Connection and trunk

After installation, the reducer is connected to the gas supply line passing under the car body. The choice of material for the supply line is at the discretion of the customer, but mainly behind a thermoplastic tube (usually a 6 mm line is used for a carburetor passenger car).

The main line is laid away from hot parts and parts subject to constant movement. For installation, staples with self-tapping screws and plastic disposable ties are used (the staples and screws should preferably be galvanized, or better yet, stainless, and the ties are weather-resistant and ozone-resistant).

Types of HBO for a car

Depending on the power system, different generations of gas equipment can be installed on a vehicle. Structurally, between the 2nd and 6th generations of gas engines there is the same gap as between the carburetor and the injector of a motor with direct fuel injection.

2nd generation

The simplest option. Used in cars with carburetor and mono-injection power systems. Although it can also be found on fuel-injected cars, this is not the best option.

The operating principle of second generation gas equipment is as simple as possible. The gas passed through the evaporator reducer is supplied to a special mixer installed upstream of the throttle valve. The engine sucks in gas along with air: the more the throttle valve opens, the more mixture enters the cylinders.

Advantages and disadvantages

cheapness; ease of setup and maintenance.

inaccuracy of adjustments; pops and small explosions of gas accumulated in the intake manifold (mainly on injection cars); long process of switching from gasoline to gas.

The settings constantly need to be adjusted, and the engine power is noticeably lower.

3rd generation

Transitional option, rarely found on cars. The main difference is the presence of injectors for injecting gas directly into the intake manifold and a stepper electric motor that regulates the amount of gas supplied.

The system is controlled based on the readings of the oxygen sensor and throttle position sensor. Therefore, the 3rd generation of LPG is not used on carburetor cars.

Diagram of the 3rd generation HBO device

Disadvantages of this type of equipment:

- difficulty of adjustment;

- slow response to changes in engine operating conditions.

The car becomes more sluggish, power and throttle response drop.

4th generation

The most common type of gas equipment, which is ideal for cars with an injector. Pressurized gas is injected directly into the intake manifold using separate injectors.

A separate block controls the process. It connects to the standard wiring of the ECU. When switching from gasoline to gas, the gasoline injectors are switched off and gas injectors start working instead. The transition from one fuel to another occurs instantly, almost unnoticed by the driver.

The gas equipment control unit relies entirely on the readings of the same sensors as the standard gasoline ECU. Therefore, gas supply correction occurs as accurately and quickly as possible, which means gas consumption and dynamics losses are minimal.

4th generation gas equipment design

Due to its complex design, the 4th generation of gas equipment is more expensive to purchase and install. But for fuel-injected cars with distributed injection, this is the most suitable option.

5th generation

Used only on vehicles with modern direct fuel injection systems into the combustion chamber. The technology is relatively new, so there are quite a few such cars with LPG. The injectors are installed, like gasoline injectors, not in the intake manifold, but in the cylinder head.

A gas reducer is used. For gas injection, higher pressure is needed, about 15-16 atmospheres. To ensure a constant pressure, an electric pump, similar to a gasoline pump, is installed inside the cylinder. The gas does not evaporate, but is injected in the liquid phase.

5th generation HBO device

It is impossible to install LPG of previous generations on cars with direct fuel injection. The fifth generation is expensive and demanding on fuel quality. The gasoline pump installed in a gas cylinder is particularly sensitive.

6th generation

The sixth generation is an evolution of the fifth. Here, individual gas injectors are excluded from the system. Instead, gas is supplied directly through gasoline ones. For this purpose, a special matching module is installed under the hood. Its task is to shut off the supply of gasoline, opening the gas, and vice versa. It’s as if it brings two fuel lines into one, switching them alternately.

6th generation HBO scheme

Setting up HBO without an ODB adapter

It’s a shame, but it’s not always possible to read the correct values from ODB. Sometimes the adapter is not just not compatible with gasoline brains. Let's consider the option of setting up Lovato HBO, when for some reason it is not possible to read the correction coefficients.

This method is not accurate; you will not be able to set ideal fuel map coefficients, but the adjustment error will be within acceptable limits.

Setting up without ODB is very similar to setting up with an adapter, but in this case, we will not be checking the correction factor, but the gas supply time. This is perhaps the most unstable value and it changes several times per second, one way or another, this is the only thing we can work with now. You need to read the average value of this value, for example, the parameter jumps from 4.5 to 5.0, in this case the average value is 4.75. To correctly adjust the timing of gasoline, it is important to drive on the smoothest possible road, with extremely equal speeds; any deviation is critical.

Let's start setting up without ODB:

- Gasoline supply is turned on (using a button in the program)

- The driver sets a constant engine speed and precisely maintains it during tuning.

- At these speeds, the average value of the gasoline injection time is read from the Lovato Easy Fast program.

- The gas is turned on (by button in the program)

- The average gasoline injection time is read again.

- The cell under the point on the fuel map is configured. If the gasoline injection time when operating on gas is longer than on gasoline, the cell value increases, if less it decreases. I recommend selecting the entire column and changing it by several units at once. (After highlighting, press the Enter key.)

