Guys, I'm in trouble, I need help!

I’ve already listened to a lot of opinions and a lot of people came and there’s no point, I’m just throwing away money.

UAZ 31512, engine 417 umz. The carburetor is 126 gm, I checked it, it doesn’t leak anything, it starts up great. Compression is very good, the engine is 2 years old. Popping sounds started in the carburetor when you pressed the gas pedal, but at idle there is no acceleration and there is no acceleration and they are not rhythmic. I changed the switch because the new distributor, spark plugs and wires were also overheating. They said ignition earlier, turned the skewer, the pops disappear, but remain with sharp gas. What else to watch, where to run? Help!

A very common problem among owners of carburetor cars is carburetor popping. This malfunction often appears when the engine starts, as well as during engine operation. The main reasons why the carburetor shoots are considered to be a too lean fuel mixture or malfunctions in the timing mechanism. But there are other reasons. This problem makes drivers significantly worried, so let's look at it in more detail.

How does the malfunction manifest itself?

It shoots into the carburetor most often when you sharply press the accelerator, when trying to start a cold engine, as well as while driving under high loads.

Depending on the specific reason that caused this behavior, the popping may appear abruptly or gradually, increasing in intensity every day. Operating the engine in this condition, in addition to driving discomfort, may lead to the need for major repairs.

Consequences of claps and shots

If you hear a pop when you sharply press the accelerator pedal, then you should definitely expect unpleasant surprises.

Among the consequences are increased fuel consumption and engine overheating. The motor in this condition will not develop full power. You shouldn't count on smooth idling either. Starting the engine is very difficult and sometimes almost impossible.

If the carburetor slams, then the engine response to the gas pedal is inadequate. All fine tuning of the motor and each of its systems is lost. These moments are often accompanied by failures and delays in response to pressing the gas. At the same time, the car moves jerkily, twitches in load mode and in transient modes. The engine will sneeze and stall.

High voltage wires

This is one of the reasons why the VAZ carburetor shoots. If repairs were carried out during which the explosive wires were removed, then we cannot exclude the possibility that they were then connected to the distributor incorrectly. As a result, the spark will not be supplied in the compression stroke. This is what causes the pops. Even if the engine can still be started, its power will not be enough for full movement.

Diagnosing this malfunction is quite simple. First of all, check whether the spark plug wires are connected correctly to the distributor. They start from the mark of the first cylinder on the ignition distributor cover. The connection must correspond to the firing order of the cylinders. On most engines it is 1-3-4-2. The wires are connected in a counterclockwise direction - the distributor rotates in this direction.

K151v carburetor on UAZ problem

#1 OFF SITE alexnaz

- User

- Registration: 20 Nov 2008

- 767 messages

- Car: Volvo, Patrol Y60 (sold), UAZ 469 (was, ehh.)

- Name: Alexander

- Gender: Man

- City: Kyiv

- Top

- ↓

- ↑

#2 OFF SITE alexnaz

- Car: Volvo, Patrol Y60 (sold), UAZ 469 (was, ehh.)

- Name: Alexander

- Gender: Man

- City: Kyiv

10 seconds and stalls, with a pulse of throttle it shoots into the carburetor and once into the muffler. We found out that the problem was in the ignition. When the variator was disconnected the ignition disappeared. But is a variator really necessary with such contactless ignition? Distributor without Hall sensor.

1. + from the ignition key - to the plus of the switch 2. + from the switch to + coils 3. Distributor sensor 4. From the switch to the ignition coil Plus from the ignition, the electrician found the CVT from here, what should I do with it? At the market, when I bought a contactless ignition, the seller said that the variator was not needed because it was already built into the switch.

- Top

- ↓

- ↑

#3 OFF SITE beag

- Car: all-wheel drive

- Name: Alexey

- Gender: Man

CVT what to do with it? At the market, when I bought a contactless ignition, the seller said that the variator was not needed because it was already built into the switch.

- Top

- ↓

- ↑

#4 OFF SITE all-terrain vehicle

- Car: UAZ-31514

- Name: Sergey

- Gender: Man

- City: Chernigov

- Top

- ↓

- ↑

#5 OFF SITE alexnaz

- Car: Volvo, Patrol Y60 (sold), UAZ 469 (was, ehh.)

- Name: Alexander

- Gender: Man

- City: Kyiv

Was the carburetor the same? Similar work can happen when the wire from the distributor coil is broken; you remove the distributor cover and look, it can be repaired with a soldering iron.

