the contacts between the slider and the resistive layer).

How can you figure out problems with this sensor yourself? To do this, you can independently diagnose the operation of your diagnostics:

- Listen to the VAZ-2110 engine idling:

- the breakdown is obvious if you notice that its speed is in a “floating” state;

- Quickly release the gas pedal:

- a malfunction is present if the engine stops after this action.

- Pick up speed:

- There is a problem with the TPS if the car starts to move jerkily, which indicates an incorrect supply of fuel to the system.

Experts say that most often the sensor fails when the resistive track is heavily contaminated or is completely broken. To verify the opposite, you need to check the working condition of the TPS.

Typical TPS problems

A malfunction of the throttle sensor can be determined by the following symptoms:

- increase in speed intensity when the load is off;

- deterioration of dynamic performance;

- the appearance of jerks when picking up speed;

- sudden stopping of the engine in neutral;

- warning light with a light bulb.

In addition, there are other malfunctions. One of the most common is a decrease in the base coating thickness in the initial part of the slider stroke. This prevents the linear voltage level of the output signal from increasing. Another causal relationship may lie in the failure of the movable core. The breakage of one tip contributes to the appearance of a large number of burrs at the base. As a result, others also break, causing the slider to lose contact with the resistive part.

You can test the throttle sensor yourself by following these steps. The first step is to start the ignition; if the warning light does not light up, then we take the converter directly. Using a multimeter, you should measure the potential difference between “−” and the slider wire. The obtained parameters should not be higher than 0.7 V.

We recommend: When, according to the law, should we change summer tires to winter tires in 2022?

Next, you need to expand the sector to fully open the damper. Then you should recheck the voltage again. The readings must be at least 4 V. After this, you need to turn on the ignition and remove the connector. Again measure the resistance at the point of contact of the slider with one of the terminals. While scrolling the sector, monitor the multimeter readings.

The pointer should be moved gently and slowly, since shocks and sudden vibrations indicate a breakdown. The smooth operation of the device depends on the condition of the film resistor.

There are several types of throttle position sensor: film-resistive and non-contact. The first of them is installed by the manufacturer, the second is chosen by the car owner while driving and operating the car. The service life of the TPS may vary depending on the quality and adherence to technology in the manufacture of the device. The standard unit may not need to be changed even for 60,000 km, and sometimes it requires replacement even after 5,000 km.

When purchasing a throttle sensor, the price depends on the choice of its type:

- Film-resistive ones are the most frequently purchased among motorists due to their budget price, but their service life practically does not stand up to criticism;

- Contactless - at a higher cost (almost twice) the long period of use covers all costs. The high-quality operation of the device is due to the principle of magnetoresistance. When purchasing, you should be aware that this type of device operates at a DC voltage proportional to the throttle valve opening angle in the electric motor fuel injection system.

The sensor shaft rotates clockwise from the damper side. The service life guarantee is 3 years. Drivers do not repair the resistive sensor, but replace it with a contactless one - it is undoubtedly more reliable. Its design includes a rotor and a stator. The rotor is not affected by the magnetic field, because there is a magnet at its base. The stator is a part that is quite sensitive to the electromagnetic field. Its assembly is associated with programming, so a device of this category is often used for installation in electrical control units.

Location and principle of operation of the meter

The sensor is installed on the throttle valve block and is mechanically connected to its axis. Thanks to this, the device is able to solve 3 problems:

- inform the controller at what angle the throttle is currently open;

- signal that the air supply is completely closed (the driver has released the accelerator pedal);

- monitor the speed at which the damper opens.

Based on this information, the electronic powertrain control unit (ECU) makes a decision to increase or decrease the fuel supply and fuel injection for intense acceleration when the gas pedal is sharply pressed.

Reference. Two types of TPS are installed on cars: resistive and non-contact. The first ones are cheaper and therefore are found on all budget cars. The latter are more reliable and more expensive, and are installed on cars of medium and high price categories.

The operating algorithm of the resistive sensor is as follows:

- At idle, the damper is closed and air flows into the engine through a separate channel. The voltage at the output of the device does not exceed 0.5 volts; the controller supplies fuel to maintain engine idle speed.

- When the driver presses the gas pedal, the sensor slider moves along the resistive film. The resistance of the electrical circuit into which the device is connected in series decreases.

- The ECU “sees” the increase in voltage in the meter circuit, makes a calculation, prepares the air-fuel mixture in the required quantity and supplies it to the cylinders. The maximum voltage at wide open throttle is about 4.5 V.

- When the driver sharply presses the accelerator pedal, the controller notes a similar voltage surge and delivers a portion of the enriched mixture for dynamic acceleration.

Note. The operating voltage values are indicated for a common Russian car - VAZ 2110.

The non-contact throttle position sensor functions identically. The difference lies in the method of influencing the electrical circuit. A resistive device changes resistance using a slider moving across the film, while a non-contact device changes resistance due to the magnetic-resistive effect. Thanks to this principle of operation, the TPS lasts much longer and does not create problems for the owner of the car.

We recommend: How to install bi-xenon H4 with your own hands: diagrams and connection sequence

Why is it needed?

The throttle position sensor is responsible for determining the current throttle position. Depending on this, the fuel supply system changes the amount of fuel supplied under one or another operating mode of the power unit.

If problems arise with it, you can contact a service station so as not to waste your energy and nerves. But in practice, changing the TPS yourself is quite simple, plus you will save a decent amount of money.

The desired regulator is located on the side of the throttle pipe on the throttle valve axis.

Regulator location

Features of work

The TPS is essentially a variable resistor, one output of which is supplied with 5 Volt power. The second contact is connected to ground, and the third is connected to the controller.

When you press the gas pedal, the voltage changes. The sensor monitors the output voltage on the controller, thereby regulating and monitoring the quality of the supplied air-fuel mixture. This directly depends on the opening angle of the damper itself.

If for some reason this regulator fails, a catastrophe will not occur, since another sensor, the mass air flow sensor, will temporarily take over its functions.

This does not mean at all that the TPS can not be changed. Each regulator has its own functions, so there is no point in transferring the tasks of the TPS to the MAF.

Communication of the throttle valve with other automotive systems of the VAZ-2110

The throttle valve of a VAZ-2110 car is a component of the engine intake system and is directly connected to a large number of other vehicle systems. These include the following systems:

- directional stability;

- anti-blocking;

- anti-slip;

- anti-slip;

- cruise control.

In addition, there are those systems that are controlled by the electronics of the gearbox. After all, it is this throttle valve that regulates the flow of air into the car system and is responsible for the quality composition of the fuel-air mixture.

Checking the operation of the throttle position sensor

To check the TPS yourself, it is not necessary to call an auto electrician for consultation. To do this you need a multimeter or voltmeter. Next, experts offer step-by-step instructions for checking the sensor.

The first step is to turn the key in the ignition switch, take the voltage readings between the sensor slider contact and the minus. In normal condition, the indicator will be up to 0.7 V.

The second step is to turn the plastic sector and open the damper, and then take measurements again. In the normal state of the sensor, the device will show a result of 4 V.

Replacement

Replacing the sensor is quite simple. To replace, all you need is a Phillips screwdriver and the desire to fix your car yourself.

- Remove the connector from the sensor

- Using a screwdriver, unscrew the two screws securing the sensor

- Remove the sensor and install a new one in reverse order