When operating a vehicle, it is necessary to monitor the functions of each unit and vehicle systems. Experienced drivers can understand the condition of the transmission of a running car by the nature of the sounds produced by each mechanism. Listening to the car is carried out both while driving and when the car is stopped. A working automatic transmission makes almost no extraneous knocking, noise, squeaks, vibrations, etc. If the automatic transmission is noisy, diagnostics must be carried out to prevent damage to the components and parts of the gearbox.

Noise in automatic transmission when cold: reasons

If the problem only appears when it’s cold, you can still drive, but when the gearbox does not stop making noise even when the unit is warmed up, then specialist intervention is necessary. Delay may result in serious damage.

The cause of the noise when the box is not yet warmed up is especially often the jamming of the generator pulley clutch. You can try opening the hood and driving back or forward a little. It will be clearly visible how the transmission belt jerks.

Typically, drivers immediately change the belt and tension pulley. Yes, the problem may be in them, but you still need to inspect the pulley first. To check it, you need to rotate the pulley several times, first in one direction and then in the other direction. If the pulley does not move smoothly when turning, it will have to be replaced. Work here for 10 minutes.

Driven clutch disc.

The play between it and the disk itself was unacceptably large. The hub was gradually gnawing on the seat and indistinctly announced this with knocks. A little more - and the Pajero would have stood in the middle of the road.

In conclusion, let me remind you the following. On modern cars, manual clutch adjustment is not provided. If during acceleration the tachometer goes off scale and the car accelerates sluggishly, the clutch must be changed immediately. It’s different with a domestic product. It is not very convenient that here you have to more often monitor the free play of the pedal and manually adjust it. But if the first signs of slipping appear, but there is still something to regulate, then you can drive for a while.

This was easier on older cars with a hydraulic clutch: as its discs wore out, the free play of the pedal decreased, and the force on it increased. The basket disk pressed the driven disk against the flywheel weaker. But as long as it was possible to maintain the required clearance in the drive, the car drove. And on modern front-wheel drive VAZ cars, for example, the drive is cable-driven, without any backlash. The gradual rise of the pedal warns of clutch wear - it becomes higher than the brake pedal. To prevent slipping, you need to adjust the cable by lowering the clutch pedal to the level of the brake pedal.

It is worth remembering that the clutch of these cars “dies” very quickly in case of slipping! People often ask: why does a car, especially a hot one, shake when starting? A common cause is a misalignment of the pressure plate diaphragm spring. For this reason, it does not grab with the entire working surface, breaks down, grabs again - until the clutch is fully engaged, it shakes the entire car. Because of this, the spring petals may break. And with strong heating, the diaphragm spring often warps, changing shape. The result will be the same. Such defects cannot be treated; the clutch will have to be replaced.

Why does first gear howl in an automatic transmission?

Sometimes the gearbox hum only appears when driving in first gear. When switching to the second, the unpleasant sound disappears. This means that the problem is in the planetary gear, or rather, in one of its satellites - a group of gears. Over time, the howl of the automatic transmission in first gear only becomes stronger. This leads to transmission scattering and complete engine stop.

The planetary gear needs to be repaired. You can, of course, not rush into a trip to the service station and wait for the mechanism to completely collapse, but such a delay can hurt your wallet. A complete replacement of a planetary gear is more expensive than repairing one of its planetary gears.

By the way, if an unpleasant sound appears only during forced (fixed) transmission, then there is no need to rush into repairs. Try changing the working fluid. But if the noise also appears while driving, this is a serious matter.

Automatic transmission hums at speed: what to do?

There may be a buzzing noise in the area of the gearbox when accelerating. As a rule, the automatic transmission hums at a certain speed limit, and then the hum only intensifies. A detailed diagnosis reveals that the place where the noise is generated is the rear part of the automatic transmission, where the connection to the driveshaft occurs. In this case, the system does not generate any errors. This is not yet a reason to panic, and the appearance of unpleasant sounds in this area is not evidence of the “death” of the gearbox. A possible cause is a broken transfer case front bearing (the bearing closest to the front driveshaft).