Gasoline injection time

Gas injection time

Generations of HBO

HBO is a technical system that is being developed and modernized. Therefore, today there are 6 generations of gas equipment. They differ in the principle of gas supply and the method of turning off the gasoline supply.

Note: by and large, all gas equipment systems can be divided into 3 main groups and intermediate hybrid types between them. The three main HBO systems are:

- for carburetor (mechanical) fuel injection;

- for distributed injection injection;

- for direct injection of fuel into the engine.

We will describe six generations of equipment - their operation and differences.

- HBO-1 is a system with mechanical blocks that are installed exclusively on carburetor engines. Their reducer injects gas through nozzles at low pressure inside the mixer. Therefore, it received the name “vacuum”. This system has many shortcomings and complaints; fires are not uncommon;

- HBO-2 is a system for carburetor and simple injection engines, but it is modernized with an electromagnetic gearbox. This made it possible to organize the supply of gas, at different pressure values in the mixer, making it easier to start the engine, making a “cold” start possible. The electromagnetic gearbox also made it possible to control the fuel selection with a button from inside the car;

- HBO-3 is a system for injection engines in which the gearbox is equipped with controllers and operates in fully automatic mode. It reads the readings of the oxygen sensor in the exhaust gases and uses them to regulate the composition of the gas mixture. The gearbox also has a temperature sensor, which allows it to turn on only after warming up. Another improvement of HBO-3 is injector emulators. They simulate the operation of gasoline injectors so that the electronic unit does not put the engine into emergency mode. Injector emulators have eliminated the need to integrate a separate gasoline valve into the system.

Gas equipment systems of the first generations are considered obsolete. Among the other three, HBO-4 has gained the most popularity due to the optimal combination of price and quality of its work. This is what most drivers prefer to install.

HBO-4 is a system for injection engines. An improvement to the HBO-4 are gas injectors. They take on the function of injecting gas into the mixer-manifold. And they eliminate the need for the reducer to build up pressure to inject gas into the mixer. The number of injectors corresponds to the number of pistons-cylinders. Each injector has a controller installed that controls its operation - it determines the amount of gas injected and the injection frequency. There are no gasoline emulators here; their function is performed by the electronic unit itself. He, the control unit, pauses the operation of the gasoline injectors and starts the gas ones. At the same time, the gasoline unit continues to operate without injecting gasoline.

We recommend: Engine malfunctions, their causes and solutions

Gas equipment of the fourth and subsequent generations are systems for periodic (cyclic, phase) supply of fuel (gas). This supply made it possible to reduce the consumption of liquefied fuel.

LPG of subsequent generations, the 5th and 6th, do not operate on methane gas, since they use exclusively liquefied gas. In their design, liquefied fuel enters the combustion chamber in liquid form, bypassing the vaporization phase.

- HBO-5 - gas is injected in the form of a liquid, which is called “liquid injection”. It is supplied to the chamber by fuel pumps built into the cylinder (similar to the gasoline supply system). To supply liquid fuel, the pump builds up pressure to 5 atm. To constantly build up pressure in the system, a pressure reducer operates. A slight increase in pressure prevents evaporation of liquid gas when heated by a running engine. This system starts easily without gasoline, without the need to warm up the engine on gasoline. They also feature reduced gas consumption and increased power. There is no evaporator reducer in HBO-5;

- HBO-6 is installed on engines with direct injection. Uses liquefied gas. The HBO-6 system consists of a tank that is connected to the gasoline fuel supply line.

GBO-5 and 6 are the most expensive options for installing gas equipment on a car.

What's the result?

As you can see, adjusting gas equipment on a carburetor engine is not a complicated procedure (with the exception of adjusting the pressure in the 2nd generation two-section LPG dispenser). Note that a properly carried out procedure allows you to achieve stable operation of the engine in all modes, the engine responds well to the accelerator pedal, there is no loss of power, etc. Gas consumption also remains within the normal range for a particular carburetor internal combustion engine.

We add that to check the quality of all adjustments and final adjustments, you should sharply press the gas pedal, after which the sensitivity screw is gradually tightened by ¼ of a full turn in one step. This must be done until a “failure” appears when the speed increases.

After the position of the screw at which the dip appears has been found, you need to loosen the specified screw half a turn. You can detect changes in speed by hearing by analyzing changes in engine operation. Also, the dispenser settings must be repeated if necessary.

The fact is that with a minimum gas supply, the power unit will operate on a lean mixture. In this case, you will not be able to save significantly on fuel, but the damage to the engine can be very large. Working on an over-lean mixture leads to overheating, detonation, burnout of valves, cracks in the block and cylinder head and other serious consequences.

How does installing gas equipment and switching to gas affect the engine and service life? Features of setting up gas equipment, selecting oil and servicing gas-powered internal combustion engines.

Advantages and disadvantages of using gas equipment. Maintenance and operation of gas equipment, the benefits and harms of gas for the engine and standard systems.

