A rack or gear mechanism is responsible for turning the front wheels of the car. The unit simultaneously transmits force to both steering knuckles through rods with hinges at the ends. These 2 parts are the weak link of the control system - the service life is 20–80 thousand km, depending on the make of the car and operating conditions. Car enthusiasts should learn to recognize the signs of faulty steering tips in time, since their technical condition is directly related to the safety of passengers.

What are tie rods and tie rods for?

In the vehicle control system, a steering rod is necessary to transmit the force (rotation) of the steering wheel to the steering knuckles of the wheels. The tie rod end joints ensure free rotation of all moving drive parts. The force on the wheels corresponding to a given angle of rotation is transmitted directly by the drive.

The complex mechanism of the steering system design is explained by the fact that when turning, each wheel must be set to a different angle. If the angle of rotation were the same, then during maneuvers the inner wheel would slip, leading to wear of the rubber itself and a decrease in the controllability of the car.

Different angles of rotation are achieved thanks to the special design of the steering part of the car, which includes rods, hinges and swing arms. The angle of rotation directly depends on the angle of inclination of the levers.

Design

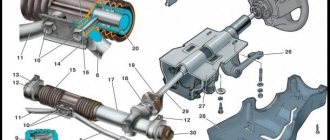

Externally, the tip is a steel rod, at one end of which there is a hinge, at the other there is a thread that serves for connection to a rack or gearbox. The tip pin is inserted into a special hole in the fist and secured with a nut and cotter pin. In more detail, the rod end consists of:

- a metal cylinder closed at the bottom with a plug;

- a compression spring placed between it and the heel;

- ball pin;

- a cover (boot) made of silicone or rubber;

- plastic liner.

The last element is necessary so that the pin rotates freely in any direction, and thanks to the spring, the backlash that occurs during operation of the car is eliminated for some time. If the tip fails, the part is replaced entirely, since it has a non-separable design. There are also composite parts that were once popular in the Soviet Union (due to a shortage of spare parts), but they are practically not used today due to low reliability.

Why do tie rod ends wear out?

The main causes of malfunctions and wear of steering rods include:

- Deformations of rods and levers that occur during strong impacts (hitting an obstacle at high speed, falling into a hole).

- Wear of hinges and their untimely replacement.

- Destruction of the tie rod boot due to dust and dirt.

Mostly, steering rod malfunctions occur due to mechanical damage, defects in the protective cover, leading to the ingress of dust, dirt, and moisture. The service life of the tips, as a rule, is about 30–40 thousand kilometers. Diagnostics of steering rods may be required much earlier than the specified mileage - the frequency of inspection and replacement directly depends on the quality of the roads and the driving style of the car.

Signs of malfunction include:

- Side noises, suspension knocks.

- Steering wheel play.

- Stiff steering wheel rotation.

Main components of the steering mechanism.

The steering linkage consists of several main elements interconnected:

- side tie rods,

- average,

- bipod,

- pendulum lever,

- steering knuckle levers.

The column itself consists of two parts - an intermediate shaft, which is connected to a trapezoid using a hinge, and a steering column on which the wheel is attached. To ensure the best connection of the steering wheel, it has conical splines.

The side rods are composite; for adjustment, there is a split coupling in the middle. There is a left-hand thread on one end of the tip, and a right-hand thread on the other. As the clutch rotates, the length of the lever can either increase or decrease. This is necessary to be able to adjust the toe angle of the wheels.

Standard clamps are used to secure the coupling. The rods end with hinges. They usually have a cone-shaped fit and nuts are used to secure them.

The hydraulic booster is a system consisting of several additional elements:

- pump,

- expansion tank for liquid,

- radiator,

- pipes

The column is attached to the left side member using three bolts. The power steering pump is located on the left side of the engine. To rotate it, an additional belt is used to connect the auxiliary units.

If the power steering fails, the ability to control the car remains, but the required force on the steering wheel only increases.

The design of the steering wheel on the Chevrolet Niva is considered injury-proof by its design. This is ensured by the ability to fold the column in the hinge area.

The tie rods themselves are metal rods, which are quite difficult to damage. They can only be bent by “catching” the wheel on a stone or other obstacle.

Much more often there are malfunctions associated with:

- Hinges. These parts are located at the ends of the steering rods. Most often, the cause of failure is excessive wear of the liner (or rubber bushing) or the spherical surface of the pin (damage to the thread, cone, surface due to corrosion or unprofessional installation/disassembly).