With such a malfunction, almost all bearings in the transfer case need to be replaced. For repairs, the box will have to be dismantled. The problem is that the transfer case is located in the same unit with the automatic transmission.

Repair procedure:

- dismantling and disassembling the transfer gear;

- accurate determination of the causes of the malfunction;

- bearing replacement;

- flushing the transfer case housing;

- reassembly;

- adding working fluid to the hydraulic transformer.

Automatic transmission hums when accelerating

Sometimes the car makes unpleasant sounds when starting to move. Perhaps it's the automatic transmission whining. It starts making noise when shifting into third gear or at a speed of 60 km/h. With further acceleration, the unpleasant noise intensifies. After reaching a certain speed (80-90 km/h), the sound from under the hood subsides. If you stop pressing on the gas, the sound will no longer appear, but further acceleration will provoke its appearance again.

Replacing the rear gearbox can solve this problem. It is also worth inspecting the rear brake discs. You need to check the back side (where the brake cylinder is located). Rusty deposits may accumulate on the discs. If their width is more than 1 centimeter and they are over the entire surface, this may cause extraneous noise. The problem is solved by cleaning the inside of the disks.

Automatic transmission whine when shifting gears

Sometimes when you start driving, you can hear a suspicious sound resembling a howl from under the hood. This usually happens when shifting into second gear. In most cases, the source is the front planetary gear. This unit begins to make sounds when the transmission is heavily worn. Some drivers do not attach much importance to this and wait until the planetary gearset completely falls apart and a “meat grinder” of gears is formed, but this should not be allowed to happen.

The constant desire to reduce the cost of mechanisms simply cannot but affect their quality. The planetary mechanism quickly begins to break down the axes of the satellite gears. This leads to a change in the contact patch between the sun gears and satellites, which causes the destruction of their “teeth”. There is only one way out of this situation - replacing the planetary mechanism.

What noise additives are best to use?

There are many additives to eliminate noise. Manufacturers promise that their use will increase the service life of the mechanism and ensure smoother operation of the automatic transmission. Let's highlight the following additives:

- ATF Additive. Slows down oil oxidation and restores the performance of rubber seals. At the same time, it cleans the valve body channels and forms a protective film on the parts. This leads to a reduction or complete elimination of extraneous noise. According to the manufacturer, the additive increases the service life of the automatic transmission. The product consists of the same components as the oil, only their concentration is increased several times.

- EX120. This additive prevents early wear of the automatic transmission and protects rubbing parts. Its use helps eliminate extraneous noise. In addition, the geometric parameters of worn parts are partially restored due to the formation of a special metal-ceramic film on the metal surface. The product can be used in all types of transmissions and mixed with any oil. This revitalizant does not enter into a chemical reaction, which means it does not cause changes in the viscosity and other parameters of the working mixture.

The appearance of extraneous noise in the automatic transmission area is a reason to diagnose and repair the mechanism. A normally operating automatic transmission never hums or makes a grinding noise; it emits only a uniform, monotonous sound. The presence of noise is a sign of a malfunction that can occur both in the selector and in the working part of the mechanism.

Source

Gearbox noise

The causes of noise in the gearbox depend on the type of transmission. So, in manual transmissions, a hum may appear, for example, due to wear of bearings, shaft gears, springs on the rocker, or differential. As for the automatic transmission, most often it hums due to low oil level, due to problems with the torque converter and the lever linkage.

To eliminate noise in the area of the box, it first makes sense to check the oil level in it. If it is not enough, then you need to top it up or replace it. As a temporary solution, an anti-noise additive is sometimes used in the box (it will not completely remove it, but at least reduce the operating noise). To effectively eliminate hum, the box should be dismantled, checked and fully repaired. Read about all the causes of noise in the gearbox in the article, and for brief information on why various types of noise appear in the gearbox, see the table.

| Conditions under which the gearbox makes noise | Possible causes of noise |

| Mechanical transmission | |

| Humming noise at speed (while driving) |

|

| At idle |

|

| When overclocking |

|

| When releasing the clutch |

|

| On a certain gear |

|

| In low gears (first, second) |

|

| In high gears (4 or 5) |

|

| In the cold |

|

| In neutral gear |

|

| Automatic transmission | |

| When driving at speed |

|

| In the cold |

|

| At idle |

|

| When overclocking |

|

| On a certain gear |

|

| At low speed (up to approximately 40.60 km/h) |

|

Troubleshooting

If the VAZ 2109 gearbox howls, then the simplest repair is to check the level and change the oil in the crankcase. To eliminate all other defects, it is necessary to remove the box from the car and completely disassemble it. To do this, you need a closed room, a large number of various tools and experience in repairing such units.