- Top

- ↓

- ↑

#6 OFF SITE alexnaz

- Car: Volvo, Patrol Y60 (sold), UAZ 469 (was, ehh.)

- Name: Alexander

- Gender: Man

- City: Kyiv

- Top

- ↓

- ↑

Number of users reading this topic: 0

0 users, 0 guests, 0 hidden users

Fuel mixture composition

If the wires are connected correctly, but the problem remains, then you should look further for the reason why the carburetor is shooting.

If a too lean or rich mixture enters the combustion chambers, frequent popping noises are possible. This situation occurs if the carburetor has been adjusted. If the mixture quality screw is set incorrectly, the air-fuel mixture will not be prepared correctly.

If the engine runs on a lean mixture, it burns longer than usual. When the intake valve opens, the mixture is still burning. It ignites a new portion and burns in the intake manifold. This is why the carburetor on GAZelle and other cars shoots. At the same time, the engine temperature rises and there is a risk of overheating.

If too rich a mixture is supplied to the cylinders, the electrodes of the spark plugs become covered with black soot. When there is a lot of this deposit, at high temperatures it can ignite the fuel-air mixture at the wrong time. This results in popping noises as the intake valve is currently open. This only appears when the engine is hot. During operation, the engine will gradually sneeze more and more often. In this case, there is practically no drop in power.

avtoexperts.ru

The main, most common causes of malfunction are problems with valve timing, fuel supply or ignition systems.

Popping noises can occur during various operating modes of the power plant, namely:

• When starting the power plant;

• At idle;

• During transient conditions;

• When releasing gas.

Why does the muffler shoot?

The main reason is unburnt fuel that got into the muffler and ignited in it. The louder the “shot” will be, the more fuel has accumulated in the exhaust pipe.

Fuel entering the exhaust system is caused by the following:

• Malfunction of fuel system elements;

• Valve timing failure;

• Violation of valve clearances;

• Carbon formation on exhaust valve plates or valve seats;

• Stuck or burnt out exhaust valve;

Supply system

Malfunctions of the fuel system are expressed in the incorrect dosage of the mixture by the carburetor due to contamination of the jets, an increased level of fuel in the float chamber, which causes an over-enrichment of the fuel mixture and, as a result, its incomplete combustion. In this case, part of the unburnt fuel enters the exhaust manifold during the exhaust stroke.

A rich mixture can also form due to a malfunction of the injector nozzles, which produce an unmetered portion of gasoline, some of which also ends up in the muffler without burning. A clogged air filter also contributes to fuel enrichment, when it is no longer able to pass the amount of air necessary to form the mixture.

If the valve timing is violated, the exhaust valves open earlier than the specified moment and part of the unburned fuel is pushed into the exhaust system.

Valve mechanism

When the prescribed gap decreases, the valve cannot “sit” tightly in the seat and part of the mixture breaks into the muffler; the same thing is observed when carbon deposits form on parts of the valve, as well as when it hangs in the guide sleeve.

When the exhaust valve plate burns out, a looseness appears in the connection and during the compression stroke, part of the fuel is also pushed into the muffler.

Ignition system

Late ignition also causes popping noises in the muffler. This is caused by the fact that the mixture is already compressed and the piston begins to reverse and only then does a spark jump out, which leads to incomplete combustion of the fuel, some of which enters the muffler, where it ignites and burns in the form of a loud bang.

Late ignition not only provokes shots in the exhaust gas system, violating the integrity of its elements, but also contributes to burnout of the exhaust valve plates, which will require further engine repair.

The fuel may not burn completely due to misfires in individual cylinders, or a weak spark, which in turn is associated with a malfunction of the distributor, ignition module, high-voltage wires or spark plugs.

Injection engines

The occurrence of shots in the muffler in engines with an injector is caused, in addition to the reasons listed above, also by a malfunction of various sensors. Thus, the operation of the engine is controlled by an electronic unit that receives information from sensors, the failure of which leads to errors in control and incorrect formation of the fuel mixture, causing it to become over-rich.

A faulty knock sensor can cause late ignition.

Engines equipped with a gas installation

Shots in the exhaust system on engines running on gas are caused by the following reasons:

• Malfunction of the gas reducer, dirty air filter, which leads to enrichment of the gas mixture, its incomplete combustion, part of which ends up in the muffler, where it burns in the form of cotton;

Additional reasons

In addition to those listed above, there are several other reasons for popping noises in the muffler, for example:

• Incorrectly installed wires on the spark plugs;

• Air leak through the intake manifold;

• Lack of tightness between the exhaust system elements;

• Violation of the gap between the contacts in the distributor.

