One of the most overlooked devices in a car engine is the so-called “check valve”. It is also called a bypass valve or fuel pressure regulator.

How critical is it, does it need to be checked and how often does it need to be done? I must say, it is quite difficult to find a car service that would have equipment for conducting “fuel tests”. As a rule, they do it the old-fashioned way: they pinch the “return” or disconnect it and look at the thickness of the fuel stream from the hose.

The only thing that can be determined by such a “test” is that the fuel pump somehow works. It is, as you understand, impossible to measure the pressure created by the pump using old-fashioned tests. Well, perhaps only in the case when no fuel comes from the return line at all or barely drips.

Where is the fuel check valve located?

Let's find out where the fuel system valve of various cars is located.

- In power plants with an injector, it can be installed in the gasoline pump housing.

- Mounted on the fuel frame or installed directly in the fuel line. This is the space between the gas tank and the fuel injectors.

On diesel power plants, the mechanical structure is hidden between the fuel injection pump and the low-pressure pump. This arrangement of the product allows you to create a stable pressure at the outlet of the high-pressure pump.

The system has proven itself well:

- on a domestic truck: KAMAZ 740;

- Czech clubfoot Tatra;

- on Mana;

- and Renault Magnum.

In diesel installations where a pre-start heating system is provided, the fuel check valve is located in front of the heating system. A typical example is the same KamAZ or Magirus trucks operating in the Far North.

On domestic passenger cars, such as the VAZ 2110 and 2114 with sixteen valves, the mechanical structure is located in the gasoline pump and on the fuel frame. This is analogous to installing a diesel engine.

Today, old carburetor cars with rear-wheel drive still run on our roads: eights and nines (VAZ 2108 and VAZ 2109). On them, the role of the return device is assigned directly to the gasoline pump.

It stands on the cylinder block and prevents the passage of fuel in the opposite direction: into the fuel tank.

The fuel supply system of automobile gasoline and diesel power units is a technically complex device that should not be approached without knowledge. And even more so, try to carry out technical treatment on your own.

The check valve plays an important role in the regular supply of fuel. Let's focus our attention on its design and installation in the car. Let's look at the problems and characteristic signs of a malfunction. We will also decide on ways to check it.

To the last drop: how to check the fuel pump yourself?

The death of a fuel pump is always sad. But it's not always obvious. Symptoms of its wear or failure are quite numerous and varied, so it is not always clear whether it is to blame for the abnormal behavior of the machine or not. Moreover, some of its malfunctions lead to symptoms that are characteristic of leaking injectors, misfires, low compression, and much more. Therefore, diagnosing a fuel pump is not only entertaining, but also often necessary. Especially if nothing else helps.

Very briefly about the symptoms

Fortunately, most engine problems can now be diagnosed using a scanner. This makes life much easier for motorists and car service workers, if only for the reason that misfires or sensor malfunctions do not need to be looked for using complex conclusions and step-by-step replacement of everything. There are exceptions, of course, and no one excludes working with the brain, but still. But what to do if all the electronic systems are in order, there are no errors, but the car is desperately stupid? This is where they usually remember that there is such a part - a fuel pump. And you have to check it the old fashioned way - with your hands, and not with a laptop.

I will not describe in detail the symptoms of the breakdown: a lot has already been said about this. In short: failures, decreased dynamics, inability to start the engine, sometimes the engine tries to stall when turning, squeals and squeaks in the area of the same fuel pump. This could be the end of the symptoms, but the fuel pump has another malfunction: the valve that holds the pressure in the rail may stop working. In this case, the symptoms of the malfunction are very similar to those that are often tried to be attributed to a leaking injector: the engine does not start immediately, you have to turn the starter for quite a long time. This rarely happens, but we’ll still talk a little about this situation below. Now let's move on directly to the diagnosis. So, the engine does not start, there are no ignition errors. Where do we start?