Lack of oil

The oil level is measured using a dipstick installed in the upper part of the gearbox housing. A volume located at any distance between the minimum and maximum marks on the probe rod is considered normal. On the oldest gearboxes that do not have an overdrive fifth gear, the amount of fluid is measured through a hole in the side, closed with a plug. The level should be at the bottom edge of this hole.

Dipstick for checking the oil level on the VAZ 2109 box

To maintain the normal condition of the oil, it should be changed after 75 thousand kilometers. When filling, use API GL-4 standard lubricants with a viscosity of 75W-90, 80W-85 or 80W-90. Some owners specially fill in thick oil of the TM-5 type, which reduces the noise of the box. If replacing the lubricant does not correct the situation and the mechanism continues to make noise, then the problem lies in worn-out gearbox parts.

Replacing the drive shaft bearing

Before replacing the bearings, the gearbox must be removed from the vehicle.

To remove the gearbox you must:

- Wash the wheel arches and the underside of the car in a pressure washer and place the car on a lift. Then you need to remove the protective sheet of the crankcase and engine.

- Disconnect the battery from the on-board network and drain the oil from the gearbox housing.

- Unscrew the hub nuts of the front wheel drives and remove the wheels themselves.

- Disconnect the speed drive rod in the box and the ground wire going to the crankcase.

- Disconnect the plug from the reverse lamp switch.

- Remove the ball joints from the steering knuckle and remove the longitudinal brace from the vehicle.

- Unscrew the fastening of the lower cover on the clutch housing.

- Unscrew the fasteners and remove the wheel drive shafts.

- Unscrew the starter mounting bolts and remove it from the unit.

- Remove the gear shift link located on the top of the manual transmission.

- Unscrew the four nuts securing the gearbox housing to the flywheel housing.

- Remove the support with which the box is attached to the body side member. To do this, the power unit is slightly raised on a jack.

- Move the box away from the engine a few centimeters and remove the input shaft from the clutch basket. When removing the gearbox, you must make sure that the shaft does not rest on the clutch basket petals. Contact may damage the basket.

- Remove the gearbox from the engine compartment.

The procedure for removing the box from a VAZ 2109 is shown in the video from the author of AUTO REZ.

After completing the steps described above, you need to disassemble the gearbox and remove the input shaft.

To remove and replace worn bearings, follow the steps:

- Clamp the shaft in a vice with soft metal jaws or through wooden spacers.

- Remove the front and rear bearings from their seats using a screw bearing puller.

- Install the new parts into place by hammering them through a metal mandrel. This must be done carefully so as not to distort the bearing ring, as this will cause nicks in the seat.

Wear of gears in the box

To perform the repair, you will need to remove the gearbox from the car according to the instructions described above and completely rebuild the gearbox. In this case, the condition of all parts of the mechanism should be assessed, since not only gears, but also other mechanisms can be worn out.

The sequence for disassembling the gearbox is as follows:

- Remove the clutch bracket and unscrew the six nuts securing the rear cover.

- Using light blows of a hammer, push the cover off the gasket and remove it. Remove any remaining sealant. Reusing such parts is undesirable because it does not ensure the tightness of the joint.

- Engage third or fourth gear and unscrew the bolt securing the fifth-speed shift fork. The bolt is located under the removed cover.

- Sliding the synchronizer along with the fork down, switch the gearbox to fifth speed. Check the position of the coupling splines, which should come into contact with the gear.

- Remove the clamps of the primary and secondary shafts, and then unscrew the fastening bolts.