- A cotter pin securing the castle nut. Incorrect installation of this small and not particularly significant, at first glance, part can lead to irreparable consequences: the cotter pin falls out -{amp}gt; the nut is loosened -{amp}gt; finger loses tight contact -{amp}gt; the steering linkage loses its geometry -{amp}gt; it is impossible to drive the car.

- Anthers or a hinge cover. When the boot breaks or the cover moves from its seat, the hinge becomes dirty and, as a result, wears out faster.

- Bushings, threaded parts of rods and other parts of the toe angle mechanism. They may become corroded or damaged when driving in poor road conditions.

How to check the tie rod end

Self-checking steering rods involves inspecting the control system parts on a lift or in a pit. You can first find out about problems with the steering tips by the knocking noise that occurs when you turn the steering wheel to the sides on a flat section of the road.

Inspection of steering tips and checking traction includes:

- Visual inspection of parts to ensure there are no deformations.

- Checking the protective covers of the ball joint of the tip (there are no cracks through which dust, water, or dirt can enter).

- Definition of tip play - movement along the axis of the fingers should not exceed 1.5 mm.

If you do not know how to check the steering ends on your car, you do not have the ability to properly diagnose, then it is better to contact a specialized car service center.

Causes of joint wear

During operation, the working pair of the tip (plastic insert and ball pin) experiences loads from the steering rack, which pulls or pushes the steering knuckle depending on the direction of movement of the car. Another type of load affects the element from the side of the wheel falling on uneven road surfaces.

In the first case, the force is applied perpendicular to the axis of the ball pin and acts on the fracture; in the second, the forces tend to pull the part out of the socket. There is a third type of load - the friction force that arises in the unit when the wheels turn. Since the finger is rigidly fixed in the eye of the fist with a nut, it rotates inside the plastic bushing and rubs against its walls.

Due to the impact of these loads, the hinge joint wears out as follows:

- Over time, the walls of the liner wear out, a gap forms between them and the ball, which is why a quiet knock is heard when moving over small uneven surfaces.

- Abrasion of the side walls of the bushing leads to loosening of the pin, because it is pressed by the spring only from below.

- When the spring and heel are unable to remove the play resulting from wear of the plastic, the ball pin moves easily in the bushing, causing the steering tip to knock heavily.

Important point! Hinge joints have an external enemy that significantly reduces the resource of the working pair. This is dust and moisture that penetrates between the rubbing surfaces as a result of the rupture of the upper rubber cover.

Such defects must be identified in a timely manner, otherwise the damaged tip will quickly become unusable.

In cars equipped with a double-wishbone front suspension, sometimes a breakdown occurs that is not related to the operation of the hinge. Since the rod is located low, if you drive carelessly on bad roads, the metal rod can bend when it hits a stone or other obstacle. In this case, knocking does not occur, but other symptoms are observed, described below.

How to change the tie rod end?

You can replace the tie rod end on your car yourself using the service manual for your car or the recommendations below. You will first need to prepare the tool, a new tip.

Required Tools

To remove and replace the tie rod, you will need the following tools:

- Ball wrench for removing wheel bolts.

- A jack for lifting a part of a car.

- Keys 17 and 19 for unscrewing the traction mechanism

- Universal pliers for loosening bolts and removing cotter pins.

- A puller or hammer to remove the tip bolt.

- Torque wrench to ensure precise torque when installing a new part.

How to remove the tie rod?

Removal of the part is carried out in several stages:

- Use a wheel wrench to loosen the wheel bolts of the vehicle.

- Using a jack, the car is partially lifted, the bolts are turned out completely and the wheel is removed.

- If the replacement and maintenance of the steering mechanism and suspension system as a whole was carried out a long time ago, then the installation site of the tip can be lubricated with WD-40.

- The steering wheel is turned all the way to the side.

- The traction mechanism is unscrewed and removed along with the tip.

- The cotter pin is removed from the pin nut and the fixing nut is unscrewed.

- By acting on the rotary rod, the tip bolt is removed with a puller or hammer.

- The hinge itself is turned out of the old rod clockwise.

Please note that after removing and installing a new end, it is necessary to perform a wheel alignment. If you carry out the work yourself, then when removing the hinge from the rod, you must accurately count the number of revolutions and take this into account when installing a new part. You can make notes for each wheel, indicating the number of revolutions.

