Changing the cylinder head gasket on an 8-valve VAZ-2110 engine

Some owners of domestic cars do not know that the cylinder head gasket needs to be changed every time the cylinder head is removed . You should never install an old part, since this spare part is disposable.

Replacing the cylinder head gasket on an 8-valve VAZ engine is almost the same as the same work for a 16-valve engine, so this article will also be useful to owners of cars with more modern engines.

Checking for microcracks

When checking the cylinder head gasket, it is important to pay attention to the presence of cracks. Several methods are used here.

Magnetic particle testing

The action algorithm is as follows:

- Place magnets on all sides of the head.

- Place metal shavings on top of the cylinder head.

- Pay attention to the "drawing". The chips will be drawn to the magnets, but they will remain in places of depressions and damage.

Using liquid

To check, do the following:

- Prepare the colored liquid using kerosene, acetone or another solvent.

- Apply the composition.

- Wait five to ten minutes.

- Remove excess liquid.

If there are defects, they are easy to notice even without a detailed inspection.

Pressure test

There are two ways used here - with or without immersion in water.

When immersed in water, do the following:

- Close all circuit channels.

- Place it in a container and pour in warm water.

- Apply compressed air to the area where bubbles appear.

Without dipping:

- Close the holes.

- Pour more liquid into the channel.

- Using a pump, pump in air to create a pressure of 0.7 MPa.

- Let the head sit for two to three hours. If the water leaks, we can talk about the need for repairs.

For repairs, a gas installation with additives is used with mandatory heating of problem areas to a temperature of 200 degrees Celsius or more. After completing the welding work, the seam is cleaned and pressed.

Replacement intervals for the cylinder head gasket on the VAZ-2110

It is very difficult to predict the exact service life of a gasket.

The most important thing that interests owners is the replacement interval for this part.

It is very difficult to say how long a particular gasket will last.

- Manufacturer of the part.

- The quality of the material from which the gasket is made.

- The conditions under which these parts were stored.

Since the gasket is made of rubber, storage conditions directly affect its service life. For example, a part purchased at the market, which was stored for a long time in a damp and unheated container, will be worse than the same spare part purchased in a store.

The main function is to ensure maximum sealing of the cylinder block with the cylinder head. If you do not monitor the condition, the engine life will be significantly reduced.

Signs of a broken gasket

Foam around the expansion tank cap is one of the signs of a cylinder head gasket failure.

You can find out that the seal of the connection is broken for the following reasons:

- White vapor appears in the exhaust gases.

- You may notice oil stains in the antifreeze.

- Leak in cylinder head connections.

- There is a large amount of oil in the pan.

- You may notice foam around the filler cap.

Although it seems that it is very difficult to notice the vapors in antifreeze, this can be done by placing a bag over the neck of the open expansion tank. If there are gases in the antifreeze, the bag will inflate.

Symptoms of a problem

So, when all the points have been considered, it remains to list the signs of cylinder head gasket failure:

White smoke from the muffler is a sign of a faulty cylinder head gasket

Sufficient amount of emulsion on the filler cap.

Emulsion on the filler cap

- Antifreeze has an oil effect.

- The oil level in the pan has increased.

- The smell of antifreeze or exhaust gases can be traced in gasoline.

This is interesting: Camshaft oil seal VAZ 2110 8 valves - how to replace it yourself

Articles

The gasket costs pennies compared to the labor of replacing it.

Before you start replacing the gasket, you should purchase this gasket. Although any car store will select a suitable spare part for you, it is better to know its part number. The most suitable gaskets for the VAZ-2110 are:

- VATI gasket , which has the article number 21083100302020.

- Part VICTOR REINZ . This item is of higher quality than the original. Its article number is 613666000 .

- TRIALLI gaskets , which have the article number GZ.

It’s better to immediately buy a better quality spare part than to bother with disassembly again later.

Bolts in VAZ family cars

Fasteners are presented in a wide range, they have different sizes and purposes. For example, the rear door shock absorber mounting bolt 2108-09 or the roof support mounting bolt. If you are repairing a generator, you will also need the appropriate fastener. Even to fix a ball license plate, certain hardware is needed.

The photo shows the cylinder head bolts of a VAZ 2108.

Bolts for alloy wheels

VAZ wheel bolts are designed for fixing alloy wheels, the total length is 51 mm. Approximate cost of elements:

- a VAZ M 12×30.5 wheel bolt costs from 35 rubles;

- secret bolts for VAZ-2101-12 set – 280 rubles;

- wheel hardware M12×1, 25×28 zinc from 45 RUR/piece;

- The eccentric bolt on the VAZ (shown in the photo) allows you to install any wheels with a 4×100 drill bit.

