Extending the service life of gearboxes

Transmission shaft assemblies

- Always try to keep the oil level in the box under control. If it drops, be sure to top it up immediately, do not put off the function until later. When the oil becomes unusable, change it one hundred percent, and do not fill in the missing amount.

- Beware of brutal operation, do not jerk the gears sharply, accelerate smoothly, and brake similarly. Obvious careful handling of the gearbox will avoid wear and tear and numerous breakdowns.

You see, solving checkpoint problems is not that easy. Therefore, the most ideal option is to prevent their occurrence.

No Comments and views from the owners of Yet! You can be first to comment this post!

Causes

The reasons why poorly or poorly engaged may be the following:

- weakening of the fastening clamp of the rocker, due to which the length of the rod is not enough to actually engage the gear;

- jamming of the reverse speed lock;

- spring breakage and debris getting into the guide grooves of the gear selection mechanism;

- spontaneous loosening of the selection mechanism mounting bolts;

- the clamp bolt is cut off;

- wear of the clutch disc and release bearing;

- incorrect adjustment of the clutch and clutch pedal;

- low oil level in the box or the need to replace it.

Spring replacement

Often, owners change the entire mechanism assembly, which costs on average about 2 thousand rubles. But you can disassemble the mechanism and get by with replacing the spring, which costs up to 50 rubles.

You need to do the following:

- Remove the stopper from the blocker axle and pull out the axle itself.

- Unscrew the lever axle nut.

- Pull out the axle and replace the spring.

- Reassemble in reverse order.

Didn't find the information you were looking for? on our forum.

If you find an error, please select a piece of text and press CtrlEnter.

Spring replacement

Why does reverse gear crunch when shifting into gear?

Often, owners change the entire mechanism assembly, which costs on average about 2 thousand rubles. But you can disassemble the mechanism and get by with replacing the spring, which costs up to 50 rubles.

You need to do the following:

- Remove the stopper from the blocker axle and pull out the axle itself.

- Unscrew the lever axle nut.

- Pull out the axle and replace the spring.

- Reassemble in reverse order.

Loading.

Replacing the gear selection mechanism

One of the common reasons why the reverse gear of a VAZ 2109 does not engage is the breakdown of spring 2 installed in a separate mechanism.

To access it, you need to remove and repair the mechanism itself, located inside the box.

- Disconnect the car.

- Remove the air filter completely.

- Remove the left wheel and loosen the CV joint hub nut.

- Drain the oil from the gearbox crankcase.

- Remove the two bolts securing the left ball joint to the steering knuckle.

- Unlock and remove the steering tip.

- Remove the fist from the CV joint splines.

- Completely remove the left drive.

- Remove the starter and negative wire from the gearbox housing.

- Remove the gear shift rods from the gearbox and clutch.

- Unscrew the speedometer drive cable.

- Place a support under the box housing and remove the box support fastening

- Remove the gearbox from the vehicle and disassemble it.

When disassembling the gearbox, it is necessary to check the condition of the gear locks, since wear is the main reason why the reverse gear spontaneously jumps out of engagement. You can get to the lock without removing and disassembling the box; it is located on the side of the crankcase and is closed with a screw plug. Disassembling the gearbox and inspecting the gear selection mechanism will also help solve the problem in which the reverse gear on the VAZ-2109 does not turn off.

READ Where is the knock sensor of the VAZ 2115

How to shift gears on an automatic transmission

So, in our previous article we looked at how to engage reverse gear on a manual transmission, as well as how to correctly shift gears on a manual transmission. Now let's look at the automatic transmission.

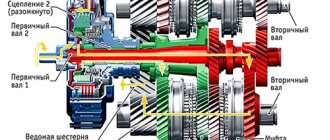

First of all, there are several types of automatic transmissions: “classic” hydromechanical automatic transmission, CVT, and also robotic gearbox. It should be noted that although these types of “automatic machines” differ from each other structurally, they are functionally similar and have similar basic operating modes.

Among these main modes are:

- R- parking, parking;

- R - reverse gear;

- N-neutral;

- D - drive, forward movement;

- M - manual control mode;

Park mode allows you to start the engine, after which the engine idles (for example, during warm-up). It is also recommended to leave the car parked in this mode.

It is noteworthy that after turning on “P” the automatic transmission shaft locking is also activated. This blocking prevents the car from rolling and is an additional “insurance”.

Mode “R” is responsible for reverse gear and is activated only after the car has come to a complete stop. Ignoring this rule may cause serious damage to the gearbox.

The “N” mode, unlike the “P” mode, allows you to separate the transmission and the engine, and this mode does not have any additional locks (as in the case of “parking”).

However, unlike “mechanics” and some individual types of robotic gearboxes (for example, AMT), during a short stop with the internal combustion engine running, there is no need to switch to neutral. In fact, “neutral” on an automatic transmission is only needed for towing the car in the event of a breakdown (if the manufacturer has provided for such a possibility), and also as a service mode.

Article on the topic: How to warm up the oil in the engine: available methods and solutions

You can also turn on the “N” mode in a traffic jam, when the car has been standing for a long time (more than 10 minutes) and the engine is running, but you need to remember that in this case you need to additionally use the handbrake (parking brake) or hold the car with the brake pedal, otherwise the car may start rolling randomly.

Mode “D” allows you to move forward, gears change automatically. No additional action is required from the driver; all that remains is to press the gas to accelerate and the brake to slow down or come to a complete stop.

You can also highlight M - manual control mode (Tiptronic automatic transmission). The mode is not available on all automatic machines; if it is available, there are additional symbols: “+” (switching to an upshift), “-” (switching to a downshift). This mode is semi-automatic (the driver himself selects one gear or another, but the electronics may still not turn it on if the speed and conditions do not correspond to it).

The gear shift lever itself (automatic transmission selector) on different cars with an automatic transmission, regardless of the type, often simply moves along special grooves. Each slot corresponds to a separate mode (as a rule, there are symbols next to the slot; also, the selected modes on most cars are duplicated on the dashboard).

To turn on one or another automatic transmission mode, you need to insert the key into the ignition and press the brake pedal. Typically, pressing the brake pedal releases the lock, which is a “protection” against accidental movement of the selector.

In parallel, on the side of the selector handle on many types of automatic transmissions there is a special button, pressing which allows you to move the lever to one mode or another. In other words, pressing the brake pedal and holding the pedal allows you to unlock the shaft in the “parking” mode, while pressing the button on the lever makes it possible to further move the selector itself, including the desired modes.

