Shifting gears in a manual transmission should be easy and quiet, regardless of whether the engine is running. In general, the engine is connected to the gearbox through a single unit - the clutch. It is with this that the difference in ease of switching is associated. There is one exception to this rule, which will be mentioned later.

Mechanism of interaction between the engine and the gearbox

The torque created by the car engine is removed and transmitted further from the flywheel. The flywheel is usually installed at the rear end of the crankshaft and is securely attached to it with several bolts. The bolts are equipped with special fixing belts in the threaded areas or are installed on an anaerobic retainer. Problems with fastening are extremely rare and are associated with gross mistakes by inattentive or unscrupulous servicemen.

The flywheel is a massive steel part with a machined end surface during manufacturing, along which the front friction lining of the clutch driven disc operates. When the clutch is engaged, the driven disk itself is tightly pressed to the flywheel by a powerful diaphragm spring of the drive disk. The spring, working surface and drive plate housing form the clutch basket. The basket is attached to the flywheel with several bolts around the perimeter of the casing.

The driven clutch disc is located between the flywheel and the drive disc, sometimes called the pressure disc. It consists of two friction linings, respectively to the flywheel and to the pressure plate, a damping device and a splined hub that slides freely along the splines of the gearbox input shaft.

When you press the pedal through a mechanical or hydraulic drive, the release bearing moves along the input shaft of the gearbox. The basket spring compresses and ceases to exert pressure on the driven disk. Zero force on the disc linings will result in zero friction between the flywheel and the linings. The primary shaft of the box, connected by splines to the disk hub, will stop its rotation. In such a situation, engaging a gear in the box is no different from the situation when the engine is not running.

The exception mentioned above is another connection between the engine and the gearbox. The front end of the input shaft rests on a bearing pressed into the end of the crankshaft. The friction in a working bearing is insignificant, and it is not able to spin the shaft when the working clutch is depressed. If rotation is difficult due to bearing wear, the shaft may continue to rotate, and the gearbox synchronizer will have to overcome the resulting parasitic torque with its internal friction. Shifting into gear will be difficult.

We recommend: How to choose tires for a car?

Difficulty shifting due to clutch fault

A sign of such a malfunction will be easy engagement of the gear when the engine is off and difficulty when trying to engage first or reverse gear with the car stationary with the engine running. Possible causes may be the following malfunctions.

- Incomplete clutch release due to problems with the drive. It is possible that the hydraulics may become airy, the mechanical drive adjustments may be disrupted, or the shape of parts may be distorted, for example, worn rods or a bent release bearing fork.

- Warping of the surfaces of friction pairs in the clutch. Happens when parts overheat. Both clutch discs and the flywheel can take on a wave-like shape. At the same time, it is not possible to completely retract the pressure plate; the clutch, as they say, “leads.”

- Exfoliated fibrous material from the linings got into the gaps between the driven disk and the driving surfaces.

- It is difficult to move the disk hub along the splines of the input shaft; the disk jams and continues to rub against the flywheel, although the force has already been removed from it.

- The clutch basket spring is deformed and the pressure plate operates skewed.

- The driven disk was stuck to the flywheel after the car had been parked for a long time.

Transmission problems

Ultimately, any malfunctions in the box lead to difficulties when switching. But this manifests itself already while the car is moving. That is, again with the engine running.

Most often the problem is caused by a faulty synchronizer. This simple device is designed, due to internal friction, to equalize the relative speeds of rotation of gears that engage in mesh. At the same time, due to the same friction, it wears out itself. It all ends with the fact that without grinding and great effort, it will not be possible to drive the gears into engagement. Treatment is to replace the synchronizer assembly. Together with the clutch and gear of a specific transmission.

There may also be problems with the switching mechanisms. For example, with forks. They rub along the annular grooves of the couplings and, despite the special very hard coating, also wear out over time. The transmissions first begin to fail, and then a complete failure occurs.

There are other causes of transmission strikes, but their occurrence can be delayed by the simple procedure of regular oil changes. You should not blindly believe the factory claims that oil is poured there for life. It may be so, but everyone will still want to extend this life. The oil ages and becomes dirty. By the end of its life, the cloudy slurry drained from there can hardly be called oil.

We recommend: Is it possible to flush the cooling system with Coca-Cola or citric acid?