Converting a diesel engine to gas: principles of operation of a gas-diesel engine, features of installing gas equipment on a diesel engine. Advantages and disadvantages of diesel gas equipment.

Gas equipment. Classification, operating principles and design. Various generations of gas systems, HBO for engines with direct injection.

Operating principle and distinctive features of gas injectors. Basic parameters when choosing nozzles for gas equipment 4. Which gas injectors are best to buy.

Features of installing gas equipment on a turbocharged engine. What gas equipment is best installed on engines with a turbine. Tips and tricks.

How to set up Lovato 4th generation HBO?

I decided to install gas equipment on my car and contacted a specialized office. They supplied me with Lovato equipment, but they couldn’t set it up correctly. My city is not large and the other companies that I could find did not install and service Lovato.

Jet selection

There is a misconception that the jets are located at the end of the hose and are installed in the manifold; in fact, the jets are installed directly into the gas injectors.

Where can I find Lovato LPG jets?

Make sure you have the correct jets selected. Here is a table of diameters, depending on the power of one cylinder.

| Power per cylinder, hp | Diameter, mm |

| 13-20 | 1,6 |

| 20-26 | 1,8 |

| 26-29 | 2,0 |

| 29-34 | 2,2 |

| 34-39 | 2,4 |

| 39-45 | 2,6 |

If necessary, drill out the jets.

The use of gas systems in cars is a justified step in saving money. The cost of gas (a mixture of propane and butane is used) is almost half the cost of gasoline, and the final result is almost the same. Installing gas cylinder systems on budget and middle-class cars will not cause serious difficulties for an experienced car enthusiast who is fluent in a jigsaw and grinder.

HBO 2nd generation

This system is of a mechanical type, supplemented by electronic dosing devices. For the latter, the main principle of operation is feedback from the oxygen content sensor. Installation is carried out on cars equipped with carburetor engines. A lambda probe is present, as is a catalytic converter, also called a catalyst. Devices of traditional varieties, with a gas mixer. Additionally equipped with special dispensers.

HBO has a 2nd generation - lambda control system. Lambda controllers use special signals from the standard probe that the car is equipped with. Additionally, a signal associated with the position of the throttle valves and the engine speed sensor is used. The result of such coordinated work is the optimization of the fuel-air mixture, especially during the transition stages of engine operation.

Euro 1 is a standard for environmental requirements that devices belonging to the second generation comply with. Some lambda control systems have two settings, so it is acceptable to maintain Euro 2 requirements. But at present, the first and second generations are practically not used due to too low characteristics.

The toxicity of exhaust gases remains at the level of Euro-1 requirements. Only in some cases do the indicators approach Euro-2 standards. In this regard, installations belonging to the third and fourth generations were developed.

Environmental standards, displacement from the market

On third-generation LPG installations, the electronic-mechanical valve remains. This did not provide the ability to adjust the fuel at the required speed. Therefore, third-generation LPG devices fully complied with Euro-2 standards. When Euro-3 standards were introduced, new OBD II, EOBD second-generation on-board diagnostic systems were developed. Third generation HBO devices have become less in demand. As a result, they were finally forced out of the LPG market by fourth-generation units.

TOP 5 myths and fables about the fifth generation of HBO

Myth one: 5th generation of HBO.

Some motorists mistakenly believe that by installing HBO with automatic adjustment of parameters via the CAN bus (OBD protocol), they are installing HBO 5. In fact, this is not so! This is still the same 4th generation gas equipment, simply equipped with parameter adjustments for distributed injection. In addition, as it turned out during operation, the OBD adjustment does not always give the required result, in some cases it is of no use, and sometimes even after installing such a “stray”, the LPG begins to work worse. As I said above, fifth-generation gas equipment is a fundamentally new system, which is devoid of a gas reducer, and gas injection occurs in the liquid phase, under high pressure.

Myth two: Fifth generation gas equipment is unreliable and expensive to maintain.

Often on forums or in “smoking rooms” you can hear from those who “understand” that the 5th generation is very “breakable” and besides, it is expensive and there is nowhere to repair it... In fact, this happened before and is only partly true. Today, when HBO 5 is being installed in full swing all over the world, there are no problems with components or repairs. Moreover, with proper operation and refueling with high-quality fuel, no problems arise.

Also, the problem of lack of knowledge used to be relevant, since most gas equipment manufacturers did not want to cooperate or reveal their “cards” until the installer received a certificate of conformity and the staff received qualified training. At first this was a problem, however, when the popularity of fifth-generation gas equipment began to grow, most reputable companies found the opportunity to train their specialists and obtain all the paper necessary for repair and installation. So today, repair of 5th generation gas equipment is not a problem, nor is its diagnosis.

Myth three: dirty gas.

Even if you are unlucky and you actually fill up with low-quality gas, the fifth-generation LPG system includes a multi-stage fuel purification system. It includes: a fine filter, which is installed in the VSU and is responsible for cleaning the fuel at the refueling stage, as well as an additional filter for removing impurities from the fuel, located in the pump. In addition, the gas pump has a design that does not allow particles larger than 0.7 mm to pass through, therefore, as you understand, dirt and sand cannot pass through such a filter.