Also, on many cars, starting the engine is only allowed in “P” or “N” mode when the brake is pressed. This solution can be considered a “protective” function that helps prevent unwanted vehicle movement and damage to the automatic transmission and internal combustion engine.

Article on the topic: Reverse gear, first and other speeds do not engage when hot

Let us also add that many automatic transmissions, in addition to the main ones, are equipped with a number of other additional modes. Such modes can have either separate slots for activation or can be activated using buttons. For example, you can select only the first gear (mode L1 or 1), inclusion in automatic mode no higher than the second gear (L2 or 2), OD (overdrive) mode, which disables the transition to upshifting fourth or fifth gear.

Also, automatic transmissions often have a “sport” mode (letter “S”), an economical “eco” mode (letter “E”), winter mode (letter “W” or a snowflake icon), etc.

First speed is not fixed

When starting to move from a standstill at first speed, especially from difficult ground such as sand and snow, you have to hold the gear shift lever, since it does not hold on its own, the gear is switched to neutral. There can be three reasons for this failure:

- The link is loose and does not fix the fork;

- gear and coupling wear;

- displacement of the engine on the mounts and knocking out the box.

The condition of the fasteners of all parts and assemblies should be completely checked. The gearbox is rigidly fixed to the engine. However, when the motor slides on cushions, the first speed may be knocked out. Tighten all bolts and check the rigidity of the mounting on the body. You can do this kind of work yourself.

Fasten the link more rigidly to the shift lever, select the backlash, because it is responsible for fixing the lever in the desired position. To do this, you need to put the car in a pit. Open the lid and check. Pay special attention to the condition of the gearing.

When worn, gears can slip and jump out without transmitting torque. When you press the lever with your hand, the clutch adheres forcefully and engagement occurs.

New box

There are problems when the car is picked up from a service station, but the gearbox of the VAZ 21093 does not engage the speed. At the same time, when the engine is not running, the shift lever moves smoothly, without a crack. As soon as you start the car, the gears stop shifting. First of all, check the movement of the gear and fork along the splines - along the axis of the shaft. Since you have opened the box, pay attention to the position of the driven disk, whether it is installed correctly.

If malfunctions are discovered shortly after servicing the car at a service center, you should not tinker with it yourself. Send your car back and let the locksmiths find and fix their problems themselves. Remember that you do not have to pay for reworking low-quality repairs.

Gearbox configurations

Below are the most successful gearbox configurations depending on the engine. For a more detailed selection, you can use a calculator on the Internet.

- The most suitable gearbox configuration for a civilian naturally aspirated engine: 18 row gearbox + main pair 3.9.

- The most suitable gearbox for a sports naturally aspirated engine: 7th row gearbox + main pair 4.3.

- The most suitable gearbox configuration for a turbo civilian engine: row 104 + main pair 3.5.

The differential is two-satellite, the tension is adjusted by different thicknesses of the adjusting ring.

Sports cars often use a differential lock.

A differential lock is a mechanism that locks the differential so that both wheels rotate evenly. Initially, locking was used on SUVs to ensure that the front and rear axles rotated evenly.

In our case, screw locks are especially popular, because they are easily installed in the gearbox, increase cross-country ability on wet roads, and provide an advantage during acceleration due to uniform constant rotation of the wheels.

Work principles

Old box with modernization

The new design is the old gearbox with significant upgrades. The previous design is known to us for its shortcomings: large lever strokes, difficult activation and low vibration comfort.

The cable driven gearbox is not a new type. The device can be safely called an updated version of the previous design, which has been made more convenient by improving it. It follows from this that the driver, accustomed to the previous version of the box, will not need to relearn. For cable gearboxes, the diameter of the clutch has been changed, increased from 200 to 215 mm. The starter was moved, installing it along the engine.

Two cables, when interacting with the box, will dampen the transmitted vibrations. This will make the shifting smoother and also reduce the travel of the gearshift knob. The cable design allows shifts to be crisp rather than harsh. In addition, the travel of the shift lever has been significantly reduced. Cable drive is superior to other design solutions in terms of seasonal changes in weather. As a result of replacing the traction drive with a cable drive, the amount of oil poured decreased by 30% due to the transfer of the gear selection mechanism to the top from the bottom.

Severe frost helps the butter thicken. A conventional gearbox requires a lot of effort to start the engine. But the cable mechanism eliminates this problem because the shift mechanism is not submerged in oil, as it is located on top.

The use of a cable drive helps to significantly reduce longitudinal movement - up to 13 cm, and transverse movement - up to 9 cm. The design is made reliable and maximally optimized. This type of gearbox is good for cars with high power engines. Since the clutch has been increased, its torque is quite high.

Box with upgrade

Shift quality and machine vibration comfort

The gearbox is a complex unit. According to many car enthusiasts, changing gears is not an easy operation. Over time, each driver gains experience in driving a car. But during the adaptation period, a huge load falls on the transmission. Drivers who lack confidence often forget to press the pedal when changing gear.

The design of the box makes it possible to have less impact on the box itself due to the reduced number of strokes. In addition, the possibility of oil leakage is eliminated. Car manufacturers believe that this box option will not affect the cost of the car.

Reviews of the updated gearbox confirm the fact that it is silent when starting the engine and when releasing the clutch. Car enthusiasts talk about easy start-up and lack of vibration. Many users agree that it is now pleasant to change gears. In reviews, some motorists point out that almost nothing has changed in the movements of the lever, but it does not dangle and clicks quietly due to the absence of play in the drive.

Gear shifting efforts have been significantly reduced. According to those who are already using the new gearbox, there is a small drawback: you have to stretch a little for 5th gear, and sometimes the reverse gear is not engaged. But in general, the updated transmission significantly improves the quality of shifts and vibration comfort of the car.

Updated transmission

For those with automatic

If your car has an automatic transmission. It will not hurt you to know the modes in which your machine can operate:

The automatic transmission also has a button on the mode shift lever with the inscription O/D OFF. When it is turned on, the inclusion is prohibited, increasing the gears of the analogue of the 5th gear of the manual transmission. That is, if your automatic machine has 4 gears for moving forward, then for more dynamic acceleration it will use only three lower gears.