Mindfulness itself

No matter how complex the car may be, there can be only two breakdowns that prevent the engine from starting: no gasoline and no spark. If there is a spark, you need to look for at what stage the gasoline disappears. And first you can make sure that it is definitely not there.

If access to the candles is easy, then the most basic action will be to unscrew these same candles. If they are dry, something is wrong with the fuel supply. So, we are going in the right direction.

When you turn on the ignition, we listen carefully: after turning on the ignition and before turning on the starter, you can usually hear a characteristic “zh-zh-zh” in the rear for a couple of seconds. It is the pump in the gas tank that turns on. If this “w-w-w” has always been heard, but now it’s not, it means the pump is not turning on. We think why.

First, we check two basic things: the alarm and the fuse. Most anti-theft systems provide for turning off the fuel pump. Therefore, you need to make sure that the alarm, immobilizer and everything else that was once installed on the car worked. If all this wonderful electronics is working properly, we check the fuse (we open the fuse diagram, look for the right one and make sure that it is intact). You can also check the relay, but it’s difficult to do without a multimeter. Therefore, you can skip this stage for now: the relay is usually intact anyway, and the reason is somewhere further.

Reference

Many people know that the fuel system valve aggregates:

- With carburetor power units running on gasoline.

- With engines equipped with an injector.

- With power supply systems for power plants, where diesel fuel is used as fuel.

There is nothing complicated about the mechanical design. This is a ball-type device with a seat, which is made of soft metal, with the most accurate balancing. Fuel flows freely through the fuel valve in one direction. The pressure that is created prevents gasoline or diesel fuel from flowing back into the fuel tank, since the non-demountable structure is locked.

Despite its simplicity, the device can cause a lot of trouble for a novice and an experienced driver. Therefore, it is necessary to know its possible vagaries and ways to eliminate breakdowns. But first of all, understand where the mechanical structure is installed.

“The concept of a fuel system check valve should not be confused with a pressure reducing device.”

Lada Priora Hatchback ✤ℨℰȴеℋÅЯ МОШℵИЯ!!! › Logbook › The main thing about the pressure in the fuel system.

Fuel pressure in the car system is one of the important parameters that is used in engine diagnostics. The behavior of the car in various operating modes depends on the pressure. How to measure the pressure in the fuel system with your own hands

For example, buy a device to check fuel pressure. A kit with a fuel pressure gauge, adapter and drain will cost you 1400-1500 rubles. Pay 300-400 rubles to the service station and take measurements there. You can also measure the pressure in the fuel system with an air pressure gauge, which is used to measure tire pressure. Here at this point in more detail. Let's take the example of the tenth VAZ 2110 family. Otherwise, the procedure is similar to any other car. The peculiarity of pressure gauges is that their initial scale values have relative inaccuracy. What does it mean. If the air pressure gauge has a scale of up to 16-20 atm (when the measurement limit for fuel is 5-7 atm), then pressure measurements will not be accurate due to this error, which will fall within the initial values of the instrument scale. Therefore, it is correct to check the fuel pressure with a fuel pressure gauge with a limit of 6-7 atm.

We take a pressure gauge and wrap a piece of foam (plumbing flax) under the pipe and put on an oxygen hose with an internal diameter of 9 mm. Secure with clamps. Place a rag on the generator (so as not to start a fire under the hood). Unscrew the plastic cap on the fuel rail.

put the hose on the pressure gauge

Under the cap there is a hole with a nipple. Unscrew it from the wheel cap. Due to the residual pressure in the rail after removing the nipple, gasoline will splash out.

If desired, you can relieve the pressure in the vehicle's fuel system. To do this, you need to remove the fuel pump fuse and wait until the running car stalls.