Wheel bolts on VAZ for alloy wheels have a thread length of 28, 30 and 33 millimeters. Standard factory fasteners come with dimensions of 12×1.25 with a total length of 44 mm and a thread length of 24 mm.

Transmission mounting bolt

M12×45 brand fasteners are suitable as standard parts for transmissions and gearboxes on VAZ 2101, 2102, 2103, 2104, 2105, 2106, 2107 models. For VAZ gearboxes, M 12×1.24 Belebey fasteners are used.

Arm bolts

A broken beam bolt (rear suspension arm) is usually discovered when trying to perform wheel alignment. The result is a discovered lever that is not properly secured. On VAZ cars, there are no problems replacing the upper arm, since the fasteners are clearly visible and easy to reach. Bend the pressing petal and knock out the 14x243 element. You will have to work longer with the rear fasteners, since you have to remove the hardware through the lower hole in the beam. It is recommended to use a screwdriver or tweezers as tools.

Using available tools, install new bolts. When replacing, do not dismantle the lower arm. When one hardware is unscrewed and removed, the second one must be fully tightened. This will allow fastening without distortion of the lower axis. It is recommended to have a jack on hand, which should be placed under the lower arm mount and at the same time adjust its position. This technique will lighten the load on the bolt and simplify installation.

Tools

It is better to change the gasket in the garage.

Although this part can be replaced right near the house, it is better to carry out all replacement operations in the inspection hole. To replace you will need the following tools:

- Set of sockets for ratchet. Heads must be from 10 to 19;

- Torx key;

- Several screwdrivers;

- Candle key;

- Torque wrench.

A special liquid WD-40 , which will help when unscrewing soured bolts, will also not be superfluous As the practice of such repairs shows, during disassembly it is often necessary to use other tools, so having them will never hurt.

Replacement procedure

The replacement process occurs as follows:

- First you need to disconnect the battery; to do this, remove the negative terminal.

- You need to disconnect the exhaust pipe from the muffler.

Unscrew the 4 nuts securing the muffler to the exhaust manifold.

Having disconnected the hoses, unscrew the nuts securing the fuel pump and remove it.

Before this, we install the first cylinder at TDC and lock the crankshaft flywheel with a toothed lock.

After this, all that remains is to unscrew the bolts and remove the block head . After removing the old gasket, you need to carefully inspect the contact surfaces of the head and cylinder block. There should be no dirt or residue from the old gasket on them. All obvious signs of contamination must be eliminated.

Installing a new part

The new part to be installed must be undamaged, dry and clean.

When installing, you need to make sure that the hole intended for the passage of oil is located between the third and fourth cylinders.

Before installing the cylinder head, you must ensure that the valves of the first cylinder are closed . The bolts must be tightened according to a certain pattern, in four stages.

Tightening sequence for cylinder head bolts.

Tightening torques for 8-valve engine

The bolt tightening torque is as follows:

- First they are tightened to 20 Nm .

- Then up to 69.4–85.7 Nm .

- At the third stage, the bolts are turned 90 degrees.

- At the last stage, you need to turn the bolts completely 90 degrees.

The rest of the assembly process occurs in the reverse order of disassembly. A prerequisite is to check the valve clearances and adjust the timing belt tension.

Work process

Disconnect the negative terminals from the battery.

As you can see, repairing the cylinder head on a VAZ-2114, which has 8 valves, is a fairly simple, albeit slightly labor-intensive task, which means that every person who has at least a slight understanding of this unit can handle it.

Replacing the cylinder head gasket of a VAZ 2110 (8 valves)

The cylinder head gasket is a perforated sheet made of iron and asbestos, sometimes of aluminum paronite, along the edge of which there are holes for chambers and connection bolts. The purpose of the gasket is to seal the connection between the cylinder blocks. At the same time, it serves to maintain oil pressure in the general engine system and inhibits the mixing of coolant with engine oil.

The photo report below clearly shows the process of changing the cylinder head gasket on a VAZ 2110 car. On a car with a carburetor, it is not the injector that needs to be disconnected, but the carburetor.

Signs indicating cylinder head failure

Nowhere is it said what the service life of the cylinder head gasket is, so its service life is influenced by many factors, such as the operation of the car, the driver’s driving style, the car model and others. But there are certain factors by which it is possible to identify a breakdown.

- Formation of drips at the connection between the block and the head.

- Light impurities and the resulting foam that occurs when connecting to the cylinder head remain on the oil dipstick.

- The color of the exhaust changes to light blue, this indicates the penetration of water into the combustion chamber of the block.

