Wind blower

Wind blower

More speed means better cooling, but this is only partly true.

As acceleration proceeds, all other things being equal, the engine power and the amount of heat “dumped” into the cooling system grow almost by the cube of the speed, and the wind pressure only by the square. It happens that at the optimal 90–100 km/h there is enough cooling even with a dirty radiator, and at maximum speed the electric fan does not turn off. One step away from overheating - it’s better to let off the gas. Of course, there are heavier driving modes - also associated with the release of high power, but at low speeds, when the oncoming flow is weak or absent (with a tailwind). Driving in first gear in deep sand, on a steep climb of a mountain road, or towing another car through the mud, you cannot do without forced airflow of the radiator! His refusal is like a death sentence for the engine. There are two types of fan drives - mechanical (usually V-belt drive) and electric. In the first, the speed of the impeller and the engine are strictly connected. At low speeds and heavy loads this is dangerous: the airflow is weak. In other modes, the fan, constantly rotating, unnecessarily consumes engine power and fuel, and after starting in cold weather, it slows down the warming up of the engine. The drive with a viscous coupling is more “conscious” - it monitors the temperature of the coolant in the radiator. UAZ-Patriot received such a system.

An electric fan is more economical: it works only when necessary, and its power is several times less than the power of a mechanical fan cranked up to maximum speed. But at low engine speeds and high loads, a mechanical “wind blower” is inferior to an electric one; the latter is more efficient. At high loads and engine speeds, an electric fan is usually inferior to a mechanical one - at high speeds the latter has a higher air flow. The choice of type is a matter for the designer. Today, electric fans predominate in passenger cars.

There seems to be nothing wrong with a mechanical fan. Unless some people managed to break off the blades or the belt broke due to oversight. The latter was replaced with anything on the road! And how could it be otherwise, if on some cars it also drives the cooling system pump. Electric fan failures vary widely.

Often it does not work due to a failure of the temperature sensor, the vagaries of which (especially on carburetor cars with a sensor in the radiator) we have talked about more than once. Causes? This, for example, is the burning of the sensor contacts in traffic jams, when it becomes unusable by repeatedly turning on and off. The sensor in the head of the block works more stable, as is done on most injection cars. There are, however, exceptions, such as fuel-injected GAZ cars with a traditional sensor in the radiator.

Some craftsmen, not trusting the sensor, install an additional switch to turn on the fan in an emergency if necessary. Our attitude towards the idea is ambiguous. How do you know when it's time to turn it on? God forbid if the temperature sensor really lies or you are forgetful. In the author's opinion, the standard system is more attractive - there is a reason to maintain it in good condition, and not to fence the garden.

Note that the cooling system fan can cause problems that you wouldn’t expect! A wonderful lesson was taught to us by the Chevrolet Niva, which has two electric fans - beautiful plastic impellers with bandages along the outer diameter, rotating for greater efficiency in plastic rings-casings! Everything is “according to science” - the most advanced, they did not take into account only a trivial circumstance: the plastic does not withstand the temperature of the air leaving the radiator. Apparently, they selected it, caring only about the low price! One day, having warmed up well, the impellers lost their rigidity, the bandage rings began to touch the casings and melt at the points of contact. The driver didn't notice this. And the next day the fans turned out to be jammed - the day before, after turning off the engine, they were welded to the casings. Is it a good story? How can one not remember the “good old” metal casings!

A long-known circuit for switching on an electric fan (carburetor VAZ-2104, 2105...2107, “Oka”, “Oda”, etc.). Electric fan 1 is started by a command from relay 3, controlled by a signal from temperature sensor 2, usually located in the radiator. The safety of the system is entrusted to fuse 4. The temperature threshold for turning on the fan is about 100°C or slightly lower. The corresponding numbers are on the sensor body - for example, for Zhiguli 87–92°C.

Fan control, typical of many fuel-injected cars. Electric fan 1 is switched on via relay 3 based on a signal from temperature sensor 2. The latter is located in the engine. Upon reaching the response temperature, contact 85 of the relay through contact 68 of controller 5 closes to ground. The threshold for turning on the fan on these machines can be above 100°C. For example, on a VAZ-2110 it is about 104°C. The decision is made by the ECM by analyzing the temperature sensor signal.

