The design and principle of operation of automobile windshield wipers

All modern cars are equipped with windshield wipers or wipers, which are designed to clear the windshield of dirt, dust or precipitation. With their help, the driver can significantly improve visibility without leaving the cabin. Automotive windshield wipers are an integral part of the vehicle design, and their malfunction prohibits the operation of the vehicle.

- Windshield wiper system

- Windshield wiper design elements

- How the device works

- How does a trapezoid work?

- Wiper motor

- Purifier management

- Types of brushes

- Methods for attaching brushes

Selection of brushes

When choosing wipers, you must be guided by the following criteria:

- Length. One of the main indicators - length - is selected in accordance with the car model or taking into account the size of the already installed product.

- Method of fastening products. If the fixing brackets do not match, you simply will not be able to install the products.

- Quality is an equally important criterion. The better quality the products are, the longer they can last.

As practice shows, high-quality products always cost more, and experts advise not to skimp on purchasing products, since they directly affect visibility. We recommend selecting wipers according to the make of the car, as this will allow you to most accurately select the required size.

In addition, it is best to choose products in accordance with the season - they can be both summer and winter. It should be taken into account that winter versions are equipped with special blades that do not freeze or freeze in the cold. Depending on the situation, you can not completely replace the product, but only one blade, of course, if the remaining elements of the leash are in good condition.

Features of the device and wiper circuit

Scheme of the glass cleaning system for Priora The glass cleaning system consists of the following elements:

- Electric motor or wiper drive. This device ensures the normal operation of the system by facilitating the movement of the wipers along the front and rear (for station wagons and hatchbacks) glass. If the windshield wiper gearbox fails, it will cause the wipers to not work. The rear wiper drive is also installed only in hatchback or station wagon vehicles.

- The windshield wiper blade holder, also known as the windshield wiper arm, is also known as the windshield wiper arm - brush holder. The wiper blade itself is fixed to this device and moves along the glass.

- Brush with a rubber or silicone blade. When it wears out, the quality of cleaning the windshield is significantly reduced.

- The fastening of the windshield wiper blades is a structural element of the wipers themselves.

- Expansion tank - liquid is poured into it, which is subsequently transferred to the glass through nozzles through hoses when the wipers are turned on.

- Nozzles - these elements are mounted on the hood, they perform the function of spraying water onto the glass.

- Rubber hoses connecting the expansion tank and injectors - consumables are transferred through them.

- Depending on the car, it may use a windshield wiper control unit or a windshield wiper breaker. The latter is a relay that, in accordance with the actions of the driver, determines the frequency of movement of the brushes at specified time intervals. As for the block, it allows the driver to independently set the required interval.

- The washer motor, which supplies water or washer fluid to the windows.

- Windshield wiper switch. The steering column switch is located inside the car, under the steering wheel. With its help, the driver can set the speed of the wipers, and also, if necessary, supply water to the glass.

- A rod that connects two brushes. Thanks to it, these elements can move synchronously.

Photo gallery “System elements”

1. Six types of fastenings

2. Wiper arm remover

3. Expansion tank

VAZ 2109 tachometer does not work

The tachometer on the VAZ-2109 was installed only on cars with a high panel, and its connection diagram depended on which engine was installed, carburetor or injection. On “nines” with a carburetor engine, the signal to the tachometer comes from the ignition coil terminal, and in case of abnormal operation, troubleshooting should begin with the ignition coil terminal, to which two wires are screwed. There are cases when they are bent so that they are located next to the central high-voltage wire and in the event of a breakdown, the spark goes to these wires, which causes the tachometer to glitch. A similar picture occurs in the case of oxidation of these contacts. If the tachometer needle moves sharply in one direction or the other, it can be assumed that the culprit of this malfunction will be the switch, which will fail after some time. The tachometer, in fact, is an indicator of malfunctions appearing in the ignition system.

There are three types of wind wipers:

- Holder device without frame

- Holder device with frame

- A holder for a hybrid brush, the structure of which is similar to the others.

