The radiator cooling fan does not work (does not turn on) - reasons, troubleshooting

– blown, check the fuse that controls the fan

– the fan switch sensor (FVS) is faulty

– fan relay is faulty

– faulty fuse box

– power cable break

– break in the output path to the radiator sensor wire

– the gasket under the head is burned out (coolant does not pass into the cylinder)

Problems with the cooling fan usually occur in used cars with decent mileage. This breakdown manifests itself in different ways; the fan may not work stably, may turn on late or not turn on at all.

There can be quite a few reasons why the fan does not turn on, from a banal fuse blown to more complex problems associated with a malfunction of the thermostat or problems with the electrical wiring of the vehicle's on-board network.

If the engine boils, but the fan still does not turn on, then the first thing that comes to mind for most motorists is problems with the fan wiring. However, very often the wiring has nothing to do with it, and the real reason lies precisely in the thermostat. The device designed to monitor the temperature of the coolant (coolant) may fail or simply jam, after which the coolant stops circulating through the radiator, as a result, the radiator sensor does not work, and the fan itself does not turn on.

Then check the fuse that controls the fan; if the fuse is blown, replace it with a intact one. If the cause is not a fuse, you need to check the fan itself directly. The power wires come to it; often they simply crumble or break off due to age. Alternatively, the reason may lie in the plug, so if everything is fine with the wiring, turn off the power to the fan and check the plug for a malfunction. Connect power to the fan directly, for example, from the battery; if the fan does not react in any way, we conclude that the fan is faulty.

Check the fan switch sensor (FSW) located on the radiator. To do this, you need to disconnect the plugs and then connect them together; if the fan does not work, the DVV is faulty and requires replacement.

It is necessary to connect the wire going to the fuse box directly to ground (usually white with a black stripe). If after this the fan starts working, we can conclude that the second black wire has broken; try to find the break and check whether its connection to ground is reliable. After that, we connect the two wires together and see what happens, if the fan turns on, then the problem was a bad connection.

Check the fan relay, it is quite possible that the problem is there. In order to find out, simply replace it with an adjacent relay, then connect the radiator sensor wires to each other, see above. The fan will turn on - the problem is a faulty relay.

Next, you need to check the voltage to see if it is supplied to the fan through the fuse box. To do this, take a piece of wire and install it in the relay connectors; if the fan is working, the reason why the fan does not work is in the fuse box.

It is likely that voltage is not being supplied to the fan relay. To check this, you can use the “old-fashioned” method. We take a light bulb that will serve as a “control”. If there is no light bulb, just lightly strike the other end of the wire against ground, if you see a spark, there should be no problems, most likely this is not the reason. If you don’t see a spark, most likely there is no voltage in this connector, that is, there is a break in the track in the fuse block.

If, after checking all of the above, you find the reason why the radiator fan does not turn on, you only have to check one wire - the radiator sensor wire. To do this, you must remove the switch as it does not allow access to the fuse box plugs. This means we remove the plug from the fuse block and check the radiator sensor wire for a break.

We check as follows: connect the wire to the “+” terminal of the battery, install the other end into the connector of the chip. Next, remove the plug from the sensor and connect the light bulb. If there is no light bulb, make a “teal” to ground. If there is no voltage, most likely this wire is broken.

If the fan does not turn on, the reason may be completely unexpected, for example, a burnt gasket under the head. Switching on does not occur for the reason that the coolant does not enter the cylinder, while gases from the cylinder penetrate into the coolant, creating an effect known as an air lock. This plug prevents normal coolant pumping. How to understand that you have a burnout? It is enough to look into the expansion tank, if bubbles come out of it every now and then during operation - you have a burnt gasket, or there is a crack in the cylinder.

WHAT TO DO IF THE RADIATOR COOLING FAN DOES NOT WORK

Making sure that the radiator cooling fan has failed and is not working is quite simple. To do this, you need to start the car engine and let it idle for some time. When the dashboard shows that the coolant temperature is approaching the critical zone, the sensor will notify the radiator fan so that it starts working. At this moment, the driver will hear additional noise from under the hood, and when he opens it, he will see that the fan impeller is spinning near the radiator. If the coolant temperature has reached a critical value, and the radiator cooling fan does not turn on, you need to find out why this is happening. The following are the main reasons why the radiator cooling fan does not work:

Problems with the electric motor. If the electric motor fails, its rotor will not spin, and accordingly, the impeller will not rotate. You can check the performance of the electric motor by connecting it directly to the battery. To do this, you will need to take two wires, connect them to two battery terminals and two electric motor terminals. If the fan does not spin when connected directly to the battery, we can conclude that the electric motor needs to be replaced; Problems with the sensor. If the sensor is unable to detect the coolant temperature and transmit a signal to turn on the electric motor, it will need to be replaced. To make sure that it is not working, you need to disconnect two wires from it and short them together. If the electric motor starts to spin the impeller, this will indicate that the sensor is faulty and needs to be replaced; There is no tension. The third and most common reason for a non-working radiator cooling fan is the lack of voltage in its power supply circuit. If there is a break in the wires or a fuse fails, the circuit will be de-energized. To make sure that this problem exists, you need to “ring” the wires and check the fuses. If the radiator cooling fan does not turn on, it is quite easy to find the cause of the problem; just perform the checks described above.