Automatic boxes

As strange as it may sound, theoretically there are no fundamental differences between automatic transmission and manual transmission. Everywhere there are friction pairs (clutches or sets of wet discs), gear transmissions and an oil bath. Therefore, the diseases are the same, as are the measures for repair and prevention. There is no need to allow power slipping during sudden starts, skip oil changes and overheat the mechanisms. It’s just that this is even more relevant for automatic transmissions. The mechanisms here are more delicate, the oil requirements are high, and the cost of repairs is many times higher.

The situation is aggravated by the presence of complex hydraulic automation. Gear shifting here is controlled by a set of valves, which are vitally important to work with clean oil. What a manual transmission can tolerate, an automatic transmission will not tolerate. And instead of a clutch, a torque converter works here, which generates a lot of heat. The properties of the oil deteriorate sharply when heated. The presence of oil radiators does not always help. And to reassemble the box you will need a highly paid specialist with the required qualifications.

Problems with switching to automatic transmission

Shifting problems with automatic transmissions are not uncommon. Problems with the automatic machine arise for several reasons.

- backstage malfunction . This mechanism is the most problematic in old-type automatic transmissions. To eliminate the malfunction, the unit will need to be replaced. In most cases, it will be necessary to dismantle the gearbox for these purposes;

- insufficient oil level . The presence of lubricant leaks on the automatic transmission housing may indicate wear of the sealing gaskets, which are not difficult to replace yourself. After this, you need to change the oil in the box. Also, owners of cars with an automatic transmission are recommended to visually inspect the gearbox for oil leaks at least once every 2000 km;

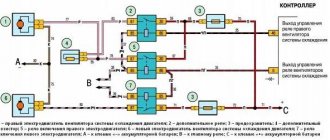

- problems with the transmission control unit can ultimately cause the automatic transmission to completely lock up. To fix the problem, you will need to replace the failed mechanism and thoroughly inspect the electrical part of the gearbox.

Important! To solve problems with automatic transmission, it is recommended to conduct computer diagnostics of transmission faults.

Insufficient lubrication

Despite the fact that if there is a lack of lubrication in a manual transmission, the gears are still engaged, shifting them can be quite difficult, since the gears cannot fully engage with each other. In addition, insufficient lubrication can even damage synchronizers over time.

Therefore, if you hear an unpleasant metallic grinding noise when changing gears, check the oil level in the manual transmission and inspect it for leaks. If any are present, replace all gaskets and seals. It would not be a bad idea to also change the oil seals located in the shank and on the input shaft.

Manual transmission: What you need to know when shifting gears

The result is premature wear of the clutch disc. In order to keep the car from rolling on an incline, you need to depress the brake pedal. In order to start, of course, you will have to press the clutch and smoothly press the gas, releasing the clutch. In this case, you will reduce the load time on the clutch basket and release bearing. You can also hold the car by maintaining certain engine speeds, catching a certain moment when you release the clutch and press the gas.

We recommend: How to make a heated steering wheel with your own hands?

Surprised? But in fact, this advice is really very important, because having a habit of leaving your hand on the gear shift knob can lead to premature transmission failure. If you most often leave your hand on the gearbox when stopped in a traffic jam or at a traffic light, then the first gear of the manual transmission suffers the most. Remember that by placing your hand on the gearshift knob, you create extra pressure on it, which is transferred to the gearbox. As a result, excess pressure on the handle can lead to unfree shifting of the desired gear. This can damage the gear shift knob as well as the transmission itself.

Main problems and their solutions

If the previous checking methods did not yield anything and the malfunction that caused problems with shifting gears on the manual transmission is not determined, then you need to inspect the condition in which the clutch basket is located. The main impetus for this should be the fact that the gears stop shifting when the engine is running.

First of all, inspect:

• Release bearing – When in normal condition, its movement along the input shaft should not be hindered in any way. If it starts to jam in some places and it moves along them with difficulty, then this is the reason. However, do not worry, as it can be solved by simply replacing the problematic part.

• Disc wear – To determine how badly it has worn, disassemble the basket and visually assess its condition. There should be no carbon deposits on the friction linings, and the rivets under the disc should not be visible. If one of these problems is present, the disk will need to be replaced. Most likely, after this procedure the problem with switching gears will be solved.

• Malfunction of the basket itself – During long-term use of the car, the so-called “petals” that make up the basket wear out greatly, as a result of which they become very susceptible to high temperatures and can no longer cope with the removal of the pressure disk. Often, to determine the condition in which the petals are located, a simple visual inspection is sufficient - its petals will be deformed or show signs of overheating. In this case, the basket will have to be replaced.