How to install a new tip

The new steering end is installed on the rod and twisted counterclockwise by the same number of turns as the old part was unscrewed. In this case, the nut is not tightened “by eye”, but strictly with the force specified in the service manual for your car. A torque wrench will help you accurately calculate the applied forces. After this, the cotter pin is installed, and the remaining work is carried out in the same way as removal, but in the reverse order.

The work of replacing the tips yourself, if you have some skills, knowledge of the structure of the car, and the appropriate tools, is not particularly difficult. The main thing to remember when servicing the steering system is the need to adjust the wheel alignment after installing a new link or end. Therefore, to ensure proper controllability of the car after self-repair, you should contact a car service or service station to have the wheels adjusted.

Replacement

Well, the symptoms of the problems and a direct check of the steering mechanism elements showed that it was the tips that were to blame. Therefore you will have to change them.

Is it difficult to do? If you have at least a little experience, you have already had to disassemble the steering system, then there should not be any difficulties. By doing everything yourself, you can save a lot on the cost of service stations.

Dismantling works

To illustrate the replacement example, we advise you to rely not only on the instructions presented in our article, but also on video materials. Detailed video lessons seriously help you master quite complex stages of work.

To work you will need a set of materials and tools. It includes:

- New high quality steering limit switches;

- The almighty WD40. If you don’t have the money to buy it, use plain brake fluid;

- A set of keys;

- Pliers;

- Brush with metal bristles;

- Puller (if you don’t have a puller, replace it with a small crowbar).

Assembly of the unit

Everything you need is ready, so you can safely get to work.

- Use a jack to jack up the side of the car where you plan to do the work to replace the tie rod ends.

- Unscrew the mounting bolts from the wheel and remove it.

- Use a wire brush to clean the joint between the tip and the steering knuckle.

- If this area is heavily contaminated, the simple force of a wire brush may not be enough. This is where WD40 comes in handy. We repeat, if it is not there, try washing off the dirt with brake fluid.

- Use pliers to remove the cotter pin. It performs the task of fixing a bolted connection. A kind of fixative.

- Unscrew the fastening nut.

- Now arm yourself with a crowbar and a small hammer. Although if you managed to find a puller, it would be much better.

- Using the selected tool, you need to remove the finger of your tip from the fist of the stand. In this way, the damaged element is removed from the retainer.

- The unit to be replaced should be carefully unscrewed.

- We recommend that you first measure the current distance between the squeegee and the center of the tip. When reinstalling, this information will be extremely useful.

- Now it's time for the new kit, which you purchased in a store or ordered online.

- Insert in place of the old unit, secure with traction.

- Return the hinge pin to its rightful place - into the steering knuckle.

- Next, you should screw the nut back, tighten it properly and secure the cotter pin in the correct place.

- This instruction fully corresponds to the features of replacing the tip on another wheel. Therefore, the manual is the same for the left and right front wheel of your VAZ 2110.

- The last stage of repair will still require you to visit a service station. This is necessary in order to check the wheel alignment. The probability of its violation is too high, so do not be lazy to spend a little time and money. They shouldn't charge you much for the check.

If you do everything correctly and consistently, it will take you about an hour to replace the steering limit switches. Experienced craftsmen can do it even in 30-40 minutes. But in any case, there is no need to rush.

Blow, more blow and bumps

The tip, and in particularly difficult cases, the steering rod can be destroyed by running over an obstacle. A stone on the road, a log or a hole - it doesn’t matter, there can be one outcome - a bent rod or a failed tip.

“As a standard, our specialists carry out routine diagnostics of the suspension at each subsequent maintenance. It also includes checking the tie rods and ends. It doesn’t matter how much the car had driven at the time of servicing - 15 or 150 thousand km; in rare cases, the rod ends can be “killed” even on a new car with low mileage.

Also interesting: VAZ Niva 2121 tuning recommendations

Check the boots on the tie rod ends!

What a pleasure it is to sit behind the wheel of your favorite car, gradually change gears, press the gas pedal to the floor and drive at maximum speed... If the car’s power and the track allow this, then why not? But don’t forget about safety! And the basis for safe driving is, of course, the serviceability of all car mechanisms.

- 1. What do you need to check the tie rod end at home?

- 2. How to properly check the condition of the steering shaft and steering tip?

- 3. Wear of the steering tip: what to do to fix the problem?