Pressure plates help connect the base to the body. In the diagram, they are made in the form of strips made of a springy alloy, with cuts along the edges that ensure fixation of the holder to the base. The base holders are inserted into special side grooves.

Then the elastic band with inserted springs is secured to the holder itself. In the case of frame fasteners, a design is used that consists of bent rocker arms - the body. Such a scheme has a main rocker arm, where there is a fastener for fixing it to the lever. At the edges of the movable rocker arms there are clamps that help hold the base with springs.

The tape of frameless fasteners is installed and secured in the clamps of an even elastic spring in the shape of an arc. This spring presses the rubber band to the surface of the glass, and an adapter is used to install it on the lever in the elastic spring. As for hybrid wipers, they have a frame hidden in a plastic housing.

How to change wipers on a car: step-by-step replacement process

Car windshield wipers, or more simply “windshield wipers,” are used to remove snow from the windshield in winter, and rain and dirt the rest of the time. They have to be changed quite often because they have a rather limited resource.

Of course, this can be done for you with pleasure at a car repair shop. But it’s so simple that you can easily do it yourself. In addition, replacing wipers is the same for all cars without exception. Now we’ll look at how to do it yourself correctly.

Source

Methods for connecting windshield wipers.

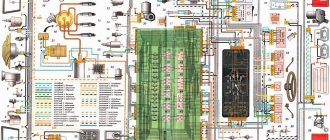

The connection diagram for windshield wipers can be divided into two types, depending on the method of connecting the operating mode switch.

In the first connection method, a constant plus is supplied to the wiper drive electric motor, and the mode switch connects the motor elements to the minus. This method is widely used in foreign and domestic cars.

The second method is completely opposite to the first, that is, power is supplied to the electric motor through the mode switch, and the minus in this case is taken from the drive housing.

I propose to consider the principle of operation of a car windshield wiper circuit using an example, where plus is supplied to the electric motor through a mode switch, since this is the more common connection method.

The diagram shows the connection of a windshield wiper drive with an electric motor powered by permanent magnets and having two operating speeds. The difference in speed in this circuit is ensured by the displacement of one of the positive brushes relative to the physical center of the electric motor armature.

Windshield wipers: design and principle of operation

A dirty car windshield significantly impairs visibility on the road, which negatively affects the quality and safety of driving. Therefore, Motorpage experts remind you of the need to keep your windshield clean.

Windshield wipers are installed in cars specifically for this purpose. On some cars they are present not only on the windshield, but also on the rear window.

Windshield wiper device

- Wipers are oblong elements that move along the glass. At rest they are located at the bottom of the windshield. Both wipers are connected by a rod, due to which they move synchronously. The main cleaning function is performed by brushes with a rubber or silicone blade or tape, located on the wipers using a special leash (brush holder). They are a consumable item, since over time the tape wears out and the quality of the cleaning procedure deteriorates. If this happens, the consumable (brush or tape) must be replaced.

- Windshield wiper drive with gearbox Provides movement of the wipers. There are different types: mechanical, pneumatic, etc. Electric drives are installed in modern passenger cars. If this unit fails, then when the windshield wiper is turned on, the wipers do not move.

- Trapezium - the element is located between the drive and the wipers. It consists of rods and levers, the task of which is to convert the rotational motion created by the electric drive into reciprocating motion and transmit it to the leashes.

- The tank is a plastic container (volume from 2.5 to 5 liters) located under the hood or fender of the car. Water is poured into the tank, which is subsequently supplied to the glass when the corresponding wiper function is activated.

- The nozzles are located on the hood and connected to the tank via rubber hoses, through which liquid is sprayed onto the glass.

- The washer motor is a pump in the reservoir that supplies water. At the moment when the car owner turns on the spraying mode, the device creates pressure in the system, which squeezes the liquid through the nozzles onto the glass.