Design and principle of operation

The designers of the Chevrolet Niva used a dual fan unit in the cooling system. This slightly complicated the connection diagram, but sharply increased the efficiency of radiator airflow. The fans are driven by 12-volt DC synchronous motors with a permanent magnet inductor. Electric motors have a closed, non-demountable design and do not require maintenance.

The power of each electric motor is 110 W. The fan assembly draws 18 amps.

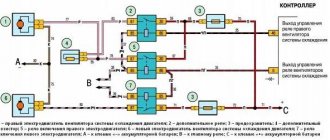

The fans are turned on one by one using an electromagnetic relay controlled by the on-board computer. When the coolant heats up above 99 degrees, the electric fan located closer to the engine air intake starts. The switch-on temperature of the second impeller is 101 degrees. The fan connection diagram is shown below.

Electrical circuit of Niva Chevrolet fans

The fan power system includes three relays and a resistor, which, if necessary, provides a reduced rotation speed of the first motor. Power is supplied from the battery through fuses that save the wiring and battery in the event of a short circuit. Control signals come from pins 29 and 68 of the motor controller.

The fans automatically turn off when the antifreeze cools to 95 degrees.

Consecutive switching on and off of engines reduces the load on the on-board electrical network. In most cases, it is possible to normalize the temperature only with the help of the first fan. This is especially useful when driving at night, when headlights and side lights put a lot of stress on the generator.

The ability to force fans on can be useful when driving off-road or in city traffic jams. However, the designers of the Chevrolet Niva did not provide the car with this function. It can be implemented independently or at a service station. It is necessary to connect backup relays parallel to the switching contacts and power them from a button installed in the car interior.

Useful video about installing and connecting the forced fan button on the Shnivy:

Important: forced activation increases the reliability of the cooling system. In case of malfunctions of sensors, relays or on-board computer, the driver can manually turn on the radiator airflow.

It is useful to equip the Chevrolet Niva with a switch that forcibly turns off the fan motors. This will protect their blades when fording water obstacles.

Popular materials

Not available, for the year of manufacture either. The fans will turn on only based on the sensor signal. Tip: The crankshaft position sensor makes it difficult to remove the fans. Starter From the chip connected to one of the fans, we remove the negative wire; it is usually black. But in this case, in order to turn on the fans at high speeds, you will need to redo everything back. The most popular are electric-driven fans, which consist of an electric motor, an electronic control unit, a temperature sensor and a fan switch relay. Crankshaft position sensor. Except for the tee. Let's look at the diagram Connecting Niva fans in a serial connection. Injection system fuse box. We drag the harness over the steering column and move a piece of hose along it so that its middle is above the steering shaft. Distributor NIVA. Control of transfer case levers in all modes. Practice. Differentials NIVA 1h

More on the topic: Energy inspection of a building

Fan relay

The additional block contains not only fuses. There are also three electromagnetic relays that control the operation of the electric motors of the cooling system. Their control circuits are powered from the ignition switch and on-board controller outputs, and the power current comes from the battery through fuses.

The relay operates as follows:

- Voltage is applied to the control terminals.

- Current passes through the inductor, resulting in an electromagnetic field.

- The steel contacts attract and close.

- The current passing through the relay drives the electric motor.

As soon as the control voltage disappears, the contacts open under the influence of the spring and the fan stops.

You can check the functionality of the relay in three ways:

- Replace the relay with a known working one and test the operation of the system.

- With the engine off and the ignition on, disconnect the temperature sensor connector. You should hear the relay click.

- Dismantle and test the output contacts with a multimeter, applying voltage to the terminals of the induction coil.

Power sensor

The control unit receives information about the antifreeze temperature from a temperature sensor. It is a resistor whose resistance changes with heating and cooling: from 1.3-1.8 kOhm at 30℃ to 155-196 Ohm at 90℃. You can check its performance using an ohmmeter and a thermometer. To do this, you need to remove the part, immerse it in water and measure the resistance at different temperatures.

The sensor is located on the engine head in the area of the exhaust pipe of the cooling system. You can unscrew it with a socket or socket wrench.

We recommend watching a video that shows where the sensor is located and how to check:

Repair of cooling fan on Niva Chevrolet

- First you need to check the fuses for integrity. If they burn out, it is necessary to replace them and try to find out the reasons for their burnout, since they will continue to burn out.