When plastic “decorations” on Russian cars warp even under the rays of the morning moon, it’s not so bad. But often plastics of unsuitable quality are used in critical components - and this is already a disaster. Here is an example: the design “led” - the impellers began to touch the fixed rings of the housing, in these places the plastic was heated until it melted, and after the motor stopped, the impellers were welded to the housing. By the way, at the top between them is that same additional resistor, but how much use is there in a smart system if it was made by defectors?

This is what the brush units of electric motors (Chevrolet Niva) look like. Four brushes contribute to obtaining sufficiently high motor power and increased impeller rotation speed. At the same time, the design is very compact. Unlike plastic casings, the electric motor is made to last. Failure is unlikely, as confirmed by the experience of the owners.

Fan motor rotor. Pay attention to the collector. Dark marks on the lamellas were left by too much current when trying to turn on the “cooked” fan. Fortunately, there were no more serious consequences - both electric motors even remained operational and, after replacing the melted fan parts, they serve us again.

Additional resistor. This is a serious product; we are not aware of any failures yet. At the same time, it is unlikely that anyone will rewind such a resistor: it is better to replace a damaged one. In addition to the Chevrolet Niva, it is designed for use in Kalina, and is sometimes found on the injection Niva VAZ-21214.

Serial connection of fans.

Let's look at the diagram Connecting Niva fans in a serial connection. To connect the fans in series we need an additional relay. A universal five-pin relay of type 98.3777 is suitable, which is best placed next to the fans. Terminals 85 and 86 of this relay are the terminals of the electromagnet coil. Pin 30 is a moving contact, and pins 87 and 87A are fixed contacts. From the chip connected to one of the fans, we remove the negative wire; it is usually black. We connect this wire to pin 87A of the relay, and connect the free space with a wire to pin 30. Pin 87 is connected to the positive wire of the second fan. Now, when the relay is closed, the fans will be connected in series, and when disabled, in parallel. From the socket of the standard fan switching relay, above which the switching was carried out, we remove the wire from the electromagnet coil coming from the engine control unit or switching sensor and connect it to pin 85 of the added relay. Pin 86 is connected to the ground of the car. The freed output of the standard relay must be connected to an additional power sensor or key.

On carburetor cars, you can use two switching sensors with different response temperatures. For example, for low speeds with a switching temperature of 78 - 82, and for full speeds 90 - 95. You can install an additional sensor in the upper pipe. For injection engines it is somewhat simpler; if there is space on the radiator, then place the sensor there. If there is no space, you can make an insert into the upper pipe and place it there.

Design and principle of operation

The designers of the Chevrolet Niva used a dual fan unit in the cooling system. This slightly complicated the connection diagram, but sharply increased the efficiency of radiator airflow. The fans are driven by 12-volt DC synchronous motors with a permanent magnet inductor. Electric motors have a closed, non-demountable design and do not require maintenance.

The power of each electric motor is 110 W. The fan assembly draws 18 amps.

The fans are turned on one by one using an electromagnetic relay controlled by the on-board computer. When the coolant heats up above 99 degrees, the electric fan located closer to the engine air intake starts. The switch-on temperature of the second impeller is 101 degrees. The fan connection diagram is shown below.

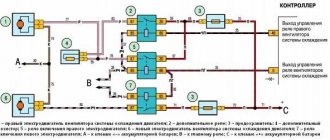

The fan power system includes three relays and a resistor, which, if necessary, provides a reduced rotation speed of the first motor. Power is supplied from the battery through fuses that save the wiring and battery in the event of a short circuit. Control signals come from pins 29 and 68 of the motor controller.

The fans automatically turn off when the antifreeze cools to 95 degrees.

Consecutive switching on and off of engines reduces the load on the on-board electrical network. In most cases, it is possible to normalize the temperature only with the help of the first fan. This is especially useful when driving at night, when headlights and side lights put a lot of stress on the generator.

The ability to force fans on can be useful when driving off-road or in city traffic jams. However, the designers of the Chevrolet Niva did not provide the car with this function. It can be implemented independently or at a service station. It is necessary to connect backup relays parallel to the switching contacts and power them from a button installed in the car interior.

