In rear-wheel drive cars, which include the VAZ “classic”, torque from the gearbox to the rear axle gearbox is transmitted via a cardan shaft. The design of the latter is simple and reliable. However, like all car components, the VAZ 2107 cardan requires condition monitoring and periodic maintenance. The need to repair the cardan arises in the following cases:

- the crosspiece has collapsed (worn out);

- the shaft alignment is broken;

- the outboard bearing has failed;

- The elastic coupling has broken.

To repair the driveshaft, it must be removed from the vehicle. This can be done even without an inspection hole and a lift, simply by lifting the front of the car with a jack. But this method is inconvenient and not entirely safe. Therefore, it is better to carry out work in a garage where there is a car lift or inspection hole.

VAZ 2107 driveshaft design

The driveshaft of the VAZ 2107 consists of a pair of main parts connected by means of a cross. An elastic rubber coupling is attached to the front of the cardan, providing connection between the cardan and the gearbox. The rubber of the coupling absorbs shock loads, and the spline connection allows the driveshaft to move back and forth when the angle of inclination of its parts changes or vibrations of the engine and gearbox when driving over bumps and holes.

- Bolt securing the flexible coupling to the flange

- Transmission output shaft flange

- Rubber element of elastic coupling

- Flange centering sleeve

- Flexible coupling insert

- Flexible coupling bolt

- Front propeller shaft flange

- Oil seal cage

- Stuffing box

- Gearbox secondary shaft

- Mud deflector

- Flange nut

- Centering ring seal

- Front driveshaft

- Centering ring

- Retaining ring

- Intermediate support

- Cork

- Rubber bushing

- Spacer

- Rear driveshaft

- Flange universal joint yoke

- Elastic coupling

- Safety bracket

- Balance plate

- Intermediate support cross member

- Retaining ring

- Front propeller shaft fork

- Retaining ring

- Needle bearing

- Stuffing box

- Oil seal cage

- Universal joint fork

- Cross

- Fork fastening nut

- Intermediate support bracket

- Elastic cushion

- Bearing shell

- Bearing

- Dirt remover

The main parts of the cardan are made of hollow pipe, which minimizes its weight. Less mass (which means inertia) reduces the load on the engine and transmission parts of the car.

To avoid vibration when the cardan rotates, its parts are balanced at the factory using special equipment. To ensure balancing, weights of the required weight are attached to the outer surface of the cardan.

Malfunctions of the VAZ 2107 driveline

You can determine that the VAZ 2107 driveshaft is faulty by the following signs:

- Knocking sound after engaging the clutch. The cause of the knocking may lie in a poorly tightened universal joint drive, worn splines, damaged elastic coupling, or failed crosspiece bearings.

- Grinding noise when the car is moving. This sound occurs when the cardan joint bearings (crosspieces) are heavily worn.

- Vibration of the cardan when driving. This phenomenon occurs when there is mechanical damage to the driveshaft or dirt adheres to the driveshaft, which disrupts its alignment. Vibrations also occur when there is significant wear on the gearbox driven shaft, outboard bearings, cardan crosspieces, drive gear flange of the rear axle gearbox, or loose fastening of the cardan drive.

- Knocking noise during sudden acceleration or engine braking. The reason for this lies in the wear of the cardan shaft crosspieces.

You can check the condition of the cardan drive by placing the machine on a lift or inspection hole. The transmission parts should not play when the cardan is “rocked” in different directions.

To eliminate malfunctions, it is necessary to replace the VAZ 2107 driveshaft crosspiece, coupling, and other damaged parts.

The main causes of vibration and its elimination

There are several reasons for vibration from the driveshaft:

- outboard bearing failure

; - crosspiece malfunction;

- broken spline connection;

- damage to the cardan itself.

What to do if vibration is detected, the rear universal joint or front universal joint is not in order? To get rid of vibration, you need to replace the faulty part with a new one. If the problem is in the crosspiece, then first the driveshaft is removed from the car. Using special pullers, the crosspiece is removed. After replacing with a new one, assembly is carried out in the reverse order.

It is important to respect the factory position of the sliding forks. Otherwise, the problem will not be solved, because the vibration will only intensify due to the imbalance of the driveshaft

If vibration of the cardan occurs again after replacing the crosspieces, you will have to disassemble it again in order to reassemble the cardan in the correct position. To avoid incorrect assembly, marks must be placed on both halves.

Since vibration can arise not only from the crosspieces, it is important to examine other parts during diagnosis. The problem may be what broke. spline connection

To determine the further direction of repair, you need to understand the degree of play. If there is very strong play, the driveshaft is completely replaced, since it is already useless to repair it. If the play is insignificant, then it is necessary to remove the shaft and disconnect the spline connection, not forgetting to make notches in order to carry out proper assembly in the future. The splines must be cleaned of dirt, rust, and lubricant residues. After this, the rubber band is replaced, the cardan is assembled and installed in place. The final step is pumping lubricant through a special fitting. This must be done before grease appears from under the dirt-repellent boot.

splined connection. To determine the further direction of repair, you need to understand the degree of play. If there is very strong play, the driveshaft is completely replaced, since it is already useless to repair it. If the play is insignificant, then it is necessary to remove the shaft and disconnect the spline connection, not forgetting to make notches in order to carry out proper assembly in the future. The splines must be cleaned of dirt, rust, and lubricant residues. After this, the rubber band is replaced, the cardan is assembled and installed in place. The final step is pumping lubricant through a special fitting. This must be done before grease appears from under the dirt-repellent boot.