• Hydraulic booster – If there is not enough fluid in the system or there is air in it, the gears on the manual transmission may periodically not turn on. To diagnose, inspect the reservoir and inspect all drive components, including hoses, tubes and release cylinder. All identified areas with leaks will need to be repaired and the system pumped.

For what reasons do interruptions occur?

There can be many reasons why gears do not shift when the engine is running. However, all of them, in one way or another, are connected with the two most important units of the car - the engine or gearbox. In case of serious damage, you should contact a good car service.

If the problem is in the gearbox, it will need to be removed for further disassembly and troubleshooting. If the problem is with engine components, they may need to be replaced. However, there are cases when, to eliminate a malfunction, it is enough to carry out preventive maintenance: removal, lubrication and careful adjustment of the components.

About the clutch and its drive

Many people often confuse faults between the gearbox and attachments. By this term I mean the clutch and its drive (in one case it is hydraulic, in the other it is mechanical). As usual, they are located outside the mechanical box, but directly affect its operation.

The clutch itself consists of a disc and a basket. Over time, the disc wears out, or rather its friction linings wear out and it can slip and simply not stop. THIS leads to poor gear shifting and slipping (when the engine growls but the car does not develop power).

If the basket is damaged, it has special “petals” that are affected by the release bearing, then as a rule they break and you simply cannot engage the gear! None at all.

If the clutch pedal has become “light”, not the same as it was before, and again there is no engagement, then this may be a problem with the drive. Either the cable broke or liquid leaked out (in the case of a classic VAZ).

Therefore, if no “speed” is activated at all, or there is slipping (no speed development), then most likely you need to look at the clutch, its drive or basket.

However, this is a problem with the attachments, now let’s go over the main faults and how to fix them, I’ll post a table.

Why is it difficult for the gear lever to shift on a manual transmission?

- After the desired shift has occurred, you need to release the clutch pedal, there is no need to hold it! Because there is increased wear on the clutch disc

- It is advisable to move in the gear that corresponds to a given speed, this relieves both the engine and the gearbox from unnecessary loads, the best is 4th gear, also called “direct”, in this connection the minimum number of gears and all two shafts are occupied (in bypassing the intermediate). This reduces wear on the manual transmission

- A lower gear should be engaged when the speed decreases, just like an upshift when accelerating.

The main causes of malfunctions Mechanics, like automatic ones, are designed to transmit and change torque from the power unit to the wheels, and this must be done comfortably and dynamically. That is, the car must accelerate as quickly as possible and do this without any “jerks” of prohibitive engine speeds (so that it does not “growl like a victim”) and, if possible, have sufficient traction forces.

Why haven't they abandoned manual transmissions yet?

Now, probably, many newcomers thought - “oh yes, “mechanics”, but who needs it, but now everyone drives an automatic transmission, and in general its days are numbered.” This is not entirely true, because this option has a lot of fans and real advantages, I won’t list them all, after all, we already thought - which is better than an automatic transmission or a manual transmission , but I will list some of the most significant ones:

- Price. As a rule, this option is 40 - 80,000 rubles cheaper than its automatic counterpart

- Fuel consumption, no automatic option has yet come close to it (but already quite a bit)

- Strength

- Simplicity of design

- Withstands heavy loads (accepts large torques )

- Temperature (difficult to overheat)

That is why this option is now used on many trucks, heavy SUVs, and many passenger cars. In general, it is premature to write off this unit, and now a version is being developed without a clutch pedal, that is, something like a semi-automatic transmission is switched manually, but there are no pedals.

The smell of burning

Take a sniff. You may smell burning oil and feel heat coming from the gearbox (this is especially noticeable with a longitudinal engine, when the gearbox is directly under the gear selector). A burning smell indicates that your transmission is overheating due to excessive load or a critical drop in the oil level in the unit. Don't forget that oil not only reduces friction losses, but also removes excess heat from the gears. Be that as it may, this malfunction indicates the need for an urgent inspection of the level and quality of the oil, as well as its subsequent topping up or replacement. A low level of lubrication quickly damages the bearings and gears of the gearbox, after which it becomes beyond repair.

Troubleshooting gearbox

Possible gearbox malfunctions, their causes and solutions

Troubleshooting the gearbox is carried out by removing it from the car, disassembling it, and troubleshooting parts if it is found that some of them are badly worn

Particular attention should be paid to the condition of the sliders and clamps. If burrs are noticed on the sliders, they must be removed with a file.

You also need to check the condition of the springs and retainer balls. The springs must be intact, and the latch must move without problems in its seat. If necessary, worn or damaged elements must be replaced.