Useful video about installing and connecting the forced fan button on the Shnivy:

Important: forced activation increases the reliability of the cooling system. In case of malfunctions of sensors, relays or on-board computer, the driver can manually turn on the radiator airflow.

It is useful to equip the Chevrolet Niva with a switch that forcibly turns off the fan motors. This will protect their blades when fording water obstacles.

Methods for connecting fans.

There are two ways to reduce fan motor speed. The first is to connect an additional resistance of sufficient power in series with each fan motor. The second way is to connect Niva fans in series. The disadvantage in the first case is the search for resistance, which will also heat up. In the second case, a minimum of alterations are required. It is enough to pull out the negative wire from the connector of the first fan, and the positive wire from the second connector. After this, connect the free terminals on the motors with a wire of the appropriate cross-section. But in this case, in order to turn on the fans at high speeds, you will need to redo everything back.

If you want the fans to be able to operate at low and high speeds depending on the heating of the engine, then you will need to install an additional relay that will switch the fans from serial to parallel connection. This relay can be controlled manually or automatically. You can also combine both control methods. The design of the Niva fan connection diagram can be different, depending on the type of engine and your preferences.

When switching manually, you need to install a switch; a key is best suited, and for automatic control, an additional switching sensor with a response temperature lower than the main one.

Circuit breakers

The electrical circuits of Niva Chevrolet cars produced before and after 2009 are different. In both cases, 50-amp fuses protecting the electric fan power circuits are located in an additional unit. It is located behind the glove box on the passenger side of the cabin. The figure shows where the fan fuses are located.

If the permissible current is exceeded, the insert melts and the circuit opens. Therefore, fuses are the first thing to check if the electric cooling fan does not work. The performance of a part can be assessed visually or using an ohmmeter (multimeter). To do this, you will first have to remove the fuse from the socket.

Tips for motorists

The favorable thermal regime of the Chevrolet Niva SUV engine is supported by a cooling system, in which two serviceable fans play a significant role, providing the required air flow through the radiator core. If the fans fail, the cooling system cannot cope with removing excess heat from the engine, and it begins to overheat. Due to the fact that the number of fans on the Chevrolet Niva has been doubled, the electrical circuit for turning them on has become more complex than on conventional passenger cars.

Fan relay

The additional block contains not only fuses. There are also three electromagnetic relays that control the operation of the electric motors of the cooling system. Their control circuits are powered from the ignition switch and on-board controller outputs, and the power current comes from the battery through fuses.

The relay operates as follows:

- Voltage is applied to the control terminals.

- Current passes through the inductor, resulting in an electromagnetic field.

- The steel contacts attract and close.

- The current passing through the relay drives the electric motor.

As soon as the control voltage disappears, the contacts open under the influence of the spring and the fan stops.

You can check the functionality of the relay in three ways:

- Replace the relay with a known working one and test the operation of the system.

- With the engine off and the ignition on, disconnect the temperature sensor connector. You should hear the relay click.

- Dismantle and test the output contacts with a multimeter, applying voltage to the terminals of the induction coil.

Checking and removing fans

To understand whether they work or not, you need to disconnect the connector from their motors, and connect a lamp to the wires through which voltage is supplied; we do the same with the sensor; if both lamps light up, then the problem is in the fans.

To remove them you need to do the following:

- Disconnect all wires

- Removing the upper pipe

- Removing the bumper

- If there is an air conditioner, bend the tubes (this must be done carefully, as they may burst) or drain the freon (filling it back will not be cheap), then remove the air conditioner radiator.

- You need to loosen the nuts on the radiator casing

- Tilt the radiator so that you can remove the fan unit

- Unscrew the bolts that secure the block and remove it

After removal, it is recommended to immediately replace both with new ones, since there is a possibility that a little time will pass and the second element will fail and all replacement work will need to be done again. You can do this procedure from below, but you will need special equipment, and you will need to move the engine ten centimeters back, which is very labor-intensive.