Corrective Action

First of all, it is necessary to check the integrity and reliability of the connections of all elements of the exhaust gas system. Lack of tight connections contributes to the appearance of shots when releasing the gas or when driving down a mountain at the moment of engine braking.

It is also necessary to adjust the valve clearances, check the compression in the engine cylinders, flush and adjust the carburetor, the injection system on injection engines, check the valve timing, as well as the ignition timing. Install a new air filter.

Ignition timing

If the OZ is too late, then combustion of the fuel and air mixture occurs during the entire working stroke of the piston. When the intake valve opens, the old mixture ignites a new portion. The motor is subject to severe overheating. Popping noises can occur not only in the carburetor, but also in the muffler of the car.

It is recommended to check the ignition timing and adjust it if necessary. Late ignition can be diagnosed by the white electrodes of the spark plugs.

If it is early, then the fuel does not ignite in a timely manner. The intake valve is not yet closed and the combustible mixture burns directly in the intake manifold. That's why it shoots into the carburetor of the 402 engine.

Particular attention should be paid to the advance angle if repair work has been carried out on the ignition system. It is necessary to adjust the moment of sparking.

Equilibrium mechanism

Why the VAZ-2107 carburetor does not start and what to do

This mechanism is designed to reduce strong engine vibration. The design is quite strong and reliable. The main failure is a broken gear. The situation can be resolved by replacing the toothed disc.

As a result, it should be said that most of the above situations can be avoided if quality maintenance is carried out on the car and, in particular, the engine. The Oka is considered a rather capricious machine, so it is recommended to constantly monitor and care for it so that it is always on the move and helps out at the right time.

Switch

Failure of the commutator usually makes it impossible to start the motor. If attempts are made to start the car engine, popping noises will appear. To accurately diagnose switch failure, you should install a new or known-good device. If the engine no longer fires, then the switch needs to be changed - it is not profitable to repair it.

This malfunction often manifests itself in the early stages. This is usually accompanied by instability of speed. When you press the accelerator sharply, the car picks up speed with dips. Popping noises are also heard.

Violation of valve timing

This is one of the reasons why the carburetor shoots. Let's look at it in more detail. So, if the engine starts with characteristic pops and shots in the carburetor, then you can suspect that the valve timing is off. The timing belt has jumped one or more teeth. If the phases have shifted by several teeth, then the motor can work. If they have moved more significantly, then the valves can be bent.

Why does the Ural shoot at the carburetor? Among the reasons why a belt can jump are the following. When repairing the engine, the pulleys were incorrectly aligned, the belt has low tension, the car has been in an accident, the timing elements are heavily worn.

You can diagnose why the UAZ carburetor is shooting and whether the timing belt is the cause by checking the timing marks on the crankshaft pulley and the cylinder block body. If the phases have shifted, then eliminating this fault depends on how much they have shifted. Sometimes only minor adjustments to the timing are enough.

If the phases have shifted, you should not attempt to start the engine. Do not press the accelerator pedal. You can try to start the power unit when the installation marks are set correctly and the reason that caused the jump has been eliminated.

Intake valves

One of the reasons why the carburetor shoots may be the intake valve. It sometimes burns out and becomes deformed. If the combustion chamber is not tightly sealed, this will provoke popping noises - gases will break through the gap between the seat and the plate into the manifold. Sometimes it is possible for new portions of the fuel mixture to ignite.

To diagnose such malfunctions, you should use a compression gauge. If a leaky cylinder is detected, a little engine oil is poured into it through the spark plug hole - this way you can eliminate wear on the piston group or malfunction of the rings. If it is the valve that is damaged, then the compression will be the same - with or without oil.

The malfunction is eliminated by replacing the valve and removing the cylinder head. If the valve is deformed, you should check whether the valve timing is set correctly. If the element burns out over short runs, then the cause of this situation should also be sought in the phases.

When the timing mechanism is equipped with hydraulic compensators, their serviceability should also be checked. If this unit “sticks”, the consequences will be the same as in the case of a burnt-out valve. In this case, it will not always shoot at the carburetor, but only under certain conditions. If there is a problem with the mechanism, it is better to contact a specialist.

Faulty timing belt

Why does the muffler shoot

? Malfunctions in the gas distribution mechanism are generally similar to problems with ignition. In particular, the exhaust valve opens at a time when the gasoline has not yet burned out. Accordingly, it enters the exhaust gas removal system, leading to the already familiar popping sounds in the muffler.

