28.09.2020

| (Votes: 1, Rating: 5) |

Issues discussed in the material:

- Steering rod device

- Causes of steering rod knocking

- Diagnostics of steering rods

- 7 Steps to the Tie Rod Replacement Process

- 3 Helpful Tips for Installing a New Tie Rod

- Advice from car owners on checking steering rods and racks

Steering rod knocking is not a sign of a malfunction that can be ignored. This vehicle component wears out over time and may eventually fail completely, which will affect the quality of vehicle control. And this will inevitably lead to dangerous situations on the road.

The conclusion here is clear: as soon as an unusual knocking noise appears in the car, you need to conduct a thorough diagnosis in order to find out where it came from and what it could mean. If problems arise due to the steering rod, immediate measures must be taken.

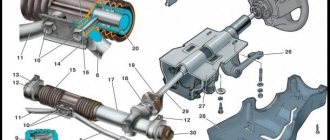

Steering rod device

What is a tie rod used for? This is a component of the steering mechanism of every car that connects the steering column and wheels (or steering knuckles). Without steering rods, driving a car would be impossible.

However, this is not the only function of the steering gear. It is also needed to prevent lateral slip of the steered wheelset. For this purpose, the wheels have different rotation angles. The outer wheel should be turned slightly less than the inner wheel. This possibility is provided by a mechanism called “steering linkage”. It, in turn, consists of rods: right, middle and left. Rods are also divided into transverse and longitudinal, which is determined by their location.

- Why are longitudinal tie rods needed?

They are connected by means of a hinge with a swing arm. This is a common steering device for all vehicles. By rotating the steering wheel bipod, the middle rod of the trapezoid moves to the right or left. At the same time, the angle of rotation of the wheels also changes through the lateral rods. If the mechanism becomes unusable, it must be replaced immediately. However, this is technically difficult to implement, since the location of this part makes it much more difficult to dismantle.

- Purpose of tie rods

Due to the transverse steering rods, the driver has a better feel for the vehicle control system. The inner tip of this rod connects the outer joint and the control system. Thanks to the complete freedom of movement of the hinges in any plane, excellent and precise controllability of the machine is achieved.

There is also a threaded connection on the cross rod for adjustment. Thanks to this design solution, it is possible to adjust the position of the front pair of wheels. The articulated ends of the transverse links must meet more stringent requirements, since the safety of the vehicle while driving depends on them.

The steering rack is designed quite simply. It consists of two rods connected to swing arms. The joint end is a consumable item that wears out depending on the driving style and frequency of use of the vehicle. Repairing the ball end is impractical, so it is replaced entirely. According to the manufacturer's regulations, a new part must be installed at intervals of 35–45 thousand km. But very often, critical wear, manifested in the form of knocking on the tie rod ends, occurs much earlier than this.

We recommend

“Car steering play: diagnostic and repair features” More details

When choosing new rods, you need to focus on the requirements of the operating manual and the design features of a specific car model. Not only original components, but also those produced by third-party companies have proven themselves well.

Causes of steering rod knocking

There is no specific time frame for using automotive tie rods. It is only known that this is the most reliable part of the steering mechanism. There is an opinion on the Internet that parts last from 100 to 150 thousand km, sometimes the figure is 250 thousand km. It should be clarified that the service life greatly depends on driving style and the condition of the road surface. It is quite obvious that driving on bad roads provokes rapid failure of steering rods.

During everyday use of the car, you need to be careful: the appearance of extraneous sounds and poor controllability are the first signals indicating an imminent failure of the steering mechanism. We list the signs by which you can diagnose problems in the steering rack:

- Moving over uneven surfaces is accompanied by grinding and knocking noises.

- There is also a slight knocking sound when turning the steering wheel.

- When the steering wheel remains in a straight position, the car drives along the road.

- Uneven wear on the tire tread is visible.

- Looseness and play appear in the mechanism as a whole.

- The steering wheel begins to tap.

- The steering movement becomes tight.

- The integrity of the anther is compromised. When sand, moisture and dirt penetrate inside the hinge, it quickly fails.

Malfunctions caused by worn fasteners are also common. This applies to both the steering tips and the mechanism as a whole. One of the most common is thread breakage. Strong shocks from the suspension do not pass without leaving a trace - the planes change and bend. If this happens, you should not waste time and effort trying to return the original geometry of the part. It is much easier to replace a damaged element. Operating a vehicle with bent steering system components is prohibited, as this directly affects the vehicle’s handling.

Special attention should be paid to the tip as a component of the steering rod. Often due to its malfunction, the above-described symptoms appear. This is due to wear of the pin or polyurethane gasket that holds the hinge in place. As a result, play forms in the connection, and the tie rod ends make a knocking noise.

Metallic tapping when turning the steering wheel can be observed not only while driving, but also when parked. The reason for this is a loose tie rod with a tip after the wheel alignment has been carried out. How to determine the knocking of steering rods? You need to shake the wheel left and right. If it responds to effort and the movement is accompanied by a characteristic knock, it’s definitely a matter of a nut that they forgot to tighten.

Diagnostics of steering rods

If the car exhibits at least one of the symptoms described above, you should urgently diagnose the steering, paying special attention to the rods. During diagnostics, you need to check the following points:

- The steering tips can move relative to the axis of the fingers by no more than 1.5 mm. In addition, you need to check the play, which indicates wear of these elements. If it is present, only replacing the hinge and steering tip will return the rod to good condition.

