Engine knock can lead to significant wear of engine parts such as the cylinder head gasket, elements of the cylinder-piston group, pistons, cylinders and other parts. All this significantly reduces the resource of the power unit until it completely fails. When this harmful phenomenon occurs, it is necessary to diagnose the reason why detonation occurred as quickly as possible and get rid of it. How to do this and what to pay attention to - read on.

How does engine detonation occur?

A serviceable engine will detonate if you “force” it to run on fuel whose characteristics do not correspond to its normal octane (gasoline) or cetane (diesel) number. Conversely, if the fuel is “ok”, then something is wrong with the engine. With the settings of the ignition system, the balance of air and fuel in the air-fuel mixture, or the operation of the gas distribution system.

The longer you ignore this sign of malfunction, the less chance you have of avoiding a major overhaul of the cylinder-piston group.

In the normal operating cycle of an internal combustion engine, the fuel in its cylinder is evenly sprayed into tiny droplets, mixed with air, and burns gradually, smoothly transferring its thermal energy to the bottom of the piston, and then to the crank. The speed of propagation of the flame “front” in this case is 20–30 m/s. During detonation, it is almost 10 times greater, and reaches supersonic (over 1200 m/s). The fuel no longer creates such a “soft” wave that presses forward on the bottom of the piston, but almost “explodes”, forming a shock force that has a destructive effect on the CPG. It's like pressing a button with your finger, or hitting it with a hammer - the difference in impact is approximately the same.

Fuel combustion diagram

Some car owners use the terms “detonates” and “knocking” for the same symptoms, but these are two different definitions. The process of engine detonation is characterized by the occurrence of this “destructive impulse” - after the spark has jumped (in a gasoline engine) or the end of the compression stroke (in a diesel engine), at the moment of maximum pressure. And “knocking fingers,” or glow ignition, which is confused with detonation, will occur, on the contrary, before the normal ignition of the mixture.

In carburetor internal combustion engines that are not equipped with a gasoline cut-off, or diesel engines with a faulty return valve, this is the reason for difficulties in stopping the engine when the key has already been removed from the lock, and the engine continues to “jerk” the car.

Useful tips and recommendations from experienced motorists

The shock wave formed during explosive combustion changes the tone of the engine. The driver needs to learn to detect the appearance of extraneous sounds indicating incorrect operation of the power unit. It should be taken into account that the sound of the motor is not allowed to change while driving. Any extraneous noise indirectly indicates a malfunction of the unit.

If detonation appears after refueling the car, then it is necessary to add gasoline with a higher octane number to the tank. If the engine is designed for fuel type A-98 or higher, topping up will not help. It is necessary to drain the fuel and wash the ramp and injectors. During long-term operation of the machine in city traffic jams, carbon deposits on the piston group parts. To remove deposits, it is necessary to travel 50-70 km along a country highway at the maximum permissible speed.

Causes of engine detonation

Each car engine is designed and tuned to run on a specific fuel. The characteristics of gasoline, diesel, or a mixture of gases (for a car with LPG) include a threshold compression ratio to which this class of fuel is resistant to self-ignition or explosive combustion. For gasoline and gases, the distribution into types is based on octane number (AI 95, AI98, AI105, etc.), for diesel - according to cetane number. If a mixture is supplied to the cylinders that does not correspond to the compression force provided by a particular engine - more resistant to self-ignition (high octane) - it will not burn completely and will create a temperature in the chamber higher than the calculated one. Less stable - it will light up earlier than necessary, at the end of the compression stroke, when the piston moves to TDC, and will create resistance to its movement.

The most common problem that can cause detonation is poor-quality contents of filling containers at gas stations that do not suit the characteristics of the car.

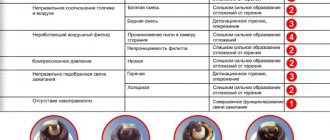

Engine detonation causes:

- Low octane fuel in engine cylinders with a high compression ratio.

- Fuel deficiency - a lean mixture is less resistant to detonation.

- Increased temperature in the combustion chamber compared to the calculated one.

The first factor is often aggravated by: problems in the fuel system, wear of the CPG, soot deposits in the combustion chamber - around the valve seats, or the threaded hole of the spark plug.

Soot deposits on the piston

The second reason has several “roots”: clogged injectors, a fuel filter, a faulty rail pressure regulator, or a pump that does not provide enough “power”.

