Most components and assemblies of modern cars have a significant resource. With proper maintenance, they rarely need to be repaired. But this does not mean at all that if symptoms of a malfunction appear, it makes sense to postpone a visit to the service center to a later date.

- How to check a wheel bearing? Video:

- Unsuitable materials

On the contrary, the sooner the breakdown is fixed, the less money will have to be spent on repairs. After all, one, even seemingly insignificant at first glance, part, being faulty, has a negative impact on many other components of the structure.

A failed front or rear wheel bearing not only affects the technical condition of the car, deteriorating its performance, but there is a risk of destruction of the wheel mounting structure while in motion.

Such a breakdown leads to loss of control of the car and, as a result, an accident, the consequences of which can be very severe.

To prevent this from happening, you need to promptly respond to emerging alarming symptoms and take immediate action.

Why is there a bearing in the hub?

The wheel rim or the wheel rim itself is attached to the hub flange. Elements of the brake system are also installed on it. If the wheels attached to the hub are driven, it acts as part of a car transmission. The front steering wheel hub is a steering element. The diameter of the hub is significantly larger than that of its internal hole, where the bearing is pressed. Its length usually exceeds the diameter of this hole.

The high strength and design of the hub does not require frequent replacement. At the same time, replacing the wheel bearing pressed into it should be done more often. This part, together with other similar bearings, holds the weight of the machine, allowing the wheels to rotate. In the hubs of driven axles that do not experience heavy loads, single-row tapered bearings are usually used. For driving applications, tapered bearings with two rows are used, which can withstand twice the load than single-row bearings.

Wheel bearings have a closed design, which means they can be used until they are almost completely worn out. They do not need to change the lubricant. However, timely replacement of the wheel bearing is necessary, first of all, because it ensures safe movement under the influence of severe radial and lateral loads.

Varieties of nodal structures

The joint structure connects the shaft, steering knuckle and wheel. A single housing of the unit is formed by pressing technology, which is used to securely fix the bearing in the hub. It is also used for securing in the cam mechanism. An alternative option is a flange connection.

The rotation path and placement of components led to the classification into the following types:

- Double row ball (roller) bearings. They belong to the first generation of HUB I. Structurally, they are represented by an outer casing that combines 2 blocks of balls or rollers, and an internal one, divided into 2 zones. For sealing to prevent the ingress of water, dust and other contaminants, the device includes a separator with O-rings.

- Hub units made of 2 single row bearings. They are equipped with the front axles of cars with rear-wheel drive and low torque (old versions of Fiat, UAZ Patriot, VAZ models). Maintenance structures must be periodically adjusted and lubricated.

- Bearings combined with the hub. Represent the 2nd and 3rd generations of HUB II, III. In the hub body, outer and inner races are fixed through flanges. One side is connected to the knuckle, the brake disc is fixed to the other and the wheel screws are tightened. The maintenance-free design is installed on the drive and driven wheels.

In units of the 3rd type, bearings rotate along the inner and outer rings. Additionally, speed sensors and ABS are built into the mechanism.

When to change a bearing

The wheel bearing directly affects the vehicle's ability to move confidently on the road without endangering those inside and outside the vehicle. If at least one of these bearings fails, there is a risk of vehicle uncontrollability and an emergency. In order to understand in time whether the wheel bearing needs to be replaced, you should rock each wheel with both hands every couple of weeks to detect any play or extraneous sounds.

Sure signs that your wheel bearing needs to be replaced are:

- detection of noticeable play in the wheel when it rocks in different planes;

- the appearance of a monotonous hum emanating from the wheel while driving;

- howling or noise that disappears when turning sharply;

- The hub or hub cap is hot to the touch.

The reasons for such phenomena may be loss of lubricant due to high temperature, washout if the car often overcomes water obstacles. Fine sand and dust can get into the bearing housing and have an abrasive effect.

In any case, it is worth thinking about how to change the wheel bearing. After all, its wear also affects the vibration of the steering wheel when the car is moving. Usually this procedure is carried out after 110-130 thousand km. mileage However, this indicator may vary depending on the operating conditions of the car and its driving style. It is believed that every fourth car with a mileage of over a hundred thousand kilometers requires special attention to the condition of such bearings. To prevent problems with them, car owners should make it a rule to regularly diagnose wheel bearings on their own or using the services of a car service center.

At the same time, it is important to remember that attempts to repair it yourself or how to replace the hub bearing cheaper will not lead to anything good, since it cannot be repaired. If it fails, it simply needs to be replaced.

What you need to replace a wheel bearing

To replace a wheel bearing with your own hands, you need to be extremely careful and not overestimate your strength. In a service station, this is much easier and faster to do. Most of these enterprises employ experienced craftsmen who use professional tools to knock the bearing out of the hub.

Having decided to carry out the work on your own, you need to answer the question of how to remove the wheel bearing and how to replace it with a new one.

To do this you need to prepare:

- new bearing, preferably made in Europe, retaining rings and hub nut;

- hub diagram and detailed instructions for carrying out work;

- a repair room with a vice and good lighting of the unit being repaired;

- special device for removing the bearing;

- a set of keys and sockets with a knob;

- round nose pliers, which may be needed to remove the retaining ring;

- lubricant (litol);

- a piece of pipe up to a meter long as a lever.

Before starting work, you should consider in detail how best to remove the wheel bearing. When doing this for the first time, it is better to invite an assistant. The wheel bearing puller deserves special attention during preparation. With its help, you can carefully remove the bearing without damaging the wheel and other parts of the car. It is better to familiarize yourself with its structure and operating principle in advance. Typically, such a wheel bearing puller has a fairly simple device.

It is based on a metal rod and two or three metal legs connected to it. Their ends are bent inward. The paws can be easily moved along the shaft for easy grip. They can be unfolded to remove the bearing or other parts. Using the clamps included in the kit, the damaged bearing can be removed more easily. To remove stuck bearings, a service station can use either a mechanical or hydraulic puller to remove the wheel bearing. Working with the bearing removal device requires care and precision. Here a sledgehammer and a drift are unacceptable, because... the hub seat may be damaged.

Replacing the front wheel bearing

When deciding how to replace the front wheel bearing, you should consider its location. After all, the front suspension is the main part that affects the handling of the car. Therefore, it is better to do this work using a puller, which helps to remove such a bearing without any problems. First of all, you need to secure the car in a position convenient for work. Put it in first gear, place chocks under the wheels, and tighten the handbrake.

Replacing the front wheel bearing requires careful preparation of the work area. You should carefully examine the parts you are dealing with, figure out how best to remove the bearing, and prepare the necessary tools. It should be taken into account that two bearings can be installed on the front hubs of the drive wheels.

To replace the wheel bearing on the front wheel, you must:

- Using a screwdriver, remove the bearing plug from the front wheel and loosen and loosen the hub nut.

- Hang up the wheel.

- Tie the caliper to the suspension part to prevent it from hanging on the front brake hose. After this, press it out with a screwdriver and remove it from the steering knuckle.

- Unscrew the brake disc bolts from the hub and remove.

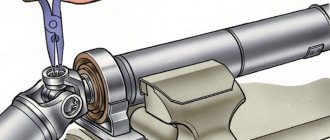

- Use a screwdriver to pry up the retaining ring and remove it.

- Using a puller, press out the wheel bearing.

- Inspect the bearing seat, clean it of corrosion and dirt, old grease, and apply new grease.

- Press the new bearing into the hub using a puller without allowing it to become distorted.

- Replace the retaining ring.

- Secure the bearing to the axle with a thrust washer and nut.

- By tightening the nut, adjust the rotation of the wheel to eliminate play.

After completing the work, make a test drive to check for noise in the bearing. After this, check again for play in the steering. There are other ways to replace the front wheel bearing. The knockout method can be used by cutting a pipe of a suitable diameter, heating the hub, etc. They require attention and caution.

Experienced auto mechanics know how to replace a rear wheel bearing. This procedure is much simpler than when replacing the front one. The hub bearings of these bearings on the rear independent suspension are almost the same as the front ones. The only difference is the absence of a steering knuckle. The type of bearing may vary depending on the machine model.

To begin with, make sure

First, you need to determine the source of the noise - make sure that it is definitely a wheel bearing. The car is driven onto a lift or placed on jacks, the wheels are hung and spun manually or using an engine. In this case, the “suspect” wheel is listened to during free rotation, that is, the gearbox is switched to “neutral” or the clutch is depressed.

The bearing is also checked for play: the suspended wheel sways in a vertical plane (up and down, away from itself). Here it is important to make sure that the detected play is caused by the bearing and not other parts of the chassis. By the way, such a check will not be superfluous during every vehicle maintenance, even if the bearings do not emit characteristic noise while driving.

Replacing the rear wheel bearing

Before replacing the bearing on the rear hub, you need to remove the wheel and brake drum as usual, and unscrew the hub nut. The brake pads can be left untouched. After removing the hub using a puller, remove the bearing from its seat. Replacement of the rear wheel bearing is carried out after a careful inspection of the hole in which it was located, cleaning it, and removing possible burrs.

The hub must be cleaned of dust and dirt, old grease. The rear wheel bearing should be replaced only after these procedures have been completed and the bearing seat has been lubricated with lithol. To do this, use a puller to press the bearing all the way and install the retaining ring. Reinstall the entire assembly in reverse order. Generously fill the bearing seat with grease. Close it with a plug placed on the sealant.

Recommendations

Replacing wheel bearings may vary from vehicle to vehicle. Modern cars may be equipped with various easily damaged electronic devices that must be removed when replacing a bearing. Therefore, if you are not a highly qualified car mechanic, it is better to entrust this work to car service specialists.

It is also worth doing a wheel alignment after replacing the wheel bearing. An adjusted wheel alignment will improve the car's road holding on turns and straights, eliminate vibration, and also reduce tire wear and fuel consumption. Vibration may also occur due to a crookedly inserted bearing. To eliminate it, you need to knock out the bearing again and check the tightness of the wheel nuts.

What bearings to put

When a wheel bearing requires replacement, the question immediately arises of which part to install. Many people advise using original components. However, today the quality of parts leaves much to be desired and the issue of choice remains quite relevant.

Table: type, installation location, and size of bearings

| Installation location | Bearing type | Size, mm | Quantity |

| Front wheel hub (outer support) | Roller, conical, single row | 19,5*45,3*15,5 | 2 |

| Front wheel hub (inner support) | Roller, conical, single row | 26*57,2*17,5 | 2 |

| Rear axle shaft | Ball, radial, single row | 30*72*19 | 2 |

Manufacturer's choice

When choosing a manufacturer of a wheel bearing for a VAZ “Seven”, we can recommend SKF , SNR, FAG, NTN, Koyo, INA, NSK. The companies listed have many locations around the world. These products are of high quality and meet the most stringent requirements.

The choice of bearing manufacturer should be given special attention, since the service life of the product depends on this

Among the domestic manufacturers that supply bearings for cars of the Togliatti plant, we can highlight:

- CJSC "LADA Image" - manufactures and sells original Lada wheel bearings through secondary markets;

- Saratov plant - produces parts under the SPZ brand;

- Volzhsky Plant - uses the Volzhsky Standard brand;

- Vologda plant - sells products under the VBF brand;

- Samara plant SPZ-9.