- Inspect the clamps on the steering linkage adjusting couplings. If there is wear and tear, it is necessary to repair the part.

- During the diagnostic process, check the protection of the ball joint tip. If it is leaking, the risk of this unit failing increases many times over. This happens due to abrasive particles (sand, dirt) getting inside. Therefore, torn covers are replaced immediately.

If, during troubleshooting, the steering tip is found unfit for use, a new one should be installed. If the hinges fail on both sides, the threads are damaged, or if the rod does not provide for maintenance, you will have to completely change the mechanism. We will outline the repair plan below, not forgetting about the various nuances.

Features of the replacement process

- Before starting work, be sure to put the car on the hand brake and install thrust bars under the rear wheels.

- If you need to dismantle the right link, then the front wheels are turned to the left; when dismantling the left, respectively, to the right.

- The front part of the car must be installed on supports. The ball joint is attached to the swing arm using a nut; it should be unscrewed after first removing the lock. For the next step, you will need a steering rod puller; use it to press the ball joint pin out of the strut swing arm. Use a screwdriver to unscrew the ends of the locking plate, this way you will loosen the bolts that secure the tie rods, then unscrew them altogether. It is necessary to rotate the connecting plate so that you can disconnect the rod from the steering mechanism. After this it can be removed.

- If it is necessary to replace the tie rod end, then it must be clamped by the hexagon of the coupling in a vice and loosen the lock nut of the tip. When unscrewing the tip itself, do not forget to count the number of revolutions completed. It is best to record this number on paper so as not to forget. When installing a new tip, screw it in exactly the same number of turns.

- If it is necessary to replace the cover, you need to remove the old one, then lubricate the surface with sealant, and only then install a new one. You need to reassemble the steering linkage in exactly the reverse order, so don’t get distracted when you disassemble your car.

Advice from car owners on checking steering rods and racks

- Need help from a friend “The first thing you need to figure out is the knocking in the steering rod or rack? This is where a partner comes in handy. One presses his fingers between the ball and the body on the steering rod directly through the boot. The thumb should touch both the body and the ball at the same time. The second person swings the steering wheel with small movements left and right, provoking impacts. It is this kind of diagnostics that allows you to identify the source of the knocking. Everything will work out!”

- Remove the boot

“If there is free movement left and right, then most likely the problem is in the traction, and if it moves up and down, then most often the rack is to blame. For a more accurate diagnosis, you need to dismantle the boot and check everything without it. If there is a leak in the rack, in 70% of cases the play will be in it. If there is no play, but there is a knocking sound, the problem is most likely also in the rack, and there will be knocking on both sides.” - Diagnostics by ear

“When the rod rattles, it’s easy to verify this. I lifted the front wheel and checked the linkage joint by touch directly through the boot. This excluded the possibility of hub wear. Next, you need to suspend the front wheels and sharply turn the steering wheel in different directions. If there is a fault in the rack, the knock should be clearly audible.” - Everyone is guided by their own experience

“I’ll describe my situation. The car was brought from Vladivostok on a car transporter. It turned out that in the pits there was a slight knock in the steering rod. I contacted the vibration stand service. Based on the diagnostic results, it was necessary to replace both steering rods, as they had become unusable at the junction with the steering rack. I purchased new parts and brought them to the service center for replacement. Other experts have already said that the steering rack has failed. Therefore, for the future I made a conclusion for myself: if you do not have repair skills, it is better to consult several specialists. After all, everyone is guided by their own knowledge and experience.” - You can’t go anywhere without the help of specialists

“I went to a service station the other day because I was worried about a knocking sound on the right side (left-hand drive). I was almost sure that the cause of the knocking was in the rack or the tie rod end. However, it turned out that the suspension was working properly. The source of the noise turned out to be the brake caliper. I couldn’t determine it myself, so you should always turn to professionals.”

Technological sequence of operations

Traction is selected according to the car manufacturer's article number. For foreign cars, the dimensions and shape of the rod often change within one generation of the model. When replacing a deformed part, auto mechanics from the S-MOTORS service:

- raise the car on a hydraulic lift;

- dismantle one or both wheels;

- disassemble the trapezoid (remove clamps, boots, tips);

- unscrew the steering rod from the rack housing;

- install a new part;

- fill the anthers and hinges with grease, and install the cotter pins correctly.

If you notice signs of a car control malfunction, call us, send a request to the S-MOTORS car service website. Our auto mechanics are well aware of the design features of foreign and Russian cars and quickly find the causes of breakdowns. Replacement operations are carried out technologically correctly, according to the positions of the car manufacturer's technological map. When installing the rod in its normal place, an adjustment is made and the car is tested in motion.

Caliper repair

Brake caliper repair

Replacing brake discs

Replacing brake discs

Replacing brake fluid

Replacing brake fluid

Marina

The pads are my headache. I constantly have problems with them. This time I installed the original ones, they were made in Lyublino at S-Motors. So far, ugh, ugh, everything is fine, I’ll keep my fingers crossed)

Gleb

The friction linings were worn out and an unpleasant squeak began to appear. I stopped by on the way home to the service center. The guys fiddled around and found the reason. Everything has been fixed, I’m riding)

Nikolai

I changed the rear brake drums at S-Motors and ordered them. I live nearby, so it was more convenient to leave the car overnight. I picked it up in the morning. Thanks guys, we were probably fiddling around late at night.

5% discount with customer card, call to make an appointment

SIGN UP

This is interesting: When to change front brake pads