There are several causes of malfunctions in the timing system:

- Timing belt wear. A sign of this malfunction is the appearance of additional metallic pops or noises when the engine is running at low speeds. In this case, you need to inspect the belt and, if necessary, tighten or replace it. You can read how to do this in the corresponding material.

- Worn toothed pulley. In this case, it is necessary to replace it.

- Partial valve failure. Over time, they become covered with soot (especially when refueling the car with low-quality gasoline), which leads to deterioration in the operation of the mechanism. And due to hanging valve springs, the engine overheats. Therefore, it is worth checking the valves. If you find slight roughness or bends on their surface, then grinding them in is a mandatory procedure. If the scratches are significant, you need to polish them or replace the valves.

Usually, if the timing belt is faulty, popping noises in the muffler are heard when the engine is warm. If the engine is “cold”, then they are not there. This is another indirect evidence of the timing's guilt. However, to find out exactly, it is necessary to perform additional diagnostics.

Valve clearances

Thermal gap may also be the reason why ZIL shoots into the carburetor (the same malfunction is observed on other cars). If the engine was repaired and the distance between the camshaft cam and the pusher was accidentally reduced, then there will be popping noises during the startup process. Also, thermal clearances may change if the necessary adjustments have not been made. Shrinkage occurs and surfaces may become deformed. If you do nothing, the engine will fire.

To diagnose the gaps, you need to remove the valve cover and measure the gaps with feeler gauges. If you do not adjust them, the valves may burn out. There is no way around this without repairs. Flames will erupt into the intake manifold even if the damaged valve is adjusted correctly.

A fairly common problem with carburetor cars is the characteristic popping noise in the carburetor. The malfunction may occur when the engine starts and fires into the carburetor, as well as during operation of the internal combustion engine after the power unit has been started. At the very beginning, we note that experts consider the main reasons to be a severe depletion of the fuel-air mixture, ignition timing, or malfunctions of the gas distribution mechanism associated with incorrectly set phases.

As for the CIS, most carburetor cars on the roads are Russian-made models. Next, we will look at problems when a VAZ engine shoots into the carburetor, why a 406 engine shoots into the carburetor, and also talk about how to detect and fix such malfunctions with your own hands.

Read in this article

What to do if the engine shoots into the carburetor and muffler

The appearance of popping noises in the muffler and carburetor is usually accompanied by a whole list of other symptoms:

- the engine “shoots” and does not start;

- work at XX is extremely unstable;

- the engine loses power and does not “pull”;

- the motor is prone to overheating;

- fuel consumption increases noticeably;

In this case, the unit’s response to pressing the gas pedal is not clear; delays and dips appear; the machine may jerk under load and in transient modes. In the language of ordinary car enthusiasts, the engine begins to “sneeze.” If the carburetor shoots when starting the engine, and the additional symptoms described above are also present, then certain elements and settings should be checked.

Diagnostics of the ignition system and OZ settings

The check should begin with the high-voltage wires of the ignition system. Violating the order of their connection will lead to the fact that the moment of spark formation on the spark plug will not occur at the end of the compression stroke, and the very order of supplying sparks to the cylinders during engine operation will also be disrupted. In this case, the engine may start, but during operation there will be shooting in the carburetor, which will be repeated at certain intervals. To solve the problem, you should connect the wires to the spark plugs, taking into account the fact that there are special marks on the distributor cover. These labels will help you make connections in the correct order.

If the engine shoots into the carburetor, the reason may be early ignition. This means that the spark appears too early. In other words, the mixture does not ignite at the end of the compression stroke, but at the moment the piston begins to approach TDC, completing the stroke.

In this case, the mixture of fuel and air in the cylinder burns untimely, as a result of which the combustion process is disrupted. The result of early combustion is a “lumbago” in the form of a pop in the carburetor. With late ignition, popping noises can go into the muffler, since combustion is still ongoing when the intake valve begins to reopen on the next stroke. Moreover, the combustion of the remaining mixture also extends to a new portion of the fuel charge, which is sucked into the engine from the carburetor into the intake manifold during intake. Under such conditions of disrupted combustion, the engine overheats. Often late or early ignition can be determined by the condition of the spark plugs. If the spark plugs are white, with carbon deposits, etc., then the OZ needs to be checked and set by adjusting the ignition timing. This adjustment is made by turning the distributor in accordance with the scale.