We put the second end of the hose on the ramp hole and secure it with a clamp. We remove the rag from the generator and start the engine. Don’t forget to cover the generator with a rag again before removing the hose from the ramp. That's it, now you know how to check the pressure in the fuel system in the field.

attach the hose with pressure gauge to the fitting

check the fuel pressure in the system

By the way, instead of clamps, you can use the classic adjusting bolt bushing. It screws perfectly onto the ramp fitting. To seal, we put a suitable rubber ring on the fitting. On the other side of the bushing we solder a fitting onto which we put a hose with a pressure gauge.

What pressure should be in the VAZ 2110 fuel system? 2.8–3.2 bar (2.8–3.2 atm)

How to measure fuel pressure in a system where there is no return? On VAZ 2110 with 1.6 liter engines, the pressure in the ramp is constant and amounts to 3.6-4.0 atm. Otherwise, the measurement technique is similar. Alternative ways:

It is measured at the outlet fitting of the fuel pump module - this is the one with one tube. You will need a flexible gas-resistant hose with an internal diameter of about 8 mm and a pressure gauge (you need to remove the tube and put on a hose with a pressure gauge instead). The pressure should be 5-7 atm. Close the return line, as is done on an internal combustion engine with a drain ramp, but you must turn it off again at the fuel pump itself. We pull off the second hose (double) and insert a plug into the removed hose, made, for example, from an old fuel filter (saw off the nipple from it and plug it). A single hose must be put on the pump fitting, and now the measurement must be made at the fuel rail. According to the power system diagram, everything will be clear.

Draw your attention to.

If the fuel check valve loses its seal, gasoline flows back into the tank without permission. In this case, starting the power unit is possible with manual pumping.

If starting the engine was difficult, craftsmen installed (embedded) a mechanical structure into the power system, closer to the carburetor.

This made it possible to easily start the engine even at negative t0. An example is the old Opel (Cadet) and 323 Mazda, which have seen time in their lives.

Analogs

There are analogues on sale from various manufacturers - domestic and Chinese. It is possible to purchase a replacement chain separately or as a complete set. The price depends on the origin of the parts and the place of purchase. It is advisable to give preference to well-established auto shops.

| Name | vendor code | Price |

| Olmi | 406.1006040-20 | From 1,300 rubles |

| Miles | 040900100011801 | From 1,150 rubles |

| Ditton | 509105011801 | From 1 117 |

Check valve problems

For what reason does the fuel system valve fail? Let's figure it out together. Today there are three obvious reasons for refusal to work.

- Installation of low-quality Chinese goods that quickly fail. Basically, these are fakes for a certain brand.

- The second reason is the natural wear and tear of the product. In this case, either the spring or the membrane fails. Note that the valve itself rarely fails.

- Another problem for a non-removable mechanical structure is low-quality fuel.

Having decided on possible problems, let's move on to the signs indicating a problem.

conclusions

The fuel system check valve is an important component of this system, the failure of which can cause a lot of problems for the driver. This will be especially painful during movement. Therefore, it is worth using only high-quality fuel, and at the slightest sign of a malfunction, which were listed above, diagnosing the fuel system.

After all, the problem may lie not only in the valve, but also in other small parts. Diagnostics at a service station almost always reveals such faults, so do not forget about timely maintenance of the car, even if everything seems to be in good order.

Characteristic symptoms of a check valve malfunction

It could be:

- unexpected change in speed of the power unit at startup or while driving;

- The engine can be started by pressing the accelerator pedal. Although before this the power unit was driven by a starter;

- Unstable engine operation at low or idle speeds;

- loss of fuel that escapes through the supply or return pipes. In this case, the sealing of the fuel hoses is not broken.

In our case, the non-removable mechanical structure can be easily repaired. This is on the one hand. On the other hand, the problem cannot be determined by scanning. Next, let's look at options for checking the device.

Design and principle of operation

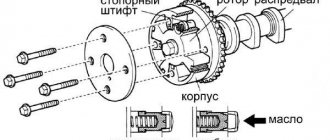

The fuel regulator consists of the following elements:

- Frame. It is made of metal and has a high tightness necessary to prevent fuel leakage and loss of pressure.