- Formation of oil stains in the coolant tank.

- Hot gases enter the cooling system, causing an increase in engine temperature.

What you need to know when changing the cylinder head

The first step is to set the crankshaft to TDC, then close the two valves of the 1st cylinder. It is best to replace the removed fastening bolts, since after several uses they are pulled out, the metal is strained, after which it breaks. When the bolt length increases to 135.5 mm, they must be replaced.

The gasket must be replaced whenever the engine head is removed, even if it is not damaged or damaged.

It is necessary to tighten the bolts with a tightening torque of 20 Nm in the first stage, and 69-85 Nm in the second stage, and in the third stage the tightening force of the bolt reaches 90 degrees.

The actions when changing the gasket on a VAZ 2110 with a 16-valve engine are similar to those with an 8-valve engine. Here it is worth paying attention to some points:

- The first step is to remove the dismantling.

- When removing the pulleys from the timing belt, two pulleys are marked and they are removed.

- The fuel rail is removed.

- Tightening occurs according to the instructions for a 16 valve engine.

Necessary tools when changing gaskets for a VAZ 2110 car

To carry out work to replace the gasket, you need to drive the car into a pit, this will make it more convenient to work, while preparing a set of tools in advance:

- Ratchet sizes 10,13,17 and 19.

- Torx key.

- A simple screwdriver.

- Special key for candles.

It is also worth taking care of the components: Gaskets included in the TRIALLI kit, item number GZ1017022, costing 500 rubles; Gasket for cylinder head VICTOR REINZ number 613666000, the cost will be approximately 280 rubles; The original cylinder head gasket is VAZ number 21083100302020, its price is 140 rubles.

Prices are indicated for Moscow and the region as of 2022.

We install the piston of the first cylinder to the TDC position of the compression stroke, fix the camshaft pulley, and remove the spark plugs.

Using a 10mm wrench, unscrew the two bolts securing the cable bracket, and then remove the bracket. We get rid of the ventilation hose, as well as the hose installed on the valve cover fittings. Using a 10mm wrench, unscrew the two nuts securing the valve cover and get rid of it.

Using a 10mm wrench, unscrew the bolts holding the front timing cover, one located in the center and two on the sides. We remove the timing cover.

The mark applied to the camshaft toothed pulley must coincide with the installation lug located on the rear cover of the timing drive; using a 17mm wrench, remove the pulley.

Armed with a 10mm wrench, remove the fastening nut on the protective casing and remove the casing.

The timing belt also requires replacement.

Disconnect the sensor connector indicating the oil pressure level.

Using a 10mm wrench, unscrew the two nuts and bolt securing the plug. Using a 13mm wrench, remove the 6 nuts securing the rear camshaft bearing housing. Remove the bearing housing.

Armed with a 14mm wrench, you need to remove the four nuts holding the housing in front of the camshaft and also remove it.

Unscrew the four nuts located on the muffler mount.

Using an E14 Torx head, unscrew the ten bolts located on the cylinder block and remove the block itself.

Burn marks are visible on the gasket.

Remove the old cylinder head gasket.

After changing the gasket, tighten the cylinder head bolts according to the diagram.

Source

conclusions

The design of the 8-valve injection engine VAZ-2114 is quite similar to the first generations of this engine - “Samara”. Of course, the designers made many changes to the features of the power unit, but in many ways they remained similar. Repair and maintenance of this engine must be carried out regularly, which will not only extend its life, but also reduce wear on the parts located inside.

The car is equipped with a gasoline, four-stroke, four-cylinder, in-line, eight-valve, overhead camshaft, liquid-cooled engine, model 2111 or 11183.

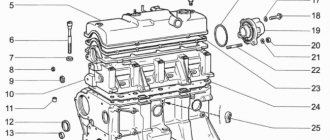

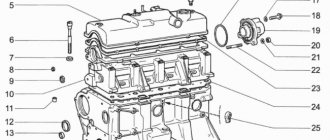

Cross section of engine 11183 (1.6i):

1 – oil pan drain plug; 2 – engine sump; 3 – crankshaft; 4 – oil filter; 5 – coolant pump; 6 – exhaust manifold; 7 – piston; 8 – rod for fastening the intake pipeline; 9 – laying of the intake pipeline and exhaust manifold; 10 – inlet pipeline; 11 – nozzle; 12 – fuel rail; 13 – receiver; 14 – bracket; 15 – cylinder head cover; 16 – camshaft bearing housing; 17 – camshaft; 18 – crankcase ventilation system hose; 19 – valve pusher; 20 – cylinder head; 21 – bolt securing the head to the cylinder block; 22 – valve; 23 – spark plug; 24 – cylinder head gasket; 25 – upper compression ring; 26 – lower compression ring; 27 – oil scraper ring; 28 – piston pin; 29 – fitting for installing the oil dipstick; 30 – connecting rod; 31 – flywheel; 32 – cylinder block; 33 – oil pan gasket; 34 – oil dipstick; 35 – oil intake