- The switch is located under the steering wheel to control the windshield wiper system. Using it, the driver adjusts the movement of the wipers (single sweep, or at a specified interval, or constant movement at low/high speed), and also activates the fluid supply, if necessary.

- Control unit - the device is not installed in all cars; its main function is to automatically start and turn off the windshield wiper. A rain sensor helps determine when to activate the cleaning system, which analyzes current weather conditions and the cleanliness of the glass.

- Interrupter - the device allows you to adjust the interval between wiper strokes when selecting the intermittent operating mode. This function is useful in light rain to prevent the wipers from rubbing the dry glass.

Why doesn't the windshield washer work?

The system for cleaning glass and car headlights includes: a liquid reservoir, a pump, nozzles, tubes, electrical wiring and a power button. Most often, the reason why the windshield washer does not work is a faulty motor or a blown fuse. The operating principle of a windshield washer is quite archaic, so simple diagnostics and simple repairs can be performed almost at the doorstep of the nearest auto parts store.

Malfunctions and operating principles of hand and foot-operated windshield washers, which were installed on some VAZ and AZLK models, deserve a separate topic and will not be discussed in this article.

Causes of failure

- The windshield washer pump fuse has blown. Manufacturers mark consumers who are protected by fuse links with graphic symbols on the inside of the relay and fuse box cover. If the markings are unclear or the required insert is not marked, a detailed fuse location diagram can be found in the repair and operating manual for your car. Attention! Installing a larger fuse may cause the vehicle to catch fire. If the new fuse-link burns out immediately after installation, there is a short circuit in the circuit.

- The windshield washer motor is burnt out or soured. The low cost of the pump makes its disassembly and repair impractical, so simply replace it with a new one.

- The contacts on the connectors have oxidized, the power wires have become frayed or broken. In field conditions, oxides can be removed from the terminals with a sharp object. At the same time, do not damage or bend the terminals so as not to disrupt the quality of contact in the connector.

- The coarse filter in front of the windshield washer pump is clogged (not installed on all cars). The filter is attached to an O-ring that seals the pump installation location. If trouble catches you on the road and you cannot clean the filter element, temporarily remove it from the line.

- The hose from the pump to the injectors has fallen off or broken.

- The injectors are clogged. In winter, injectors can become clogged not only with debris and plaque, but also with ice. After using the windshield wiper, a washer fluid remains on the nozzles, from which the alcohol evaporates over time. The water remaining near the nozzle freezes, which is why the windshield washer does not work. You can pierce the injectors with a thin needle.

- The fluid in the washer reservoir has frozen.

The principle of operation of the drive, engine and other mechanism components

If the circuit and design of the windshield wiper do not raise any questions, let’s move on to the next point - the principle of operation. The windshield wiper holder, together with the blade mounted on it, moves left and right, which allows you to almost completely clean the windshield. As stated above, using the switch, the driver can adjust the speed at which the wiper blade holder will move. Some modern cars are equipped with hidden cleaners. In this case, the windshield wiper mechanism is installed under the windshield, and when the driver needs to turn on the wipers, the device pushes up this mechanism, which, after being turned off, “hides” back.

In general, windshield and rear window cleaners are almost identical products, but there are differences in their operation. For example, the windshield wiper blade holder can only operate in one mode, without the possibility of adjustment. That is, if the front wipers are part of a whole system that includes many elements and a control unit, then the rear wiper has only one function. One of the main components of the washer is a pump designed to activate the system’s electric motor.

Let's briefly consider the principle of operation of the system:

- The driver presses the steering column switch, giving the control unit a signal to turn on the wipers and also supply water.

- Through the operation of the electric motor, the liquid begins to be transmitted through hoses through nozzles to the windshield or rear window.

- The windshield wiper blade holder begins to rotate under the influence of an electric motor, to which the control device has sent a signal - at what speed the holders should move.

- With a short-term supply of liquid, a certain volume is applied to the glass. When the water stops flowing, the wipers continue to work for some time, usually 1-3 strokes (the author of the video is the Volkswagen channel RUS-LAN center).