- Pry the fifth speed synchronizer with a flat tool (for example, a screwdriver) and remove it from the shaft along with the fork. When removing the part, you must hold it with your hand so as not to lose the balls and springs that fix the coupling.

- Remove the blocking ring and fifth gear from the secondary shaft by prying it off with a screwdriver.

- Remove the needle bearing cage along with the thrust ring. Then remove the fifth gear from the drive shaft.

- Remove the four slotted screws that secure the shaft bearing plate. The screws are tightened with a high torque, so they can only be unscrewed with an impact tool.

- Remove the driven shaft needle bearing plate and bushing along with the thrust ring. Remove the bearing retaining rings installed in the grooves on the shafts.

- Unscrew the three gear shift lock plugs. After this, remove the balls and springs from the holes.

- Remove the two bolts that secure the box support bracket to the crankcase. Separate the gearbox and clutch housings, which are secured with twelve nuts. For this purpose, there are special grooves at the junction into which the awl of a flat-head screwdriver is inserted. Trying to insert a screwdriver into another joint is prohibited, as the mating surfaces will be damaged.

- Place the box on the plane of the removed fifth gear cover and unscrew the bolts securing the shift forks of the first two speeds in the gearbox. Lift the forks up and out of their seats. Using a similar procedure, remove the third and fourth speed forks. To remove the overdrive fork rod, turn it to the side to disengage the rod heads.

- Remove the retaining ring and remove the reverse gear fork along with the gear. Then you need to carefully pick up the drive and driven shafts and remove them from the box housing.

- Unscrew the three bolts securing the gear selector mechanism. Through a mandrel, press the roller bearing of the driven shaft along with the oil seal out of the crankcase.

Why is the gearbox noisy?

Most often, noise in the gearbox, both manual and automatic, occurs when the oil level has become lower or the gear lubricant is no longer suitable for use. The nature of the sound resembles a metallic clang, which intensifies as the vehicle speed increases. So, noise in a gearbox with a low oil level occurs:

ATF level dipstick

- when the car is moving at speed (the higher the speed, the louder the clang);

- at engine idle speed;

- during acceleration (there is a gradual increase in the volume of the hum);

- in neutral gear;

- when the engine is running cold.

The reason for the hum from the gearbox when the engine is running cold may lie in the thickness of the transmission oil and its contamination.

The next common reason why a gearbox hums is partial failure of the bearings of the primary or secondary shafts. In this case, the sound will resemble a metallic hum. The input (drive) shaft bearings will hum in the following situations:

- immediately after starting the engine when cold;

- when the engine is running at low speeds (at first, second, then the hum decreases);

- when coasting in a car;

- when the engine is running at high speeds.

Anatoly Vaisman

Another customer wanted to “shake up the entire gearbox” - they say, I was really getting tired of the mournful singing! Indeed, extraneous noises in a car are always disturbing, especially if you don’t know the reason. But why is any noise coming from the box area attributed only to it? Clients say different things. One is confident in his absolute pitch, another believes his wife, the third refers to the verdict of certain specialists. However, very often the noise does not occur due to the fault of the box!

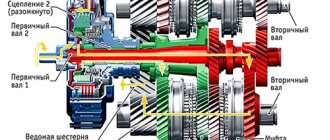

When is it worth sinning on the box? Probably, you heard how an old truck howls on the rise? “Singing” is characteristic of a gear transmission (especially a heavily worn one) and is caused by the process of meshing the working teeth. The gears, transferring the load from tooth to tooth, oscillate and produce this very song. And its volume depends on the gaps between parts, wear of teeth, viscosity of the oil in the mechanism, etc.

Noises from a working gearbox from teeth engaging, oil mixing, or bearings operating while driving are inaudible. But a loud howl is as serious a reason for diagnosis as the hum of the beginning destruction of tracks, balls or rollers in bearings. If these sounds make their way against the background of many others - from the engine, tires, suspension, then you cannot delay the repair! At any moment, the box can break and jam, which is especially sad at high speed.