You should also carefully inspect the power forks for bending. Even a slight bend can affect the ease of gear engagement.

After assembly, gear shift adjustment must also be performed. To be precise, the position of the scenes is set.

Noise in neutral

Start the engine and listen. You may notice a strange noise that changes in character when you depress the clutch. Did you notice? The noise may come from excessively worn input shaft bearings. This may also indicate a low oil level or the wrong type, or severe wear on the release bearing. A malfunction of the latter can be detected by pressing the clutch pedal all the way. When the bearing is worn out, you will hear a strong rustling or humming sound. When you release the pedal, the noise becomes muted again.

Manual transmission malfunctions: why did the gear start to slip out?

Most often, in order to get to the repair site, you can simply not use this gear. With modern multi-stage gearboxes, the gap between the stages is not very large, which makes it possible to freely dispense with one gear. And the wide dynamic range of a modern injection engine makes it possible to use crankshaft speeds from 1200 to 5500 rpm. You can get to the garage, but the defect must be eliminated.

Reasons for knocking out a gear

Wear of power unit supports.

The power unit swings much more than it should, and instead of the driver turning gears on and off, the jumping gearbox does it itself. More often, gearboxes with rigid rod control drives react to such a defect.

With such a defect, it sometimes knocks out paired gears, for example the second and fourth, since the direction of turning on (and off) these gears is the same. Although this does not always happen: some gears are worn more, others less, and, accordingly, the possibilities of keeping the gear engaged are different. Plus, dynamic jerks in second, for example, gear are much stronger than in fourth.

The treatment is simple. It is necessary to replace the power unit mounts - and quickly, because it is not only the gearbox that is suffering. Due to the increased mobility of the unit, tubes, hoses, cables, and wiring harnesses that connect the power unit with the rest of the car components are bent and may break, and believe me, there are a lot of them.

The drive mechanism is worn out.

A severely misaligned or worn drive does not allow the gear to be fully engaged. And if it is not fully turned on, it will pop out at the first opportunity. The transmission is more prone to knocking out when driving without a load (coasting): when the engine spins the wheels, the engagement of the clutch teeth is much “stronger” than when the engine is braking. Or as people say: “Try to pull out the gear under the gas or when releasing the gas - and you’ll understand everything.”

Clutch.

But the clutch has practically no effect on knocking out gears. But if the clutch is not depressed enough, it makes it difficult to engage the gear completely. However, such a defect cannot be called gear knockout.

Internal gearbox defects

The cause of wear on the teeth on the couplings may be a malfunction of the clutch mechanism or its drive, when the engine flywheel is not disconnected from the gearbox input shaft. Naturally, this knocks out the gear whose parts have damaged teeth. Most often, a gear will be knocked out in such a situation during sharp acceleration in this gear or intensive engine braking.

A possible reason for the gear being knocked out could also be weakening of the synchronizer springs. This cause can only be accurately diagnosed after completely disassembling the gearbox.

The gear can also be knocked out due to large axial play of the shafts, when the forks simply do not “press” the clutches to the full engagement position. Hence the next reason: wear of the forks, leading to the gears not being engaged. It can also knock out a gear due to severe wear of the gear selection mechanism.

conclusions

If a defect such as gear knockout occurs, you should immediately divide the causes into external ones, which you can try to diagnose and eliminate on your own, and internal causes. The latter require dismantling and qualified disassembly and troubleshooting of the gearbox. Therefore, I would advise you to contact a service whose specialists have already gotten their hands on repairing these cars, or a specialized company for repairing gearboxes.

Of course, some car enthusiasts drive holding the shifting gear with their hand, but this is not the case at all. There is no point in delaying repairs, because one day the transmission may not turn on at all, and that’s not so bad. It can also jam, and as a result, the car will have to make its way to the service station on a tow truck.

Source

Clutch assembly

If in order to detect a problem with gear shifting you had to disassemble the clutch, be extremely careful when reassembling it. Tighten all threaded connections with extreme care. And be sure to center the clutch before installing the manual transmission. For this purpose, you can use either a special tool or the input shaft, which will have to be removed from the old gearbox.

WE RECOMMEND ALSO READ:

So, a little background... Approaching a toll booth on the highway, having switched to neutral while braking, I heard a not loud, but immediately disliked sound, as if “something had fallen off”

, perhaps some kind of bolt, I thought.

