another replacement of crosspieces is already a tradition

Replacing

crosspieces is already becoming

a good tradition

, at first I didn’t realize that

the crosspieces in

classic Lada

are consumables

that sometimes wear out faster than the front brake pads run back...

wow!

the car started to boil and crunch

...well, I think

I recently changed

10-15 thousand ago, probably the handbrake needs to be tightened, the handbrake cable rubs against the cardan, I drove until I finally got the skip, I got to the service garage - oops, the crosspieces are a mess, at the same time they changed the cardan bearing - and it seems the resonant hum from below that has been there since purchasing the car has disappeared

fuck

no words... I change crosspieces almost

every year

, only now I realized that

I need to choose a manufacturer

and not run into

a fake.

For some reason, the crosspieces from Volga Auto Prom have been covered up very quickly already 2 times in a row, I’m switching to imported crosspieces (GKN, Trialli)

there was no time to think and there was 1 piece of Cedar

and 1 piece

GKN

(standard manufacturer but many fakes), they installed it, I’ll see how long it lasts

CARDAN were highly praised

, but I already installed others ((

Which crosspiece is better to install?

Car service specialists say that if the time has come to change the crosspiece, then it is better to change them as a set, both of them. In fact, this is not always the case. The front crosspiece, as a rule, lasts much longer than the rear one. Sometimes three crosspieces are replaced at the shank, but at the outboard bearing the crosspiece remains fully functional.

Experts advise not to “kill the ears of the cardan”, and not to change the crosspiece unless necessary.

When purchasing, you should not save on cost, it will be more expensive. Quite good crosspieces made in Germany are of high quality and come complete with retaining rings, which come in very handy if the “original” ones break during disassembly.

Crosspieces

(with oiler) are made of a special stainless steel alloy that is resistant to corrosion. The manufacturer guarantees high quality based on multi-stage control during the production process.

Crosspieces from Weber, GKN, etc.

The only disadvantage of imported crosspieces is that the retaining rings often need to be adjusted.

Well, the most affordable crosspiece for the VAZ 2107 of domestic production. Quality depends on your luck.

also replaced the cardan outboard bearing

We also replaced the rear gearbox oil seal, the gearbox is leaking, we need to change the top gasket and the front gearbox oil seal

PS:

after replacing the crosspieces the car does not creak! The resonant hum of the cardan has disappeared! I haven’t heard that for a long time, it was as if a bucket was tied from below - that’s how I drove

also ordered from www.exist.ru/ 1. gear oil 4l ZIC

Article:

167103

for gearbox and rear axle,

GL-4/GL-5 Synthetics

Source

Features of replacing the VAZ-2107 driveshaft crosspiece: 3 important tips for choosing a part

In the age of advanced technology, more and more cars have front-wheel drive, which does not use a driveshaft with hinges. Nevertheless, many companies continue to make rear-wheel drive cars, using the old classic drive-wheel drive scheme. Along with Mercedes and BMW, our VAZs continue the tradition. Therefore, car owners are interested in how to replace the VAZ-2107 driveshaft crosspiece themselves.

Crosspieces: dimensions, markings, applicability

The crosspiece is one of the most important elements of the driveshaft. As calculations of the loads on the driveshaft show, the spider is the weakest part of the driveshaft, so the quality of the spider is very important.

Crosspiece for domestic automobiles and tractors

| Number | Application, Analogues | Size DxH |

| 2101-2202025 | Crosspiece VAZ 2101-2107 | 23.8x61.2 |

| 2105-2202025 | Crosspiece VAZ 2101-2107 (reinforced) | 23.8x61.2 |

| 412-2201025 | Cardan crosspiece Moskvich 412, steering. KrAZ | 28x83.05 |

| 2121-2201025 | Crossing VAZ 2121 "Niva" | 28x71 |

| 21211-2202025 | Crosspiece VAZ 21213 reinforced “Niva Taiga” | 28x71 |

| 2126-3422205 | Steering crosspiece VAZ, UAZ | |

| 408-2201025 | Crosspiece “Moskvich 408″ | 28x73 |

| 69-2201025 SB | Cardan shaft crosspiece Volga, GAZelle, UAZ, MTZ | 30x88 |

| 3110-2201025 SB | Cardan shaft crosspiece Volga, GAZelle, UAZ, MTZ | 30x88 |

| 53A-2201025 | Crosspiece for GAZ-53, GAZ-52 shaft, agricultural joint 400 | 35x98 |

| 5320-3422039 | Steering crosspiece KAMAZ | 28x68 |

| NO.51-02.607 | Cardan crosspiece for agricultural purposes, agricultural joint 160 | 28x73 |

| 50-3401062 | Steering crosspiece MTZ, YuMZ | 19x44.6 |

| 4301-3401485 | Steering crosspiece “Gazelle” with oil. | 19x44.6 |

| 3307-3401485SB | Half-cross joint of cardan-steering control GAZ set. 3 pcs. | |

| 4301-2201025A | Cardan shaft crosspiece ZIL 130, cx joint 630, tr. T150 | 39x118 |

| 5320-2201025 SB | KamAZ driveshaft crosspiece small (interaxial) | 39x118 |

| 5320-2201025-01 | KAMAZ cardan shaft crosspiece main EURO (for locking ring) | |

| 5320-2205025 SB | KamAZ main driveshaft crosspiece | 50x135 |

| 255B-2201025 | KRAZ crosspiece, T-150 | 50x155 |

| 700-2201080 | Cross K-700 | 62x173 |

| AP.2B0520 | Crosspiece analog /GKN U730 / TATA, Standard | 38x100 |

| AP.2C07317 | Crosspiece analog /GKN U895/ RENAULT, MERSEDES, Fiat, Iveco | 49.2x154.9 |

| AP.2B07807 | Crosspiece analog /GKN U450, U451,U909/ VOLVO, IVECO, DAF, SCANIA, MAN | 52x147.2 |

| AR.6520-2205025-10 | Crossing KamAZ 6520, DAF, IVECO, MAN, VOLVO, HOWA, DONG FENG, FOTON(F, H, DF, 3313)) | 57x144 |

| AR.6520-2205025 | Crosspiece KamAZ 6520 (57×152, DAF, IVECO, MAN, VOLVO, FOTON) | 57x152 |

| 7555-2201025 | Cross BelAZ (72×185) dump truck with a capacity of 55 tons | 72x185 |

| 037-3401485 SB | Half-cross joint for cardan steering joint, set 3 pcs. |

Cardan shaft crosspieces for imported agricultural machinery

| Number | Application, Analogues | Size DxH |

| AR.2V00501 | Cardan shafts from Walterscheid series 2000 | 18x47 |

| AR. S00101 | Crosspiece analog /GKN U138/ Bondioli&pavesi | 22x54 |

| Cardan shafts manufactured by Walterscheid (Germany) series 2100, Series 02 manufactured by La Magdalena (Spain), Series 2 Bondioli&Pavesi, Benzi&Di Terlizzi, Eurocardan (Italy) | 22x55 | |

