In most cars, the crankshaft rotation speed after starting a cold engine is 2-3 times higher than at idle after warming up. This ensures stable operation of the internal combustion engine in this mode and reduces the time it takes to reach operating temperature. Too low speeds when the engine warms up are usually a sign of an imbalance in the air-fuel mixture.

In this article we will tell you what speed should be when starting on a cold one and for what reasons they fall below normal most often.

What engine speed should be when starting from cold?

In the first seconds after starting a cooled gasoline engine, the crankshaft speed is usually set at 1200-1500 rpm using a mechanical or electronic idle speed controller, or independently. The diesel engine warms up at a speed of about 1100 rpm .

In the case of automatic control, as it warms up, the speed decreases smoothly or abruptly until it reaches 600-800 rpm. However, exceptions are possible when this value changes according to a more complex pattern. The exact number of engine revolutions at cold start, also called warm-up, and at idle depends on the design of the power system, the settings of the electronic control unit (ECU), and the temperature of the coolant.

What should the warm-up speed be: video

In models that meet the EURO-5 and EURO-6 environmental classes, the electronic control unit often does not raise the cold speed above 1100 rpm. This is explained by the need to limit the amount of harmful emissions. In some cars, the crankshaft rotation speed immediately after starting the engine is 800-1000 rpm and only then increases. This mode is due to the desire of automakers to reduce the load on the engine at low temperatures, when it is most vulnerable.

The number of engine revolutions during a cold start and the time it takes to reduce them to idle also vary depending on the temperature. In cold weather, it takes longer to warm up the coolant, so the crankshaft speed may not drop to the required idle speed for more than 5 minutes. In summer, it stabilizes in 2-3 minutes.

Thus, engine speeds below 1200 rpm or their slight fluctuations immediately after starting are not always a sign of trouble. You should only worry when the crankshaft rotation speed when cold does not rise above 600 rpm , falls below 400 , or does not stabilize as it warms up, and the engine stalls or stalls when starting!

Throttle problems

Quite often, the reason that the engine starts to stall is the throttle valve itself. It is quite possible that the air filter has worn out, so the entire surface of the damper inside is dirty. To fix this breakdown, it is enough to clean the damper completely from the inside. Please note that after thorough cleaning the problem may persist; the engine still stalls when you press the gas. In this case, you need to make sure that the position sensor is in good condition. This sensor is a variable resistor. It is installed on the damper axis. Moreover, maximum wear is observed in the extreme position (corresponding to idle speed). If it fails, it must be completely replaced. The cost of the part is quite low, and replacement occurs literally in a matter of minutes. But it is possible that the engine begins to stall, despite the fact that all sensors are in perfect condition.

What are warm-up speeds for and how are they regulated?

Warm-up speeds ensure stable operation of a cold engine at idle, efficient supply of more viscous oil, warming up the engine and coolant to operating temperatures. Thanks to this mode, the operating time at a pace at which engine parts are most susceptible to increased wear is reduced. In models with catalytic converters, rapid heating of their surface is additionally ensured.

Excessively low warm-up speeds and the problems that cause them can lead to more serious problems. And at a lower temperature, the engine may simply not start.

How to regulate warm-up speed on an Audi 80: video

On older carburetor models, for example, VAZ 2101-2107 before 2006, engine speed during cold start is adjusted manually. Using a special cable-operated lever known as a “choke,” the driver changes the position of the choke in the carburetor, which in turn limits the flow of air into the combustion chamber. On older cars with a diesel engine, the operating mode of the high-pressure fuel pump (HPF) is manually changed in the same way. As it warms up, the speed will increase, and the damper can be gradually closed.

In modern cars with an ECU, the crankshaft speed during warm-up is set automatically depending on the coolant temperature. In injection models, the idle speed regulator is responsible for regulating the composition of the air-fuel mixture. In the case of a diesel engine, it usually comes down to changing the operating mode of the fuel injection pump.

Fuel quality

Always watch what kind of gasoline you fill your car with. In most cases, all of the above symptoms appear as soon as you fill the tank with fuel. Of course, the engine may stall after some time. Therefore, it will be difficult to immediately determine the breakdown. It is also worth paying attention: the reason that the engine begins to stall or stall should always be sought in the gasoline itself. To cure such a “disease”, you will need to completely drain the gasoline from the tank and also replace the fuel filter. Unfortunately, you don’t always buy high-quality fuel at gas stations. Therefore, it is worth choosing one brand of manufacturer that sells the highest quality gasoline. Of course, there are times when the car stalls while driving (the reason for this does not lie in gasoline). Please note that an excessively low cost is the first sign that gasoline is of dubious origin. And pouring it into the tank is equivalent to driving a car at full speed into a pole.