The third - can be caused, in addition to poor fuel, by insufficient cooling of the engine, or the air entering it (from the turbine), or the entry of engine oil into the chamber through worn oil scraper rings.

Unsuitable fuel

If fuel enters the engine, the octane number of which is lower than the recommended one, the chance of encountering detonation inside the cylinders increases to one hundred percent. The thing is that automakers calculate compression ratios only for a specific type of fuel. You can correct the situation with low-quality fuel using a special Octane corrector from LAVR.

Octane number of gasoline and cetane number of diesel

The gasoline index we are used to at gas stations is its detonation resistance coefficient. The comparison is made in relation to a mixture of gasoline derivative - heptane, with isooctane - one of the most resistant to compression ignition components. Heptane has 0% stability (none), isooctane has 100% stability. For example, the marking “95” indicates that the stability of this gasoline, like isooctane, is 95% “strength”.

To control the combustion of the air-fuel mixture, achieving more “predictable” behavior from it, anti-knock additives that slow down the reaction are added to gasoline and diesel fuel.

Comparison of gasoline composition

The measurement scale up to 100 was quite logical until additives that inhibit compression ignition, more effective than tetraethyl lead, appeared, with the help of which 95 and 98 gasoline (from 92) are now produced.

The quality of the resulting “feed” for the engine depends on how “legal” the compounds are used: its resistance to separation into fractions, to carbon formation, resinity, percentage of sulfur content. Ferrocene, manganese additives, the same tetraethyl lead, now prohibited by law, are not just carcinogenic and harmful to the environment - they are slowly “killing” internal combustion engines equipped with distributed injection and a catalyst. The approved additives - monomethylaniline (MMA), with methyl tert-butyl ether (MTBE) - are also unsafe. The first one increases tar formation (and soot), the second one quickly evaporates in warm weather (if the tank is not sealed), thereby reducing the octane number of gasoline.

Diesel fuel has its own stability equivalent - cetane, which exhibits a large compression ignition delay (100%). Methylnaphthalene (0%) is used as an “antagonist” for it.

The cetane number of modern diesel fuel ranges from 45 to 55. Diesel fuel with a lower number provokes a nonlinear increase in pressure in the combustion chamber, prematurely wearing out the CPG, and with a higher number (58–60) it does not burn completely, causing the internal combustion engine to “smoke.”

Detonation and glow ignition

There are cases when detonation occurs when the ignition of a VAZ-2106 or any other version is turned off. That is, the power plant continues to operate independently even after the spark supply is stopped. Here, too, the process of self-ignition occurs, but it occurs for slightly different reasons. Such ignition occurs from some excessively heated elements of the CPG. This effect is called “glow ignition”, and this is no longer detonation of the VAZ-2106 engine. These two concepts should not be confused as they are completely different.

Related link:

How to start a VAZ engine in winter

Article on the topic - How to deal with glow ignition

Incorrectly configured ignition

Symptoms similar to engine knocking can occur when the ignition timing is set earlier than necessary. Now this is mostly a feature of archaic carburetor power units equipped with a distributor, where the torque was set manually. For internal combustion engines equipped with an electronic ignition and injection control unit, failures occur: due to spark plugs that do not match the heat rating, from overheating, or due to a malfunction of the oxygen sensor (lambda), based on the readings of which the injection control unit adjusts the volume of fuel supplied (leans the mixture) . A separate point is incorrect ignition settings during inept chip tuning. But this reason is quickly revealed by diagnostics.

Popular brands:

Hyundai Solaris, Mitsubishi Pajero Sport, Toyota Land Cruiser

Renting a trailer: where to rent and what you need for it

There are several tips that you can follow in such situations. But do not forget that taking specific measures directly depends on what exactly was the cause of the detonation.

- If everything was fine before visiting the gas station, and then problems appeared, the reason is probably the fuel. It is better to drain it and refuel with higher quality fuel;

- When a machine is operated for a long time without load, carbon deposits often appear in the cylinders. It is he who provokes detonation. The best solution here would be to give the engine a load. That is, just accelerate the car to maximum speed for how many minutes, choosing a safe road;

- If it's a diesel engine that produces black or green exhaust when running, the pistons in the cylinders are probably damaged. Such smoke indicates the release of aluminum. You will have to change the entire piston group;

- If the spark plug malfunctions, you can try cleaning it. It’s better to just take a new and high-quality part;

- Check and adjust the ignition angle if necessary. Early ignition provokes overheating of the internal combustion engine. As a result, detonation occurs.