And also interesting: Replacing the axle bearing of a Niva Chevrolet

The second, and on domestic cars the first, mortal enemy of the steering tips is torn boots. Dirt caps are designed to protect against dirt, water, sand and reagents. As soon as it breaks, depressurizes due to wear and tear on the inside, corrosion begins to progress rapidly, aggravated by increased wear due to the abrasive effect of sand and dirt. The lubricant is washed away by water, and very soon you will not recognize your car on the road.

Symptoms of malfunctions

If you do not pay attention to the wear of the tie rod ends, the ball pin will become loose and jump out of its socket at the first decent bump. There is no need to explain for a long time what this entails: the wheel will become uncontrollable, and the driver will lose control of the car. How to determine that there are problems with the hinges and the car’s chassis needs to be checked:

- the first sign is a dull, frequent knocking sound when driving over small bumps, especially in turns;

- as a rule, extraneous sounds are heard from one side, but simultaneous wear of two tips also occurs;

- the free play of the steering wheel increases;

- when negotiating a turn on an uneven road, you can feel a tapping sound on the steering wheel;

- At the last stage of wear of the tips, the car has to be literally “caught” on the road, since due to the play of the ball pins, the wheels can deviate by 2–3° from the straight line.

If you find one of the listed symptoms in your own car, you should not delay diagnosis. Especially if the tips have served more than 40 thousand kilometers. To perform the check, you will need an inspection ditch; hanging the car on a jack will not allow you to swing the rod in the desired direction.

To check the tie rod ends yourself, use the step-by-step instructions:

- Drive the car exactly in the center of the inspection hole so that you can easily reach the hinges. If the ditch is too narrow, the car will have to be moved twice in different directions.

- Support the rear wheels with wheel chocks.

- Grab the rod with your hand as close to the tip as possible. Rock the hinge up and down to feel the play.

- A small elastic resistance indicates that the spring is working and there are no critical gaps. Significant play is felt immediately.

- Rotate the rod several times around its own axis. If it flows easily, literally dangling on the ball pin, the tip should be replaced.

When swinging the rod, do not confuse the hinge play with free play of the steering rack or a broken pendulum bearing.

To check the integrity of the anthers, an inspection hole is not needed. It is enough to turn the wheel and lift the car with a jack. The hole in the rubber boot is discovered thanks to thick lubricant, which is squeezed out from the inside through a gust.

Replacing the steering tip is also not a big problem; the only special tools you need are a puller to push the ball pin out of the steering knuckle eye. Please note an important nuance: after replacing the linkage, the camber angles of the wheels must be adjusted. You cannot make the adjustment yourself, so you will have to visit a car service center.

Revealing the essence of the problem

The answer to the question of how to check tie rod ends is not difficult. The inspection itself is not difficult. Initially, you can assess the degree of wear of the tips when driving on uneven roads or when accelerating (braking). In this case, it is possible to feel play on the steering rack and a slight kickback in the fuel adjustment pedal.

To conduct a more detailed inspection, you need to jack up the car and remove the wheel. Then, having reached the steering rod, find the tip. The first step is to press the hinge from above, resting your fingers on the nut from below.

If it can be compressed and play is felt, then it means that the spherical part is already worn out and the element needs to be replaced. But this play when pressed may not be detected the first time. It is necessary to turn the steering wheel to different positions and repeat the procedure until the steering wheel is in almost all positions. It happens that it can dangle up and down only every other time.

You also need to check the anthers

. In order to check the serviceability of the ball joint without removing the wheel, you need to rock the wheel in different positions with your foot; if you feel wobbly and metallic sounds, then you need to remove the wheel and inspect the steering joint in detail.

Check while driving

Failure of the steering tips can be determined by the behavior of the car while driving. While driving a car on a safe section of the road, you need to make several small turns with the steering wheel. If the wheels turn with some delay, this indicates the presence of play, which is caused by increased gaps between the hinge and the tip body. Also, a malfunction can be indicated by extraneous sounds that occur while driving the car.

Checking in a garage

If a check while the vehicle is moving shows that the steering tips are likely to be faulty, they should be checked in the parking position. The car is installed above the inspection hole, and if there is no inspection hole, the front of the car is raised on jacks. For better visibility, the front wheels are temporarily removed.

There are 3 types of tie rod end malfunctions: mechanical damage and deformation, depressurization of rubber seals, and the presence of play. Defects in rubber seals allow contaminants to enter the lubricant, which can lead to mechanical damage to the spherical joint.

In all cases of detection of malfunctions, the steering tip must be replaced. When purchasing a new tip, you should check that the serial part number indicated on the body matches.