When the time comes for a planned replacement of the cardan crosspiece or (more likely) vibration, beating, noise and crackling begin in the area of the cardan, car owners are prepared to pay a significant amount for repairing the cardan. Most often the cardan crosspiece requires replacement. This part cannot be restored, it can only be replaced. It is not expensive, but replacement work will require removing the cardan, so be prepared to spend a whole day at the service station. If you are not afraid of difficulties, then you can change the cardan cross with your own hands.

The cardan serves to connect the gearbox and the rear (in a rear-wheel drive car) or front (in all-wheel drive) axle. Its task is to transmit rotation from the engine to the bridge or bridges. The connection point for these elements is the hinge, the main part of which is the cross. It has the shape of a cross, at the ends of which there are cups with needle bearings. The bearing is separated from the housing by a sealing ring made of rubber or plastic. For each car model, the dimensions of the crosspieces differ from each other.

Cardan shaft crosspiece – Techno Cardan

The crosspiece is the main element of cardan shafts, on which the service life of cardan transmissions directly depends.

This part is found in any car. The main purpose of this part is to dampen the resistance of the cardan and transmit torque to the wheels. In addition, the driveshaft crosspiece provides a permanent movable connection, which is so important for the balance of the car on bad roads. It is most susceptible to loads on trucks, as it experiences constant pressure from transporting heavy loads.

The crosspiece is a fairly durable part, but sometimes the time comes when you need to replace it. In addition, there are times when on a bad road, stones fly under the bottom, which can damage the mechanism.

If you feel body vibrations at turning angles, then it is urgently necessary to replace it. If you continue to drive a car with a damaged spider, this can lead to more costly breakdowns over time, and you will also put your life and the lives of those around you at risk.

Let's find out what the universal joint includes:

6) Needle bearing housing (sometimes called a glass)

When purchasing, it is very important to choose crosspieces from branded manufacturers, since only products from well-known manufacturers can provide the required quality and durability.

Source

Spring for cross.

AREA recommends either a double spring, which is placed in front of the core and is placed on a bolt passed through both guard rails, or a single spring connected to the spring guard rail above the second core beam and supported by a pad attached here. The spring is usually a double helix, with the larger spring being called the outer helix and the smaller spring being called the inner helix. The spring pressure is transferred to a metal cylinder called a guide bushing; springs are placed in metal cups. The guide bracket consists of a bracket protruding at right angles from the reinforcing strip, riveted or bolted, according to the AREA project, to the wing of the spring guardrail; this bracket moves back and forth inside a wrapped U-shaped bracket in small increments to prevent the moving guard from lifting, especially if ice forms underneath it. Usually two of these guide brackets are sufficient. The guide shoe is a structure, according to the old design, riveted to the load-bearing lining, and according to the AREA project, welded to it, in order to absorb a side impact when the spring rail is in the open position; the guide shoe acts as a rail stop.

Design and purpose of crosses

Any driveshaft that is part of a vehicle's transmission has a spider. It is a critical part of the cardan transmission, which transmits torque from the gearbox to the axle at an angle that constantly changes while the vehicle is moving.

Cross device

The crosspiece is nothing more than a cross-shaped joint that ensures the alignment of the rotating transmission elements. The propeller shaft joint includes two forks, which are connected by the crosspiece itself: their ends are attached to the four spikes (ends) of the crosspieces. One of the forks has a rigid attachment to the cardan shaft pipe. The hinge moves with the help of needle bearings, which are mounted on four spikes of the crosses. The forks have holes in which needle bearings are installed. They are secured from displacement by stoppers (circlips). The thickness of the rings can be different, depending on the permissible axial clearance. When disassembling the crosspiece, you can change the retaining rings to reduce play and vibration.

Purpose of the cross

The lifespan of the driveshaft and the entire transmission depends on the condition of the crosspieces. In a rear-wheel drive car, the gearbox, engine and front driveshaft are fixed to the car body, and the rear axle and wheels constantly move vertically relative to the body. The angle between the front driveshaft and the reverse gear changes. The purpose of the crosspiece is to provide a movable connection that can change the angle on an uneven road, dampen the dynamic deformation of the cardan and transmit torque to the wheels. The sizes of the crosspieces can be different, depending on the gear in which they are used - front or rear, and the crosspieces of different brands of cars also differ.

Source

When to replace the rear propeller shaft spider

Important!

Rear driveshaft crosspieces are important parts of the driveshaft. It is necessary to install high-quality and good parts, because this determines how effectively the rotation from the engine will be transmitted, as well as safety while driving. If you hear a knock, noise, or feel vibration while the vehicle is moving or when changing gears, you need to check the universal joint and may need replacement. It is worth noting that the rear crosspiece deteriorates faster. It has a large load. But such signs can indicate not only the breakdown of these parts, therefore, before making a replacement, it is necessary to perform diagnostics.