| No | Cardan shafts manufactured by Walterscheid (Germany) series 2200, Series 03 manufactured by La Magdalena (Spain), Series 2 Bondioli&Pavesi, Benzi&Di Terlizzi, Eurocardan (Italy) | 23.8x61.3 |

| AR.2V02407 | Crosspiece analogue Series 3; China | 27x70 |

| AP.2B02417 | Crosspiece analog /GKN U082, U083/ Waltershaid | 27x74.5 |

| No | Cardan shafts manufactured by Walterscheid (Germany) series 2300, Series 05 manufactured by La Magdalena (Spain), Series 4 Bondioli&Pavesi, Benzi&Di Terlizzi, Eurocardan (Italy) | 27x75 |

| AR.S00401 | Cardan shafts Series 06 manufactured by La Magdalena (Spain), Series 5 Bondioli&Pavesi, Benzi&Di Terlizzi, Eurocardan (Italy) | 30.2x80 |

| AR.2V03409 | Cardan shafts Series 07 manufactured by La Magdalena (Spain), Series 6 Bondioli&Pavesi, Benzi&Di Terlizzi, Eurocardan (Italy), analogue of Agro Series 7; GKN U220 | 30.2x92 |

| AR.2V03415 | Cardan shafts Series 08 manufactured by La Magdalena (Spain), Series 7 Bondioli&Pavesi, Benzi&Di Terlizzi, Eurocardan (Italy), analogue of Agro Series 8; GKN U200 | 30.2x106.5 |

| AP.2D03903 | Cardan shafts manufactured by Walterscheid (Germany) series 2400, Series 35 manufactured by La Magdalena (Spain), analogue of Waltershaid W2400 | 32x76 |

| No | Cardan shafts Series 09 manufactured by La Magdalena (Spain), Series 8 Bondioli&Pavesi, Benzi&Di Terlizzi, Eurocardan (Italy) | 34.9x106.5 |

| No | Cardan shafts Series 7 (old model) Italy, | 35x93.5 |

| AR.2D04901 | Cardan shafts manufactured by Walterscheid (Germany) series 2500, Series 36 manufactured by La Magdalena (Spain) | 36x89 |

| No | Cardan shafts Series 09 manufactured by Bondioli&Pavesi, Benzi&Di Terlizzi, Eurocardan (Italy) | 41x108.4 |

| No | Cardan shafts manufactured by Walterscheid (Germany) series 2600 | 42x104 |

| No | Cardan shafts manufactured by Walterscheid (Germany) series 2700 | 50x118 |

Node device

Before you begin dismantling it yourself, you need to at least in general understand the structure of the entire unit, then repairs can be done according to all the rules. Cardan shaft device:

To the eternal question, how many crosspieces are there on this car, there is a very clear answer: two.

Structurally, everything is done exactly this way due to the fact that the gearbox and the rear axle gearbox are not located in the same axis, that is, they are offset relative to each other. From this it is absolutely clear that the driveshaft cannot be solid, since this is structurally impossible.

The design also provides a suspension device - an additional support consisting of a rubber cushion enclosed in a steel cage and a bearing in the center of the structure.

This is the brief structure of this node.

Removing the shaft from a VAZ 2107 car

Attention! Before separating the transmission parts relative to each other, you need to make marks with chalk so as not to rotate the position of the parts differently and not cause alignment problems!

- We hang up any drive wheel using a jack;

- We put the gear shift lever, or “stick”, in neutral, lock the “handbrake”;

- Remove the safety bracket by unscrewing the nuts and washers;

- Now we release the coupling from the gearbox flange by unscrewing 3 nuts;

- We turn the cardan, take out all the bolts from the flange and coupling; to make work easier, you can carefully knock them out with a punch and a hammer.

- Now you can disconnect the front end from the gearbox flange;

- Now we unscrew the nuts of the rear half of the transmission from the differential flange (there are 4 of them);

- Now you can separate the driveshaft and differential flange:

- We unscrew the nuts securing the cross member and remove it;

- And only now we remove the cardan from the VAZ 2107

That's it, the withdrawal is complete. The reverse installation is carried out in exactly the same way, you just need to make sure that the cardan coupling with its liners (2) fits into the grooves of the gearbox flange (1,3).

After installation, you need to check how the cardan rotates with one wheel hanging.

Basic faults

Any component or mechanism sooner or later wears out and requires complete or partial replacement (repair). The most common driveshaft malfunctions:

The latter malfunction occurs for various reasons. The most likely of them:

The signal to replace these parts is increased noise while driving, vibration and extraneous sounds emanating from under the car.

Spare part selection

In order to repair this unit less often, you need to purchase good quality spare parts. The correct choice of crosspiece determines how often it will need to be replaced. Choice of cross:

And another effective way to check. The crosspiece taken out of the package should be placed on a piece of glass - a glass counter is quite suitable, or on the same side-view mirror (removed, of course). Holding your fingers opposite the axis of the cross, you need to try to swing them on this surface. Next, you need to do the same with other axes. Then turn the part and do the same operation again. During the inspection process there should be no knocks on the glass surface, which will indicate the absence of deformation of the part.

You should buy two parts at once, because after replacing one, the replacement of the other will very soon follow. Many people immediately change the bearing of the suspension device, so as not to have to repeat what they have done before, that is, disassemble everything, wasting time and their own nerves.

Preparing for work

You can't do any job without the right tool. You should prepare:

And, of course, it is better to carry out the work on a lift, overpass or inspection ditch - it will be both more convenient and safer.

If work is carried out on the first two structures, then you need to fix the wheels by placing blocks under them, which will prevent unwanted rolling of the car forward or backward. You must always remember safety precautions before removing the crosspiece from the VAZ-2107 cardan or performing any other work under the car.

Removal of worn parts

Replacing them does not present any particular difficulties, and it is not at all necessary to take your “seven” to a service station in order to perform such a simple operation.

Replacing crosspieces on a VAZ-2107 is impossible without dismantling the driveshaft.

This does not require any special training, great skills or special tools - everything is very simply done in a garage. Operating procedure:

Such a tool can be either universal (working for both compression and expansion) or single-acting. However, many craftsmen manage to do this with a simple screwdriver or an awl, which is undesirable for safety reasons.

After all the rings have been removed, you can remove the crosspiece on the VAZ-2107. This is done like this:

What faults occur in this connection?

Of course, most often the most loaded elements fail: the universal joint and bearings. There are reasons for this: lack of necessary lubrication in the bearings and defects in the production of crosspieces. In the USSR, there was a terrible shortage of crosspieces: there is no crosspiece - the transmission is faulty - the car is stuck. Repairing the cardan shaft often cost a week's family budget, and replacing the crosspiece (or rather, the need for it) led many to despondency.