About a faulty automatic transmission, an automatic transmission is much more complex than those encountered with a manual transmission, and the chances of repairing it in your garage are slim. But despite this, you still need to know something about it, if only in order not to harm it through improper use.

An automatic transmission is much more demanding in terms of accuracy in maintaining the oil level in it than a manual transmission. Both too low and too high oil levels are very harmful to her. Both of these can lead to serious damage. In both cases, oil foaming occurs. When there is a lack of oil due to the fact that the oil pump begins to capture air along with the oil. When there is excess oil, it foams on the rotating parts, which in this case are immersed in it. Foamed oil compresses better and has low thermal conductivity. Therefore, if you operate a machine with such oil, the pressure in its control systems will be low. Which will lead to slipping of the clutches and their intensive wear. Deteriorated thermal conductivity will not allow all excess heat to be removed. Which, together with low pressure, will lead to the machine failing and requiring serious repairs.

Foamed oil has more volume. Therefore, checking the oil will show the level is too high. If you find that the oil level has risen for no apparent reason, you need to turn off the engine and let the oil settle. After this, check the level again. If it turns out to be low, you need to safely add the required amount and repeat the test.

The oil level in the machine is checked using a dipstick or through a control hole closed with a plug.

How to check the oil level using a dipstick

- Warm up the oil to operating temperature (to do this you need to drive about 15 km).

Select a flat horizontal area for measurement. Put the car on the handbrake.

- Move the lever to select the operating mode of the box through all positions, holding in each position for 3 to 5 seconds, until the machine operates.

- Leave the mode selector in position P, and in this position determine the oil level.

- Without turning off the engine, remove the oil dipstick, wipe it dry and reinsert it into the tube until it stops, then pull it out and read the readings. The upper limit of oil traces on a dry dipstick should be at the mark with the inscription “hot” or in an area with intersecting notches.

If the level is insufficient, you can add oil through the tube into which the dipstick is inserted. Do not forget that the automatic transmission is afraid of dirt, so add only clean new oil. Wipe the dipstick with a clean cloth from which the threads do not fall out.

When checking the oil level, pay attention to its appearance. Dark liquid with a burning smell indicates that not everything is in order in the unit. First, try changing the oil and filter in the automatic transmission. The milky color of ATF indicates that coolant has entered the box. The coolant softens and swells the material from which the clutches are made. Do not hesitate to change such oil, having first eliminated the cause of antifreeze getting into the box, otherwise significant damage will be caused to the machine. Coolant may enter the box due to a leak in the oil section in the radiator of the cooling system. In this case, the emulsion will be observed both in the box and in the engine cooling system.

The most common machine malfunctions

- The car does not move forward or reverse normally. Possible reasons: wear of the forward clutch clutches, a defect in the piston of this clutch, breakage of the rings of the same clutch, jamming of the valve body valves.

- There is no reverse speed, forward there are only 1 and 2. Probable causes: wear of the reverse clutch clutches, a malfunction of the piston of this clutch, damage to the spline joint in the drum body, another defect of this drum.

- There is no rear, everything works forward. Reasons: wear of the brake band, malfunction of the piston of this band or breakage of its rod, defects in the braking package.

- There is no movement either forward or backward when you turn on any mode, there is a shift push, but the car stands still. Causes: torque converter malfunction, lack of oil, clogged filter.

- Only reverse, 1st and 2nd gears are engaged. Reasons: valve jamming in the valve body, low oil level, general wear of pistons and clutch clutches that do not engage.

The clarity of gear engagement and the operation of the entire shift mechanism often worries owners of cars with a manual transmission. A common problem is that after starting the engine, one or more gears are engaged with great effort or not completely, it is not possible to change gears, at the moment of switching on, extraneous noise is heard, unnecessary vibrations appear, etc.

Such malfunctions appear unexpectedly, and difficulties when shifting gears can increase gradually. Speeds may be difficult to switch on “cold” and/or “hot”. It is noteworthy that gears in a manual transmission often shift normally when the engine is turned off.

Read in this article

How to shift gears on an automatic transmission

So, in our previous article we looked at how to engage reverse gear on a manual transmission, as well as how to correctly shift gears on a manual transmission. Now let's look at the automatic transmission.

First of all, there are several types of automatic transmissions: “classic” hydromechanical automatic transmission, CVT, and also robotic gearbox. It should be noted that although these types of “automatic machines” differ from each other structurally, they are functionally similar and have similar basic operating modes.

Among these main modes are:

- R- parking, parking;

- R - reverse gear;

- N-neutral;

- D - drive, forward movement;

- M - manual control mode;

Park mode allows you to start the engine, after which the engine idles (for example, during warm-up). It is also recommended to leave the car parked in this mode.

It is noteworthy that after turning on “P” the automatic transmission shaft locking is also activated. This blocking prevents the car from rolling and is an additional “insurance”.

Mode “R” is responsible for reverse gear and is activated only after the car has come to a complete stop. Ignoring this rule may cause serious damage to the gearbox.

The “N” mode, unlike the “P” mode, allows you to separate the transmission and the engine, and this mode does not have any additional locks (as in the case of “parking”).

However, unlike “mechanics” and some individual types of robotic gearboxes (for example, AMT), during a short stop with the internal combustion engine running, there is no need to switch to neutral. In fact, “neutral” on an automatic transmission is only needed for towing the car in the event of a breakdown (if the manufacturer has provided for such a possibility), and also as a service mode.

Article on the topic: How to solder a car radiator and save engine life?

You can also turn on the “N” mode in a traffic jam, when the car has been standing for a long time (more than 10 minutes) and the engine is running, but you need to remember that in this case you need to additionally use the handbrake (parking brake) or hold the car with the brake pedal, otherwise the car may start rolling randomly.

Mode “D” allows you to move forward, gears change automatically. No additional action is required from the driver; all that remains is to press the gas to accelerate and the brake to slow down or come to a complete stop.

You can also highlight M - manual control mode (Tiptronic automatic transmission). The mode is not available on all automatic machines; if it is available, there are additional symbols: “+” (switching to an upshift), “-” (switching to a downshift). This mode is semi-automatic (the driver himself selects one gear or another, but the electronics may still not turn it on if the speed and conditions do not correspond to it).

The gear shift lever itself (automatic transmission selector) on different cars with an automatic transmission, regardless of the type, often simply moves along special grooves. Each slot corresponds to a separate mode (as a rule, there are symbols next to the slot; also, the selected modes on most cars are duplicated on the dashboard).