ICE detonation is definitely not something to joke about. This is a serious sign that requires immediate action from the motorist aimed at identifying the causes of internal explosions in the engine, as well as eliminating them.

Sometimes it is right to turn to specialists right away, rather than trying to figure out the reasons at random on your own. Don't be afraid to ask for help and consult with more experienced motorists. This is the only way to gain a solid store of knowledge by learning from others, and not from your own mistakes.

Thank you all for your attention! Be sure to subscribe, leave comments and ask relevant questions on the topic!

Candles

A gasoline engine detonates due to overheating of the cylinder head, especially if it is “provoked” from the inside. Self-ignition of gasoline can occur when the spark plugs in the engine do not meet the required temperature characteristics. “Hotter” spark plugs have a long skirt that shields the central electrode, which prevents it from cooling quickly.

Spark plug

When operating in a high-speed engine with intense temperature conditions, “hot” spark plugs overheat and can cause overheating or detonation, so it is recommended to install spark plugs of the rating specified by the manufacturer.

Signs of detonation

There are a number of signs by which you can indirectly determine that detonation is occurring in the engine of a particular car. It’s worth mentioning right away that some of them may indicate other breakdowns in the car, but it still makes sense to check for knocking in the engine. So, the signs include:

- The appearance of a metallic sound from the engine when it is running . This is especially true when the engine is running under load and/or at high speeds. The sound is very similar to what happens when two iron structures hit each other. This sound is precisely caused by the blast wave.

- Decrease in engine power . Usually, in this case, the engine does not operate stably, it may stall when idling (this is important for carburetor cars), it takes a long time to gain speed, and the car’s dynamic characteristics drop (it does not accelerate, especially if the car is loaded).

Diagnostic scanner Rokodil ScanX for connecting to the car ECU

It also makes sense to give signs of failure of the knock sensor. As in the previous list, signs may indicate other breakdowns, but for injection machines it is better to check the error using an electronic scanner (the most convenient way to do this is with a multi-brand Rokodil ScanX , which is compatible with all cars from 1993 onwards and allows you to connect to a smartphone on iOS and Android via Bluetooth). Such a device will make it possible to see the indicators of the knock sensor and others in real time.

So, signs of a knock sensor failure:

- Unstable engine operation at idle speed;

- a drop in engine power and in general the dynamic characteristics of the car (accelerates poorly, does not pull);

- increased fuel consumption;

- Difficulty starting the engine, this is especially noticeable at low temperatures.

In general, the symptoms are identical to those that occur with late ignition.

Lean air/fuel mixture

Less fuel means more air, higher combustion temperature, higher tendency to self-ignition from compression. Most cars with a mileage of 180 thousand km, which have never been subjected to the injector cleaning procedure, have problems with mixture formation and are prone to detonation. Another likely reason why problems with a lean mixture and overheating may occur is the installation of a high-performance turbine. Excessive boost, without proper cooling and adjustment of injection settings, only leads to increased load on the engine.

Why else can depletion occur:

- The performance of the fuel pump has decreased.

- The fuel filter is clogged.

- Low pressure in the line - the valve drains into the return line.

- Air locks in the system.

- Failure or incorrect readings of the oxygen sensor (lambda).

Regardless of whether a “check” appears on the dashboard, a lambda error seriously affects the further “behavior” of the car, so it must not only be removed, but diagnosed and eliminated.

How to make your own bike rack

- low quality fuel;

- improper operation of the vehicle;

- dirty fuel filter;

- using gasoline with a low octane number;

- malfunctions and incorrect operation of the fuel pump;

- mismatched spark plugs;

- contamination or breakdown of nozzles;

- problems with the oxygen sensor;

- cooling system malfunctions;

- design features, etc.

But how can you determine what exactly the car encountered in a particular situation? For this it is worth considering the reasons in more detail.

Carbon deposits and design features of internal combustion engines

An implicit reason for engine detonation is the shape of the combustion chamber, which is very different from the “ideal” hemispherical one. Depending on the design operating mode of the internal combustion engine, the shape of its chamber can affect the ease of starting, efficiency (completeness of combustion of the mixture), noise, vibration level, and thermal operating conditions. A specific symptom is glow ignition, which occurs due to poor evacuation of combustion products. The accumulated soot becomes hot, early igniting fresh portions of fuel in the “corners” of the chamber, or provoking engine vibrations after the ignition is turned off.