A stethoscope will help you listen well to the box, but it’s not easy to do this on the go. When the car is parked with the engine running, the “neutral” in the gearbox must be turned on or the clutch pedal must be depressed. In the first case, the primary and intermediate (if any) shafts with gears, couplings, etc., mounted on them, rotate from the engine, while the secondary one stands. At idle, the rotating parts of the box are not loaded, so powerful torsional vibrations of the crankshaft cause collisions between these loose parts. The larger the gaps, the stronger the knocking. But if you press the clutch, then all the gearbox shafts are in place, there is no noise.

Here are some more examples. Squeeze the clutch while driving, leaving the gear engaged: everything in the box rotates, but from the wheels. Now release the pedal and brake with the engine: the transmission parts will receive reverse loads, and the noise will change. If the difference is noticeable, then there is work for the diagnostician. Let's try to coast with the "neutral" in the box: the wheels turn the unloaded secondary shaft, and the engine turns the primary... Again, if the noise changes tone, you will have to look for the reason.

So, the main thing. If the noise disappears when you press the clutch in a stationary car, it means that it was created by the gearbox. But if the cabin is quiet when the pedal is released, and noise occurs when you press it, then the box has nothing to do with it. Look for the cause in the clutch, most likely in the release bearing.

Although there are exceptions here too. Here's one of them. The owner of the VAZ-2112 was frightened by the grinding noise coming from the clutch housing when pressing the pedal, and he rashly ordered a replacement of the entire assembly. We checked - there is sound. But the pedal seemed too tight - was the fork sticking? Let's say, but you still have to press on the pedal with almost both feet! Let's first look at the clutch cable.

This is where the “replacement of the entire assembly” ended! With the new cable everything worked perfectly, and we studied the old one with interest. It bristled with wires like a ruff!

What kind of noise could there be in the gearbox?

The noise from the box can come from a different nature; depending on the damage, it not only operates with increased noise, but also howls or hums. Let us briefly describe the reasons why the above components lead to the gearbox howling and humming. So that you understand what to do about it and how to fix the problem.

Gearbox howls

The most common reason for noise in the gearbox resembling a howl is old, contaminated or incorrectly selected gear oil . If its level is insufficient, then as a result, the bearings and other moving parts of the box will run dry, producing significant noise. This is not only uncomfortable when driving, but also harmful to parts. Therefore, you should always monitor the oil level in the gearbox and its viscosity.

The second reason why a gearbox howls is because its bearings are worn out . They can howl due to natural wear, poor quality, a small amount of lubricant in them, or dirt that has gotten inside.

If the gearbox is noisy at idle when the clutch is released, in neutral gear and when the car is stationary, then most likely the bearing on the input shaft is noisy. If the box hums more in first or second gear, then a greater load is placed on the front bearings . Accordingly, it is necessary to diagnose the input shaft bearing.

Likewise, the input shaft bearing can make noise when the car is coasting or simply after starting the engine, and it doesn’t matter at what speed. Often the noise disappears in this case when the clutch is depressed. The reason for this is that when the clutch is depressed, the primary does not rotate, the bearing also does not rotate, and, accordingly, does not make noise.

If the box is noisy in 4th or 5th gear, then in this case a large load goes to the rear bearings , that is, the secondary shaft. These bearings can also make noise not only in high gears, but in any gear, including reverse. Moreover, the hum intensifies in this case with increasing gears (in the fifth gear the hum will be maximum).

Gear wear is the third reason why the gearbox howls. This noise occurs in two cases: teeth slipping and improper contact patch between them. This sound is different from noise, it is more like a metallic screeching sound. This squeal also occurs under load or during acceleration.

Often the cause of noise is the gear itself if the sound occurs in one specific gear. The gearbox makes noise when driving at speed due to banal wear of the corresponding gear on the secondary shaft. This is especially typical for gearboxes with high mileage (from 300 thousand kilometers or more) as a result of significant metal production and/or low oil level in the box.

Automatic transmission howls

In an automatic transmission, the “culprit” of the howl can be the torque converter . This knot is colloquially referred to as a "doughnut" because of its corresponding shape. The torque converter hums when changing gears and at low speeds. As driving speed increases, the noise disappears (after approximately 60 km/h). Additional signs that the donut is broken include:

- car slipping at start;

- vibration of the car when driving;

- jerking of the car during uniform movement;

- the appearance of a burnt smell from the automatic transmission;

- The speed does not rise above certain values (for example, above 2000 rpm).