Myth four: gas fuel consumption.

There is an opinion that on the fifth generation of gas equipment, gas consumption is the same as gasoline consumption. In short, this is not true! Among the installers, there are those who, intentionally or due to their own incompetence, spread false information that the gas consumption for LPG 5 is the same as for gasoline, since the gas is supplied to the injectors in a liquid state. However, the truth is that the consumption will actually always be about 10-15% higher. Those who really have gas consumption equal to gasoline consumption are most likely victims of incorrect or incorrect settings of gas equipment; the mixture is most likely lean or poor. Driving with such a setting will end with the fact that one day your engine will simply have to be “overhauled”.

Myth five: payback.

You all know what payback is and, most likely, everyone, before installing gas equipment, thought about how long it would take to get back the money spent in the form of significant savings that gas fuel provides. So, indeed, the price of installing the 5th generation of gas equipment is an order of magnitude higher compared to the 4th generation. However, if you constantly drive and use your car not only for trips to the store, the 5th generation LPG will pay for itself quite quickly. It’s difficult to say anything about timing here, since everything is largely individual. It is also impossible not to mention the fact that, unlike the fourth generation, in the fifth there is no need to regularly change filters, as well as install repair kits for the gas reducer, and this, no matter how you look at it, is an expense, and what a cost...

With this, dear friends, I will end my story; I hope it was interesting and I managed to dispel most of these myths. Write in the comments about what myths about HBO 5 you have heard, as well as what you think about the fifth generation, whether it is worth installing and whether it has a future.

If you liked the article, you can share this article on social media as a thank you to the author. networks with your loved ones, thereby you will help us in the development of our project. Thanks in advance and see you again at gboshnik.ru!

Easy to maintain

The next important difference between the two latest versions of gas equipment is the almost complete absence of the need for any maintenance. As you know, the operation of version 4 requires regular cleaning and repair of the gearbox, maintenance and replacement of the gas injector, and frequent adjustment of the injection system

The new model does not have any of this: it only requires timely replacement of the pump filter.

An important difference between HBO 5 and HBO 4 is the use of the highest quality components in the latest model. Thus, instead of unreliable rubber tubes, which were present in large quantities in the 4th model of equipment, high-quality plastic tubes are used, which, even over long periods of operation, are not impregnated with odorants, without allowing gas to pass through their walls.

Thanks to this, in a vehicle running on the 5th generation, there will be no smell of gas in the cabin, as well as under the hood or even near the car itself: all connections of the system are as tight as possible.

In model 4, over time, even the rubber tubes begin to smell of gas, as a result of which an unpleasant odor can be felt both in the cabin and near the car. The new version completely eliminates this problem.

As you can see, progress does not stand still, I have a friend who installed the latest generation of LPG on his PRIORU - according to him, the installation has already paid for itself (he rode for about six months, although he drives a lot), then only the “gain” comes, the consumption is the same as About 8 liters of gasoline in the city, with manual transmission. As you can see, there is a lot to think about here.

Now let’s watch a visual video.

That's all, read our AUTOBLOG, it will be interesting.

Similar news

- Cost of gasoline. Let's look at the example of 1 liter in Russia and the United States...

- Odorants. What are they and why do natural gas need them?

- Gasoline additives. To increase octane number, clean injector...

What does the equipment consist of and how does it work?

2nd generation LPG (propane or methane) is used in cars with injection and carburetor engines. Such equipment is best suited for cars up to the 3rd environmental class (Euro 0,1,2). Starting from Euro 3, it is more rational to install the 4th generation of gas equipment.

Device on the carburetor

HBO 2 kit for carburetor Second generation kit includes:

- filling valve;

- gas cylinder with multi-valve and level sensor;

- filling, consumable lines;

- reducer with a coarse filter (sometimes a remote filter with a solenoid gas supply valve);

- fuel type selection button;

- gas mixture dispenser (power register);

- device for mixing gas with air (mixer);

- an electromagnetic valve that blocks the access of gasoline to the power unit when switching it to gas.

The operating principle of 2nd generation equipment on a carburetor engine is as follows:

The engine starts and warms up using gasoline. Next, the key is moved to the neutral position to produce fuel from the carburetor float chamber. Thus, the solenoid valve is activated, which shuts off the gasoline supply.

After which the switch is set to the gas supply position, activating the gas valve. So the gas, which is in a liquid state in the cylinder, flows through the multivalve and the main pipeline to the reducer. At this stage, the mixture undergoes preliminary rough cleaning.

When the gearbox warms up from the engine coolant, the liquefied gas is converted into steam. In the vapor phase, the fuel, passing through the power register, mixes with air in the carburetor.

Then the finished gas mixture, entering through the intake manifold and cylinder head valves, is ignited by a spark in the combustion chamber of the engine cylinder.

To switch back to base fuel, the LPG button is moved to the position of working on gasoline, bypassing the neutral position.