Having paid the fare, turning on 1st gear, I continued driving... but I couldn’t turn on 2nd. Just like everyone else, actually. The shift lever literally dangled from side to side. I didn’t hear the terrible roar of the manual transmission falling apart, the clutch was working... In general, I found a solution to the problem later, in an elementary way... I’ll get ahead of myself and say that some time ago, before this incident, the lever began to “play” a lot horizontally

.

Algorithm for mechanical-magic restoration of manual transmission: First, I twisted the left wheel to the left all the way (for convenience). Next, having glanced at the box and having confirmed that there was no bolt securing the cable rocker (manual transmission lever) to the shift shaft, I headed to the nearest store, where one good person advised me to buy two

bolt. One for 6, the other for 8. In the end, an M8 fit... although on emex, in the catalog of our car, an M6 screw is shown (which specifically did not suit me). I screwed it into place and was glad not only that I could continue driving the car, but also that the play in the handle had disappeared.

Bottom line, comrades, those who are not aware of this, but have symptoms (backlash, for example), do not be lazy

look there and tighten this screw, it's not hard.

I didn’t know this, I missed it, and it just got out of the way along the way and made me nervous... Good luck to everyone!

Oil stains

Oil leaks on the gearbox housing or under the bottom of the car require an immediate solution to the problem. Oil can ooze through damaged gear selector rod seals, wheel drive boots, or due to mechanical damage to the unit housing. If a manual transmission loses oil, it overheats and quickly fails, and the automatic transmission stops working altogether. It is difficult to confuse torque converter fluid with other oils used in a car - it has a reddish tint, a pungent odor and a sweetish taste. Unlike the engine, the transmission should not lose oil over time - it does not burn out and does not go anywhere if the unit is in good condition. Checking the oil level is sometimes difficult - there is usually no special dipstick for this; control and addition of fluid is carried out through the filler plug on the housing.

3rd 4th gear of manual transmission Megan 2 does not engage

Communities DRIVE2 Audi 80 Club Blog Gears are difficult to engage.

Clutch I have almost the same problem. Mileage 118000 km. Yesterday I went to Rai-Auto to have the rocker adjusted. It turns out that under the gearshift lever there is a plas, a kind of fist, and so over time it also becomes loose and play appears, as a result of which the gears may also not engage. Although the rest of the gear shift mechanism is new and set to the factory marks, the problem mentioned above still existed because of this “ball”. After additional adjustments, as my two-day test drive showed, all gears fit perfectly, only the lever is now slightly shifted to the right, at first it was a little unusual. Those.

For those with automatic

If your car has an automatic transmission. It will not hurt you to know the modes in which your machine can operate:

- P – For parking and starting the engine. Switching to this mode is possible only after the machine has completely stopped.

- R – To move backwards. Switching to this mode is also possible only after stopping the car and with the brake pedal pressed.

- N – Neutral. When the engine is completely disconnected from the gearbox.

- D – Moving forward without restrictions on gear shifting (the most commonly used operating mode of the automatic transmission).

- D3(S) – Low gears for climbing and braking engines on descents.

- D2 – Mode for difficult conditions (slippery or mountainous roads). Gears above second are not shifted, that is, only first and second gears are engaged.

- D1(L) - Movement occurs only in 1st gear, used off-road on mud, snow or ice, where you need to drive without changing the throttle, and also to overcome steep climbs.

The automatic transmission also has a button on the mode shift lever with the inscription O/D OFF. When it is turned on, the inclusion is prohibited, increasing the gears of the analogue of the 5th gear of the manual transmission. That is, if your automatic machine has 4 gears for moving forward, then for more dynamic acceleration it will use only three lower gears.

About a faulty automatic transmission, an automatic transmission is much more complex than those encountered with a manual transmission, and the chances of repairing it in your garage are slim. But despite this, you still need to know something about it, if only in order not to harm it through improper use.

An automatic transmission is much more demanding in terms of accuracy in maintaining the oil level in it than a manual transmission. Both too low and too high oil levels are very harmful to her. Both of these can lead to serious damage. In both cases, oil foaming occurs. When there is a lack of oil due to the fact that the oil pump begins to capture air along with the oil. When there is excess oil, it foams on the rotating parts, which in this case are immersed in it. Foamed oil compresses better and has low thermal conductivity. Therefore, if you operate a machine with such oil, the pressure in its control systems will be low. Which will lead to slipping of the clutches and their intensive wear. Deteriorated thermal conductivity will not allow all excess heat to be removed. Which, together with low pressure, will lead to the machine failing and requiring serious repairs.