In turn, torque converter malfunctions occur for the following reasons:

Torque converter with automatic transmission

- wear of individual friction discs, usually one or more pairs of them;

- wear or damage to blade blades;

- depressurization due to destruction of seals;

- wear of intermediate and support bearings (most often between the pump and the turbine);

- failure of the mechanical connection with the box shaft;

- overrunning clutch failure.

How to identify automatic transmission faults by sound

The ability to diagnose a unit by sounds applies not only to the engine, but also to the gearbox, as well as other components of the vehicle. The automatic machine is also no exception. This approach allows you to quickly identify suspicious automatic transmission noises in the event of malfunctions and, in some cases, localize the breakdown.

At the initial stage, you need to make sure that it is the automatic transmission that is humming. To do this, you should check the pump, the quality of the engine cooling system, evaluate the operation of the engine, generator, check the timing belts or chain, power steering, steering elements, bearings, etc.

If the noise definitely comes from the automatic transmission, you need to pay attention to its frequency, tone and volume. You should evaluate the operation of the transmission in motion under load in different modes, also turn it on and drive in reverse gear, listen to how the automatic transmission works at idle.

During operation of the automatic transmission, a howling, buzzing, crackling, grinding, hum, etc. may be heard. Metallic impacts of greater or lesser intensity and sounds of surface friction may also be heard. Based on the nature and characteristics of automatic transmission noise, you can determine the nature of the malfunction.

For example, when braking, you can hear a loud sound similar to a howl. This noise is associated with the torque converter and is often not a serious problem if it occurs only briefly. If the automatic transmission howls constantly, and the tone changes depending on the engine speed, then this may indicate the following automatic transmission problems:

- wear of the automatic transmission oil pump gears is possible;

- insufficient automatic transmission oil level;

- transmission oil has become unusable;

- seal failure, air enters the oil pump;

- the engagement of the oil pump gears is broken;

Also, in some cases, the automatic transmission buzzes. Moreover, the intensity of such sound directly depends on the speed of rotation of the output shaft. Such noises arise as a result of increased vibration, as well as oscillations of the line pressure valve (regulator valve). To get rid of the problem, it is often enough to replace the seals, cuffs and other sealing elements.

We also recommend reading the article about why the automatic transmission kicks and pushes. From this article you will learn about the main reasons why kicks and jolts of an automatic transmission occur; an automatic transmission jerks on the move, when switching speeds, modes, etc.

Often rattling can be heard in the automatic transmission, especially when the engine is running at low speeds. In this case, diagnostics of the gas turbine engine is needed to determine its performance. Possible problems include damage to the hydraulic pump blades, problems with the turbine wheel, and malfunctions of the damper springs.

Frequent vibrations and rattling while driving appear as a result of damage to the engine flywheel, to which the torque converter is attached. In this case, a characteristic feature is that the vibrations disappear for a short time if the selector is switched from mode “D” to “P” or “N”.

Even when idling, you can hear the clanging of metal in the automatic transmission area. Often the cause is clutch gaskets (friction discs) that are sufficiently worn out. To eliminate such automatic transmission clanging, you need to change the clutches in batches. This operation involves removing the automatic transmission.

You can also often hear a hum and grinding noise in the differential area. This noise is often mistaken for wheel bearing noise. If the automatic transmission differential hums, this may indicate that the gear teeth, bearings and other elements of the mechanism are worn out.

Read also: How to check the prescription for tinting

In this case, the problem must be solved immediately, since the differential elements are likely to jam, play in the satellite occurs, wear increases, etc. At the same time, noise may occur in the automatic transmission when the gear is engaged, when the driver switches from one operating mode of the automatic transmission to another. Most often, the cause is wear or breakdown of the elements of the gears involved in the ranks of the planetary mechanism.

If the noise changes (becomes louder, the pitch changes) when the automatic transmission selector is switched to R (reverse) mode, this often indicates that there are problems with the thrust bearings (liners).