To turn on one or another automatic transmission mode, you need to insert the key into the ignition and press the brake pedal. Typically, pressing the brake pedal releases the lock, which is a “protection” against accidental movement of the selector.

In parallel, on the side of the selector handle on many types of automatic transmissions there is a special button, pressing which allows you to move the lever to one mode or another. In other words, pressing the brake pedal and holding the pedal allows you to unlock the shaft in the “parking” mode, while pressing the button on the lever makes it possible to further move the selector itself, including the desired modes.

Also, on many cars, starting the engine is only allowed in “P” or “N” mode when the brake is pressed. This solution can be considered a “protective” function that helps prevent unwanted vehicle movement and damage to the automatic transmission and internal combustion engine.

Article on the topic: Oil pressure light is on: causes and troubleshooting

Let us also add that many automatic transmissions, in addition to the main ones, are equipped with a number of other additional modes. Such modes can have either separate slots for activation or can be activated using buttons. For example, you can select only the first gear (mode L1 or 1), inclusion in automatic mode no higher than the second gear (L2 or 2), OD (overdrive) mode, which disables the transition to upshifting fourth or fifth gear.

Also, automatic transmissions often have a “sport” mode (letter “S”), an economical “eco” mode (letter “E”), winter mode (letter “W” or a snowflake icon), etc.

Main problems and their solutions

If the previous checking methods did not yield anything and the malfunction that caused problems with shifting gears on the manual transmission is not determined, then you need to inspect the condition in which the clutch basket is located. The main impetus for this should be the fact that the gears stop shifting when the engine is running.

Release bearing - In normal condition, its movement along the input shaft should not be hampered in any way. If it starts to jam in some places and it moves along them with difficulty, then this is the reason. However, do not worry, as it can be solved by simply replacing the problematic part.

Disc wear – To determine how badly it has worn, disassemble the basket and visually assess its condition. There should be no carbon deposits on the friction linings, and the rivets under the disc should not be visible. If one of these problems is present, the disk will need to be replaced. Most likely, after this procedure the problem with switching gears will be solved.

Malfunction of the basket itself - During long-term use of the car, the so-called “petals” that make up the basket wear out greatly, as a result of which they become very susceptible to high temperatures and can no longer cope with the removal of the pressure disk. Often, to determine the condition in which the petals are located, a simple visual inspection is sufficient - its petals will be deformed or show signs of overheating. In this case, the basket will have to be replaced.

Hydraulic booster - If there is not enough fluid in the system or there is air in it, the gears on the manual transmission may periodically not turn on. To diagnose, inspect the reservoir and inspect all drive components, including hoses, tubes and release cylinder. All identified areas with leaks will need to be repaired and the system pumped.

How to replace the universal joint

In most cases, it is not the rocker itself that fails, but the cardan. Due to its displacement, even a small one, a failure occurs in the gear shift mechanism.

Standard VAZ-2109,2114 scenes are rarely installed during repairs; similar parts from Lada Kalina are used. The replacement looks like this:

- Using two keys set to “13”, unscrew the clamp securing the cardan to the rod.

- Using a screwdriver, pull the boot towards the box housing. If desired, you can remove it completely, and if it has cuts or other damage, replace it with a new one.

- Unscrew the fixing bolt with a “10” key.

- Knock down the cardan with a hammer, strike carefully so as not to damage anything.

- The Kalinovsky universal joint is much more durable and reliable, so install it instead of the standard one.

- Reassemble the entire structure in reverse order. But do not rush to tighten the bolt on the clamp - adjustment is necessary.

Third gear

Rice. 36. Third gear

When shifting from second to third gear, novice drivers very often make a serious mistake.

The ball must travel the path “B–C” (Fig. 36) under the influence of the spring, and not the driver’s hand!

You should make not three, but only two movements with a short pause allotted for the spring to work independently.

Here are your actions: a short push forward into the ball - a pause - and again a short push forward.

“Is it difficult for me to move the ball to the right?”

It’s not difficult if you’ve already put more than one thousand kilometers on the wheels and got your hands full. Although even then you shouldn’t waste your energy on unnecessary action.

If you want to get exactly the third gear, and not the first or fifth, then I advise you not to forget about the spring.

Insufficient lubrication

Despite the fact that if there is a lack of lubrication in a manual transmission, the gears are still engaged, shifting them can be quite difficult, since the gears cannot fully engage with each other. In addition, insufficient lubrication can even damage synchronizers over time.

Therefore, if you hear an unpleasant metallic grinding noise when changing gears, check the oil level in the manual transmission and inspect it for leaks. If any are present, replace all gaskets and seals. It would not be a bad idea to also change the oil seals located in the shank and on the input shaft.

VAZ 2115 | Gear shift

Gear shift

| Gear shift and lever position |

Manual transmission

When changing gears, fully depress the clutch pedal and then release it smoothly. It is not recommended to drive the car with one hand on the gearshift lever, as this increases wear on the gearbox.

When shifting from fifth to fourth gear, do not push the lever laterally to avoid accidentally engaging second gear, which could cause the engine to overspeed and cause engine damage.

Before engaging reverse gear, make sure that the car is at rest and your foot is not on the accelerator pedal. Move the lever from neutral to the right all the way, and then engage reverse.

The table below shows the driving speeds at which you should engage the next gear for maximum fuel economy.

| Gear change | Travel speed |

| 1-2 | 25 km/h |

| 2-3 | 40 km/h |

| 3-4 | 65 km/h |

| 4-5 | 75 km/h |

Gear shift - automatic transmission

“P” Park “R” Reverse “N” Neutral position

Forward gears:

| You cannot set the position “P”, “R”, or “N” while the vehicle is moving. If the driving position is reset, it may cause an accident or damage to the transmission. |

Selector lever positions

| Always keep your foot on the brake pedal when setting the driving position. Do not place your hand on the selector lever as this may cause wear to the transmission. |

| Gear shift lever |

| Between placing the lever in the drive position and accelerating, you should pause for a few seconds to allow the gear to engage. |

“D” ›”3″ “N” › “R” “R” › “P” “P” › “R” “3” › “2”

"P"

Before driving off, you should wait a few seconds for reverse gear to engage.

"N"

"D"

«3»

When moving the lever from position “D” or from position 3 to position 2, switching from third to second gear occurs only at a speed lower than a certain predetermined speed, in order to avoid increasing engine speed to unacceptable values.