Carbon deposits on valves

Eliminating such shortcomings is the job of the factory, but sometimes a similar “jamb” occurs after a major overhaul, when when grinding the cylinder head (to increase the compression ratio), a thin layer of metal remains at the edges of the combustion chamber (not chamfered), which later becomes red-hot, performing the role of soot.

What is the fine for driving on the sidewalk: can it be avoided?

If the engine is operating normally and no malfunctions are observed, then the speed of fuel propagation is about 20-30 meters per second. When detonation occurs, this figure can increase tens of times. It is quite simple to recognize the occurrence of such a phenomenon, since a corresponding metallic sound occurs from the internal combustion engine. Among motorists, the concept of finger tapping is quite common. The reason for this noise is due to the fact that the blast waves contact the walls inside the combustion chamber. This contributes to a drop in the power of the internal combustion engine with a parallel rapid increase in consumption.

Detonation can also occur in a situation where the engine has already been turned off and the ignition has been turned off. The engine does not stop immediately, but still runs for about 20-25 seconds, and only then stalls. In such a situation, you should not wait until the engine stops on its own. It is necessary to help reduce the temperature inside by supplying additional fuel. To do this, simply press the gas pedal.

Cooling system malfunction

An air lock in the line impairs heat dissipation and can cause overheating of the cylinder head, due to which the fuel will begin to flare up in the combustion chamber before the intended moment - already during injection.

A “boiling” engine means there is almost a 100% chance of detonation, even if everything is fine with the fuel system or ignition.

The tendency of the car to quickly warm up, especially in winter, frequent overflow of the expansion tank, or, conversely, its dry bottom are the first signs of problems with the cooling system.

The same manifestations indicate burnout of the cylinder block gasket when exhaust gases enter the antifreeze through a microcrack. As a preventive measure, you need to change the coolant, or, if it was recently replaced, simply drain it into a container, then pour it back into the system - according to the instructions. After making sure that there is no air lock, you need to check whether the radiator and pipes are inflated by excess pressure: remove the radiator cap, tightly put a condom or a whole plastic bag on the neck, then start the engine. In a working system they should not swell.

Testing the cooling system with a condom

Prevention methods

Basic methods to reduce the risk of detonation combustion:

- Periodically check the condition of the ignition system components on carburetor engines. Failures or malfunction of sensors that correct the advance angle lead to disruption of spark formation and a drop in power simultaneously with an increase in fuel consumption.

- When the Check Engine light turns on, diagnose the vehicle's electronics; the detected codes allow you to identify faulty sensors or damaged wiring harnesses.

- Use motor oils with appropriate base stocks and viscosity indices, which prevents the formation of carbon deposits on the surface of the combustion chamber.

- Change worn valve stem seals in a timely manner and carry out chemical or mechanical decoking of the engine (to remove a layer of carbon deposits).

- Maintain the cooling system in accordance with the manufacturer's recommendations. During operation, antifreeze degrades, which leads to a drop in performance and local overheating of the cooling jacket.

- Do not drive at low speeds in low gears. Some manual cars are equipped with an electronic prompt that indicates when to shift up or down. The computer operating algorithm is designed to reduce fuel consumption; short-term detonation is allowed during acceleration.

Violation of engine operating conditions

Some drivers deliberately fill the tank with higher or lower octane gasoline, trying to save money, reduce consumption, or increase the speed characteristics of the car without spending money on serious tuning. This approach will not only deprive the car owner of the existing warranty, and will reduce the life of the engine: for highly forced engines, a few minutes of operation in this mode is fatal.

Sometimes the cause of a similar problem in diesel engines is a consequence of eliminating the “environmental friendliness” of the engine - the plug of the USR system. Replacing part of the mixture with exhaust gases coming from the USR into the cylinders slightly reduces the temperature in the combustion chamber.

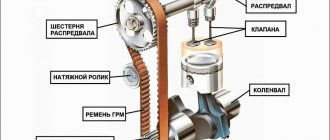

Design solutions to prevent detonation

To combat detonation, engineers at different times used certain design solutions. Such solutions are aimed at the most efficient and rapid combustion of the fuel charge in the flame front, complete combustion from a spark, and slowing down oxidation processes, which result in uncontrolled ignition.

It must be added that in order to counteract detonation, engine speed can be increased, resulting in a shorter time for oxidative reactions to occur and a reduced likelihood of self-ignition of the fuel-air mixture.

Another engineering solution is turbulization. Due to the design features, the mixture flows in the combustion chamber receive a certain rotation, and the flame front from the spark spreads faster. Reducing the distance the flame front travels also helps resist detonation. To shorten the distance, the cylinder can be made with a smaller diameter, and it is also possible to install another spark plug.