Power sensor

The control unit receives information about the antifreeze temperature from a temperature sensor. It is a resistor whose resistance changes with heating and cooling: from 1.3-1.8 kOhm at 30℃ to 155-196 Ohm at 90℃. You can check its performance using an ohmmeter and a thermometer. To do this, you need to remove the part, immerse it in water and measure the resistance at different temperatures.

The sensor is located on the engine head in the area of the exhaust pipe of the cooling system. You can unscrew it with a socket or socket wrench.

We recommend watching a video that shows where the sensor is located and how to check:

Airlock

Engine overheating on VAZ 21213 and 21214 is often possible due to an air lock in the cooling system. An air lock usually forms after replacing one of the system elements. Air enters the circuit and remains there. He is unable to go outside. An air lock disrupts the operation of the cooling system, causing the Niva engine to overheat.

To remove an air lock on a Chevy Niva, when refilling antifreeze, you need to remove one of the hoses from the throttle valve and fill in coolant until coolant flows out of it. Then quickly put on the hose and secure the clamp. After this, the air should leave the system.

Possible malfunctions and their causes

1.Both fans do not work. The electric motors may fail, the temperature sensor may malfunction, or the power wires coming from the battery or ignition switch may be broken.

2. The second fan does not work. Causes: sensor malfunction, fuse or electromagnetic relay failure. It is also possible that the power cable may be broken.

3. The left fan does not turn on. Causes: faulty power resistor or temperature sensor, blown fuse or relay. It is also possible that the power cable may be broken.

4. Only two fans turn on at a time. This happens when an additional resistor in the circuit of the first electric motor breaks.

5. The fan does not turn off. Typically, the fan runs constantly when the relay is broken or the coolant temperature sensor is faulty.

Repair of fans, sensor, relays, fuses and additional resistor is not provided. If these parts break, they should be replaced with new ones.

Replacing fans

If the fan motors do not start when the wires from the battery are connected directly to the power terminals, the devices must be replaced.

To do this, you will need a set of wrenches ranging in size from 10 to 17 mm and a Phillips screwdriver.

Before starting work, you need to drive the car onto an inspection ditch or a lift and turn off the power to the on-board network by removing the negative terminal of the battery.

Fans are dismantled as follows:

- Remove the crankcase protection and mud guard.

- Unscrew the screws and remove the thick spider-shaped plate and a couple of tin covers that are located in front under the bottom of the car.

- Unscrew the radiator frame cross member.

- Loosen the tension and remove the power steering belt and pump.

- Remove the 4 bolts holding the power steering pump.

Useful video showing how to remove and change fans:

Important: to get to the bolt covered by the oil filter, you need to move the amplifier away from the bracket.

- Push the pump back, hanging it on the hoses.

- Remove the air conditioner drive belt.

- Remove the bolt holding the timing belt pulley.

- Remove the pulley and belt.

- Unscrew the four nuts at the corners of the electric fan housing and the two bolts securing it in the middle.

- Remove the fan unit from the studs and pull it down.

Tip: The crankshaft position sensor makes it difficult to remove the fans. Therefore, they need to be pulled out gradually. The left side is lowered first, then the block is moved to the left, raising the right edge so that the casing becomes vertical.

This method is probably suitable for restyled Niva Chevrolet models. On older cars, you will have to remove the radiator grille and bumper, unscrew the fasteners and move the air conditioning and cooling radiators forward. After this, access to the electric fans will be open.

During dismantling, you should carefully remember the procedure. Assembly is carried out in reverse order.

Important: the service life of the fan motors is approximately the same. Therefore, even if one of them fails, both must be replaced. Otherwise, you will soon have to repair the car again.

Removing and replacing the fan resistor

Before starting work, you must go to the inspection hole and remove the terminal from the battery. For repairs you will need 10-13 wrenches, a screwdriver and a new resistor. The part is installed in the beam below the radiator. The removal procedure is as follows:

- Unscrew the fastening bolts and remove the crankcase protection along with the mudguard.

- Remove the protective strip of the resistor and unscrew the part.

Assembly is performed in reverse order.

How do fans work on a Chevrolet Niva?

How should fans work on a Chevrolet Niva?

Because You are not logged in. To come in.

Because you are not a trust user. How to become a trustee.

Because The topic is archived.

Because You are not logged in. To come in.