«1»

Squeezing the accelerator pedal to the floor (“kick-down”)

Check the condition of the main gearbox mechanisms

Place the car in the hole and check the condition of the clutch. All teeth must be intact and undamaged. Find behind the scenes and pull more tightly, securing your attachment. If everything is good at this stage, then you will have to watch the programs. Wear of the gear teeth leads to the fact that the transmission of torque is disrupted.

READ Replacement of ball joint VAZ 2115

You push the lever with your hand so the clutch has to fit snugly, which causes the gear to shift. As soon as you release your hand, the handle will loosen and the handle will stop. These are the main reasons why second gear

not included on VAZ 2109. I came across this and in my case replacing the coupling helped.

Any transmission fails.

When driving at 9, there is a hum, when I press the clutch the hum does not stop. What's humming, bearings?

Hello everyone, help me, on 09, speed 2 stuck and won’t let go, what should I do? but we already sorted it out, now it’s set to 3 speed again, what should I do?

Possibly a bearing. Soon he’s still walking freely along the shaft. The shaft must be together with the internal part of the bearing. spin, and he rotates freely in it. It is also likely that this is the reason for the rumble.

I have a similar situation. I went through the box twice. I changed all the bearings, but the noise never went away. I'm already starting to get used to it.

The situation is exactly like this, it’s like my car in the video. Most likely you need to make a mistake in 5th gear, the only question is how to check. But one idea has appeared, you can remove the 5th gear cover, open two nuts, remove the 5th gear gears, close the cover, add oil, and then everything will be clear. I’m thinking about doing this one of these days. Report the results.

Second gear

Rice. 35. Second gear

From neutral, second gear is engaged in the same way as first gear. There is only one difference - the ball along the left corridor must be directed not forward, but backward. However, in practice, drivers of passenger cars rarely have to engage second gear from the neutral position; generally, the second gear follows the first (Fig. 35).

To switch from first gear to second without error, you need to perform three specific actions:

- Lightly press the ball against the left wall of the corridor (when it is still in the “hole” of the first gear) and hold it near this wall during subsequent actions (red arrows in Fig. 35);

- With a short movement, push the ball out of the “hole” of the first gear into a neutral position in the left corridor, without allowing the spring to move the ball into the right corridor (Fig. 35, position 0′);

- After a short pause in the neutral position 0′, move the ball along the left wall back to the end of the corridor and drop it into the “hole” of the second gear.

Do not change gear from first to second in one motion!

There are many reasons to pause in neutral. This is both the technical side of the matter (the work of synchronizers and gears in the gearbox), and moments for planning your next actions. And most importantly, you need to initially accustom your right hand to the correct actions, since all gears must be switched with a pause in the neutral position.

The second gear is turned off in the same way as the first, only the ball must be pushed forward, not backward. By the way, all other gears are turned off with the same movement, only some by moving the hand forward, and others backward.

Let's immediately formulate a rule on this topic:

First gear does not engage when driving

Often, when you turn on first gear while the car is moving, it jams and does not work. There are no problems when starting to move from a place. Some “experts” even put forward the theory that you should only start moving from the first gear, and should not use it during maneuvers.

This problem occurs because the injectors do not have time to equalize the torque of the gears, and the driver forcibly tries to connect them. The flywheel spins much faster than the drive shaft and the teeth can fly if the force is large.

Don't rush to press the lever. Bring it to neutral, push it lightly into first gear, and wait for the synchronizers to do their job and the gear to engage.

For old boxes there are instructions for switching with re-gas. When downshifting while driving, move the handle to neutral, step on the gas, increase the speed, and then smoothly change gear. This method is used by owners of preserved vintage cars, the price of which has recently increased significantly.

As a result of the constant stress to which the manual transmission and clutch are subjected, most drivers are increasingly beginning to notice problems with shifting gears.

However, not everyone has time to respond to them in a timely manner, because often the only sign of a manual transmission malfunction is not fully engaging the gears or starting them with a slight stretch. Therefore, in order to avoid serious problems in the future, you should very carefully monitor such manifestations and promptly eliminate the cause that provoked their occurrence. It is better to immediately seek help from a car service, for example, if you are from St. Petersburg, then here https://spb-avtoremont.ru/p264438239-remont-kpp-mkpp.html.

Types of resistance forces

There are several types of resistance force, differing in the nature of the impact on moving objects.

Rolling resistance force

The rolling resistance force is designated as Pf. In this case, strength is determined by several factors:

- the type and condition of the support along which the object moves;

- speed of body movement;

- air pressure and other environmental parameters.

The condition and type of the supporting surface determines the value of the rolling resistance coefficient, which is denoted f. If the temperature in the environment increases and the pressure increases, then this indicator will decrease.

Air resistance force

The force of air resistance or the magnitude of the frontal collision Pв is formed as a result of various pressure indicators. This characteristic directly depends on the intensity of vortex formation in front and behind a moving object. These parameters are determined by the shape of the moving body.

Note

The vortex formation in the front part of the object will have a greater influence on the drag force. If the flat-walled figure is rounded at the front and back, the resistance can be reduced to 72%.

The drag force can be calculated using the formula:

\($$P=cx\times p\times F_{b}$$\)

сх — streamlining or drag coefficient; p—air density; Fв is the drag area (midship section).

During translational motion, the mass of an object encounters resistance to acceleration, that is, acceleration. This force can be found using Newton's second law.

\($$Pj=m\times dVdt$$\)

where m expresses the mass of the moving object, and \(dVdt\) denotes the acceleration of the center of mass.

How to find friction

The resistance force can be determined by applying Newton's third law. In order for an object to move evenly along the support in the horizontal direction, a force must be applied to it that is commensurate with the resistance force. These values can be calculated correctly using a dynamometer. The drag force will be directly proportional to the mass of the object. More accurate calculations are made taking into account the u coefficient, which depends on the following factors:

- the material from which the support base is made;

- the material of which the moving body is composed.

When calculating the resistance force, use a constant value of g equal to 9.8 meters per centimeter squared. Moreover, if the movement of a body occurs at a certain height, it is affected by the force of air friction. This value depends on the speed at which the object is moving. The required value is determined using the following formula only under the condition that the object is moving at low speed:

\($$F=V\times a$$\)

where V is the speed of movement of the body, a is the drag coefficient of the medium.