Refinement stages

It is easy to modify or replace wipers. To do this you need to take several sequential steps:

- Disconnect the negative cable from the battery;

- Pull the wiper towards you;

- Remove the existing brushes;

- If there is a decorative trim, remove it;

- Unscrew the mounting bolt, thereby removing the old wiper;

- Compare the dimensions of the old and new cleaner;

- Ideally, the new device should not exceed the old one by more than 20 millimeters;

- Reverse the assembly procedure.

As you can see, changing windshield wipers is not difficult. But with the repair procedure, everything is somewhat different. But following the instructions, even an inexperienced VAZ 2110 owner will be able to do everything with his own hands.

The operating mechanism of windshield wipers is designed for a long service life and, as a rule, malfunctions and breakdowns occur due to improper operation. Most often, the failure of their wipers happens in winter, when the windshield wiper blades freeze to the windshield, and the driver, without noticing this, turns on the electric motor. In this case, both the electrical and mechanical parts of the windshield wiper may fail. In this article we will analyze the nuances when troubleshooting and repairing windshield wipers on VAZ cars.

Windshield wiper motor repair

There are several factors and reasons that can cause such an important device to fail.

In most cases, this occurs when there is no contact between the commutators and the brushes. If after inspecting the motor and thoroughly cleaning the contacts the problem does not disappear, you will most likely have to disassemble it and replace it. However, before taking such drastic action, there are a few more ways to take decisive action to consider. If the gearbox is jammed and the levers are jammed, most likely a certain fuse in the system has tripped , which is called a bimetallic fuse. As a result, the system will not be able to cope with its responsibilities and will cause additional problems for the driver.

True, if you remove the part in time and carry out the appropriate repairs by replacing the fuse , most likely the malfunction will be eliminated in a short time. Provided that everything is done correctly, the windshield wiper will start working normally, as before.

The development of cases where the device is capable of operating only in a specific speed mode cannot be ruled out. This problem is of a completely different nature and lies in a problem with the switch or resistor . Here the brushes do not come to the lower position at all, which makes it necessary to adjust the stopping mechanism.

Situations where strange sounds and noises are heard when starting the windshield wiper are also not uncommon. If such phenomena are in no way related to dry glass, perhaps we are talking about some more serious problem.

As mentioned above, the design characteristics of the wiper motor are extremely simple and understandable. There are small brush levers on the fingers, which most often make an unpleasant sound. Sometimes it happens that the mechanism begins to sour in the bracket bushings due to a violation of the protection. As a result, dirt and water get inside .

If, after a final check of the device, no malfunctions are found, but the noise still does not allow you to live in peace, the need to replace the motor . Now you should disconnect the device from the electrical supply, and then begin dismantling work.

Motor Troubleshooting

There are several different types of failure. The electric motor stopped working, the bimetal fuse is also faulty, while the integrity of the fuse link, which is an indispensable part of the power circuit, is still preserved.

Car device

Purpose of windshield wipers

Cars are operated in different climatic, road and meteorological conditions, and to ensure traffic safety and comfortable conditions for the driver, it is necessary to ensure perfect visibility of the road situation. The main factors that reduce visibility and visibility to the driver are contamination or moisture (for example, precipitation) of the windshield, rear and side windows, while reduced visibility through the windshield is the most dangerous from the point of view of traffic safety. Contaminated headlight glasses significantly impair visibility at night.

Based on the above, a windshield wiper is designed for mechanical cleaning of the windshield (in many models of passenger cars and the rear window) from precipitation and dirt. Headlight cleaners, recently installed on many passenger cars, are designed to clean the headlight glasses from dirt.

Wiper blades

Glass cleaning is carried out with special rubber-coated brushes, pressed tightly against the glass by the working surface and making oscillatory movements along the surface of the glass.

The number of windshield wiper blades depends on its size and shape; Most cars use two wipers, one on the driver's side and one on the passenger's side, but there are also cars with three windshield wiper blades on the windshield.