Because you are not a trusted user (phone number is not verified). Enter and confirm your phone number. Read more about trusts.

Because The topic is archived.

Because You are not logged in. To come in.

Because you are not a trusted user (phone number is not verified). Enter and confirm your phone number. Read more about trusts.

Because The topic is archived.

Because You are not logged in. To come in.

Because you are not a trusted user (phone number is not verified). Enter and confirm your phone number. Read more about trusts.

Because The topic is archived.

Because You are not logged in. To come in.

Because you are not a trusted user (phone number is not verified). Enter and confirm your phone number. Read more about trusts.

Because The topic is archived.

Because You are not logged in. To come in.

Because you are not a trusted user (phone number is not verified). Enter and confirm your phone number. Read more about trusts.

Because The topic is archived.

Because You are not logged in. To come in.

Because you are not a trusted user (phone number is not verified). Enter and confirm your phone number. Read more about trusts.

Because The topic is archived.

Because You are not logged in. To come in.

Because you are not a trusted user (phone number is not verified). Enter and confirm your phone number. Read more about trusts.

Because The topic is archived.

Because You are not logged in. To come in.

Because you are not a trusted user (phone number is not verified). Enter and confirm your phone number. Read more about trusts.

Because The topic is archived.

Because You are not logged in. To come in.

Because you are not a trusted user (phone number is not verified). Enter and confirm your phone number. Read more about trusts.

Because The topic is archived.

Because You are not logged in. To come in.

Because you are not a trusted user (phone number is not verified). Enter and confirm your phone number. Read more about trusts.

Because The topic is archived.

Because You are not logged in. To come in.

Because you are not a trusted user (phone number is not verified). Enter and confirm your phone number. Read more about trusts.

Because The topic is archived.

Because You are not logged in. To come in.

Because you are not a trusted user (phone number is not verified). Enter and confirm your phone number. Read more about trusts.

Because The topic is archived.

Because You are not logged in. To come in.

Because you are not a trusted user (phone number is not verified). Enter and confirm your phone number. Read more about trusts.

Because The topic is archived.

Because You are not logged in. To come in.

Because you are not a trusted user (phone number is not verified). Enter and confirm your phone number. Read more about trusts.

Because The topic is archived.

Because You are not logged in. To come in.

Because you are not a trusted user (phone number is not verified). Enter and confirm your phone number. Read more about trusts.

Because The topic is archived.

Because You are not logged in. To come in.

Because you are not a trusted user (phone number is not verified). Enter and confirm your phone number. Read more about trusts.

Because The topic is archived.

Because You are not logged in. To come in.

Because you are not a trusted user (phone number is not verified). Enter and confirm your phone number. Read more about trusts.

Because The topic is archived.

Because You are not logged in. To come in.

Because you are not a trusted user (phone number is not verified). Enter and confirm your phone number. Read more about trusts.

Because The topic is archived.

Because You are not logged in. To come in.

Because you are not a trusted user (phone number is not verified). Enter and confirm your phone number. Read more about trusts.

Because The topic is archived.

Because You are not logged in. To come in.

Because you are not a trusted user (phone number is not verified). Enter and confirm your phone number. Read more about trusts.

Because The topic is archived.

Because You are not logged in. To come in.

Because you are not a trusted user (phone number is not verified). Enter and confirm your phone number. Read more about trusts.

Because The topic is archived.

Because You are not logged in. To come in.

Because you are not a trusted user (phone number is not verified). Enter and confirm your phone number. Read more about trusts.

Because The topic is archived.

Because You are not logged in. To come in.

Because you are not a trusted user (phone number is not verified). Enter and confirm your phone number. Read more about trusts.

What to do if the engine on the Niva gets hot?

If the engine begins to overheat while driving, it is recommended to do the following:

- Accelerate to the permitted speed.

- In a higher gear, release the gas pedal.

- While the car is rolling, the engine should cool slightly.

- Leave the car and turn off the engine.

The point is that with this movement the pump rotates without load, which means the engine will cool down. But this is provided that the thermostat is open, and the pump has an impeller and it is intact.