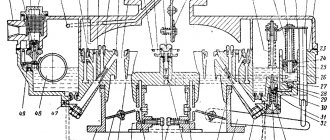

Disassembling the VAZ 2115 gearbox

Wash the gearbox, preventing water from entering the crankcase, and place it on a disassembly stand. Remove the power unit suspension bracket and the clutch release cable mounting bracket.

Remove the primary and secondary shafts at the same time (

| Rice. 3.13. Removing the gear selector mechanism |

Unscrew the gear selector mounting bolts (

| Rice. 3.14. Secondary shaft parts: 1 – nut; 2 – thrust plate; 3 – sliding clutch of the 5th gear synchronizer; 4 – sliding coupling hub; 5 – synchronizer blocking ring; 6 – 5th gear gear; 7 – distance ring of the needle bearing; 8 – needle bearing; 9 – 5th gear gear bushing; 10 – thrust washer; 11 – ball bearing; 12 – thrust washer; 13 – 4th gear gear bushing; 14 – 4th gear gear; 15 – sliding clutch for synchronizer of 3rd and 4th gears; 16 – sliding clutch hub; 17 – third gear gear; 18 – retaining ring; 19 – thrust half-rings of the secondary shaft; 20 – 2nd gear gear; 21 – sliding clutch for synchronizer of 1st and 2nd gears with reverse gear; 22 – retaining ring of the synchronizer hub; 23 – hub of the sliding clutch for the synchronizer of 1st and 2nd gears; 24 – synchronizer spring; 25 – cracker; 26 – retainer; 27 – 1st gear gear; 28 – roller bearing |

If it is necessary to disassemble the secondary shaft, clamp it in a vice with soft pads and use a universal puller to press the ball bearing from the shaft. The bearing is pressed off the input shaft in the same way. Then remove the driven gears of IV, III, II and I gears and synchronizers assemblies from the secondary shaft in the order indicated on

| Rice. 3.15. Differential assembly: 1 – satellite axis; 2 – retaining ring; 3 – semi-axial gears; 4 – speedometer drive drive gear; 5 – differential box; 6 – satellite; 7 – driven gear of the main drive |

– if it is necessary to replace the driven gear, unscrew the bolts securing it and compress gear 7 (

| Rice. 3.16. Details of the gear selection mechanism: 1 – gear selection rod; 2 – gear selection rod lever; 3 – housing of the gear selection mechanism; 4 – three-arm gear selection lever; 5 – blocking brackets; 6 – axis of the gear selection lever; 7 – guide axis of locking brackets; 8 – reverse fork; 9 – clamp; 10 – thrust washer; 11 – spring |

If necessary, disassemble the gear selection mechanism by unscrewing the nut securing axle 6 (Fig. 3.16) of the gear selection lever and remove the retaining rings from the reverse fork axle and from the axle 7 of the locking brackets, remove the reverse fork 8, gear selection lever 4 assembly with a locking bracket 5, a lever axis 6 and a spring 11 with a thrust washer 10.

If necessary, remove the speedometer drive by unscrewing the nut securing it and, supporting the driven gear shaft, remove the speedometer drive.

Problems with switching to automatic transmission

Shifting problems with automatic transmissions are not uncommon. Problems with the automatic machine arise for several reasons.

- backstage malfunction. This mechanism is the most problematic in old-type automatic transmissions. To eliminate the malfunction, the unit will need to be replaced. In most cases, it will be necessary to dismantle the gearbox for these purposes;

- insufficient oil level. The presence of lubricant leaks on the automatic transmission housing may indicate wear of the sealing gaskets, which are not difficult to replace yourself. After this, you need to change the oil in the box. Also, owners of cars with an automatic transmission are recommended to visually inspect the gearbox for oil leaks at least once every 2000 km;

- problems with the transmission control unit can ultimately cause the automatic transmission to completely lock up. To fix the problem, you will need to replace the failed mechanism and thoroughly inspect the electrical part of the gearbox.

Reverse and other gears slip out

The synchronizer blocking ring and gears have specially shaped teeth with which the clutch engages when changing speeds. If the coupling splines, teeth on the ring and gear are ground down, then when the load is applied and the accelerator pedal is released, the transmission spontaneously switches off. In this case, you won’t be able to limit yourself to replacing synchronizers; you should definitely change the gear of the warped transmission and the gear shift clutch.

Direct your attention. Regardless of the brand of your car, the breakdown principle is actually the same for all manual transmissions.

READ How to clean injectors on a VAZ 2115

The speed will be knocked out even if it is not turned on completely. Possible causes of mechanical transmission failure:

- wear of the rod, gear shift fork;

- cable jamming;

- incorrect installation, wear of the intermediate shaft bearing;

- wear of the manual transmission cushion, which causes the box to move under load;

- loose bolts securing the box body.

Changing the gearbox oil

If the oil seal on the rod is damaged, oil leaks out of the gearbox housing, and dirt can get into the box itself. These reasons may be the reason why the reverse gear . In addition, the oil in the box loses its properties during operation, so it must be replaced preventively at least once every 35–40 thousand kilometers. Before replacing, you need to check the condition of the oil in the box. To do this, you need to remove the oil dipstick installed in the gearbox housing and visually assess the quality of the oil. The presence of metal and dirt particles in the oil on the dipstick is unacceptable. The oil itself should be quite liquid and not stick to your hands in a thick layer.

To replace, you will need the following materials and tools:

- New oil. When purchasing oil, you need to consider the type of gearbox. For fairly rare four-speed gearboxes, three liters of oil are required, for newer five-speed ones - 3.3 liters. The oil itself must have a tolerance of 80W-85, the manufacturer does not matter.

- A container for draining old oil with a volume of at least 4 liters.

- A funnel with a hose for pouring new oil or a syringe.

- Wrenches 12 and 17 mm of any type.

- Rags and cleaning solvent.

The actual work order is as follows:

- Place the car with the heated gearbox on the pit.

- Remove the rubber plug from the gearbox ventilation valve installed on the top of the crankcase.

- Clean the valve and plug from dust and dirt. It is convenient to clean parts with thin wire and a rag.

- Reinstall clean parts.

- Wipe off dirt from the bottom of the box. Unscrew the plug on the bottom of the box housing.

- Place a container under the drain hole and drain the oil. It will completely merge in at least 20-25 minutes.