Why are the revs low when cold?

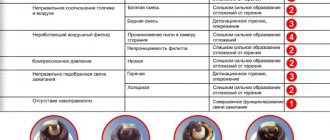

In most cases, excessively low engine speeds when cold are a sign of a lean air-fuel mixture . This may be due to excess air in it or interruptions in the fuel supply. The list of malfunctions leading to this problem directly depends on the design features of the power system. The most common causes of low speed on a cold engine with a carburetor, injector and fuel injection pump are discussed in the table below.

| Fuel supply system | Regulation principle | Malfunction | Reason for the drop in speed |

| Injector | The idle speed regulator changes the warm-up speed according to a signal from the ECU, based on the readings of the coolant temperature sensor. | The coolant temperature sensor has failed. | The ECU does not receive reliable data on the coolant temperature and, as a result, sends an incorrect signal to the IAC or goes into emergency mode. |

| The IAC is jammed. | Leaning of the mixture due to excessive opening of the IAC. | ||

| The throttle valve is not closed. | The entry of excess air due to contamination, jamming or incorrect adaptation of the throttle valve leads to a lean mixture. | ||

| Carburetor | During warm-up, the speed is adjusted by changing the position of the damper that limits the air supply. | The idle speed control is broken. | Lean mixture due to incorrect position of quantity/quality screws. |

| Low fuel level in the float chamber. | Lack of fuel due to incorrect float installation. | ||

| Excess air is sucked in through the carburetor. | Leaking seals or casings will result in a lean mixture. | ||

| EPH system malfunction. | Jamming of the solenoid valve leads to a violation of the composition of the fuel assembly. | ||

| The idle jet is clogged. | Interruptions in the fuel supply due to a decrease in the valve flow area. | ||

| Diesel | The crankshaft rotation speed to cold is set by changing the operating mode of the fuel injection pump using a speed compensator. | The thermal valve/speed compensator is faulty. | There is no adjustment of the fuel injection pump operating mode depending on the temperature. |

| The mass air flow sensor (MAF sensor) has failed. | The ECU receives incorrect data about the amount of air entering the combustion chamber, which leads to incorrect control of the operation of the injection pump in transient mode. | ||

| The EGR valve is stuck. | The composition of the air-fuel mixture is disrupted due to a failure in the supply of exhaust gases to the combustion chamber. | ||

| Fuel injection pump malfunction. | The fuel injection pump does not work correctly, which leads to disruption of mixture formation. |

A number of malfunctions can cause low speeds when cold, and in some cases even after warming up, regardless of the type of fuel and the method of formation of the air-fuel mixture. The most likely problems are:

Low speed on a cold engine, possible causes: video

- Suction of unaccounted air from the intake manifold due to mechanical damage or leakage of connections.

- Problems with fuel delivery due to a faulty fuel pump, worn or clogged injectors, or a clogged fuel filter.

- A drop in compression in the combustion chamber due to worn CPG parts, damage or incomplete closing of the valves.

- Failure in the ignition system due to incorrect adjustment, failure of spark plugs, coils, high-voltage wires and sensors.

Finding out why it does not develop speed when cold is possible only by elimination, checking sequentially all possible causes.

Main reasons

There are many reasons for this phenomenon and in most cases they are associated with a malfunction of the systems and mechanisms of the power plant.

Some of them are trivial and very easy to fix, others require quite serious repairs.

The main problem with the fact that the engine does not pull is not related to eliminating the malfunction, but to finding it.

In some cases, it is very difficult to determine what caused the reduction in traction effort and you have to go through almost the entire engine.

Therefore, we will try to indicate the main reasons why the car accelerates very “sluggishly”.

Since engines on different cars have their own design features, we will consider specific models.

Spark plug

To make sure the spark plugs are working properly, you need to unscrew them all, check the gap size, as well as the presence of carbon deposits. And your car stalls while driving. The reason may be hidden in the candles. If there is heavy carbon deposits, but the gap is within acceptable values, it is necessary to clean the spark plug electrodes. But the best way out is to install new spark plugs. In the same case, if the gap is very large, there is excessive wear of the electrode, cleaning will not help, it is necessary to completely replace the set of spark plugs.