Main reasons

When dips appear when you press the pedal, you need to check the following elements.

- Set of high-voltage wires and spark plugs. The latter are criticized more often than other details. If the owner regularly refuels with fuel with harmful additives, over time the electrode becomes overgrown with carbon deposits, as a result of which the spark supply deteriorates. If the source of the problem is a high-voltage wire, you will have to replace it. Better - the whole set at once.

- Injectors. Again, the injection engine does not respond well to clogged fuel injectors. A lean fuel mixture results in the engine not responding to pressing the gas pedal. There are two options - washing in an ultrasonic bath, or completely replacing the kit.

- Throttle valve. If there is a large layer of dirt, it jams, which leads to incorrect operation. The resulting deposit prevents the throttle from functioning normally.

Note! If the cause of the breakdown is a broken wire, it is better to buy the entire set - it is possible that other wires will begin to behave the same way.

When pressed hard

Causes:

- incorrect ignition setting;

- air filter clogged;

- failure of the high pressure fuel pump.

These are the main reasons why a car behaves this way when you press the gas pedal hard. Typically, this behavior is observed for one or two seconds, after which the engine, having reached medium speed, continues to operate without problems.

RPM failure

A drop in speed is manifested by the lack of engine response to the pressed gas pedal. When the driver tries to pick up speed, the car does not react at all, or does it too late. This manifests itself as follows:

- A short dip lasting 3-5 seconds. But this is enough to create a dangerous situation on the road.

- Prolonged lack of response. Up to ten seconds, sometimes more. The car has every chance of stalling.

- Jerks with jerking. Duration - about two seconds.

- Numerous consecutive jerks. The engine operates differently when the gas pedal is in one position.

- A series of deep failures. The car is shaking seriously.

How problems manifest themselves

Failure is a lack of response, an unexpected disturbance that appears in the operation of the motor. Occurs periodically in different modes, not only during sharp, but also smooth operation of the accelerator. At the same time, acceleration decreases and stops are possible.

How interruptions manifest themselves:

- short - no reaction for up to 2-3 seconds;

- deep - loss of speed occurs over a period of 3 to 10 seconds, stopping is possible;

- jerks – last up to 2 seconds;

- twitching - represented by a series of jerks when the car either develops or loses speed without changing the position of the accelerator;

- rocking - multiple interruptions, reminiscent of twitching, lasting about 4 seconds.

Experts note that the main cause of such problems is over-enrichment or over-leanness of the air-fuel mixture. This helps to diagnose and find the cause.

Diagnostics

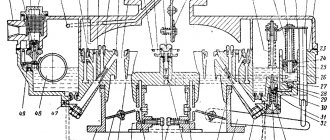

Checking the injector is faster because there is an electronic control unit. After reading the error codes, the source of the problem can be clearly identified. Carburetor cars do not have this option. Therefore, such a system is diagnosed in its own way.

First you need to check the coherence and correct operation of the fuel system. You have to probe all the places where air leaks may occur. The fuel pump and fuel line are also checked. There should be no deposits or blockages.

If the test results do not reveal any problems, the failure most likely occurs due to the carburetor. This is the main device responsible for mixture formation and intake into the manifold. When the carburetor is working properly, fuel flows evenly without interruption.

Why are the revs dropping?

There are many reasons that can provoke failure when pressing the gas pedal. This circumstance significantly complicates diagnosis.

- Spark plugs and high voltage wires are the first thing you need to pay attention to when this problem occurs. The problem with spark plugs is carbon deposits that occur during vehicle operation. Carbon deposits cause incorrect operation of the spark plugs, which in turn leads to engine failure. Wires do not often become the cause of such a malfunction, but still their condition is also checked without fail. During the diagnostic process, a fracture or poor contact may be detected.

Carbon deposits on spark plugs

- Injectors worry owners of cars with high mileage. These elements are prone to blockages, which cause interruptions in their operation. The consequence of this state of affairs is a lean fuel mixture.

- The throttle valve can also become clogged and stick. A coating forms on the surface of the valve, which does not allow the throttle to perform its functions normally. This prevents the engine from gaining momentum.

- Incorrectly adjusted ignition is a rare cause, but it does occur. This malfunction can be eliminated in a few minutes by properly adjusting the mechanism. But only an experienced specialist can do this.

- Errors in the ECU that can accumulate during operation of the machine. When a lot of them accumulate, the engine's response to the accelerator may be delayed.

- Blockages in the air filter lead to suffocation of the engine, which experiences “oxygen starvation”.

- Incorrect operation of the fuel pump can be associated with various problems (poor contacts, blockages in the filter, power failure, breakdown of working units).

Troubleshooting

The sequence of actions is as follows.

- Eliminate air leaks caused by loose fasteners on the exhaust manifold.

- Check the condition of the fuel filter.

- Remove the idle air control valve with the sealing ring and check their condition. It works correctly when a click appears when connected to the positive terminal (the negative is connected in advance).

- Check the fluid level in the float chamber. The tolerance is the middle of the inclined wall.

- Blow out the fuel and air jets with an air compressor and clean the emulsion tubes.

- Use carburetor cleaner to remove carbon deposits from the carburetor walls.