You should also check the Hall sensor and pay attention to the ignition distributor bearing. Problems with bearing fastening or other nuances may indicate the need to replace the distributor. Let us add that during diagnostics it is optimal to install an initially serviceable device on the car, which will allow faster and more accurate localization of faults in the ignition distributor. Similar actions should be performed with the ignition system switch. If it breaks down, sparking is disrupted and the spark itself is not supplied at exactly the specified moment.

Site about off-road vehicles, SUVs, off-road vehicles

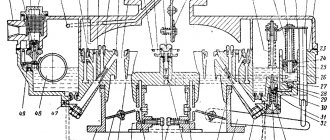

Difficulty starting a cold and warm UMZ-417 and UMZ-421 engine with a K-151 carburetor, interruptions in its operation causing failures, jerking or twitching while the vehicle is moving, as well as its sluggish acceleration and increased fuel consumption, can also be caused not only malfunctions in the ignition and fuel supply systems, but also poor performance and failure of the systems and components of the carburetor itself.

Unstable operation of the UMZ-417 and UMZ-421 engines at idle associated with the K-151 carburetor.

Unstable operation of the engine at idle speed when the idle system and float mechanism of the K-151 carburetor are in good working order can be caused by malfunctions of its EPHH pneumatic valve or elements of the EPHH system - a microswitch, solenoid valve and control unit.

Interruptions in the operation of UMZ-417 and UMZ-421 engines at partial and full load modes associated with the K-151 carburetor.

Interruptions in engine operation at partial and full loads and, as a consequence, twitching of the car in the form of a series of light short jerks, following one after another, indicate disturbances in the operation of the main metering systems of the K-151 carburetor, due to contamination of their metering elements and channels, or leakage of additional air in the connections of the carburetor body parts due to damage to the sealing gaskets or warping of the mating surfaces.

Engine malfunctions in these modes can also be caused by an excessively low fuel level in the float chamber, in which the air-fuel mixture becomes lean due to a high vacuum in the main air channels of the carburetor, and also the econostat does not come into operation in a timely manner.

Dips and jerks during operation of the UMZ-417 and UMZ-421 engines associated with the K-151 carburetor.

Long dips, up to five seconds, a decrease in acceleration down to deceleration and jerks lasting no more than half a second, during vigorous acceleration of the car with a sharp opening of the throttle valves, are caused by malfunctions of the accelerator pump - damage to its diaphragm, sticking of the drive lever, clogged valves and nozzle, etc. , or a reduced fuel level in the float chamber, at which the pump flow is reduced.

If the fuel or emulsion nozzle of the idle system is clogged, a failure may occur even with a smooth opening of the throttle valve. At the same time, the engine is extremely unstable when idling.

During normal operation of the idle system, the cause of failure may be improper adjustment of the fuel level or clogging of the main fuel jets of the K-151 carburetor. An attempt to open the throttle valves when it fails due to clogged nozzles may result in a complete engine stop. The same thing happens if small diffusers are installed incorrectly after completely disassembling the carburetor, for example, to wash it.

Rocking of the car or a series of deep failures in the operation of the UMZ-417 and UMZ-421 engines associated with the K-151 carburetor.

Rocking of the car or a series of deep dips after short-term operation of the engine with the throttle valves fully open, which stops after they are partially closed, is caused by a violation of the fuel supply.

If the fuel pump is working properly and the fuel line is clean, the cause of rocking is a clogged carburetor fuel filter or a stuck fuel valve needle in the closed position.

Insufficient power of the UMZ-417 and UMZ-421 engines and their low throttle response.

Insufficient engine power and low throttle response are caused by incomplete opening of the throttle valves as a result of a malfunction of their drive. The same is observed when the fuel level in the carburetor float chamber decreases.

Increased fuel consumption when operating the UMZ-417 and UMZ-421 engines.

It is caused by a complex of the above malfunctions in various combinations and is observed when the carburetor starting device is incorrectly adjusted, the fuel level is high, the air jets are clogged, the fuel jets are not tightened tightly, so in K-151 carburetors the tightening of the idle system jet block is especially often loosened.

And also in case of malfunctions or shutdown of the EPH system, fuel leakage from under the screw securing the fitting block or the fuel supply hose.

Over-lean or over-rich air-fuel mixture.

Most malfunctions of K-151 carburetors, and therefore of UMZ-417 and UMZ-421 engines in general, are in one way or another associated with over-leaning or over-riching of the air-fuel mixture.

Additional external subjective signs of an over-lean mixture are popping noises in the carburetor when starting the engine and its overheating due to the slow combustion of such a mixture throughout almost the entire operating cycle.