The cylinder block is cast iron, with cylinders machined into it. The internal cavities of the block for coolant are formed during casting, and the oil supply channels are made by drilling. At the bottom of the block, five supports for the crankshaft main bearings are machined. The main bearing caps are machined together with their bearings and are therefore not interchangeable. In order not to confuse the covers during installation, they are marked with the serial number of the bearing, starting from the crankshaft pulley. The cover of the second main bearing has two threaded holes for the oil intake bolts. Steel-aluminum liners are installed in the supports and main bearing caps. On both sides of the third main bearing support there are sockets for installing thrust half-rings that prevent axial movement of the crankshaft. The front half-ring is steel-aluminum (yellow on one side, steel-colored on the other), the rear half-ring is metal-ceramic (yellow on both sides).

Signs of failure of the cylinder head gasket of a VAZ 2110

There are no specific warranty periods for the use of a cylinder head gasket. Its durability is influenced by such factors as: the degree of operation of the engine, its model, driving style and other reasons. However, there are several symptoms by which you can determine that the gasket has failed:

- at the junction of the block and the head there are leaks of engine oil or coolant ;

- using an oil dipstick, foreign light impurities or foam-like emulsion , which occurs when antifreeze penetrates through the connection with the cylinder head;

- the color of the exhaust changes to bluish-white, which indicates water entering the combustion chamber of the cylinder block;

- presence of oil stains in the coolant reservoir;

- The engine temperature rises due to the breakthrough of hot gases into the cooling system, which immediately heat the coolant.

Tips for replacing the cylinder head gasket

Removal and installation of the cylinder head gasket is carried out with the crankshaft set to TDC. It is also necessary to ensure that both valves of the 1st cylinder are closed.

It must be remembered that the cylinder head gasket must be changed after each removal of the engine head, even if this is not due to its unsuitability.

The procedure for replacing the cylinder head gasket on a VAZ 2110 on a 16-valve engine is generally similar to how to change the cylinder head gasket on an 8-valve engine, but has several nuances :

- The receiver must be dismantled.

- When removing timing belt pulleys, a mark is placed on two pulleys and two pulleys are removed.

- The fuel rail is removed.

- The order and tightening torques are carried out in accordance with the requirements for a 16-valve engine.

Cylinder head

Essentially, the head is the cylinder block cover that covers the cylinders. It contains the upper parts of the combustion chambers, spark plugs, intake and exhaust ports, as well as the entire gas distribution mechanism. The VAZ 2107 cylinder head is a monolithic part cast from an aluminum alloy, but inside it there are channels where oil and coolant circulate.

The head is the housing for the timing mechanism

Are there any differences in the design of the cylinder head for the carburetor and injection engines of the VAZ 2107

The cylinder heads of the carburetor and injection engines of the “seven” are almost the same. The only difference is the shape of the intake channels. For the former it is round, for the latter it is oval. A manifold from a carburetor car without modifications will not be able to completely block the intake windows. Therefore, if there is a need to replace the head, this point should be taken into account.

The device of the cylinder head of the VAZ 2107

The main task of the cylinder head is to ensure the operation of the gas distribution mechanism. It serves as a housing for all its elements:

- camshaft assembly with “bed”;

- levers;

- valves;

- valve seats;

- guide bushings;

- oil seals;

- springs;

- "plates";

- "crackers";

- retaining rings;

- adjusting bolts with bushings, etc.

The valve mechanism is part of the cylinder head

Malfunctions when removal and installation of the cylinder head are required

There are a number of malfunctions due to which the cylinder head of the VAZ “six” has to be removed from the car for further diagnostics or repairs. Let's look at them in more detail.

Gasket burnt out

The following signs indicate that the cylinder head gasket has failed (burnt out or was punctured):

Video: Damage to the cylinder head gasket

Damage to the cylinder head mating plane

The following reasons can lead to the formation of defects in the mating surface of the block head:

Defects of this kind are eliminated by processing the plane, with preliminary dismantling of the head.

Cracks in the block head

The main reasons that lead to the appearance of cracks in the cylinder head are overheating of the engine, as well as improper tightening of the mounting bolts during installation. Depending on the nature of the damage, the head can be repaired using argon welding. In case of serious defects, the cylinder head will have to be replaced.