Thanks to this test, you will find out exactly what causes failure when you press the gas pedal. Luck with searching!

Engine stalls when switching to gas

The presence of gas equipment in a car, along with certain advantages, can cause a number of inconveniences to the driver. One of the common problems is that the engine stalls when switching from gasoline to gas. The problem can manifest itself in different ways. In the first case, the unit stalls immediately, that is, at the moment of transition; in the second, the engine choke after the driver presses the accelerator after the transition, that is, when the engine is already running on gas in idle mode.

In such a situation, it should be taken into account that the gearbox on many gas equipment requires heating to a certain temperature (for example, 35, 40 or 50 degrees Celsius). To save gasoline during warm-up, some drivers and LPG adjusters set a minimum temperature threshold, after which switching occurs. As a result, a switch to gas occurs, the gearbox is still cold and the engine does not have enough fuel.

The reason is that a cold reducer does not evaporate the supplied gas in the required volume. Please note that we should not exclude the fact that the degree of heating of the gearbox depends on the characteristics of its connection (to the manifold, to the heater hoses, etc.), as well as on the level of coolant in the system. Let us add that another common cause may be the gas injectors themselves. In some cases they need to be cleaned, in others it is better to replace them with more efficient ones.

Injector

To determine the causes of failure when pressing the gas pedal in the injector, special diagnostic equipment is used. In most cases, improper operation occurs due to a faulty throttle position sensor. First it checks:

- fine filter clogging level;

- stability of the fuel pump;

- cleanliness of the mesh filter on the intake;

- pressure level inside the fuel rail. Range – 2.8-3.2 bar;

- condition of fuel supply and mixture formation sensors;

- number of errors in the ECU memory;

- condition of the injectors.

The condition of the throttle valve, control unit and injector set is assessed only at a service center.

If there are no obvious reasons, you will have to check the ignition system.

[custom_ads_shortcode1]

Checking the carburetor system

Initially, the operation of the fuel system is checked to see how smoothly and correctly it works. Every working unit and detail matters. Air leaks are checked, fuel lines are examined and the fuel pump is diagnosed. All blockages and deposits are removed.

Fuel pump If the diagnostics do not reveal any problems, then the carburetor may cause a failure in the engine when the gas pedal is pressed. This part is responsible for supplying fuel. During normal operation of the carburetor, fuel is supplied without interruption, constantly and evenly.

To identify and eliminate the cause of the problem, you must proceed as follows:

- We exclude air leaks, which may occur due to a loose fastening on the exhaust manifold.

- We study the condition of the mesh-type filter, which is located in the area where the pipe from the fuel pump connects.

- We dismantle the EPH valve and the sealing ring and examine their condition. If the EPHH is working properly, then when you connect one side of the wire to the terminal, and the opposite end to the positive terminal of the battery, a clicking sound will be heard.

- Check the liquid level in the float chamber. To do this, start the engine, leave it to run for a while, remove the top carburetor cover and filter housing. Now let's evaluate the fuel level. In normal condition, it should be in the middle of the inclined wall.

- The dosing system may become clogged and this is a common problem. To eliminate it, you will need to remove the top part of the dispenser and the jets. We look for blockages and remove them using wooden parts. Emulsion tubes, which are often forgotten, also need inspection and maintenance.

- Special products are used to clean the carburetor channels.

[custom_ads_shortcode1]

Adjusting the drive:

- Checking the length between the tips. The required size is 80 millimeters.

- If you deviate from this size, remove one tip.

- Loosen its lock nut and by rotating adjust the distance to the desired size.

- Tighten the nut and return the rod.

- You need to check the adjustment. To do this, our assistant presses the gas pedal. We observe the throttle valve to see if it has opened completely.

- If not, then you need to remove the tip from the lever and reduce the length of the rod.

- Now you need to see what position the damper is in when the gas pedal is released: does it close completely. If not, the pull needs to be lengthened a little.

- Next we work with the air damper. We weaken its drive. In the cabin, we completely recess the damper.

- Press the three-arm lever so that the flap opens all the way. In this position, tighten the locking screw.

- Checking the adjustment. To do this, we completely close and open the door from the passenger compartment again. If the damper has not opened completely, we carry out the adjustment again. If the outcome is positive, fully tighten the screw.

Engine tripping

This problem is a fairly common cause of pedal failure. This term means that one or even several cylinders in the engine are not working, which is extremely dangerous for the engine and can also cause pedal failure when driving. An experienced motorist can easily determine by ear whether the engine is stalling. Beginners can be guided by the following signs:

- Poor acceleration even at high speeds.

- Slight engine shaking.

- Noticeably higher fuel consumption.

- The formation of dark spots on one or more candles.

To determine which cylinder specifically has failed, it is necessary to disconnect the high-voltage cable one by one. Be extremely careful if you perform this procedure yourself. There is a risk of electric shock. After this, the engine speed increases to one and a half thousand. If the sound does not change, it means you have removed the working cylinder. The wire is returned to its place, and then another is removed. Oxidation of the contact in a high-voltage wire often occurs. Diagnostics can be carried out using a conventional multimeter.