More rare transmission malfunctions of the VAZ 2107:

- Damage and misconfiguration (hitting rocks when driving in the mountains);

- Abundant amounts of dirt in parts and bearings;

- Failure of flanges, splines and couplings under load.

For lubrication, maintenance, if a part needs to be replaced, first of all, you need to properly remove it from the car and put it back. Repair of the driveshaft is also possible only after removal.

Installing new items

Now that the hinge is disassembled, you can begin installing the new part. To do this, you need to remove the new cross from the packaging and carefully remove the caps from it, so that its needle bearings do not fall apart. Further:

All these operations must be repeated with the second cross - there are no differences as such.

Installation of the cardan shaft is carried out in the reverse order of dismantling. To do this you need to do:

Don’t forget about the retaining rings to avoid early failure of the propeller shaft joints! And you also need to carefully, but without fanaticism, tighten all the bolts and nuts. In addition, we must not forget about aligning the marks on the hinge joint.

Now you need to check the car while driving for the absence of vibrations and noise under it.

Differences between original NIVA-BELKARD cardan shafts and analogues from other suppliers

Belkard OJSC products are painted with matte paint, but the flange surfaces are not painted. Shafts from third-party manufacturers are often painted with glossy paint.

Belkard driveshaft is painted with matte paint

cardan shafts from other manufacturers, painted with glossy paint

The designation of drive shafts of Belkard OJSC is carried out using:

- holograms,

- stickers (stickers) with barcodes,

- plant logo in the form of a capital Russian letter “g”, part name, factory code, production date.

(barcode deliberately blurred)

The Belkard OJSC logo is often confused with a similar-looking logo from another manufacturer, resembling an “X” symbol intersecting three circles. Below is a visual comparison of these logos:

logo of OJSC "Belkard"

third party logo

The Belkard OJSC logo is additionally stamped on the welded fork...

...the logo is also stamped on the sliding fork

In addition to the main sticker on the propeller shaft pipe, a duplicate sticker is also used in the flange cavity indicating the production date.

Along with the labels on the shafts, protective holograms “Technosphere” are used

Belkard received the honorary right to use this mark as the best innovative enterprise of the Republic of Belarus in 2006 and to this day uses this hologram to designate its products.

Under different viewing angles and under different lighting, the hologram takes on different colors and shapes; when it is dismantled (removed), the holographic properties are lost.

Thus, a hologram is another reliable means of confirming the originality of a product.

The balance plates must be installed evenly, with a snug fit to the driveshaft tube. The absence of balancing plates and sloppy welding indicate that the shaft was manufactured in “makeshift” conditions. The propeller shaft pipe must be smooth and dents are not allowed.

Special attention to the splined connection of the driveshaft. Free movement indicates the presence of circumferential clearance, which can lead to premature failure.

If it was not possible to stretch the driveshaft, or it was necessary to apply significant force, the spline connection was not selected selectively. The relative position marks of the balanced set must be located strictly opposite each other.

The propeller shaft joints should not turn too tightly, and the grease fittings should be protected with rubber caps.

The welded and sliding forks must have a stamp of the Belkard OJSC logo.

There are no grease nipples in the spline connection as it is unnecessary. The spline connection design is highly reliable and does not require maintenance during operation.

The absence of any of the above signs when analyzing driveshafts indicates their production by third-party manufacturers.

Conclusion

It must be remembered that work done correctly, as well as high-quality spare parts, will help the car owner forget about this unit for a long time. And don’t forget about timely lubrication of the bearings through a grease nipple - then the next repair will not have to be done soon.

Of course, taking on this work yourself or entrusting it to service station mechanics is the job of every car owner. But, taking into account that the owners of VAZs (especially “classics”), as a rule, are not rich people, there is a reason to do this work yourself, thus saving a decent amount.

Source

Which crosspieces are better for the VAZ 2107

In this article we will look at how to replace the crosspiece and suspension bearing of the propeller shaft of a VAZ 2106, VAZ 2107, VAZ 2105, VAZ 2104, VAZ 2101, VAZ 2102. I was prompted to write an article on this topic by the special interest of car owners in the issue of replacing the driveshaft crosspiece with VAZ cars.

What auto parts will be needed for the upcoming work?

The first step is to buy a driveshaft suspension bearing (when purchasing a bearing, check the elasticity of the rubber band and the bearing stroke). The bearing must rotate smoothly and without interruption, which will ensure its long and high-quality operation. The use of high-quality rubber in the bearing increases its service life.

The driveshaft support should be selected according to the catalog number. Catalog number of the driveshaft support VAZ 2106, VAZ 2107, VAZ 2101, VAZ 2102, VAZ 2103, VAZ 2104, VAZ 2105:

If you're on a budget and can't replace the driveshaft support, you can simply replace the driveshaft bearing.

The truth about Niva cardan shafts

Vibration and noise of the cardan

This is one of the problems with Niva -21213, 21214 and Niva CHEVROLET - 2123.

However, there may be several reasons for these troubles:

- malfunction of the vehicle's running system;

- transmission malfunction,

- gearbox malfunction

- transfer case malfunction.

Often the cause is vibration, which is noticeable at speeds from 75 km/h to 90 km/h. This is due to an imbalance of the front and rear driveshafts.

How to check the condition of the crosses:

- You can check the condition of the crosspieces in the pit, without dismantling them. To do this, you need to fix the flange and rotate the cardan shaft in different directions by hand. The presence of play indicates a malfunction of the crosspiece and its urgent replacement.

- When installing a new crosspiece, check the presence of grease in the bearings (we recommend using synthetic lithium grease CASTROL LMX, heat-resistant grease Multipurpose HT-2 blue, Mannol LC-2 blue)

If the universal joints with crosspieces are good, then the vibration may be due to improper installation of the transfer case.

How to eliminate cardan vibration:

In order to correctly install the RC you need:

Raise the car so that the wheels do not touch the ground. inspect the transfer case mountings (supports, nuts) IMPORTANT: Pay attention to the intermediate shaft

Checking the intermediate shaft spider is similar to checking the condition of the spiders on the cardans. When all the inspection is completed, hang the transfer case without tightening the fastening nuts to the end. After this, ask an assistant to accelerate the hanging car to 80 km/h and carefully, so as not to get your hands into the rotating parts of the transmission, tighten the transfer case fastening nuts until the end. When all inspection is completed, hang the transfer case without fully tightening the fastening nuts

After this, ask an assistant to accelerate the hanging car to 80 km/h and, carefully, so as not to get your hands into the rotating parts of the transmission, tighten the transfer case mounting nuts completely

When all inspection is completed, hang the transfer case without fully tightening the fastening nuts

After this, ask an assistant to accelerate the hanging car to 80 km/h and, carefully, so as not to get your hands into the rotating parts of the transmission, tighten the transfer case mounting nuts completely

To reduce vibration, you can replace the cardan shafts “on the cross” with cardan shafts on CV joints. They usually cost more, but are really less susceptible to vibration. VAZ-2123 catalog number: 2123-2201015-20.

What kind of cardans are on the NIVA and CHEVY NIVA

Cars NIVA-2121,21213,21214 and NIVA CHEVROLET 2123 could be equipped from the factory with driveshafts from different manufacturers.

If it is necessary to replace the spiders, it is important to know the manufacturer of the cardan, since the spiders have different sizes and are not interchangeable. NIVA CHEVROLET 2123 cars are equipped with two cardans of equal length: these are the rear ones from the NIVA 2121

NIVA CHEVROLET 2123 cars are equipped with two cardans of equal length: these are the rear ones from the NIVA 2121.

The rear propeller shaft is long, size - 690 mm from flange to flange from NIVY-2121, 21213 fits CHEVY NIVA-2123 catalog number 21211-220115-01.

On VAZ-2120 Nadezhda and VAZ-2131 cars an additional cardan is installed (length 500mm)

catalog number: 2120-2204010

Cardans of JSC "KARDAN".

2121-2201012-02 Rear universal joint (thin splined, thick pipe, VAZ cross).

Suitable: Niva-2121, -21213, -21214, -2131 and NIVA CHEVROLET-2123 (there is one in front and behind).

2121-2203012-04 Front universal joint (thick splined, thin pipe, VAZ cross). Its size (length) is 490 mm along the flanges,

Cardans Türkiye TIRSAN. Crosspieces - D=27mm!

2121-2201012-02 Rear cardan (thin spline, thick pipe, TRIALLI cross).

Suitable: Niva-2121, -21213, -21214 and NIVA CHEVROLET-2123 (both in front and behind there is one).

2121-2203012-04 Front cardan (thick splined, thin pipe, TRIALLI cross).

Cardans in Belarus are produced by one plant in Grodno, JSC BELKARD.

2121-2201012-02 Rear cardan (thin splined, thick pipe, Moskvich cross).

Suitable: Niva-2121, -21213, -21214, -2131 and NIVA CHEVROLET-2123 (there is one in front and behind).

2121-2203012-02 Front cardan (thick splined, thick pipe, Moskvich cross).

Factory driveshafts are properly balanced

To fasten the cardans, use M8x27 mm bolts (2101-2201107/1610):

How to replace a driveshaft bearing?

In order to change the propeller shaft bearing , it is enough to knock out the old bearing, after first removing the retaining ring. And slowly hammer the new bearing into place.

Catalog number of the propeller shaft support bearing:

“When you choose a driveshaft crosspiece, it is better to give preference to the VAZ crosspiece”

How to buy a driveshaft crosspiece for VAZ 2106, VAZ 2107, VAZ 2101, VAZ 2105, VAZ 2102, VAZ 2104?

Before buying a driveshaft crosspiece , you should go through two stages, the first is to select a driveshaft crosspiece and check the driveshaft crosspiece.

I decided to write down information on how to buy a universal joint for a driveshaft because of frequent requests on the Internet about: What are the best manufacturers of universal joints? What are the quality crosspieces? How to buy a high-quality driveshaft crosspiece? How to determine if the driveshaft crosspieces are defective?

Let's look at a list of reliable and inexpensive crosspieces for the VAZ 2106, VAZ 2105, VAZ 2107, VAZ 2101, VAZ 2102, VAZ 2104, VAZ 2103 (Fig. 1).

Checking the driveshaft cross

You can check the driveshaft crosspiece using a regular mirror. Place the mirror on the table surface and place the cross on top. Take the propeller shaft crosspiece by the ends and rock it, checking for any play. If, when checking the crosspiece using a mirror, slight play and knocking are observed, then such a crosspiece can also be installed, but slight vibration will be observed, which is not very pleasant.

Tool for replacing the crosspiece and the outboard bearing of the propeller shaft of VAZ-2101, VAZ-2102, VAZ-2104, VAZ-2105, VAZ-2106, VAZ-2107 (Fig. 2).

Sequence of work for replacing the suspension bearing and driveshaft crosspiece on a VAZ 2106, VAZ 2107, VAZ 2105, VAZ 2104, VAZ 2101, VAZ 2102

How to install the driveshaft crosspiece in place?

Remove the two cups of the crosspiece, tuck the crosspiece into the eyes. Put on the cup (Fig. 10). Install the locking ring and put it on (Fig. 11).

The cardan cross in classic VAZ cars is a cross-shaped joint that secures the rotating axles of the transmission. The VAZ 2107 has two crosspieces: one in the central part, and the other at the junction of the propeller shaft with the gearbox. Replacing these parts on a relatively new car is quite simple. However, over time, the crosspieces rust, and the procedure for dismantling them becomes real torture for an inexperienced driver.

A starter is necessary to start the engine by turning the engine crankshaft. It is a four-pole DC electric motor with a combined connection of excitation windings. The field windings of two poles are connected in series with the armature winding, and the other two are connected in parallel. The car starter is turned on remotely electromagnetically, using a traction relay located on the starter housing. The relay windings are powered through an additional starter relay, which eliminates accidental activation of the starter while the engine is running.

The WEBER series winding and armature winding are made of thick conductor. For better conductivity, copper-graphite brushes are used. Two minus brushes are connected to ground, and two plus brushes are connected to the field winding

A special drive is installed on the armature shaft, ensuring the engagement of the starter gear with the flywheel ring when starting and the disconnection of the gear after starting. This drive includes an operating lever with a return spring, a splined sleeve with a free-moving clutch, gears and a buffer spring. The free-moving clutch consists of a splined bushing, which is manufactured together with the drive race, and an outer driven race, manufactured together with the gear. On the inside of the driven cage there are four inclined grooves in which rollers are placed, which are pressed by spring pushers into the narrow part of the groove. During starter operation, when the armature and the drive race begin to rotate, the rollers move along the inclined surfaces of the grooves and jam the driven race of the freewheel, due to which both races with the gear begin to rotate together.

The starter is turned on by turning the ignition key. At this time, a small current from the battery will first pass into the winding of the start relay, magnetize its core, which will attract the armature, thereby closing the contacts of the starter circuit. After this small current will flow from the battery to the terminal of the traction relay, then to the ignition switch and to the terminal along the pull-in winding of the traction relay, and through another terminal to the starter winding. At the same time, the current will flow through the thin holding winding of the traction relay.

Under the influence of a magnetic field, the core of the traction relay will be drawn into the bushing and move the activation lever, which, with its lower end, will move the starter drive along the thread and engage its gear with the flywheel ring gear.

At the same time, the traction relay core will move a contact disk through the rod, which will close the traction relay contacts of the main starter circuit, which has low resistance, and because of this, a greater current will be directed into the starter winding, and the armature will begin to rotate the engine crankshaft.

At the same time, the contact disk will connect to a contact that allows current to pass into the primary winding of the ignition coil, bypassing the additional resistance. When the engine starts, the starter is turned off with the key, and all drive parts return to their original position using a spring.

Today there are several types of car starters:

- starters with and without planetary gear

- starters with permanent magnets and using a brush assembly.

WEBER pays special attention to the latest developments in the production of starters. Our technicians are acutely aware of the need for smaller, lighter and more efficient starter models. This approach has led to the development of advanced geared starters, which are gradually replacing direct drive starters.

A variety of starter modifications guarantee a long service life under adverse operating conditions. They are extremely resistant to salt fog, humidity, water, dust, dirt, vibration, high and low temperatures and caustic liquids. Their design complies with electromagnetic compatibility standards and other international directives and standards.

WEBER starters are manufactured using environmentally friendly technologies and environmentally friendly materials.

| 7102.3708 | 3,50 | 0,95 | 12 | ||

| ST 2101G | Starter for VAZ 2101-2107, 2121, 2123 gearbox, 12V, 1.55kW | 5722.3708 | 4,25 | 1,55 | 12 |

| ST 2110G | Starter for VAZ 2110-2112, 1118 Kalina, 2170 Priora, 2190 Granta gearbox, 12V, 1.55 kW | 5702.3708 | 4,00 | 1,55 | 12 |

| ST 2108G | Starter for VAZ 2108-21099 gearbox, 12V, 1.55kW | 5712.3708 | 4,03 | 1,55 | 12 |

| ST 4601 | Starter for Lada Largus, Renault Logan, Sandero, Kangu 1.4, 1.6, 12V, 0.85 kW | 0 986 022 810 | 3,31 | 0,85 | 12 |

| ST 1118G | Starter for VAZ 2115, 1118 for a reinforced gearbox, gearbox (for 2 bolts), 12V, 1.55 kW | 5702.3708-10 | 4,07 | 1,55 | 12 |

| ST 2170G | Starter for VAZ 2170, 1118 for a reinforced gearbox, gearbox (for 3 bolts), 12V, 1.55 kW | 5702.3708-15 | 4,05 | 1,55 | 12 |

| ST 402-20G | Starter for GAZ engine ZMZ 402 gearbox (large), 12V, 1.9KW | 6002.3708 | 4,60 | 1,9 | 12 |

| ST 406-18G | Starter for GAZ 3102, 3110 engine ZMZ 406 gearbox (small), 12V, 1.8KW | 6012.3708 | 4,275 | 1,8 | 12 |

| ST 406-20G | Starter for GAZ 3102, 3110 engine ZMZ 406 gearbox (large), 12V, 1.9KW | 6012.3708 | 4,71 | 1,9 | 12 |

| ST 7162 | Starter for Daewoo Nexia, 12V, 0.8KW | 25192219 | 2,94 | 0,8 | 12 |

| ST 5732G | Starter for GAZ, UAZ with engine UMZ 4178.10,4218.10,4215.10-10,4215.10-30 gearbox, 12 V, 1.7 kW | 5732.3708 | 4,30 | 1,7 | 12 |

Purpose of VAZ 2107 cardan crosspieces

The need to use cardan crosses (CC) in the design of a car is due to changes in the position of the shafts relative to each other during movement. If the axes of these shafts were constantly on the same straight line, then crosspieces would not be needed. However, when moving, the distance between the axes changes in both vertical and horizontal planes.

The cardan joint is involved in the transmission of torque from the gearbox to the drive axles. Thanks to the KK, a flexible connection of the VAZ 2107 engine with the driving rear axle is ensured. The cardan design also includes hinges, intermediate supports and connecting devices. But it is the crosspieces that are responsible for transmitting torque at constantly changing angles between the shafts during movement.

The VAZ 2107 is a rear-wheel drive car, and its design provides a special role for the cardan. It transfers all engine work only to the rear wheels. Therefore, on the “seven” the cardan is located under the bottom and the floor in the cabin is raised in the middle.

Cardan transmission

The cardan transmission is used to transmit torque from the driven shaft of the gearbox to the drive shaft of the main gear. And since the relative position of the rear axle, in which the main gear is mounted, and the gearbox changes when the load changes and when shocks occur during movement, torque must be transmitted at a changing angle. Cardan shafts allow torque to be transmitted from the gearbox to the rear axle, despite its vibrations.

The cardan drive consists of two tubular shafts, two universal joints with needle bearings, an intermediate support, a splined flange and an elastic coupling.

The front 19 and rear 24 cardan shafts are made of thin-walled steel pipe with an internal diameter of 66 mm. Two identical forks 36 are pressed and welded into each end of the rear propeller shaft. Cross bearings 33 are pressed into the holes of the eyes of the forks 36, which are held from falling out by spring retaining rings. Each cardan bearing has 22 needles with a difference in needle diameters in one bearing of no more than 0.004 mm.

Between the ends of the crosspiece and the bottoms of the needle bearing housings, an axial clearance is established in the range of 0.01-0.04 mm, as a result of which the crosspiece is centered in the forks and cannot move along the axes of the journals.

The required axial clearance at the crosspiece is ensured by the selection of locking rings 32, manufactured in different thicknesses and colors. The color of the ring depends on its thickness: a ring with a thickness of 1.50 mm is natural, 1.53 is dark brown, 1.56 is blue, 1.59 is black and 1.62 is yellow.

When assembling the cardan parts, a 1.56 mm thick ring is installed in the groove of one of the eyes and, when the second bearing is pressed in (in this case, the cross rests on the bottoms and there is no gap), the distance between the end of the second groove and the bottom of the bearing is measured with a feeler gauge. And if this distance is, for example, 1.56 mm, then to ensure the required axial clearance, a ring with a thickness of 1.53 mm should be installed. If this distance is less than 1.53 mm, then the first ring should be replaced with a ring with a thickness of 1.50 mm. If the measured distance is more than 1.62 mm, then the originally supplied ring with a thickness of 1.56 mm should be replaced with a 1.62 mm ring.

After installing the retaining rings, hit the bearing with a hammer with a plastic striker. Under the influence of the impact and elastically compressed rubber seals, the gap between the bottom of the bearing and the retaining ring will be removed and gaps will appear between the ends of the spider spikes and the bottoms of the bearing housings.

When disassembling the cardan, marks should be made on the parts, by which their previous position could be determined if assembly is carried out without replacing parts. You should also not interchange circlips of different thicknesses. To lubricate the cardan needle bearings during assembly, lubricate the inner surface of the housing with LITOL-24 grease (0.4-0.6 g per bearing) and fill the cavities 35 in the crosspiece studs.

To retain lubricant in the needle bearings and prevent dirt and water from entering them, rubber seals are installed on the spikes of the cross in stamped steel cages. The sealing of the crosspiece needle bearings is ensured by the interference between the end of the bearing housing and the rubber seal ring.

Splined tips are pressed and welded into the front propeller shaft pipe. A flange slides on the splines of the front tip, connecting the driven shaft of the gearbox and the cardan drive through an elastic coupling. The flange, and with it the entire front shaft with an elastic coupling, is centered on ring 14 mounted on the driven shaft of the gearbox.

The front propeller shaft can move in the splines of flange 9, thereby changing its length. Shortening or lengthening the shaft is necessary because when the suspension of a moving vehicle oscillates, the distance between the gearbox and the rear axle does not remain constant. To retain the lubricant in the spline joint and to protect it from contamination, a rubber seal 10 is installed at the rear end of the flange 9 in a steel cage 11, and a rubber sealing ring is installed in front, at the end of the driven shaft of the gearbox. The spline connection is lubricated through a hole closed with plug 12.

The rear tip of the front driveshaft passes through the ball bearing of the elastic intermediate support 20. The elastic rubber cushion of the support absorbs vibration of the driveshaft and allows axial movement of the front driveshaft. The ball radial bearing of the intermediate support is a sealed bearing with seals and LITOL-24 lubricant applied during assembly. For additional protection, dirt deflectors 26 are installed on both sides of the bearing. From axial movements, the outer ring of the bearing is held on one side by the flange of the housing, and on the other by a spring lock ring 28 installed in the groove of the housing. The final processing of the bearing hole in the housing is performed after vulcanization of the rubber cushion with the housing and the propeller shaft support bracket.

The bracket for the intermediate support of the propeller shaft is attached to the cross member with two bolts and nuts, and the cross member is attached with nuts to two welded bolts on the body floor with the installation of steel spacer bushings 22 and rubber insulating bushings 23.

On the splines of the rear end of the front propeller shaft, a fork 29 of the cardan joint is installed and secured with a nut 30. Between the end of the fork 29 and the protrusion of the rear tip, the inner ring of the bearing 27 of the intermediate support and the mud deflectors 26 are clamped.

The driven shaft of the gearbox is connected to the cardan transmission by an elastic coupling 16, which reduces noise and vibration and allows torque to be transmitted at an angle. An elastic coupling consists of six round rubber elements with rigid metal liners placed between them with holes for fastening bolts.

The elastic coupling insert is a reinforcement welded from two stamped halves with a ∅12 +0.25 +0.1 hole for the fastening bolt and a protrusion that fits into the groove on the connecting flanges when the coupling is installed.

The elastic coupling is centered on the flange 4 of the driven shaft of the gearbox with the projections of three liners and three bolts 3 with nuts attached to it. Three other liners serve to center and secure the coupling to flange 9 of the front propeller shaft. The protrusions of the liners, which fit into the grooves of the flanges, in addition, fix the liners when tightening the nuts of the bolts securing the elastic coupling to the flanges.

The coupling in the assembled unit, as well as during transportation and storage, is in a pre-compressed state of rubber elements. During transportation and storage, a bandage made of steel tape with a special lock is used.

In the assembled unit, the elastic coupling mounting bolts are located on a circle of ∅100 mm, while in the free state of the coupling, the mounting holes in the liners are located on a circle of ∅110 mm. The ratio of the length and thickness of the straight rubber elements of the coupling is chosen so that each of them acts as a beam, engaged at the ends and loaded in the longitudinal direction.

The connection of the cardan transmission with the drive gear of the rear axle reducer is carried out using a flanged fork 25, the lugs of which include two bearings of the rear universal joint. The flange yoke is attached by four special bolts with self-locking nuts with a nylon insert to the rear axle drive gear flange.

A safety bracket 17 is installed under the front driveshaft, which protects the shaft from falling when the vehicle is moving in the event of a joint failure.

During manufacturing, the cardan transmission assembly is subjected to dynamic balancing on special machines. The imbalance is eliminated by welding balancing plates 18 at the ends of the pipes. The imbalance is allowed no more than 22 gf cm. In this regard, when disassembling the transmission, it is necessary to mark the relative positions of the separated parts so that during assembly they can be installed in their previous position. Violation of this condition will lead to imbalance of the transmission, which will cause vibrations that destroy the transmission and car body. If the pipe bends as a result of an impact and it is impossible to dynamically balance the gear, the bent shaft must be replaced.

Cardan cross device

KK is a hinge that ensures the alignment of all rotating elements, and consists of:

Each CC has four cups, which are the protruding elements of the assembly. All of them must be periodically checked for rotation, which should be smooth and even. The cups can be easily removed to check for lubrication.

Bearings are designed to move the cross in different planes. The needle elements located in the cups are secured with retaining rings and prevent the bearings from moving during rotation. The size of the rings depends on the diameter of the axial clearance. They are selected using a four-leaf feeler gauge, which is used to measure the distance from the cup to the edge of the groove - this will be the diameter of the restrictive ring. Depending on the size of the crosspieces, rings with a thickness of 1.50, 1.52, 1.56, 1.59 or 1.62 mm are installed on the VAZ 2107.

The size of the crosspiece of the steering shaft of the VAZ 2107

Note! Below are the shipping methods available specifically for this product. Payment options may vary depending on the shipping method. Detailed information can be found on the “Delivery and Payment” page.

Parcel by Russian Post

Available payment methods:

- Cash on delivery (payment upon receipt)

- Using cards Sberbank, VTB, Post Bank, Tinkoff

- Yandex money

- QIWI

- ROBOKASSA

Shipping throughout Russia. Delivery time is from 5 to 12 days.

Parcel by Russian Post 1st class

Available payment methods:

- Cash on delivery (payment upon receipt)

- Using cards Sberbank, VTB, Post Bank, Tinkoff

- Yandex money

- QIWI

- ROBOKASSA

Shipping throughout Russia. Delivery time is from 2 to 5 days. More expensive than regular delivery by Russian Post, approximately 50%. Parcel weight up to 2.5 kg

Express Parcel EMS

Available payment methods:

- Cash on delivery (payment upon receipt)

- Using cards Sberbank, VTB, Post Bank, Tinkoff

- Yandex money

- QIWI

- ROBOKASSA

Shipping throughout Russia. Delivery time is from 3 to 7 days. More expensive than regular delivery by Russian Post, approximately 100%.

Choosing a universal joint for a VAZ 2107

I once had an argument with a mechanic. He argued that crosspieces should not have an oil nipple, since it provides an extra hole for dirt to enter. The hinge quickly becomes clogged and fails. I insisted that without a grease can there would be no way to lubricate the crosspiece - it was somewhat offensive, since before that I had found an almost new screw syringe for lubrication in my grandfather’s garage. “Why, if each part has its own resource,” my opponent answered, “if the lubricant runs out, change the part, especially since it is inexpensive. It is better to pay attention to the seals (O-rings). If they dry out, new lubricant will not save.” Indeed, it is so.

When purchasing new crosspieces for the VAZ 2107, you should be guided by the following points.

Among the manufacturers of crosspieces, the following companies have proven themselves to be the best:

Signs of malfunction of VAZ 2107 crosspieces

Malfunctions of crosspieces are usually associated with wear of the sealing collars and dirt getting inside the bearings, which, having abrasive properties, begins to destroy the metal. This manifests itself as follows.

It is much easier to identify a faulty crosspiece on a removed cardan. If the bearings are damaged, the hinge will rotate poorly in one of the planes, and sounds resembling crunching or rustling will appear.

Clicking noise when starting

The first sign of a faulty universal joint is a loud clicking sound when turning on first gear at the start of movement. When such sounds, reminiscent of a clinking pan, appear, it is recommended to rotate the parts of the cardan in different directions with your hands, while holding the hinges. If large play is detected, the crosspieces must be replaced. It is noteworthy that sometimes clicks can appear only during a sharp start from a standstill, and when the movement begins smoothly, they may not appear.

Vibration

Often, if the crosspieces are faulty, vibration occurs when reversing. Sometimes it does not disappear even after replacing the crosspieces, but begins to appear at average speed. Moreover, the vibration may become even stronger than before replacing the CC. Such situations are a consequence of non-compliance with the alignment of the cardan elements during its assembly.

Sometimes vibration persists even after work has been done correctly. The reason for this is usually the use of low-quality products when replacing CC. Experts advise tapping the cups on all sides with a metal tube before installing new crosses. This will allow the stuck circlips to move and the vibration will go away.

Replacement of VAZ 2107 cardan crosspieces

Faulty crosspieces cannot be repaired. Theoretically, the universal joint is considered a very reliable part with a service life of more than 500 thousand km. In reality, even the highest quality crosspiece requires replacement after 50–70 thousand km. The reason for this is bad roads, intensive use of the car, etc. To replace the VAZ 2107 CC you will need the following tools and materials.

Dismantling the VAZ 2107 cardan

Before replacing the CC, it is necessary to dismantle the cardan drive. This is done as follows.

Removing the VAZ 2107 cardan cross

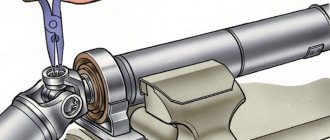

The cups and bearings can be removed from the driveshaft clamped in a vice using a special puller. However, this device is not very convenient and is used extremely rarely. Usually a standard set of tools is used. Dismantling the cross is carried out in the following order.

- Using round-nose pliers or pliers, remove the retaining rings from four sides of the cross.

Before installing new CCs, the lugs, fork and grooves for the retaining rings are cleaned of dirt and rust with a metal brush. The installation itself is carried out as follows.

Installing the cardan

When installing a cardan with new crosspieces in place, you must:

Video: replacing the VAZ 2107 universal joint

Thus, to replace the cardan cross, all you need is the car owner’s desire to do it himself and a standard set of mechanic’s tools. Carefully following the instructions of specialists will allow you to do the work efficiently and avoid possible mistakes.

The rear-wheel drive VAZ classic seems reliable and indestructible, at least this concerns the Fiat transmission, from which you can’t expect a stab in the back. However, in order to be confident in reliability, you must carefully select spare parts. Using the example of replacing the universal joint crosspiece of the seven, we will see how important it is to buy high-quality hardware and distinguish it from junk.

Content:

Steering shaft crosspiece VAZ 2107 dimensions

Crosspiece for domestic vehicles and tractors

Cardan shaft crosspieces for imported agricultural machinery

"CROSSROADS" OF CARDAN SHAFTS

"CROSSROADS" OF CARDAN SHAFTS

When you come to the store to buy a driveshaft crosspiece for a VAZ car, you can see three types of them on the counter - “small”, “medium” and “large”.

Our correspondent Sergei MISHIN received advice on their use from the chassis development department of the VAZ Scientific and Technical Center.

Let's start with the fact that the cars leaving the factory gates today have crosspieces manufactured at VAZ under a German license.

All Zhiguli cars use “fifth” crosspieces (joint catalog number - 2105–2202025), which replaced the old “zero first” (2101–2202025) in mid-1987. But both are available for spare parts, both separately and with a driveshaft.

What is the difference between the new cross and the old one? Despite the same external dimensions (outer diameter of the bearing and center distances), there are many differences. Firstly, the “fifth” crosspiece has a tenon diameter that is approximately two millimeters larger than the “first” one. The number of needles in the bearing is also larger, although their diameter is smaller. These changes made it possible to reduce the specific load in the bearing, which made it more durable. By the way, the bearing housings of the new crosspiece are stamped, and not turned, like the old one.

Secondly, the new crosspiece has a fundamentally different bearing seal - it protects against dirt much more reliably. This was done again to increase durability.

Thirdly, the supply of lubricant from the stud hole to the bearing is organized more evenly thanks to the use of special plastic spacers in each stud, which have three radial channels (at an angle of 120 degrees to each other) for supplying lubricant to the needles.

From all this it becomes clear that the bearings from the “first” will not fit on the tenon of the “fifth” crosspiece, and vice versa. So when purchasing bearings separately from the crosspiece, this must be kept in mind.

CROSSINGS FOR NIVA

Since 1987, “Nivas” have also been produced with their own, original cross. Its most serious differences from the “classic” one are its increased dimensions and the presence of a grease fitting.

This crosspiece has part number 21211–2202025. The outer diameter of its bearing is slightly more than 28 millimeters, so even if it is without a grease nipple (which should not be the case), it is impossible to confuse it with a “classic” one. Naturally, this cross is not interchangeable with the previous two. It differs fundamentally from the “fifth” in that it has a double bearing seal. Let us take this opportunity to remind you that the crosspieces are supposed to be injected every 10 thousand kilometers. Lubricant 158 is best suited for these purposes. You can also use Fiol-2U, but the latter is produced in very limited quantities.

Having received information about VAZ crosspieces, we also learned that there are

Today, a variety of cardan shaft assemblies are available for spare parts. The fact is that, in addition to the mechanical assembly production of VAZ and the Saratov 3rd GPP, several factories of cardan shafts also produce them (not to mention the “wild” manufacturers). Even on the spare parts market in Tolyatti you can find cardan shafts produced by GZKV (Grodno Cardan Shaft Plant), Chimkent ZKV and others. “Non-brand” driveshafts are distinguishable by the catalog number stamped directly on the shaft tube. For example, the Nivovsky front driveshaft is numbered 21211–2203012, and the rear driveshaft is numbered 21211–2201012. So, a shaft produced by any ZKV is marked with two additional numbers. This could be 21211-2203012-10, 21211-2201012-01 or some other numbers in addition to the main catalog number. Not only are such cardan shafts, as a rule, poorly balanced, they may also contain non-standard crosspieces - GAZ or Moskvich. In this case, the total length of the driveshaft will be normal.

By the way, VAZ crosspieces can be distinguished from non-VAZ ones by appearance. Only products from Togliatti have the OTK mark painted on the body. All other crosspieces bear a molded trademark or designation of the manufacturer - emblem, letters, numbers, etc. As a rule, such products are not made in the best way, which means they cannot compete with today’s VAZ ones in quality and, accordingly, in mileage.

WEBER crosspieces are a high-quality certified product, excellent for working in harsh climatic and operating conditions. WEBER crosspieces guarantee a flexible connection between cardan shafts and steering shafts of cars and trucks, as well as agricultural machinery.

The design of WEBER crosspieces incorporates the knowledge and experience of engineers and designers from global automakers. The latest technologies have been integrated to meet modern requirements.

Only high-alloy steel is used in production. Processing is carried out on high-precision CNC equipment, which ensures the most accurate compliance of all dimensions with specifications and minimizes tolerance values. The increased hardness of the upper layers of steel, combined with the elasticity of the middle layers, provides resistance to deformation and vibration loads, which allows increasing the service life of Weber crosspieces.

An increase in the hardness of the top layer of steel is achieved by carburizing it followed by heat treatment. The crosspiece is supplied with a fully charged lubrication system. Lubricants with high anti-friction and water-heat-resistant properties are used. The seals are made of polymer-ceramic materials developed by specialists in the defense industry. They are resistant to high temperature and mechanical loads and ensure the tightness of the lubrication system throughout its entire service life.

As a result, Weber crosspieces have increased strength, resistance to vibration loads and external influences, and remain operational throughout their entire service life.

When to change crosses

In fact, replacing the VAZ 2107 driveshaft crosspiece, like a similar operation in all rear-wheel drive cars, is not particularly difficult and does not require the talent of a born mechanic. An hour of work and everything is ready. We will definitely touch on replacement technology too, but first you need to make sure that replacement is necessary.

It’s not difficult to know that the days of the cross are numbered. This will be indicated by vibrations of the driveshaft of the VAZ 2107, knocking and ringing when starting from a stop, sharp acceleration or, conversely, sharp deceleration, when the difference between the speed of rotation of the gearbox shank and the secondary shaft falls on the shoulders of the driveshaft. In principle, to smooth out vibrations, there is an elastic coupling for the driveshaft of the VAZ 2107; to some extent it is smoothed out by the suspension bearing in the support of the driveshaft 2107. The cost of replacing one crosspiece at a service station is about 800 rubles, plus the crosspiece itself is 300-350 rubles. At a critical level of wear on the crosspiece, additional uncontrolled play appears, which we will eliminate.

Choosing the right crosspiece

Buying the first crosspiece you come across means dooming yourself to further headaches with the cardan, since in 80% of cases, what is offered in car dealerships is complete rubbish. The dimensions of the VAZ 2107 crosspiece are identical to the same crosspieces from all rear-wheel drive Zhigulis, but in the early 80s a special crosspiece with the index 2105-2202025-00 was released. It is called reinforced. It was standardly installed on all Zhiguli cars after 1988. In principle, the crosspiece 2101-2202025-01 is interchangeable with a new part, but the plant does not recommend such a replacement.

Engineers explain this by saying that the rigidity of the hinges on the new crosspiece does not correspond to the operating conditions of the old 2101 driveshaft. Actually, you can change it, but at your own peril and risk. The difference in size is so insignificant that you can ignore it - a little less than a millimeter, although this may be a consequence of inaccuracy in manufacturing. The main differences between the five and old crosses are as follows:

But this is not the most important thing in choosing a part. Before purchasing, you need to check the crosspiece for compliance with the plane. Few people do this, as a result of which a beautiful new crosspiece successfully finishes off the gearbox shank and its bearings with increased vibrations.

Crosspieces: selection and replacement

Name: Alexey Reg.: 06/19/2017 Threads / Messages: 2 / 1497 From: Tula Age: 50 Car: VAZ-21213 1999

Reg.: 04/03/2015 Messages: 160 From: Russia, Volgograd Age: 34 Car: VAZ 21214, 2009

Alexpr, it is loosened so that you can install the cross without the help of tools. In the package, in separate sealed bags, there was a cross and locking rings with a grease fitting.

The size of my cross is 28x71. Of course, you can measure it accurately with a micrometer, but even a caliper showed 28 mm the glass size of the new cross and 28.1 mm the size of the old glass.

Name: Alex Reg.: 01/04/2018 Posts: 639 From: Saratov Age: 44 Car: 2131 2009

Reg.: 04/03/2015 Messages: 160 From: Russia, Volgograd Age: 34 Car: VAZ 21214, 2009

I will look for such a cross, but I will go with a sliding fork to be sure to try it on. By the way, on the original cardans the key for the grease fitting is set to 13, and on the new crosspiece - neither here nor there - at 11.

Today in the garage I took a video on my phone so that instead of a thousand words, it’s better to see it once and be prepared for such a turn of events, stopping this in the store. First the new crosspiece, then the glass from the old crosspiece.

https://youtube.com/watch?v=vgohv_T7tFA

Name: Alex Reg.: 01/04/2018 Posts: 639 From: Saratov Age: 44 Car: 2131 2009

Name: Alexey Reg.: 06/19/2017 Threads / Messages: 2 / 1497 From: Tula Age: 50 Car: VAZ-21213 1999

Name: Alex Reg.: 01/04/2018 Posts: 639 From: Saratov Age: 44 Car: 2131 2009

Reg.: 04/03/2015 Messages: 160 From: Russia, Volgograd Age: 34 Car: VAZ 21214, 2009

My epic with the cross is over. I went to the store where I bought it, and surprisingly, without even swearing, they returned the money.

Further on the display case there were about three more brands of crosspieces - I tried them all on for fun - they slip through just as easily as in the video. And only the crosspiece of Kardan JSC did not want to slip through - I bought it. I pressed it in a vice using glasses from an old cross - it became like original and as it should be.

But still, here I was “lucky” - there was no ball in the grease fitting; I replaced it with a grease fitting from an old cross. So keep your eyes open when buying even proven items)

How to check a crosspiece for quality

To check the crosspiece, you must first look at the manufacturer, and then, if he has inspired trust, remove the part from the packaging and place it assembled on a flat mirror plane. Ideally, of course, this is an ordinary mirror. When the cross is laid, when trying to rock it, the ends of the bearings should not come off the surface on either side.

Then you need to swing the next two bearings. If everything is normal, there are no backlashes or wobbles, the crosspiece does not knock on the surface, the part is turned over and checked on the other side. It will only take a minute, but if someone repeats this experiment when purchasing even branded VAZ crosspieces, he will be unpleasantly surprised when he selects one of a dozen parts.