Wear of guide bushings

With a high mileage of the engine or the use of low-quality engine oil, the valve guides wear out, which leads to a violation of the tightness between the seat and the valve plate. The main sign of such a malfunction is increased oil consumption, as well as the appearance of bluish smoke from the exhaust pipe. The problem is resolved by replacing the guide bushings.

Valve seat wear

Valve seats can wear out for several reasons:

The malfunction can be solved by straightening or replacing the saddles. In addition, the ignition system must be checked.

Broken spark plug

Quite rarely, but it happens that as a result of over-tightening the spark plug, a part breaks off on the thread in the spark plug hole. To remove the remains of the cylinder head spark plug element, you need to dismantle the threaded part and unscrew it using available tools.

CPG malfunctions

If there is a problem with the cylinder-piston group of the engine, the cylinder head also has to be removed. The most common failures of the CPG include:

If the cylinders are worn excessively, the engine is completely disassembled to replace the piston group, as well as to bore the internal cavity of the cylinders on a machine. As for the damage to the pistons themselves, although they rarely burn out. All this leads to the need to dismantle the cylinder head and replace faulty parts. If the rings are stuck, normal operation of the cylinder and the engine as a whole becomes impossible.

Sequence of repair work

Installing the cylinder head

Also need a new head gasket and valve cover gasket. Having all this, you can begin the renovation. The sequence of actions for repairs is as follows:

- The car is placed in the garage, the gearbox is set to neutral, and chocks are placed under the rear wheels. The first thing that is done after setting up the car is to de-energize the on-board network by disconnecting the “-” terminal from the battery.

- The pressure in the fuel system is relieved. For this purpose, there is a control valve on the fuel rail in the form of a regular tire valve. You need to place a container under this valve and clamp the spool. When the pressure is released, gasoline will leak out. You will also need to drain the coolant using drain plugs.

- On the engine, you need to set the piston of the 1st cylinder to the TDC position. To do this, remove the protective cover of the timing belt and rotate the crankshaft until the marks on the pulley, camshaft and flywheel match.

- The next step is to remove the valve covers. To do this, all pipes, the throttle drive rod, the accelerator drive bracket and the valve cover mounting nuts are disconnected from the cover fittings.

- The exhaust pipe of the exhaust gas removal system is disconnected from the exhaust manifold. These works are carried out under the car.

- The wiring is disconnected from the mass flow sensor, the air supply pipe to the throttle assembly is removed, after which it is completely dismantled along with the air filter housing.

- Then you need to disconnect from the head all the elements suitable for the head - pipes of the cooling system of the throttle assembly, vacuum booster, throttle drive linkage, ground wires, bracket for the exhaust manifold supply pipe.

- The intake manifold strut mounts are also loosened, and the struts themselves are removed. Next, the wiring is disconnected from - oil pressure sensors, coolant temperature and throttle position sensors, XX regulator, injectors, high-voltage wires from spark plugs.

- Then the timing belt is removed. Before this, you need to once again check the alignment of the marks on the crankshaft pulley and the timing gear. After this, the belt tension is loosened and it is removed from the timing gear.

- To remove the camshaft gear, you will need to fix it through the technological holes and unscrew the fastening bolt. You need to remove it from the shaft carefully so as not to lose the key. After this, you will need to remove the rear cover, located behind the removed gear, from the head and block.

- The cooling system pipes are removed from the head along with the thermostat from the head, as well as the rest of the wiring. The fuel supply and drain pipes are also disconnected.

- All that remains is to unscrew the head bolts. But to do this, they must first be weakened, and in a strictly defined order. And only after relaxation do they completely unscrew. If disassembly is done correctly, after removing the bolts, you can remove the head and remove the damaged gasket. At this point, the first part of the repair is considered complete.

Installing a new camshaft

In order to install a new timing shaft, you will need the same tools as to dismantle it. The installation procedure is as follows:

Be sure to lubricate the surfaces of the cams, bearing journals and bearings with engine oil. We install the camshaft in the “bed”. Using a 10 mm wrench, tighten the bolts of the thrust flange. We check how the shaft rotates. It should turn easily around its axis. We set the shaft to such a position that its pin would coincide with the hole on the fixing flange. We install the bed on the studs, screw on the nuts, and tighten them

It is important to follow the established procedure. Tightening torque - within 18.3–22.6 Nm

The nuts are tightened using a torque wrench with a torque of 18.3–22.6 Nm

We do not install the valve cover and camshaft sprocket in place, since it will still be necessary to set the valve timing.