Diagram on engines with injector

Second generation gas equipment kit for injection internal combustion engines

Here the equipment differs in several components:

- the button is specifically for the injection system, but there are also universal ones;

- a mixer with an anti-popping mechanism is installed in front of the throttle valve;

- petrol injector emulator;

- lambda probe emulator (installation is not required on all machines).

There are no radical differences in the operating principles of both gas equipment schemes. Major changes have been made to the design of the gas equipment due to the presence in a car with an injector of injectors for supplying fuel (or a mono injector - one nozzle for all cylinders). Which are controlled by the standard engine control unit (ECU).

The engine can switch to gas in semi-automatic mode (middle position of the toggle switch). Until the engine reaches a given number of rpm (1500-2000), gasoline is supplied to the combustion chamber. Then the switch to gas occurs automatically.

An injector emulator is needed to turn off gasoline injectors; it also sends a signal to the controller (ECU) simulating their operation. Due to this, the control unit does not display an error (“check engine”) about non-working injectors through an alarm on the instrument panel.

The lambda probe emulator (oxygen sensor) blocks the engine control unit from outputting a false error about a lean fuel mixture. Sensor advantages:

- facilitates setting up HBO due to the display of an indication of the quality of the mixture (poor green, rich red);

- reduces gas consumption by an average of 7-10%;

- allows you to detect real errors in engine operation.

Due to possible malfunctions in the ignition system (missing sparks) or gas distribution mechanism, popping noises occur in the engine. The reason for this is the ignition of fuel in the intake manifold, which can lead to its rupture.

The second generation gas equipment is equipped with an “anti-pop” valve, which is installed in the gas mixer or may be additional in the air filter housing.

Lovato Easy Fast

Lovato Easy Fast is the official software for setting up Lovato LPG. To run the software, you do not need a license key, and it can work with both an original and a homemade cable. It is strange that the manufacturer does not distribute its product on the official website.

I used Lovato Easy Fast 1.7.4, it was easy to google and download.

Lovato Easy Fast - main menu

Main parameters of the “Configuration” section

Configuration Tab

- This tab contains the characteristics of your engine and gas system. Make sure all parameters are correct.

Switching

Lovato Easy Fast - “Switching” section

- Allow injectors to warm up - in this mode, in case of frost, the injectors will first turn on, work for a while, and only then gas will be supplied. This parameter will increase gasoline consumption.

- Idling Which fuel system will provide idle speed. Feel free to put on the gas.

- for switching : when decelerating, which corresponds to decreasing pressure on the gas pedal, and when accelerating, which corresponds to increasing pressure on the gas pedal. Most often, switching occurs without these actions, but sometimes in order to switch the car to gas, these conditions must be met.

- Reducer temperature for switching: Until the reducer warms up to the set temperature, the system will not switch to gas. If the gearbox is in good condition, we set as little as possible.

- Starting on gas with a warm engine after turning the ignition key, if the engine is warmer than the specified temperature, it will automatically switch to gas.

- Switching delay when the engine is hot: if the engine is hotter than the gearbox, but not hotter than the starting temperature on gas, then this rule works.

- Operation at high speeds.

- Gas In this menu you can configure the addition of gasoline when gas injectors cannot cope.

- Adding gasoline is a more detailed setting of the “Gas” option.

- Gasoline, everything is simple here, we exceeded the speed, turned off the gas, turned on gasoline.

Map

Lovato Easy Fast - “Map” section

- The Time/Rpm table is the most interesting part, this is where the settings will be made

- Sensitivity of additional injection - adding gasoline to the gas-air mixture during sudden acceleration.

Main parameters of the “Self-configuration” section

Lovato Easy Fast - “Self-configuration” section

- Time Gas time of opening of gas injectors

- Benz time. petrol injector opening time

- D.Gas gas pressure

- Self-tuning button automatic idle speed adjustment

Disadvantages of 5th generation HBO

The main disadvantage of 5th generation gas equipment is its fuel pump, which quickly fails due to the presence of impurities in the gas. The cost of the pump is two-thirds of the cost of the entire system.

Another drawback is the high price, 3 times more than the 4th generation. The cost of installing HBO 5 with cylinders, labor and engine compartment starts from 80,000 rubles. for a 4-cylinder car, and from 100,000 rubles. for six and eight cylinder engines.

Another important disadvantage is the low popularity of HBO 5 in Russia compared to previous generations. Today, HBO 4 is the most common in our country. For those who have an older car, installing HBO 2 would be an excellent solution.

Incompatibility with methane is one of the weakest aspects of LPG 5. LPG equipment of the 5th generation can only operate on liquid fuel, namely propane-butane. In turn, the demand for gas equipment for methane in Russia is growing every year, especially after our government’s decree to transfer 50% of transport to gas fuel. It is still unclear whether HBO 5 will develop in Russia or not. But as long as the high cost and low availability of components remain, the demand for the installation of LPG 5 will be low.

Conclusion

The third generation is considered outdated and is relevant only for a few cars. All these nuances should be carefully considered and discussed with a specialist. If the car owner decides to install this particular system, then the installation must be carried out only with the help of a competent car mechanic, who will be able to point out all possible faults and conduct a thorough diagnosis of all systems to prevent future breakdowns.