The nature of transmission breakdowns and their symptoms vary. If the manual transmission is humming, it is too early to sound the alarm - the car is still suitable for use. But if we are talking about an automatic transmission, then the hum here is a very alarming sign. The problem needs to be resolved immediately.

Noise additives in the box

Transmission noise reduction additives can temporarily reduce the noise during operation. However, the cause of the hum will not be eliminated. Therefore, it makes sense to use additives only for preventive purposes or during pre-sale preparation of a car in order to get rid of it as quickly as possible.

Different types of additives are suitable for different problems, so when choosing one it is important to determine exactly what is humming in the box. The most popular attachments for reducing noise in manual transmissions are:

- Liqui Moly Getriebeoil-Additiv . Forms a protective film on the surface of parts due to molybdenum disulfide, and also fills microcracks. It effectively reduces noise in manual transmissions and extends the service life of the transmission.

- RVS Master TR3 and TR5 are designed for optimal heat removal during constant overheating of the unit. Which also helps reduce noise in the box.

- XADO 1Stage . This additive can be used in any transmission - mechanical, automatic and robotic. Contains boron nitride. Removes noise and vibration in the gearbox. Allows you to get to the workshop in the event of a critical loss of oil in the gearbox.

There are similar additives in automatic transmissions. Examples for automatic transmissions include:

- Liqui Moly ATF Additive . Complex additive. Removes noise and vibrations, eliminates shocks when shifting gears, restores rubber and plastic transmission parts. Can be used with ATF Dexron II and ATF Dexron III fluids.

- Tribotechnical composition Suprotek . Can be used with both automatic transmissions and CVTs. The additive is restorative, including removing vibration and noise in automatic transmissions.

- XADO Revitalizant EX120 . This is a revitalizant for the restoration of automatic transmissions and transmission oil. Eliminates shocks when shifting gears, eliminates vibration and noise.

The additive market is constantly being replenished with new compounds to replace old ones. Therefore, the lists in this case are far from complete.

Conclusion

Most often, a manual transmission is noisy because the oil level in it is low, or the oil is of the wrong viscosity or is old. In second place is bearing wear. Less commonly, wear of gears and couplings. As for automatic transmissions, similarly, most often the cause of the hum is low oil level, wear of gears and bearings, and malfunctions of hydraulic system elements. Therefore, the first thing to do when a howling or noise of a different nature appears is to check the oil level, and then look at the situation, under what conditions it occurs, how big the noise is, and so on.

In any case, it is not recommended to operate any transmission that makes a hum or shows other signs of malfunction. In this case, the box will wear out even more and its repair will cost more. The exact cause can only be found out by disassembling and troubleshooting the unit.

Source

A cable that has turned into a “ruff” cannot work normally.

But it's almost a detective story. The owner of the Mitsubishi Pajero asked to diagnose the box. Previously, the clutch was changed at a service center, after which miracles began: release the pedal - a light knock, press a little - the knock is clearer, and squeeze it all the way - silence. The service rejected these complaints, reproaching the owner for buying the clutch on the side: it was his own fault. But is it?

We had to figure out the mystery. At first, the mistake was due to incorrect installation of the box. It is known that to replace the clutch it is moved away or completely removed. The new clutch is centered along the hole in the flywheel using a mandrel: the crankshaft and driven disk must be coaxial, otherwise the splined end of the input shaft may not fit into the splines of the disk hub or, worse, “bite” in them. Then you can only put the box in place with incredible effort, and even by twisting it!

Where the disk is centered with the first mandrel that comes to hand, or even with a rod with electrical tape wound around it, they often manage to bend the input shaft and destroy the bearings. It’s not noticeable on the outside, but it will have an impact later. What kind of accuracy in “hundredths” can we talk about when dealing with electrical tape?! If the repairman has simplified his work, “unexplained” noises in the gearbox are natural. It was with these interesting thoughts that we removed the box from the Pajero. But it turned out to be completely serviceable: the input shaft rotated easily, no play in the bearing, no runout of the shank was found. And the clutch looked like new! Have we witnessed a miracle? And then I accidentally grabbed the driven disk hub.