Separately, it is worth noting the prechamber-torch ignition, which at one time was designed to effectively combat detonation. Motors with a pre-chamber are structurally designed to have two chambers: a pre-chamber and a main chamber. The principle of operation is that an enriched mixture is created in the small chamber, and a lean mixture is found in the main chamber. After ignition of the mixture in the prechamber, the flame front ignites the mixture in the main chamber, eliminating the possibility of detonation.

We also recommend reading the article about what a prechamber engine is. From this article you will learn about the design features and operating principles of pre-chamber motors.

On modern engines, electronics actively resist detonation. The advent of microprocessor-based engine control units (ECUs) made it possible to automatically change the ignition timing (IAF) based on readings from sensors, as well as dynamically make adjustments to the composition of the combustible mixture.

Consequences of engine detonation

The most unpleasant consequence is the destruction of the surface of the piston and cylinder head. From impacts and high temperatures, metals crack, crumble, and melt. The oil burns out, depriving the rubbing moving parts of protection. The partitions between the sealing rings break, their parts can jam the exhaust valve or get into the crank chamber. Sometimes the pistons completely “lose” part of the bottom. The cylinder head is caused by overheating and microcracks also appear in it. The walls of the cylinder are covered with a coating of molten metal of the piston, ripped open by fragments of rings, or by a finger that has lost support. If engine detonation was “stopped” in time before the process went far, traces of the impact will be limited to individual “notches” on the bottom of the piston, which will only be visible with an endoscope, or after disassembly.

Consequences of detonation

Why is detonation dangerous for internal combustion engines?

The main consequence of detonation is destructive loads. As a result of its impact, parts of the crankshaft and crankshaft engine break: pistons, rings, connecting rods, liners quickly wear out - in a word, elements that are loaded to the maximum extent even during normal engine operation. Another unpleasant moment is the increase in temperature. This causes gradual destruction of the cylinder bore, valves and breakdown of the cylinder head gasket.

The overall result of the impact of temperature and shock loads caused by detonation is premature engine wear, which seriously reduces its service life. For an ordinary car owner, the presence of constant detonation means an unscheduled overhaul of the power unit.

How to eliminate engine detonation

Immediate protection against destruction of the power unit is a decrease in the temperature in the combustion chamber: cooling the incoming air, increasing the fuel content in the mixture, adding heat-intensive compounds to it. The sensor of the same name (SD) is designed to combat the manifestations of engine detonation in a car. This is a piezoelectric element that responds to a clearly defined type of vibration. Once activated, it sends a signal to the injection control unit about the need to add fuel to the cylinders, thereby slightly reducing the temperature in the chambers.

Some injection cars, in order to stabilize the working process and reduce the temperature in the cylinders, are equipped with tuning units with the injection of water-methanol, or water (unlike nitrous oxide - automatic). The second method is to install a high-performance intercooler at the intake.

The very first piece of advice is to change the gas station where you regularly fill up. Fuel can be “scorched”, regardless of class or cost - it all depends on the primary raw material and the quantitative content of anti-knock additives in it.

Reliable elimination of a phenomenon is impossible without eliminating the causes that led to it, and which are very difficult to find without a full diagnosis. If you are tired of removing the possible causes and consequences of detonation one by one, but still haven’t gotten rid of it, contact our technical center, we will definitely help.

Let's sum it up

Engine knocking is a problem that the owner of any make and model of car can encounter. There are many reasons for this unpleasant phenomenon, but they all involve the use of unauthorized equipment, low-quality parts or consumables during machine maintenance, as well as inattention to the functionality of the motor. Detonation is a potentially dangerous phenomenon, which is fraught with costly repairs to the power unit. Be attentive to the car engine, react immediately to unpleasant changes in its operation - this will help ensure the engine has a long period of operation and an accident-free life.

Replacing the sensor

We figured out how to check the knock sensor of a VAZ-2114 or any other model. Please note that this sensor cannot be repaired and if it is faulty, it must be replaced.

Replacing the VAZ-2114 knock sensor is a simple operation, but it can be difficult due to poor access to it (16-valve engines). To change, you just need a new element and an open-end wrench of the appropriate size.

Before unscrewing the mounting bolt, you must first disconnect the block with wires. Then the bolt is unscrewed, the old sensor is removed, and a new one is installed in its place and securely fixed with the same fastener. And only after that the block with wires is connected.