Advertisements on NN.RU - Auto

A wide selection of hydraulic pumps and hydraulic motors of all series: spline hydraulic pump of right rotation. It is used in road construction and... Price: 1,000 rub.

Extend the chassis (frame) on Gazelle Next, Gazelle farmer under a body of 4.2 m, 5.1 m and 6.2 m. Extend the frame on Gazelle Next, Gazelle Gas 3302. Price: 25,000 rubles.

Lengthen Kamaz under a body 7.5 m Lengthen Maz Zubrenok, Maz under a body 9 m Re-equipment of the chassis of an extended truck.

Manufacturing of a broken-type platform with retractable ramps on the GAZ-33023 Gazelle-farmer chassis. Technical characteristics of the tow truck.

Cooling fans do not work on Niva Chevrolet

In the cold season, such a malfunction can be noticed when moving at low speed and stopping frequently. In summer it will appear much faster. For the engines of this car, the use of two fans in the cooling system is provided, since the car was originally designed for driving in difficult road conditions. The reason the fan fails to turn on may be a small “problem” that will only take a couple of minutes to fix.

Where to start the search

Since the fan is driven by an electric motor, a car tester is needed to troubleshoot; in extreme cases, a test light will do. It is small in size, so you can carry it in your car all the time. The electric motors are switched on through the contacts of electromagnetic relays, of which there are three in the cooling system on this car. Pulses to turn on the fans come from two temperature sensors. There are two of them in the system, and they are installed on the engine.

They operate when different temperatures are reached. One of them turns on when the temperature reaches 99 degrees and turns on the first fan, and the second turns on when the temperature reaches 101 degrees. Auto electricians recommend starting the check with the electric motors of these fans. It can be done this way. You should disconnect the connectors from the electric motors and apply power to them directly from the battery. If they work, the temperature sensors are checked.

What else should you pay attention to?

Next, you should check the supply voltage to the electric motor connectors. Pulses to turn on the relay are received from the engine control unit, and it, in turn, from temperature sensors. If, with the ignition on, remove the connector from them and short-circuit the wires, the fan should turn on. If this happens, then the reason is in the sensor itself. If not, check the power supply to this connector.

To check the relays and fuses, you need to find the block with them under the instrument panel. It has fan relays, fuel pumps and fuses installed on it. The relays used are domestic ones with 5 legs. In some models they may have additional fastening with self-tapping screws to the body. To check, they are simply replaced with others. If the additional resistor fails, the fan will not operate at low speed.

Chevrolet Niva Quartz turbolux › Logbook › Reworking the fan switching circuit (part 1).

Another small tuning that everyone somehow never got around to. Today I had time and implemented it. For those who are not in the know, the shniva has two fans and the standard switching circuit implies a two-stage adjustment of their rotation speed. First (at 99 degrees), one fan is turned on at low speed (through a powerful current-limiting resistor), and then (at 102 degrees) both are turned on simultaneously at maximum speed. This circuit has disadvantages: 1. The current-limiting resistor may fail over time and only the second speed will remain. It is quite inconvenient to crawl up to it to replace it. 2. During normal operation, as a rule, only one fan runs at low speed. The second speed is rarely turned on in summer (under heavy loads or high air temperatures), and in winter it may not turn on at all. This leads to its gradual “souring” and subsequent failure at the moment of switching on. 3. If the car has an air conditioner, then when it is running, the “brains” turn on the fan based on the freon pressure sensor in the system, while the fan operates with noise at full strength (additional power drawdown in traffic jams).

On cars since 2014, the plant has finally redesigned this scheme. Additional resistance is excluded from the circuit. At first speed, both fans operate simultaneously, switched on in series. On the second - both at maximum speed. Anyone can upgrade the standard system to a new algorithm.

I found the most understandable step-by-step description of the modification in a magazine from a friend of coff’s at the link: Description of the modification, thanks to him for the instructions.

Actually, further I will describe how it all worked out for me with additional comments. First of all, I was concerned about choosing suitable relays. According to the diagram, it is necessary to replace two 4-pin ones with two 5-pin ones. A feature of all 5-contact relays with NC (normally closed) contacts is the different permissible current strength on NC and NO (normally open) contacts. On the relay, for example, this is what they write: