The Niva family of cars differs from VAZ passenger cars in permanent all-wheel drive - they have two drive axles. In total, the VAZ SUV has three differentials in its transmission - one for each axle and another center differential.

1. Oil seal; 2. Thrust ring of the front bearing of the drive shaft; 3. Front bearing cover; 4. Front drive shaft bearing; 5. Transfer case front cover; 6. High gear; 7. Gear clutch hub; 8. Gear clutch; 9. Low gear; 10. Transfer case housing; 11. Rear drive shaft bearing; 12. Drive shaft; 13. Transfer case rear cover; 14. Intermediate shaft; 15. Rear intermediate shaft bearing; 16. Rear differential housing bearing; 17. Installation ring of the rear axle drive shaft bearing; 18. Rear axle drive shaft bearing; 19. Oil seal deflector; 20. Rear axle drive shaft flange; 21. Rear axle drive shaft; 22. Bearing thrust ring; 23. Differential housing; 24. Rear axle drive gear; 25. Satellite; 26. Axle of satellites; 27. Retaining ring of the satellite axis; 28. Spring washer; 29. Driven gear; 30. Differential housing bearing retaining ring; 31. Differential locking clutch; 32. Front axle drive shaft; 33. Front axle drive housing; 34. Retaining ring of the front axle drive shaft bearing; 35. Differential bearing spring washer; 36. Front differential housing bearing; 37. Driven gear of the speedometer drive; 38. Speedometer drive housing; 39. Front intermediate shaft bearing; 40. Gearbox; 41. Elastic coupling; 42. Constant velocity joint; 43. Transfer case; 44. Shims; 45. Transfer case suspension bracket; 46. Rear engine mount bracket.

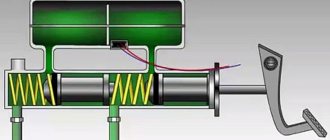

I. High gear engaged; II. Low gear engaged; III. Low gear is engaged, differential is locked.

The Niva transfer case is designed to distribute traction forces between axles, and operates on the principle of a 2-speed gearbox.

The device of the VAZ Niva transfer case

The transfer case is not present in all VAZ passenger cars, but only on cars with two drive axles. In the transmission, the transfer case (TC) is installed at the rear of the gearbox; a rear driveshaft is attached to its shank, which connects the transfer case to the rear axle. The front axle is also driven by the steering wheel; it is connected to the transfer case by a front driveshaft.

The reduction gear in the Republic of Kazakhstan is designed to obtain high torque, it is used to overcome difficult sections of the road, and helps to cope with off-road conditions. The VAZ Niva transfer case contains the following main parts:

- the body itself;

- front axle drive shaft;

- intermediate shaft;

- drive shaft;

- gears;

- bearings;

- differential housing;

- satellites;

- differential lock clutch;

- gear shift clutch;

- flanges (for connection to cardan shafts);

- oil seals;

- control levers.

Blocking

It is worth noting that on domestic SUVs the transfer case (including Chevrolet Niva) has a differential locking function. Thus, torque transmission can occur either symmetrically or asymmetrically, depending on the position of the shift lever in the cabin. To connect the front axle, a chain drive is used. This unit consists of gear links (driven and driven) and a drive chain. On modern SUVs, all-wheel drive is engaged automatically. But here the transfer transmission is made in the form of a bevel gearbox.

Transfer case Niva 21213

Model VAZ-21213 is an all-terrain passenger car with permanent all-wheel drive and differential lock. Brand 21213 is a restyled version of the first VAZ SUV, VAZ-2121. RK Niva 21213 has three gears:

- the first - with a gear ratio of 1.2;

- the second, lowered – with the number 2.135;

- neutral

21213 is equipped with 4-speed and 5-speed gearboxes, and when the first speed of the transfer case is turned on, the car operates in standard mode, the gear ratios in the transmission are from 5-speed. The checkpoints are as follows:

- 1 – 4,4;

- 2 – 2,52;

- 3 – 1,63;

- 4 – 1,2;

- 5 – 0,98.

When you turn on the second position of the transfer case lever (reverse position), the gear ratios change (lower):

- 1 – 7,83;

- 2 –4,48;

- 3 – 2,90;

- 4 – 2,14;

- 5 – 1,75.

On ordinary roads, the transfer case is always in first gear, the transfer case control lever (reduction gear) is pushed forward. The neutral gear of the RK disconnects the transmission, and in this position the car does not drive; there is also a neutral in the gearbox.

Motorists often ask the question: why is neutral gear needed in a transfer case? The neutral is used when connecting additional units to the transmission, for example, a mechanical winch; in this case, a power take-off must also be installed.

Differential lock on a Chevrolet Niva - Online auto workshop

A self-locking differential (popularly “self-locking”) is a device that automatically redistributes power flows from the difference in torque on the drive wheels, depending on their coefficient of adhesion to the road. In other words, a wheel that is hanging out or slipping will receive a minimal amount of torque. Is such a differential needed for Lada 4×4?

The Chevrolet Niva owes its good off-road characteristics to its predecessors - the VAZ2121, namely permanent all-wheel drive, with the possibility of forced differential locking. But before setting up the transfer case and using the gearshift levers correctly, you must first understand how this mechanism works and what happens during its operation.

The transmission of this type of car consists of several main components: cardan, gearbox, transfer case and axles. The main component in the bridge structure is the differential. If it were not there, the wheels would rotate at the same speed, which would lead to wheel slipping and excessive load on the axle. The presence of a differential allows you to avoid destruction of the axle due to the fact that when turning, torque is transmitted to one of the wheels.

The design itself provides for the transmission of torque to the wheel, which experiences less traction with the surface. Therefore, for example, a wheel that stands on ice or sand will spin faster than one that stands on asphalt.

The Niva design provides for the presence of three differentials. This is due to the presence of permanent all-wheel drive in the car. If the same force were transmitted to all wheels, then the car could only move in a straight line. But when turning, the forces between the wheels are distributed unevenly.

Also interesting: Construction and repair of the VAZ 2121 Niva transfer case

There are some SUV models that do not have a center differential installed, but they use other technical solutions, such as clutches or all-wheel drive is not permanent.

A differential is a device designed specifically to transmit the so-called torque from a car engine to its wheels using transmission elements. A free differential, installed on vehicles during assembly at the factory, cannot affect the other when one of the wheels slips.

Differential locking can help achieve different wheel speeds when necessary (for example, on poor, usually dirt roads). It increases torque on one of the wheels, usually the one with the best traction. To achieve this result, a self-locking differential is used. An alternative option could be a forced blocking method.

It is important to understand whether it is worth installing a self-locking differential on the Niva, what this will do for the car and how to carry out the installation of the device.

Return

All-wheel drive in the Niva is equipped for all 4 wheels, and the center differential is locked. The mechanism consists of a gearbox, a transfer case designed for 2 stages, and cardan shafts located in the front and rear of the machine. This also includes the front and rear axles.

When the engine starts to rotate, an impulse is sent to the gearbox and transfer case, after which the torque is distributed to the front and rear axles simultaneously. Afterwards, the gearboxes are activated, and behind them the front and rear wheels of the Niva begin to rotate. Torque causes 4 wheels to rotate at once, which is why it is called full torque. But the rear wheels still drive.

7 The cutouts of the segments on the diff housing tenon are not shown.

8 Extension lines should protrude beyond the dimension lines by 3.

After they pass, it necessarily turns off. These mechanisms are a compromise between hard locking and free-running differential operation. So, on the basis of such systems you can use both.

A self-locking differential is installed on the Niva to reduce tire wear. Driving in urban environments, on country roads and highways requires different speed limits.

That is why proper operation of the device is a guarantee of long-term trouble-free driving. It is a mistake to assume that the differential controls the load applied to the wheels in any road conditions.

The purpose of the differential (also called a self-locking differential) is to help the car overcome off-road conditions. Much here depends on the operation of the gearbox.

This mechanism is a kind of distributor of traction forces coming from the motor to the wheels. An important feature is that the latter have the ability to rotate at different speeds. The importance of having a differential mechanism is due to the fact that during turning maneuvers, the wheel located inside makes fewer revolutions when compared with the number of turns of the outer wheel.

In the absence of a differential mechanism, this would cause detrimental consequences, such as wear and damage, because the result would be the following: when turning, one wheel would be in a slip state, and the second would simply rub against the road surface. The design features of the Niva transmission provide for the presence of 3 differentials. They are located in each of the bridges and in the transfer mechanism.

When the car moves on a flat road and in a straight line with differentials, the traction force is divided equally between all 4 wheels. If there is insufficient adhesion of the wheels to the surface or slipping occurs, the differentials will redistribute the load on the slipping and sliding wheel so that the first receives more force, and the second, accordingly, less.

We have already mentioned UAZ. Despite many similarities, it should be understood that the VAZ’s all-wheel drive is made in the “pat-time” style. This means that when connected, the axes are firmly connected to each other, and rotation occurs at the same speeds. This device imposes some restrictions on the use of all-wheel drive - it can only be used in cases where road conditions allow slipping. In cases with hard asphalt roads and highways, it is recommended to switch the car to single-drive mode.

Sometimes you can come across a misconception about why a small handle is needed next to the shift lever on a Niva. Some car owners believe that it is needed to connect front-wheel drive. However, the front-wheel drive of this car is permanently connected. As is the rear one. Cars of the Niva family have permanent all-wheel drive. The handle actually serves to switch the operating modes of the differential of the transfer mechanism.

In the “forward” position, the differential operates as usual, but if you move it back, the differential is locked, and the forces from the motor are applied to the differentials of the axles, which makes the drive more rigid. It is worth noting that there are also special types of locks for front and rear axles.

In theory, when used in conditions where the car is stuck, it will be able to overcome the obstacle if there is sufficient traction on at least one wheel. In this case, it is better to lock the differential before overcoming an obstacle, but never after entering an area that is difficult to overcome. This application of locking will avoid wear and damage to the transmission.

To lock the differential on the Niva, the manufacturer has provided a clutch for the locker. When forced locking is turned on, the wheels become interconnected and rotate in the same mode. When the inter-axle lock is activated, the axles located at the front and rear interact and distribute traction to all wheels. This mechanism is easy to use, which is confirmed by the unique cross-country ability of the Chevrolet Niva.

This mechanism is a kind of distributor of traction forces coming from the motor to the wheels. An important feature is that the latter have the ability to rotate at different speeds. The importance of having a differential mechanism is due to the fact that during turning maneuvers, the wheel located inside makes fewer revolutions when compared with the number of turns of the outer wheel.

If manufacturers decided not to include a differential in the transfer case structure, the result would be frequent tire wear. This would have been a blessing for tire manufacturers, but the developers turned out to be smarter. In addition, the differential reduces the load on the axle.

Malfunctions of VAZ transfer cases

The transfer case on the Niva is a fairly reliable unit; problems with repairs in the mechanism itself arise mainly due to insufficient oil level in the valve - if for some reason the oil leaks out, intensive wear of all parts occurs. Among the frequently occurring malfunctions are:

- vibration in the body at various speeds when the car is moving;

- vibration when the vehicle starts moving;

- noise in the transfer case when the car is slipping or turning;

- difficult upshift or downshift, difficult engagement of the lock.

Possible problems

Harsh operation and insufficient attention to how to use the transfer case on the Niva 2121 lead to the appearance of:

- Vibrations in the body while driving

- Vibrations at start

- Gula

- Noise when maneuvering

- Tight switching modes

Experience shows that the culprits are: insufficient oil level, incorrect centering of the steering wheel, loosening of the support fastenings and damage to the rubber bands. An additional influence is exerted by the condition of the cardan and the engine itself.

Vibration

Vibration in the body is the main “disease” of the Niva; it often occurs due to improper alignment of the transfer case. Most often, vibration occurs on VAZ 21213/21214 cars, since the transfer case is mounted only on two supports on the sides of the body; on the Chevrolet Niva, the transfer case is already installed on three supports. But before you start adjusting the position of the transfer case, you should check the condition of other parts of the chassis - vibration can occur for other reasons:

- driveshafts are poorly secured;

- wheels are not balanced;

- there is play in the cardan crosspieces (vibration is especially affected by play in the rear driveshaft crosspieces);

- The vibration comes from the engine itself.

Vibration when starting off on a Niva can also occur for the following reasons:

- the mounting supports of the transfer case have become loose;

- The rubber on the RK supports themselves broke.

Modified versions

The Niva's standard transmission, for all its advantages, often causes uncomfortable noise in the cabin. This is generally related to the design, but using engineering developments, you can modernize it and make the car much quieter.

This approach has already been applied in VAZ-21213 cars; as a result, even at a speed of 100 km/h you don’t feel any unpleasant noise, you can talk calmly and hear your interlocutor without effort. For these purposes, a number of modernization methods have been used: from unloading the floor near the transfer case and manual transmission mounts, reducing the load on shaft bearings to smoothing out peak torques under conditions of increasing loads on the transmission.

And also interesting: Air intake for Niva 21214 - installation on the hood with your own hands Video | TuningKod

The noise in the modernized Niva transmission is comparable to that of a Zhiguli. It becomes more comfortable to be in the car when driving off-road. Upgrade costs are negligible; modification requires only the master's understanding of the design itself and a little time.

Transfer case alignment

Correct installation of the transfer case can be done in several ways. Most often in auto repair shops, repairmen use the following method:

- hang the car on a lift;

- loosen the transfer case;

- start the engine;

- engage the gear and accelerate the car according to the speedometer to the speed at which vibration occurs (often it occurs at speeds from 40 to 80 km/h);

- without using the brakes, reduce the engine speed, then turn off the ignition.

The transfer case itself is centered in place, all that remains is to tighten the fastenings of the supports.

You can also adjust the position of the RC using a wire; we do it as follows:

- loosen all four fastenings of the transfer case supports;

- fasten one end of the wire to the rubber coupling of the propeller shaft;

- we attach another piece of wire to the CV joint, bring the other ends of the wire to each other;

- rotate the shaft; if the transfer case is not centered, the ends of the wire will diverge during rotation;

- the task comes down to installing the transfer case using the selection method so that the ends of the wire practically do not diverge from each other in any position when turning the shaft.

Idle move

The Chevrolet Niva idle speed sensor ensures the supply of air to the engine during idling. When a signal is received by the ECU, the sensor moves the valve, changing the flow hole in the air valve. If it fails, it will not be possible to repair it, since it has a non-demountable design.

To replace it, you need to prepare a thirteen socket wrench, pliers and a Phillips screwdriver and do the following:

- Unscrew the mounting bolts and remove the housing from the throttle valve

- Disconnect the wiring connector of the engine regulator

- Unscrew a couple of screws on the throttle body

- Removing the regulator

- Remove the O-ring from the existing hole.

To summarize, we can conclude that the failure of any of the above elements can seriously affect the operation of the car, therefore, in the event of a malfunction, you need to replace a new part as soon as possible. All replacement work can be carried out independently.

The transfer case is used to change the amount of torque and distribute it between the front and rear axles. The box has two gears with ratios of 1.20 and 2.135. The front and rear axles are constantly driven and connected by a center differential, dividing the torque equally. To increase the vehicle's cross-country ability, the differential can be blocked, and the front and rear drive shafts become rigidly connected to each other (their rotation speeds are equal).

The transfer case is attached to the body floor on three brackets - rubber-metal supports. The transfer case housing parts are cast from aluminum alloy and connected to each other with studs and nuts. There is a hatch in the upper part of the crankcase, closed with a stamped steel cover. The front cover is centered on the crankcase using two locating pins.

There are cardboard gaskets between the covers and the crankcase (during repairs, a sealant gasket can be used instead). All shafts are sealed with rubber-metal seals (oil seals). The speed sensor drive shaft, gear shift fork rods and differential locks are sealed with rubber rings. There are two holes in the front cover - a filler hole (also known as a control hole) and a drain hole.

Transfer case with drive: 1 — differential lock clutch fork; 2 — differential lock fork rod; 3 — protective cover of the rod; 4 — lock washer; 5 — bushing of the lever axis; 6 — lever axis; 7 — differential lock lever; 8 — fork locking bolt; 9 — switch for the differential lock warning lamp;

10 — gear shift fork rod; 11 — differential lock lever rod; 12 — control lever bracket fork; 13 — control lever; 14 — gear clutch fork; 15 — spacer sleeve; 16 — spring and locking ball; 17 — clamp spring bushing; 18 — drive shaft flange;

https://www.youtube.com/watch?v=ytadvertiseru

19 — front cover; 20 — drive shaft oil seal; 21 — thrust ring of the bearing; 22 — front bearing of the drive shaft; 23 — high gear; 24 — gear clutch; 25 — transfer case housing; 26 — low gear; 27 — rear bearing of the drive shaft; 28 — adjusting ring of the rear bearing of the drive shaft;

29 — drive shaft; 30 - bushing; 31 — hub; 32 — back cover; 33 — rear bearing of the intermediate shaft; 34 — intermediate shaft; 35 — rear differential bearing; 36 — rear axle drive shaft bearing; 37 - flange; 38 — rear axle drive shaft oil seal; 39 — rear differential housing;

40 — gear support washer; 41 — rear axle drive gear; 42 — satellite axis; 43 — retaining ring; 44 — spring washer; 45 — side suspension bracket; 46 — satellite thrust washer; 47 — front axle drive housing; 48 — satellite; 49 — differential driven gear; 50 — front differential housing;

51 — retaining ring; 52 — spring washer; 53 — front bearing of the differential housing; 54 — differential lock clutch; 55 — installation ring of the front differential bearing; 56 — oil deflector; 57 — front axle drive shaft oil seal; 58 — front axle drive shaft bearing;

The drive shaft is mounted on two ball bearings, the outer rings of which are located in the sockets of the front cover and crankcase. The front bearing inner race is sandwiched between the shaft shoulder and the thrust ring by a self-locking shaft flange nut. The rear bearing inner race is sandwiched between the shaft shoulder and a thrust washer located under the shaft rear end nut.

Also interesting: Colors that previously existed for the Chevrolet Niva

The nut is locked by pressing its edge into the grooves on the shaft. The drive shaft is secured against axial displacement by an adjusting ring in a groove on the outer ring of the rear bearing, sandwiched between the crankcase and the rear cover. There are two drive gears on the drive shaft. The front (large) is the highest gear; it rotates freely on a heat-treated shaft journal.

Rear (smaller) - lowest gear, rotates freely on a heat-treated bushing mounted on the shaft with tension. The gears have two crowns. The helical (large) rings are in constant mesh with the corresponding gears of the intermediate shaft, and the gear shift clutch is connected to the spur (small) rings when the gear is engaged.

View of the front side of the transfer case: 1 - right suspension bracket; 2 - filler plug; 3 - intermediate shaft; 4 — speed sensor; 5 — speed sensor drive housing; 6 — front driveshaft; 7 — front axle drive housing cover; 8 — left suspension bracket; 9 — rear propeller shaft; 10 — front cover of the transfer case; 11 — transfer case housing; 12 — drain plug.

Eliminate vibration with additional fasteners

Installing the third support of the transfer case on VAZ 21213/21214 vehicles allows you to reduce the level of vibration of the transfer case; with this support it is easier to center the transfer case. The part can be purchased at auto stores or made yourself. The finished product comes with three long studs (for model 2121); to install the third support on this machine, you will need to unscrew the short studs from the transfer case housing and install new studs from the kit. We carry out repairs as follows:

- dismantle the front passenger seat in the cabin;

- remove the floor tunnel lining;

- in the cabin we move aside the carpet covering the body amplifier (in front of the handbrake lever);

- remove the transfer case (alternatively, you can simply hang it up, but removing the third support makes it easier to install);

- We attach the bracket of the new support to the body of the RC;

- we install the transfer case in place, center it in the optimal position, and fasten the side supports;

- we combine the third support with the body, drill two holes in the bottom;

- Using washers, bolts and nuts (from the kit) we attach the support to the bottom of the body.

Vibration is eliminated more effectively by installing a subframe under the transfer case. You can also make such a device yourself or buy a finished product at a car store.

In order to install the subframe, the transfer case must be removed. It is more convenient to carry out such work in a pit; we carry out repairs as follows:

- leave the car in neutral gear;

- disconnect the propeller shaft from the transfer case, it is advisable to mark the driveshaft flange and the drive shaft so that during installation, align the driveshaft according to the marks - this way, the occurrence of unnecessary vibrations is eliminated;

- dismantle the muffler mounting bracket;

- remove the gearbox traverse;

- jack up the transfer case, remove the side fastenings of the transfer case;

- We treat the places where the subframe fits to the body with Movil;

- place the subframe on the gearbox studs;

- we mark the attachment points of the subframe on the side members, drill holes, attach bolts to the body;

- we tighten all fastenings, except for the transfer case supports themselves;

- we perform alignment of the steering wheel;

- Finally tighten the transfer case supports.

It should be noted that installing an additional support or subframe on the steering wheel does not always lead to the desired effect; in some cases, vibration only increases.

Nivov transmission units

The legendary Niva is an all-wheel drive vehicle. This ensures unprecedented road holding and reliability comparable to expensive high-performance cars. With the exception of updated versions under the Chevrolet brand, the traditional Niva has always had a rather modest design, but this did not prevent it from being the undisputed leader among car owners who prefer high-end car platforms.

What distinguishes the Niva's chassis from other all-wheel drive vehicles is the transmission of torque to two axles at once without disabling the axles, which significantly affects cross-country ability while simultaneously reducing the influence of critical loads on the transmission. This same quality makes this legendary Russian SUV very uneconomical in terms of fuel consumption.

The developed Niva transmission turned out to be so successful and efficient that it later became a prototype for the Vitara. This made the new model more adaptable to difficult roads. Niva transmission units can easily meet the requirements of any engine up to 2 liters, so if you want to upgrade, think about the fact that each car has its own capabilities. Many advantages are due precisely to the circuit and design of the transmission.

Niva transmission and its components:

- front-wheel drive;

- front axle;

- wheel grip;

- manual transmission;

- driveshaft (front);

- shaft (intermediate);

- transfer case;

- shift lever;

- center differential and locking lever;

- wheel differentials;

- driveshaft (rear);

- rear axle;

- rear drive.

The design implies the following states:

- unlocked differential;

- locked differential;

- low gear when engaged;

- neutral position;

- top gear engaged.

The features of the Nivov transmission include the presence of a center differential that connects the rear and front axles. As a result, the wheels can rotate not only at different angles, but also at different angular speeds, which significantly affects controllability in impassable roads.

The key difference between the Niva’s center differential is the ability to lock when driveshafts rotate with the same characteristics. The center differential is manually locked only in difficult terrain conditions, when you need to overcome a large hole, rut or snow drift without slipping.

In practice, mechanical locking, although somewhat inconvenient, turns out to be better than the modern electromagnetic clutch used for these purposes. For example, the Renault Duster is not so easy to cope with the task in harsh off-road conditions, since the digital control unit can provide limited torque transmission. However, this effect will not be observed in a Niva with a mechanical lock.

Leaving the center differential locked will not only cause increased wear, but will also significantly reduce the vehicle's handling. The activated differential lock mode will be indicated by a lit indicator on the Niva dashboard. Please note that locking will not prevent one wheel from losing traction.

To overcome difficult areas, the transmission allows the use of a low gear with a high gear ratio (2.135); in the highest gear, the parameter is 1.2 and is intended for driving in normal conditions. The transfer case indicates different high and low gear modes. The lower one is turned on before entering a snowy area, unsteady soils, hills, and when a towed load is connected.

Some drivers master the skill of shifting gears at speeds of 30-35 km/h. Otherwise, you will have to stop the car and perform the operation in the parking lot.

Please note that Niva requires a competent approach to the selection of tires, the quality of which can affect the degree of wear of the transmission in just one season. The tires must be the same in terms of wear and, of course, in size. Different characteristics will lead to increased load on the transmission and slipping in low gear, and during normal driving will increase wear on the differentials.

1, 3 – Front wheel drive; 2 – front axle; 4 – clutch; 5 – gearbox; 6 – front driveshaft; 7 – intermediate shaft; 8 – transfer case; 9 – transfer case gear shift lever; 10 – differential lock lever;

11 – rear propeller shaft; 12 – rear axle; I – differential unlocked; II – differential locked; III – low gear engaged; IV – neutral position; V – high gear engaged

Transmission Specifications

The Niva car is all-wheel drive, i.e. All wheels are driven. All-wheel drive is permanent: torque from the engine is always transmitted to both axles at once (the axles are not disabled). This scheme increases the vehicle’s cross-country ability, while simultaneously reducing the load on the transmission units, but slightly increases fuel consumption.

The front and rear axles are connected through a center differential, allowing the front and rear wheels to rotate at different angular speeds depending on the trajectory and driving conditions. The center differential is located in the transfer case and is similar to the cross-axle differentials located in the front and rear axles.

However, unlike them, the center differential can be forcibly locked (the locking lever is located on the floor tunnel). In this case, the front and rear driveshafts become rigidly connected to each other and rotate at the same frequency. This significantly increases the vehicle’s maneuverability (on slippery slopes, in mud, snow, etc.

), but worsens handling and increases wear on transmission parts and tires on surfaces with good grip. Therefore, the differential lock can only be used to overcome difficult areas and at low speeds. A warning lamp on the instrument panel serves to warn the driver that the locking mode is on.

And also interesting: Which cardan is better to install on a Niva (Chevrolet, 21213/4, etc.) » EXPERT OPINION

You can engage the differential lock while the car is moving, if the wheels do not slip. Locking the center differential does not relieve the car from the danger of “diagonal hanging”, when one of the wheels on each axle loses traction with the ground - in this case, pour soil under the suspended wheels or dig it under the others.

To increase the torque supplied to the wheels, a low gear in the transfer case is used, its gear ratio is 2.135. The highest gear, intended for normal driving conditions, has a gear ratio of 1.20. Thus, the driver can use one of two rows of gear ratios - with a high or low gear in the transfer case.

The total gear ratios of the “top” row (from 1st to 5th gear) are 4.40; 2.52; 1.63; 1.20; 0.98, “lower” – 7.82; 4.47; 2.90; 2.13; 1.75. The low gear in the transfer case is switched on before overcoming snowy, sandy areas, steep climbs, when towing loads, etc., when there is a lack of engine traction or for driving at very low speeds.

It is necessary to engage a low gear in the transfer case in advance, with the car stationary, since the gear shift clutch does not have synchronizers. With some skill, it is possible to engage the highest gear even when driving at a speed no higher than 30–35 km/h, however, if possible, it is better to reduce the speed or stop.

A vehicle with permanent all-wheel drive places special demands on tires. They should be the same not only in size, but also in the degree of wear. Different tire rolling radii will cause increased wear on the differentials under normal driving conditions, and when the lock is engaged, increased wear on other transmission parts and wheel slip.

Video

The normal position for the RK handles, ensuring adequate behavior on the road of good quality:

- Front - away from you Back - towards you

The special operating mode of the transmission is switched on not long before the car begins to overcome an obstacle (rut, mud, ford or rise). The transition to the lowest row must be done while stopping. Returning to top gear is allowed on the go, although it causes problems for beginners due to the lack of the usual synchronizer.

It is somewhat more difficult to properly handle the forced manual locking of the center differential. On the contrary, it turns on when the car moves slightly (up to 20 km/h) due to misalignment of the grooves on the locking clutch, satellites and ring gear. To simplify turning the lever into the desired position, taking into account the Niva 2121 transfer case, pick up a small speed, then, shaking the steering wheel, pull the handle towards you.

Problems can also arise when disengaging the lockout, as the clutch teeth literally catch on the ring gear. Engage reverse and, rocking the steering wheel, push the lever away from you. This action is performed immediately after overcoming a difficult section in order to avoid overloading the gearbox. It is most effective to disable the differential together with the transition to lower stages.

Removing the Niva transfer case

To repair the transfer case on a VAZ 21213 (21214), the unit must first be removed. We carry out removal in the following order:

- in the cabin we dismantle the plastic lining of the gearbox and gearbox levers;

- unscrew the knobs of the transfer case shift levers, remove the casing under them;

- disconnect the speedometer cable, for RK 21214 you will need to additionally disconnect the speed sensor;

- we unscrew the bolts with nuts securing the elastic coupling of the front and rear propeller shafts; in order to remove the bolts, the cardan shafts must be turned - they are removed one at a time in one specific position of the shaft;

- We install a jack (or other support) under the transfer case and mark the places where the side supports of the RC were attached. This is done in order to minimize the alignment of the transfer case during installation;

- unscrew the 4 nuts securing the gearbox to the gearbox;

- unscrew the 4 fastenings of the RC supports to the car body;

- Now all that remains is to dismantle the transfer case.