There can be four reasons for their burnout:

- fan wedge: fuses simply cannot withstand the load;

- fuses with a lower current strength than necessary are installed (check that the current strength of the installed fuses should be 30 A);

- the reason is the plugs: they are clogged with dirt, water, rusted or melted;

- it is necessary to check the wiring for abrasions, melting, etc.;

- The reason is the fan wedge: first of all, twist the blades with a stick, but in no case with your hands. Check the bearings for wear; there may be a problem with them and will require replacement.

- It is necessary to check the fan start sensor. Disconnect both plugs and connect them together. If the fan does not work, you will have to replace the sensor.

- The problem may lie in the relay. It is very simple to check its serviceability: we change the relay with the one located next to it and connect the wires of the radiator sensor to each other. If the fan starts up, then the problem is in the relay.

- If the electric motor fails, its rotor will stop rotating, and so will the fan blades. The performance of the engine is checked by direct connection to the battery. To do this, you need to connect two wires to two engine terminals and to two battery terminals. If the fan blades do not rotate, the motor will need to be replaced.

- The reason is the temperature sensor that records the temperature of the antifreeze. The malfunction can be determined by the following method: disconnect two wires from the sensor and connect them together. If the fan blades start to rotate, then the sensor needs to be replaced with a new one.

- If there is a break in the wires, then there will be no voltage in the circuit. In this case, it is necessary to “ring” the wires.

Possible malfunctions and their causes

1.Both fans do not work. The electric motors may fail, the temperature sensor may malfunction, or the power wires coming from the battery or ignition switch may be broken.

2. The second fan does not work. Causes: sensor malfunction, fuse or electromagnetic relay failure. It is also possible that the power cable may be broken.

3. The left fan does not turn on. Causes: faulty power resistor or temperature sensor, blown fuse or relay. It is also possible that the power cable may be broken.

4. Only two fans turn on at a time. This happens when an additional resistor in the circuit of the first electric motor breaks.

5. The fan does not turn off. Typically, the fan runs constantly when the relay is broken or the coolant temperature sensor is faulty.

Reasons why Chevrolet Niva cooling fans do not work

The cooling fan does not work on a Chevrolet Niva - let's look at some reasons why this could happen.

The performance of cooling fans could be affected by various factors:

- fuse burned out;

- problem with the fan switch sensor;

- the motor winding has broken;

- the fan is jammed;

- the connections were oxidized, which led to a lack of voltage supply to the fans;

- the relay is in a technically faulty condition;

- problem with the antifreeze temperature sensor.

Replacing fans

If the fan motors do not start when the wires from the battery are connected directly to the power terminals, the devices must be replaced.

To do this, you will need a set of wrenches ranging in size from 10 to 17 mm and a Phillips screwdriver.

Before starting work, you need to drive the car onto an inspection ditch or a lift and turn off the power to the on-board network by removing the negative terminal of the battery.

Fans are dismantled as follows:

- Remove the crankcase protection and mud guard.

- Unscrew the screws and remove the thick spider-shaped plate and a couple of tin covers that are located in front under the bottom of the car.

- Unscrew the radiator frame cross member.

- Loosen the tension and remove the power steering belt and pump.

- Remove the 4 bolts holding the power steering pump.

Important: to get to the bolt covered by the oil filter, you need to move the amplifier away from the bracket.

- Push the pump back, hanging it on the hoses.

- Remove the air conditioner drive belt.

- Remove the bolt holding the timing belt pulley.

- Remove the pulley and belt.

- Unscrew the four nuts at the corners of the electric fan housing and the two bolts securing it in the middle.

- Remove the fan unit from the studs and pull it down.

Tip: The crankshaft position sensor makes it difficult to remove the fans. Therefore, they need to be pulled out gradually. The left side is lowered first, then the block is moved to the left, raising the right edge so that the casing becomes vertical.

This method is probably suitable for restyled Niva Chevrolet models. On older cars, you will have to remove the radiator grille and bumper, unscrew the fasteners and move the air conditioning and cooling radiators forward. After this, access to the electric fans will be open.

During dismantling, you should carefully remember the procedure. Assembly is carried out in reverse order.

Important: the service life of the fan motors is approximately the same. Therefore, even if one of them fails, both must be replaced. Otherwise, you will soon have to repair the car again.

Checking and removing fans

To understand whether they work or not, you need to disconnect the connector from their motors, and connect a lamp to the wires through which voltage is supplied; we do the same with the sensor; if both lamps light up, then the problem is in the fans.

To remove them you need to do the following:

- Disconnect all wires

- Removing the upper pipe

- Removing the bumper

- If there is an air conditioner, bend the tubes (this must be done carefully, as they may burst) or drain the freon (filling it back will not be cheap), then remove the air conditioner radiator.

- You need to loosen the nuts on the radiator casing

- Tilt the radiator so that you can remove the fan unit

- Unscrew the bolts that secure the block and remove it

After removal, it is recommended to immediately replace both with new ones, since there is a possibility that a little time will pass and the second element will fail and all replacement work will need to be done again. You can do this procedure from below, but you will need special equipment, and you will need to move the engine ten centimeters back, which is very labor-intensive.