The rapid introduction and development of gasoline injection systems in internal combustion engines, new requirements and technologies have not left manufacturers and design engineers of gas equipment aside. It was decided to make some changes to the well-functioning HBO 2 system to ensure the possibility of “feedback” communication with the engine, entrusting part of the control to the electronic brain. This is how the 3rd generation HBO was born. Although, according to the European classification, this gas-cylinder equipment remains the second generation.

Looking for an alternative to gasoline

Gas is much cheaper than gasoline and it is enough to install special gas equipment on your car and refueling costs will decrease.

Attempts to use gas as a fuel for cars have been made almost since the advent of the automobile.

But much later, a set of equipment appeared, with which it was possible to convert any car to run on gas.

Passenger cars use equipment that runs on liquefied gas (propane-butane). It is not advisable to use compressed gas on such vehicles due to the large weight of the cylinders.

Several generations of this equipment are produced, in accordance with the design features of the car and Euro toxicity standards:

- HBO 1st generation. Toxicity is below Euro, used on carburetor cars and on cars with a monoinjector;

- HBO 2nd generation. Toxicity up to Euro-2, also installed on carburetor and injection cars;

- HBO 3rd generation. Toxicity up to Euro-3, used on injection cars;

- HBO 4 generations. Toxicity – Euro-4, used on injection cars;

- HBO 5th generation. Provides precise control of liquid gas injection. The operating principle is 100% similar to the operation of the gasoline system;

- HBO 6th generation. It differs from the 5th in the presence of a fuel substitution unit - FSU, to which gas and gasoline are simultaneously suitable. The operating principle of all systems will be discussed in the following articles.

Setting up the fuel system

Correct adjustment of 3rd generation gas equipment is carried out by adjusting the gas pressure in the evaporator reducer; it can be done with your own hands, if you have certain skills and equipment. ECU calibration is not required (the controller does not use standard fuel maps).

After checking the functionality of the standard gasoline system and eliminating gas leaks, to adjust the pressure in the gearbox stages, you will need a special differential pressure gauge.

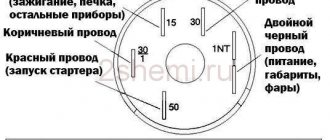

Pressure gauge connection diagram

1st stage:

By connecting the pressure gauge to the hole on the gearbox (remove the plug) and the hose from the intake manifold, start the internal combustion engine. After warming up the engine at idle speed, adjust the pressure using the screw on the rear cover of the evaporator (1.4 atm.). Disconnect the device, insert the plug, check for leaks.

2nd stage:

Connect the pressure gauge to the manifold (as in the first option), and its second hose to the distributor (removing the cover at the bottom). Then adjust the screw on the front cover of the gearbox (0.95 atm). Disconnect the device and check the functionality of the system.

Advantages and disadvantages of HBO 2

Despite some imperfections, 2nd generation gas equipment has its advantages:

suitable for engines with fuel injection and for cars with carburetors; the design of second-generation gas equipment is simple and reliable; easy connection diagram and installation of gas equipment; it is easy to configure and regulate the system; An important advantage is that you can regularly start the engine on gas at an ambient temperature above 10 degrees Celsius.

The advantages of second-generation gas equipment include the low cost of repair kits.

Flaws:

- There is no feedback from the car engine, which leads to unstable operation in some modes (motor elements fail prematurely due to incorrect settings for the mixture quality or ignition timing).

- Increased gas consumption.

- There is a danger of a backfire of the gas mixture in the intake manifold.

- The emission of spent fuel in 2nd generation gas equipment does not comply with Euro-3 standards and higher.

- Slow response to pressing the accelerator pedal.

- The need to constantly adjust the valve clearance to prevent uneven engine operation under heavy loads.

When operating HBO 2, it should be borne in mind that water entering the air intake affects the number of revolutions.

You can’t do business with the 2nd generation of gas equipment today, since new versions of gas equipment have been released, which take into account many of the shortcomings.

What is HBO?

The system that allows a vehicle to run on gas is called LPG. Such installations can operate on propane (liquefied processed gas) and methane (natural vapor gas).

Blue fuel is better than gasoline in that it has a higher octane number (105 and higher). The ability to resist detonation is higher, so the spark plugs are not so exposed to soot, and the mixture coming out of the exhaust pipe is cleaner than after gasoline. The advantage of such systems is that you can switch to gasoline (diesel) at any time.

During the existence of gas structures for cars, separate generations of such systems have been formed. This happens in parallel with the improvement of the engines themselves.

Adjustment

After completing the checks, we begin adjusting the system.

- By switching the toggle switch on the button for selecting the type of fuel on which the car operates to the “Gasoline” position, we start the car engine in normal mode and warm it up with gasoline to operating temperature (80-90°C).

- While the engine warms up to operating temperature, unscrew the screw/screws on the dispenser to completely open the channel for the gas mixture to enter the mixer.