Often the cause of vibration is the suspension bearing. Its malfunction may also be accompanied by a hum. He reports that the part has clearly become unusable. In most cases, the outboard bearing assembly will need to be replaced. To do this, the cardan shaft is dismantled, after which the cross is disassembled and the sliding fork is unscrewed. Often, replacing the suspension bearing is accompanied by replacing the crosspiece, because it can be problematic to assemble it into its original position. After installing new parts, assembly is carried out in the reverse order, and the factory position of the flanges and sliding forks must be strictly observed. Otherwise, the vibration problem described above will occur again.

Vibration may also occur

due to the fact that the outboard bearing was not centered after replacement. Bearing alignment is carried out with the vehicle on a lift. To do this, it is necessary to loosen the fasteners to the extent that the part moves freely in different directions. The person behind the wheel smoothly brings the speedometer needle to 100 km/h in fourth gear, depresses the clutch pedal and releases the gas pedal. After this, you need to wait until the wheels come to a complete stop on their own and turn off the car. Next, the outboard bearing fasteners are tightened. Vibration usually disappears when using this method.

It is also possible that vibration may occur due to mechanical damage to the driveshaft during a collision with a large obstacle: a stump, a curb, a well. In such a situation, you will have to replace either the damaged part or the entire driveshaft assembly. Further actions are determined only after a complete inspection of the parts.

The device of the VAZ 2107 cross

The VAZ 2107 driveshaft crosspiece is a flexible connection between the gearbox and the rear axle of the car. This hinge ensures the coincidence of the rotation axes of the cardan parts and makes it possible to transmit torque when bending the cardan parts. The cross connects the forks of the cardan halves, which are attached to its ends. The main element of the cross is needle bearings, which ensure the mobility of the hinge. The bearings are inserted into the fork holes and secured with retaining rings. Bearing wear causes joint play, knocking and other extraneous noise when moving. In this case, it is necessary to replace the VAZ 2107 crosspiece.

What is needed to replace the VAZ 2107 crosspiece

First of all, you need a new crosspiece for the VAZ 2107. Replacing it is quite labor-intensive, so you should not skimp on this part. Original spare parts, made of high-strength heat-treated steel, provide a mileage of up to half a million kilometers without replacing the spider. At the same time as the cross, the retaining rings are also replaced, so these parts are often included in the kit.

To replace the parts you will need:

- set of open-end wrenches;

- hammer;

- pliers;

- puller for bearing replacement;

- metal brush for cleaning dirt and rust.

Replacing the crosspiece begins with dismantling the driveshaft.

Preparing for work

When buying a new crosspiece for a VAZ 2107, you don’t need to try to save money. Everyone knows that “the miser pays twice,” so it’s better to buy an original part right away than to change a couple of crosses in six months.

The body of the crosspiece is made of heat-treated steel. This is necessary to ensure the special hardness of the studs. Thus, the quality of the material plays a big role in the service life of the part. How long can a car run without replacing crosspieces? It is believed that approximately 500 thousand km!

The retaining rings and bearing also need replacement. Please note that the rubber of the bearing itself must be sufficiently elastic.

Removing the VAZ 2107 cardan

It is better to remove the cardan on a lift or inspection hole. In the latter case, it is necessary to secure the car wheel with boots and secure it with the handbrake so that the car does not roll away. Only after this can you begin dismantling.

The work is performed in the following sequence:

- unscrew the bolts connecting the cardan to the gearbox flange;

- unscrew the nuts securing the outboard bearing to the bottom of the car;

- Carefully, using a wooden hammer, knock the cardan out of the splines of the elastic coupling.

You need to knock on the cardan parts with a wooden hammer or use a regular hammer and a wooden spacer. Otherwise, the cardan pipes may be deformed.

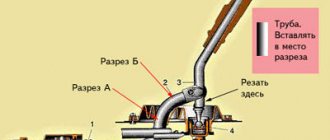

Replacing the VAZ 2107 crosspiece

To make disassembling the cardan transmission easier, you should first clean the parts with a wire brush and treat the mating areas with kerosene or WD-40.

Before disassembling the cardan, it should be placed on a flat surface in a well-lit place. Replacing the VAZ 2107 crosspiece begins with removing the retaining rings using a puller.

Before dismantling the crosspiece, it should be tapped with a hammer through a wooden spacer and treated with WD-40.

The crosspiece is removed by successively beating its bowls with a hammer and removing them from the holes of the forks. After the cross is removed, it is necessary to thoroughly clean its seats and grooves for installing the retaining rings.

Installation of the part begins with dismantling its bowls, which are sequentially installed in the seats on the cardan forks, while simultaneously being put on the cross.

The metal of the crosspiece bowls is very hard, but fragile. Therefore, they should be driven into the seats very carefully. After the bowl has taken its place, it must be secured with a locking ring.

Installation of the cardan is carried out in the reverse order of removal. The spline assembly should connect without effort and should be lubricated before assembly.

So which lubricant is better?

Many car enthusiasts are interested in the question of what is the best lubricant for crosspieces? In fact, this question in itself is incorrect and cannot have a single correct answer. The main thing for a car owner is to choose a lubricant that will optimally suit its performance characteristics! This means that it will be both of sufficient quality and moderately expensive. The choice depends on the operating conditions of the car, the make of the car, the cost and condition of its transmission and other factors.

For example, it makes sense for owners of expensive SUVs to use more expensive lubricants for crosspieces produced by world-famous manufacturers, while owners of budget cars or drivers who use cars sparingly can get by with products that are average in quality and price. However, we can say with confidence that any of the above tools copes with their tasks quite well. Therefore, all of them can be recommended for purchase. Therefore, the choice remains only with the car owner.