- After this, screw the drain plug back into place and carefully tighten it with a wrench. First, the plug and hole must be thoroughly wiped with a rag.

- Pour fresh oil through the oil level dipstick hole in the box.

- During filling, it is necessary to check the oil level, which normally should be between o and “MAX” on the dipstick rod.

- If there is an overflow, the oil can be pumped out with a large medical syringe with a tube on the spout.

- Within a few days after the change, it is advisable to check the level and appearance of the oil. You also need to make sure that there are no leaks through the plug and box seals.

Sources:

https://www.vazzz.ru/vyletaet-zadnyaya-peredacha-na-vaz-2114-ne-vklyuchaetsya-skorost-prichiny-neispravnosti/

Backstage adjustment

There is nothing complicated in the procedure; you can do it yourself, but you will have to run from the pit to the salon.

Yes, it is advisable to do this work in a pit or overpass. You need to act approximately according to this principle:

- Loosen the nut on the clamp.

- Set the gearshift lever to the reverse gear position.

- Set the box rod to the reverse speed position. This is difficult to achieve, so adjustments will have to be made.

- Check how the gears shift. If the rear one is too far to the left, loosen the clamp and turn the cardan counterclockwise. If the fifth speed (including reverse) has gone too far to the right, then the cardan rotates clockwise.

By adjusting the position of the gearshift rocker, you will notice that when the lever is installed in the middle, neutral speed will be engaged. When turning on the fifth gear, the lever should not catch the passenger seat, and when moving in reverse, the driver's seat should not interfere with the movement of the lever.

Causes of gearbox failure

The complex mechanism constantly works under load and under extreme conditions. Constant vibration, rising temperatures, dust and dirt. If one or more speeds fail to turn on, you should check:

- cable tension and integrity;

- fastening the scenes;

- wear on the clutch disc;

- petals on a basket;

- bearing integrity;

- plug condition.

Clutch

When the clutch discs wear out, the pedal moves up and its position becomes higher than the others. In this case, when turned on, a crunching sound may be heard and the lever does not move, as if it is resting against an obstacle. You should not force the assembly, as this can lead to more serious damage - the gears will fly.

It is typical for such wear that the clutch pedal falls to the floor and you can hear from drivers that the VAZ 2109 does not engage the gears. Usually this applies to all gears, but only first and reverse can fail.

You can check by removing the rubber plug. The destroyed disc leaves fibers that look like tangled strands of hair. If such a phenomenon occurs, then a new clutch disc should be installed.

Cable

Due to constant loads, the cable stretches and must be periodically adjusted and tightened. In this case, the VAZ 21093 does not engage the first and second gears, and the rear may also fail. To fix the breakdown, you need to drive into the pit and tighten the cable. If it is worn out, replace it immediately. You can do this yourself.

A similar breakdown can also manifest itself in the failure of the gears to engage while the engine is running. Sliding along the splines is limited and fixation does not occur.

Basket

The reason for difficult shifting of individual gears, especially if there is a crackling sound that gradually fades while moving, may be the destruction of the spacer ring in the basket. Notice that there are drops of oil on the outside. Then remove the basket and check the O-ring and disc blades. Pay attention when purchasing new parts, because on some models the disk is missing and then you have to install pins and secure it yourself.

Backstage

A loose link must be tightened with an assistant. No special knowledge or skills are required, just the ability to hold the lever in the desired position while you crawl under the car and tighten the bolts. When the scenes on the VAZ 2109 are loosened, the speeds do not engage, and especially the rear ones.

Place the car on a hole or hill to have access to the bottom. Set the lever to neutral if several speeds do not engage. When only the reverse gear does not work, make adjustments using it. An assistant must hold the shift knob in the specified position without moving it anywhere.

It is necessary to loosen the bolt from below by 13, check the engagement of the gears, and having installed everything in place, tighten the bolt. If there is a problem with several gears, everything is done the same way, but it is set to neutral, or rather the shift knob is in the middle position. You can watch the video on how to do this.

Fork

Most often it fails on the road. If you slow down at a traffic light, the speed will not turn on to continue driving. A crack that forms on the fork body can lead to its destruction at any time, even under minor loads.

Unit repair

The owner studies the structure of the walk-behind tractor and corrects faults in a timely manner. When the engine is running, ignition may occur, black smoke may come out of the muffler, and carbon deposits may form on the spark plug.

In this case, it is necessary to disassemble the air filter and clean it. If the spark is lost, the engine does not start, and the spark plug is wet, the reasons for the failure in the ignition system are determined. The owner of the walk-behind tractor cleans the electrodes, rinses and dries the parts. It is necessary to disassemble the walk-behind tractor engine, observing the following rules:

- drain the oil from the crankcase;

- install the filler plug;

- Disconnect the hose and air filter.

Next, you should dismantle the remaining parts of the engine. Before assembling the engine, parts are cleaned of dirt and components to be installed are washed. When setting up the crank mechanism, check the suitability of the oil scraper rings for operation.

Piston rings are replaced only as a set.

Manual transmission bearings

And the last thing that could be the bearings - although they are very strong in the box, sometimes they also “stick”. The box will work like a tractor, especially when warm.

In any case, if you have problems in the gearbox itself, then this is an expensive repair. It is also better to entrust it to professionals, because the gearbox is a very complex mechanism.

As you can see, there are quite a few reasons, but in fairness it is worth noting that mechanical transmissions are a fairly reliable unit; they themselves break down quite rarely, especially if you change the transmission fluid on time and pour a branded one of very good quality.

If the gears do not engage, then these are most likely “attached” problems, starting from the rockers and cables, ending with the basket, clutch disc and flywheel.

Now let’s take a look at a short video version of my article.

(10 votes, average: 4.70 out of 5)

Clutch faults

Simply put, the clutch is a mechanism that serves to transmit the torque of the internal combustion engine to the transmission, and also opens the engine and transmission so that gear can be changed. Failure of individual components of this unit may make it impossible to shift gears while the engine is running.

Brake fluid leaks

The design of many modern cars assumes that the working fluid for the clutch is brake fluid. If there is not enough fluid in the clutch drive hydraulic system, then the clutch will not engage fully.

In this case, the gears will engage slowly or not engage at all. For an initial check, you should look at the fluid level in the reservoir. If the level is low, it is necessary to check for leaks, eliminate defects and bleed the clutch.