The brushes must move smoothly across the glass, without jolts (which is often the “sin” of vacuum and pneumatic drives) with a certain swing angle and pressing force against the glass.

The use of spheroidal glazing of the body and headlight glasses of complex spatial shape on modern cars complicates the operation of the windshield wiper blades, since it is difficult to ensure a tight fit of the blades to the glass surface. Therefore, windshield wiper blades are made flexible and increase the force of the springs pressing them to the glass. The flexibility of the brushes is ensured by increasing the number of rocker arms (joints) of the holder and the use of an optimally shaped brush profile.

Wiper drive types

The main design difference between windshield wipers used on cars is the type of drive of their blades, which can be mechanical (manual), electric, vacuum or pneumatic. Currently, the most widely used electric windshield wiper drive operates stably in all conditions (including when the engine is not running).

Mechanical (manual) windshield wipers, which were equipped with many cars until the middle of the last century, are now practically not used. They are the simplest in design, but are inconvenient to use, and also distract the driver from monitoring the road situation.

Vacuum-driven windshield wipers for their operation use the vacuum formed in the intake tract of the engine power supply system (the same as vacuum brake boosters). Significant disadvantages of such windshield wipers are the impossibility of using them when the engine is not running, as well as the dependence of their operation on the magnitude of the vacuum in the intake tract. However, vacuum-powered windshield wipers are occasionally used on some types of vehicles.

Pneumatic windshield wiper drives are sometimes used on trucks equipped with a pneumatic network. Such windshield wipers were used, for example, on the first models of KamAZ cars, but due to the lack of stability and reliability of the pneumatic valve control system, they were subsequently replaced by electrically driven windshield wipers. The pneumatic type of windshield wiper drive is currently found on some trucks.

Design and operation of electric windshield wipers

The kinematic and design solution of the windshield and rear window wiper mechanisms is quite simple. An electric windshield wiper (Fig. 1) consists of an electric motor, a worm gear (usually made in the same housing as the electric motor), a crank mechanism, a system of levers and brushes.

| Rice. 1. Schematic diagram of a windshield wiper: 1 - levers and brushes; 2 — crank; 3 - electric motor; 4 - gearbox; 5 - operating mode switch | Rice. 2. Rear window wiper motor 47.3730: 1 — gear; 2 - worm; 3 - output shaft; 4 — gear housing; 5, 7 — gear sectors; 6 — earring; 8 — electric motor housing; 9 - permanent magnet; 10 - anchor |

The electric motor 3 of the windshield wiper, through a worm gear 4, rotates the crank 2, which, through a system of drive levers and rods, imparts a rocking motion to the brushes.

On some cars (in particular, on buses with a large windshield area), the windshield wiper blades do not swing, but plane-parallel movements due to a special lever drive design. This allows the brushes to clean a larger surface of the windshield from dirt and moisture, but somewhat complicates the design of the drive.

The gearmotor has a built-in limit switch, which ensures that the brushes are placed in the extreme position when the gearmotor is turned off, and a bimetallic fuse that protects the circuit from overloads.

The limit switch breaks the power supply circuit to the motor when its rod gets into the recess on the output gear. Many windshield wiper gearmotors do not have a crank mechanism, in which the rotation of the motor armature is converted into oscillatory motion using the lever mechanism of the brush.

Different climatic conditions and vehicle speeds necessitate changes in windshield wiper performance. Obviously, in heavy rain or when the car is moving at high speed, even with slight precipitation, the windshield wipers should work more efficiently. Therefore, modern windshield wipers have devices that allow you to adapt the speed of movement of the brushes to the intensity of contamination or wetting of the glass. As a rule, such devices are electronic.

Where does which wire go, or just a diagram

Connecting wipers and washer

“Plus” power is supplied from the ignition switch through fuse No. 2 at 10 Amp of the mounting block. The permanent “plus” goes along the black and yellow wires to contacts “4” of the connectors of the gear motor and the steering column switch. It should not disappear even when the switch is in the “off” position. The blue wire supplies “+” 12 V power to the motor when the switch is in the “continuous mode” position. On the blue-white wire, in the “off” position there should be a “minus”, and in the “continuous mode on” position the “minus” is turned off. This is done to slow down the motor when the power to the closer is turned off.