Tips for owners

To make driving your car comfortable, read some important points:

- The usual, standard arrangement of the front and rear handles is forward and backward, respectively. Movement in this mode can and should be carried out in areas characterized by even and smooth surfaces.

- Locking the differential by switching the front handle to the rear position is best on roads characterized by increased slipperiness. This measure will give Niva stability. It is worth understanding that after overcoming the problem area, the handle will need to be returned to its original position.

- As noted earlier, downshift should be activated before a potential obstacle, but not while the car is already stuck.

- It is worth understanding that activating the lock when the vehicle is stationary is sometimes impossible, even if the clutch is depressed. This may be caused by the clutch teeth hitting the gear teeth. In this case, you can try to activate the lock by starting to drive slowly and make a slight turn. If problems arise with disabling the lock, it is recommended to perform the same procedure with the clutch depressed and the steering wheel slightly rocked.

Read news about the new Niva

- Diagram and location of the fuse box Niva VAZ-21213 and 21214

- Diagram and location of the fuse box Niva VAZ-21213 and 21214

- Front lower suspension arms VAZ-2121 - Drawings, 3D Models, Projects, Cars and automotive industry (Car service)

- Timing marks on a Chevrolet Niva car

- Chassis, front suspension, device, Design, operation, description, device, car repair Niva VAZ 2121, engine, assembly, disassembly, transmission, gearbox

- Suspension lift in the field yourself | Niva Repair

- Niva 2121 suspension lift do-it-yourself drawings

- Tuning Niva 2121 with your own hands: body, interior, suspension

Disassembly

1 — front axle drive housing; 2 — crankcase cover; 3 — speedometer drive housing fig. 3-39fig. 3-38

rice. 3-38fig. 3-39

1- intermediate shaft; 2 - drive shaft; 3 — differential; 4 - front cover

1 - flange; 2 — oil seal; 3 — thrust ring of the bearing, 4 — front bearing; 5 - drive shaft; 6—high gear; 7 — hub; 8 - coupling; 9 — low gear; 10 — bushing: 11 — rear bearing; 12 — bearing installation ring; 13 — intermediate shaft bearing; 14 - intermediate shaft

- remove the lock ring 1 (Fig. 3-45) and spring washer 2 of the front bearing;

- remove the rear and front bearings from the differential housing (Fig. 3-46), using a universal puller and stop 67.7853.9559;

- by turning the bolts of the differential housing, separate the housing;

- remove the differential driven gear;

- remove retaining rings 8 (Fig. 3-45) and spring washer 14, then press out the pinion axis and remove the satellites and drive axle drive gears with support washers.

Also interesting: Adjusting VAZ 2114 and 2115 headlights: tips and tricks

1 - retaining ring; 2 - spring washer; 3 - bearing mounting ring; 4 — differential housing bearings; 5 — driven gear; 6 - front differential housing; 7 — front axle drive gear; 8 — retaining ring of the satellite axis; 9 — satellite; 10 — rear differential housing; 11, 15 — support washer; 12 — rear axle drive gear; 13 — satellite axis; 14 - spring washer

1 — puller A.40005/1/6; 2 — stop 67.7853.9559; 3 - bearing

- the axial clearance of each axle drive gear should be 0-0.10 mm, and the moment of resistance to rotation of the gears should not exceed 14.7 N m (1.5 kgf m). If the gap is increased, replace the support washers with others of greater thickness; if the specified gap cannot be obtained when installing support washers of the greatest thickness, replace the gears with new ones due to their excessive wear;

- The drive and intermediate shafts are installed in the transfer case housing simultaneously (see Fig. 3-47);

- Press the bearings onto the differential housing using mandrel 67.7853.9558 (see Fig. 3-48);

- Before installation in covers and crankcases, lubricate the working surfaces of the oil seals with LITOL-24 grease;

- Tighten threaded connections to the torques specified in Appendix 2;

- when compressing the transfer case shaft nuts, use mandrel 67.7820.9520 (see Fig. 3-49).