- Membrane (diaphragm). Reacts to excess pressure and opens the drain line.

- Check valve. Located at the entrance.

- Spring. Places additional pressure on the valve diaphragm.

- Fittings for fastening fuel inlet and drain lines.

- Seals. Ensure the tightness of the system at the inlet and outlet.

The operating principle of a mechanical fuel volume regulator is simple. The membrane divides the internal space of the housing into two chambers (fuel and air). The first is supplied with fuel using a pump, which exerts some pressure on the membrane. The check valve prevents fuel from returning to the intake manifold, which allows the pressure necessary for engine operation to be created.

The classic valve design is a mechanical unit whose operation is based on pressure differences. In common rail systems, instead of a fuel regulator, a solenoid valve controlled by the engine ECU can be used.

On the reverse side of the membrane (in the second chamber) there is a spring that locks the regulator. This chamber is connected with a hose to the intake manifold, in which, under various modes, a certain level of air rarefaction is formed, which also affects the diaphragm. At the moment when the fuel pressure exceeds the total effect of the spring and vacuum in the intake manifold, the valve opens, dumping part of the fuel.

How can you check a check valve?

You can find out what condition the fuel valve is in as follows.

Using a pressure gauge, check the pressure. It should be within 3 kg per cm2. These are figures for passenger cars.

You can find out how the device works by pinching the “return” fuel hoses. If the permanent mechanical structure is in order, the pressure should increase.

For your information.

This method is only for cars that have rubber hoses installed.

Self-diagnosis can be carried out without using a pressure gauge. This concerns the problem of unstable operation of the internal combustion engine (ICE) and poor acceleration. Having pinched the rubber hose that moves the fuel in the opposite direction, you need to pay attention to the operation of the engine. If the speed increases and the engine cylinders operate as planned, then the check valve is faulty.

Examination

If you find characteristic symptoms, first we recommend that you make sure that the problem with the car is related specifically to this sensor.

The inspection is carried out as follows:

- At the end of the ramp block there is a fitting designed to check the pressure indicator;

- It is covered with a plug that you need to unscrew;

- At the bottom of this plug there is a ring that compensates for the distance;

- If there are signs of damage or defects on the ring, be sure to replace it with a new one;

- Now take the cap from the tire and unscrew the spool with its back. It is located in the middle of the fitting;

- Now a flexible hose from the measuring device is connected to the fitting. You can use a regular pressure gauge that you use when inflating tires;

- Clamp the hose with a clamp and start checking;

- Turn on idle, since this is where the vacuum is the lowest and the fuel pressure is the highest;

- Start the engine. The device should show 2.9-3.3 units;

- Now check the readings, only without the vacuum hose;

- Having removed it, the pressure gauge should give about 0.2-0.8 units. If no changes occur, then the regulator is definitely out of order and needs to be replaced.

Article on the topic: We remove, check (3 methods) and replace the diode bridge on a VAZ 2114

RDT Gazelle

Welcome to ChipTuner Forum.

Theme Options

Hello everyone) tell me how an RDT machine should work correctly (Gazelle ZMZ 405 22 euros 2) I finally fixed it, it was working terribly due to the pressure of the pump, I changed it, it worked like clockwork. but when working all day in the evening it gave errors(

I checked the pressure: at idle the fuel pressure is 2.5 -2.6, when the throttle is opened (increasing rpm) the pressure rises to 3.

At idle, gasoline constantly flows from the return line, when you hold the gas pedal at 3 thousand rpm, gasoline flows a little less, and when you rev the gas at different speeds from 3 and above (without holding the pedal), gasoline stops flowing through the return line.

Does this mean the RTD is working or not?

There were simply errors: no signal from the crankshaft sensor (although the car starts without problems) Misfire in 1 cylinder Random multiple misfires Too rich mixture Too lean mixture Oxygen sensor to the converter, open signal circuit (although the chip is on all right)