- We tighten the screw for supplying the mixture to chamber 2 until it stops.

There are 2 screws on the evaporate gearbox:

- 1st – idle speed screw; it regulates the amount of propane-butane mixture that will be supplied to the engine when the gearbox diaphragm is closed.

- 2nd sensitivity screw, which regulates the opening moment of the membrane and the gas pressure when pressing the throttle.

- Before starting adjustments, turn screw 1 all the way, then unscrew it 1 turn, screw 2 turn it all the way and unscrew it 3 turns.

- When the engine reaches operating temperature (80-90°C), we move the fuel type switch to the neutral position (for engines equipped with a carburetor) to produce gasoline from the float chamber.

- After the remaining gasoline has been completely exhausted from the float chamber (the engine is trying to stall), we move the toggle switch for the fuel mode selection button to the “GAS” position.

- Using screw 1, we try to set the idle speed to about 750-850 rpm. Preventing the engine from stalling using the throttle.

- After setting a stable idle speed, we begin to carefully tighten screw 2 and look for the moment when the car begins to change its operation, trying to stall.

- Next, by opening the throttle, we bring the engine speed to 3000 -3500, maintain them, and begin to tighten the feed screw on the mixer (with 2 chambers, tighten the feed screw “I” of the 1st chamber) until we hear that the engine becomes “sluggish” - this is a transitional moment .

- After detecting this behavior of the engine, unscrew the feed screw on the mixer by 0.5 - 0.75 turns and leave it like that.

- Again, use screw 1 on the gearbox to set the stable idle speed to about 750-850 rpm. Unscrew the mixture supply screw on the mixer “II” into chamber 2 by 1 turn. We check the settings of the gearbox and dispenser of the car while driving, and if necessary, adjust the settings.

If it is necessary to increase or decrease the speed at which the injection engine itself switches to operating on a propane-butane mixture, you must:

by turning the adjusting resistance on the switch button, achieve the required value of the desired parameter.

For a carburetor car, the delay time for automatically turning off the gas when starting the engine on a gas mixture is adjusted in the same way by turning the adjusting resistance on the switch button clockwise (decreases), counterclockwise - increases.

This concludes the adjustment of the 2nd generation HBO.

Do-it-yourself HBO installation

Despite the fact that the technologies of the automobile world do not stand still, they are constantly developing and some car owners can already boast of having installed 6th generation LPG, the vast majority of drivers remain faithful to the old, proven LPG 2. And now we’ll figure out how to configure it correctly.

- The engine does not idle confidently

- Acceleration has become less dynamic, the engine has difficulty picking up speed

- Gas consumption has increased

The adjustment must be carried out on a fully warmed up engine and gearbox, respectively.

Setting the “response” to pressing the gas pedal and the amount of gas supplied

Once the idle speed has been set, it is necessary to ensure that the engine responds quickly and picks up speed when you press the gas. To do this, you need to gradually unscrew the sensitivity adjusting screw until the idle speed begins to change. As soon as a change in idle speed has been noticed, the specified screw must be screwed back 2/3 of 1 full turn or one and a quarter turns (depending on the particular internal combustion engine, etc.).

When finished, you need to press the gas pedal, first smoothly, then you can press it sharply. The main thing is that if the setting is done correctly, there should be no failures, the engine should quickly exit the idle mode, respond adequately to pedaling, rev up well and respond quickly to any pressing of the gas pedal.

- After the settings have been completed and the response to the gas pedal is satisfactory, you need to move on to the settings of the dispenser itself. To do this, you should raise the speed, on average, to 3 or 3.5 thousand rpm without suction. For these purposes, it is better to invite an assistant who will press the gas.

So, when the position of the screw leading to a change in speed has been found, the screw should be unscrewed from this position by half or 3/4 of a quarter of a turn. Please note that if a dispenser is installed that has two sections, then all the manipulations described above are carried out with the first chamber.

The second chamber is set to 1/3 of the first. If the reducer also has the ability to adjust the pressure of the first stage, then additional actions will be required.

- First of all, the engine must be turned off, after which the gas line is closed. Then a pressure gauge is connected to the cavity of the first stage. The connection itself is made through a control hole, which is closed with a screw.

- As for the pressure gauge, the device should have a scale of 1.5 kgf per square centimeter. After connecting, open the gas supply and start the engine. In idle mode, the pressure in the first stage is adjusted using the pressure gauge.

- The indicator should remain 0.38-0.42. Having set the pressure, adjustments to the idle speed and sensitivity of the gearbox should be carried out again.

Mounting the gearbox, dispenser and control panel

Installation of a gas reducer

The next step is to install the gas reducer. It is best to install it near the carburetor. The gas reducer should be installed vertically, since in a different position its diaphragm will not be able to fully ensure the gas supply. The best option would be to connect the gearbox to the pipes that go to the stove.

To do this, you will need to cut into the inlet and outlet pipes of the stove using two tees. Moreover, connecting the gearbox in series to one of the pipes can disrupt the operation of the system under certain conditions, so the inlet pipe of the gearbox cuts into the inlet pipe of the stove, and the outlet pipe into the outlet pipe.