The red wire supplies the relay with “+” 12 V from the switch when the intermittent mode is turned on. At the moment of operation, contacts “2” and “4” close, and “1” and “3” open, the motor starts working and the brushes make one or two movements. Then “+” 12 V is turned off, and contacts “1” and “3” are closed to each other and to “minus”. The motor stops for a few seconds and then the cycle repeats.

The washer pump motor is connected to “+” 12 V constantly with a black and yellow wire through the same fuse No. 2. “Minus” is applied when you press the windshield wiper lever from bottom to top.

Video about how a windshield wiper works

Electric motor for windshield wiper VAZ 2107, diagram

The VAZ 2107 car is equipped with an electric windshield wiper motor (wipers), which can clean it in intermittent and continuous modes.

Here is a diagram of its connection with a description of its features and operating procedure, which can help if any malfunction occurs with it.

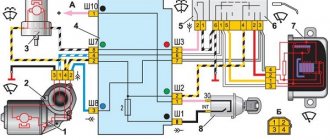

Wiring diagram for the electric motor of the windshield of a VAZ 2107 car

Description of the connection diagram for the electric motor of the windshield wiper VAZ 2107

— Voltage in the electrical circuit for switching on the windshield wiper motor is supplied from the positive terminal of the battery through terminal “30” of the generator and the ignition switch. That is, you can turn on the wipers only after turning the key in the lock.

— The electrical circuit is protected by fuse F2 (10A) in the mounting block.

— The electric motor of the wiper is turned on using the lever of the right steering column switch: the first position is intermittent mode of the wipers, the second position is the brushes work constantly.

— When the intermittent operation mode of the wipers is turned on, electric current flows through the breaker relay RS-514. There it goes from the steering column switch through the red wire to the relay electromagnet and its thermobimetallic breaker and then through the gray wire to the wiper motor.

When current passes, the relay breaker plate heats up, bends and opens the breaker contacts. In this case, the contact of the electric motor switch is closed to ground (yellow wire from the steering column switch to the relay and blue-white wire from the relay to the electric motor). The electric motor stops. After which the breaker plate cools down, straightens and again closes the contacts inside the relay, the voltage is again supplied to the electric motor. He starts working. Such on and off cycles are repeated with a frequency of 9-17 times per minute.

Notes and additions

— On a VAZ 2107 car and its modifications of different years of production, as well as on VAZ 2104, 2105 cars, the color of the wires in the windshield electric motor connection diagram may differ from the one shown above.

— In addition to the windshield cleaner, the VAZ 2107 has a washer, consisting of an electric motor for a pump in the washer fluid reservoir, pipes and spray nozzles. It is turned on by the same right steering column lever (move it towards you to an unfixed position). Here is its connection diagram “Windshield washer connection diagram for a VAZ 2107 car.”

Source

Motor repair

Many people think that replacing the motor with a similar one from a foreign car can solve the problem with the slow operation of the wipers, but in fact, it is often enough just to clean and lubricate the “original” engine.

If the speed of operation causes complaints, then it is necessary to check how easily the armature rotates: if movement is difficult, damage or excessive wear of the brushes should be suspected. They are easy to replace with new ones.

Cleaning the collector will also help - this will require fine sandpaper. The need for this procedure is said:

- visible contamination;

- noticeable scratches;

- grooves on the metal.

It will be necessary to replace the armature or gearbox along with the complete motor if the manifold is too worn or burnt.

Adjusting the operating speed is necessary if the windshield wipers operate too slowly. This is facilitated by:

- incorrect (too tight) lubrication;

- gear wear;

- rod deformation

Eliminating these problems basically makes it possible to speed up the wipers and, moreover, significantly.