If the fluid level is normal and no other reasons have been identified, you will need to remove the gearbox to inspect the clutch elements. Usually, when you try to turn on the speed and this mechanism breaks down, no loud grinding metallic sounds are heard from the gearbox itself.

Gears may not engage or may not engage fully if the fault is related to the clutch basket. The release bearing may also be the cause. If the specified bearing does not move freely along the input shaft or is jammed, then replacement of the part is necessary.

It is necessary to separately add that the primary sign of problems with the release valve is the appearance of a rustling or distinct hum when the car is running. The noise appears only when the clutch pedal is pressed to the floor. Such extraneous sounds can be present both on a cold car and on a warm one. After releasing the clutch pedal, the noise should disappear. A jammed release lever will not allow the clutch to engage, which complicates gear shifting and can also lead to rapid wear and destruction of other elements of the clutch mechanism.

Basket malfunctions are often associated with critical wear of the petals. Wear means that the basket stops performing its functions as it heats up. An increase in temperature leads to the fact that the clutch basket cannot completely remove the pressure plate. The result is very difficult gear shifting after the engine has warmed up a little.

After removing the box, it is necessary to inspect the basket for deformation, signs of overheating and other defects. If found, the element must be replaced.

Another reason why the gears do not engage when the car is running or engages with effort may be a worn clutch disc.

After disassembly, it is necessary to inspect the friction linings on the disk. They should not be critically worn, burnt or damaged, and the disc should not be deformed. Additionally, during the clutch inspection process, a check of the diaphragm springs is required. After replacing failed clutch elements, the box must be well centered during subsequent assembly, and the clutch must be pumped.

New or refurbished old?

If replacing the gearbox cannot be avoided, it is worth considering one very attractive option - installing a rebuilt gearbox. To do this, companies purchase old, damaged boxes, restore them to the highest possible quality and offer installation with a guarantee.

Disassembled gearbox

As practice shows, such gearboxes are approximately 30-70% cheaper than purchasing a new gearbox.

There is only one important condition for successful savings on such significant repairs. It must be a reliable, trusted company

Such companies value their own reputation, so they do not deal with fakes or low-quality repairs. In order to receive positive customer feedback and attract new customers, they simply must do everything well, conscientiously. That’s why today there are fly-by-night companies and companies where, over the years of work, they have established themselves as a reliable and responsible specialist in repairing and replacing gearboxes. You yourself understand perfectly well who you need to contact if you have problems with your box.

Tin packaging for gifts for car enthusiasts

Tin packaging for gifts for a car enthusiast can look very festive and attractive. Stylish and…

Next 06/28/2021

Sources:

https://tazovod.ru/raznoe-2/vaz-2115-ploxo-vklyuchaetsya-zadnyaya-peredacha-vaz-2115-inogda-ne-vklyuchaetsya-zadnyaya-skorost.html https://soloserv.ru/avto/ne -vklyuchaetsya-zadnyaya-peredacha-na-vaz-2114-ustranyaem-neispravnost

What is drag force in physics

Resistance force is a force that arises during the movement of a body in a liquid or gaseous medium and prevents this movement.

It is important to be able to distinguish the force of resistance from the force of friction. In the second case, the nature of the interaction of solid bodies with each other is considered

Thus, friction can be observed when an object moves on the surface of another. The vector of this force will be directed in the opposite direction of the direction of movement.

In order to calculate the resistance force, it is necessary to multiply the resistance coefficient of the material by the force that provokes the movement of this object.

Note

As an example of drag force, consider the movement of a train. The air surrounding the composition slows down the speed of its movement, that is, a resistance force arises.

What does it depend on in mechanics and dynamics?

The strength of resistance depends on several factors. Its value is influenced by the following characteristics:

- Features of the medium and indicators of its density, for example, a liquid has a higher density than a gaseous substance.

- The shape of the body, since objects with streamlined shapes elongated along the direction of movement are subject to less resistance than bodies with many planes located perpendicular to the movement.

- Speed of body movement.

The resistance force can be observed experimentally. For example, if an object has moved by a distance l, when it is acted upon by a resistance force, the designation of which is represented as \($$F_{r}$$\), work is expended, which can be calculated using the formula:

\($$A=F_{r}\times l$$\)

In the case when the cross-sectional area of a moving object is S, it will collide with particles whose volume is Sl. The total mass of these particles can be represented as \($$\rho_{ a}\times Sl$$\). If particles are completely entrained by a body, they acquire speed V. Kinetic energy can be calculated using the formula:

\($$K=\frac{\rho_{ a}\times Sl\times V^{2}}{2}$$\)

Energy is created by external forces due to their work with power by determining the resistance force. From where, A=K. Thus,

\($$F_{r}=\frac{\rho_{ a}\times S\times V^{2}}{2}$$\)

In this case, the dependence of the resistance force on the speed of movement of the object increases and becomes proportional to its second power. In contrast to the force of internal friction, it is designated as the force of dynamic drag.

It should be noted that the theory in which particles of the medium are completely carried away by transported bodies is exaggerated. In real-time conditions, any moving object is surrounded by a flow, which reduces the impact of drag forces on it. Therefore, in calculations, the drag coefficient C is often used, denoting the drag force with the formula:

\($$F_{r}=C\times S\times \frac{\rho_{ a}\times V^{2}}{2}$$\)

Drive and clutch cables

For rear-wheel drive models (VAZ 2101 - 2107), the gears are engaged hydraulically. That is, when you press the clutch, the fluid pushes the piston, which in turn pushes the clutch fork, which retracts the disc. For front-wheel drive models (VAZ 2108 - 2115), there is no hydraulic connection; everything is done here by mechanics, or rather by the clutch cable, which is connected to the pedals. If your slave cylinder leaks on a rear-wheel drive car or the cable breaks on a front-wheel drive car, the car will not engage in gear. The “fork” simply won’t work. We just check and replace damaged parts.

Clutch assembly

If in order to detect a problem with gear shifting you had to disassemble the clutch, be extremely careful when reassembling it. Tighten all threaded connections with extreme care. And be sure to center the clutch before installing the manual transmission. For this purpose, you can use either a special tool or the input shaft, which will have to be removed from the old gearbox.

When gears shift poorly, driving a car becomes not only unpleasant, but also unsafe. Let's look at the main reasons why gears shift poorly or don't shift at all. And since the automatic transmission and manual transmission are too different, we will consider them separately.