Read only on vse-provse.com Do-it-yourself car soundproofing

A gas pipeline coming from the gas shut-off valve is connected to the reducer itself.

Installation of a gas mixture dispenser

There remains the last step of working under the hood. The gas mixture dispenser is installed between the reducer and the mixer. It is better to install it closer to the carburetor. We connect a gas pipeline to the dispenser, coming from the reducer, and from it we lead a gas pipeline to the mixer.

All elements of the gas equipment must be well secured to each other with clamps. But it is better to check the tightness after filling the cylinder with gas.

Remote Control

Finally we have reached the final stage - installing the LPG control panel.

Basically, complete with equipment, there should be a connection diagram. Using these instructions, you can install and connect the remote control. That's all, the installation is complete and you can go refuel your car.

Installing gas equipment on a carburetor is not a difficult process if you understand cars. If not, then of course it is better to contact a specialist.

(7 : 5,00 5)

Installation of equipment on a car

In order to adapt the engine for gas fuel and configure all equipment, you need to perform the following steps:

- Place the gearbox next to the engine and connect it to the cooling system. It should be parallel to the engine.

- Install the gasoline valve into the hose from the gasoline pump.

- The gas valve is installed on the engine shield. This is advisable from a safety point of view and for the ability to manually restore the gasoline supply in the event of gas valve malfunctions. But there are also built-in ones, directly into the gearbox.

- The mixer must be mounted under the engine. To avoid leaks, you must use a sealant, since the joining surfaces may be deformed.

- It is advisable to purchase a plastic pipeline, since, unlike copper, it bends easily.

- Gas cylinders are secured in the trunk shelf. To do this, drill 2 holes with a diameter of 10 mm. The fastening tape is laminated or has a rubber braid to avoid contact of the metal strips with the surface of the cylinders. The angle of inclination of the multivalve on the gas cylinder must be 30° to ensure correct gas supply to the system. To avoid explosion, cylinders should not be filled to more than 80% of their volume.

- The filling device can be located anywhere under the rear bumper.

- The fuel switch should be installed in the passenger compartment. Its installation diagram depends on the make and model of the machine.

Important: before connecting LPG to your car, you need to choose an installation method that is compatible with the specific type of car engine.

- How to turn on a BOSCH gas water heater?

Design and principle of operation of the system

3rd generation gas equipment includes the same basic components as its predecessors:

- filling valve;

- gas cylinder with multi-valve;

- filling and supply lines;

- reducer-evaporator (with temperature sensor);

- button to switch from one fuel to another;

- electromagnetic gas valve with built-in coarse filter.

Third generation LPG gas distributor The main difference is the presence of:

- gas mixture distributor (dispenser) with a stepper motor and electric valve;

- microprocessor or electronic control unit (ECU);

- mechanical injectors (zero pressure valves); Mechanical nozzle of gas equipment

- relay for controlling standard gasoline injectors and dispenser;

- diagnostic connector for reading errors.

Installation diagram for HBO 3.

Schematic diagram for connecting HBO 3rd generation to an injector.

Regardless of the position of the equipment key, the engine is started and warmed up using gasoline. When the engine coolant temperature reaches 20-30°C, the system automatically switches to gas, provided that the LPG button is in the appropriate position.

Under the control of the equipment ECU, the gasoline injectors are turned off, and the gas valve passes the mixture, filtering it in a liquefied form, to the evaporator reducer. The fuel, passing through the 1st and 2nd stages of the reducer, goes into a gaseous state with a decrease in pressure, which at the outlet is 0.9-0.95 atmospheres.

Next, the gas enters a distributor with a stepper motor, which doses the fuel mixture in a certain volume to each engine cylinder through injector valves (nozzles). Control and adjustment of the supply occurs using an electronic gas microprocessor, which receives signals from:

- throttle position sensor;

- MAP sensor (intake tract pressure);

- engine speed sensor;

- lambda probe;

- evaporator coolant temperature sensor.

As a result, the amount of gas required for optimal engine operation under certain conditions (different modes) is more accurately distributed.

The injectors cut into the engine intake manifold individually for each cylinder, as close as possible to the intake valves. To minimize the risk of explosion (“pop”) of the air-fuel mixture.

Installation of 3rd generation gas equipment

Installation of 3rd generation HBO on the injector is carried out similarly to the scheme of other systems. The sequence is as follows:

- place a gas cylinder with a multi-valve in the selected location;

- filling device;

- highways;

- gearbox;

- gas valve;

- dispenser;

- HBO button;

- ECU;

- nozzles are inserted;

- the wiring harness is laid and connected to the sensors.

It is also possible to install a 3rd generation LPG on a carburetor engine, but for its correct operation you will need to install a lambda regulation of the fuel mixture, a vacuum sensor, throttle position, crankshaft speed, and also a gasoline valve.

Such a solution would not be entirely appropriate. For cars with carburetor engines, it is still recommended to install simple and cheap gas equipment of the first or second type.