Cardan crosspiece

Cars with rear-wheel drive or all-wheel drive have a cardan drive. This applies equally to both cars and trucks. The cardan transmission (CP) consists of:

- a cardan consisting of a hollow pipe;

- crosses;

- sliding fork.

Some machines use an articulated driveshaft consisting of sections. Such a device includes a suspension bearing, rigidly attached to the machine body, and another cross. On some cars it may consist of several sections - one, two, and sometimes three. The crosspiece plays a major role in transmitting torque from the gearbox to the rear axle gearbox.

Other types of movable joints and their combinations

One of the alternative types of movable connection for transmitting torque is the angular velocity joint, or CV joint. This connection helps to avoid uneven rotation of the connected shafts when the angle between the mating parts is more than 20 degrees - from 30 to 70.

The transmission of torque in situations of large misalignment is carried out by the intermediate shaft. It consists of an elastic coupling, a flange and a constant velocity joint. The mobility of the connection of misaligned elements in this design is ensured by an elastic coupling. It is a structure of steel liners and rubber bridges connected together. Jerks of the car transmission are damped due to the elasticity of the coupling. Cardan joints are also used in the shaft design, since there is a large misalignment between the shafts that are connected by the shaft.

The intermediate shaft is used, for example, in the design of the transmission of all-wheel drive VAZ vehicles (21213, 21214, 2131) of the Niva - Lada 4x4 families. At the same time, in cars of the current VAZ 21214 model, the universal joints of the industrial shaft are replaced with CV joints - less noisy and do not require alignment adjustment.

How does the driveshaft cross work?

The main purpose of the crosspiece is to transmit rotation; it mates the rotating shafts at an angle to each other. Effective work is carried out at angles from 0 to 200; at larger angles it is subject to greater overloads.

An imbalance appears, resulting in strong vibration of the car.

In the production of the device, high-alloy steel is used, which is processed and hardened in a special way. Structurally, it is made in the form of a cross, at the ends of which there are four needle bearings. The use of special materials allows it to work for a long time. The resource is about one hundred thousand kilometers. If a car enthusiast drives carefully, the service life can be extended to two hundred thousand or more.

Cardan joint: device, purpose

The device with two forks is made in the form of a universal joint, which performs the main function in the gearbox. It is divided according to the type of transmitted rotation:

- transmitting rotation of equal angular velocities (CV joint);

- transmitting rotation of unequal angular velocities;

- with a semi-cardan elastic and rigid hinge.

Mechanisms are single-shaft, double-shaft and multi-shaft; based on the number of hinges, they can be divided into single-, double- and multi-hinge.

In front-wheel drive cars, CV joints are installed that do not use crosspieces.

The mechanism is mounted on vehicles with rear-wheel drive or all-wheel drive. When transmitting unequal angular velocities, one and sometimes two cardans are used, it all depends on the distance over which the rotation needs to be transmitted.

The first shaft, located from the gearbox to the support, is called the intermediate shaft, and the second is called the rear shaft. They are connected using a support, rigidly fixed with a clamp on the bottom of the car. This is the so-called suspension bearing.

This device is designed to properly maintain HF. This design uses an additional hinge with a cross. In addition to this gearbox, a compensating device is used, which is called a sliding clutch. It is designed to lengthen or shorten the cardan while the machine is moving and is a splined connection between the cardan and the fork tip. When overcoming obstacles, a mutual change occurs between the rear axle and the car body. As a result, the cardan is compressed or stretched. These changes are compensated by a sliding clutch. If it is necessary to transmit rotation to two shafts at an angle, a mechanism with a semi-elastic hinge is used.

Self-protecting crosses

The cost-effectiveness and safety of self-protecting crosses, or crosses with flanges, used on station tracks at moderate speeds, is well known. This type of crosspiece (Fig. 5) eliminates the use of counter rails, as a result of which the cost of them and their accessories and the added cost of their maintenance are eliminated. This is especially important in the presence of ice and snow. The absence of counter rails eliminates the worries and costs of maintaining them within the limits of standards and ensuring traffic safety conditions. The crosspiece is designed to ensure that the wheel flanges, passing at the tip of the core, are guided with the help of rising guard flanges; The outer parts of the wheel tires, easily touching them, are deflected in the required direction without a push. These devices come in three types: one casting with a cross, made from rails with raised flanges that are part of the cross, and special devices with adjustable parts. AREA has approved standards for solid cast manganese steel self-protecting spiders for grades 1/4 to 1/10 inclusive. Their design is similar in general terms to the design of solid manganese steel crosspieces, but with the addition of security flanges common to the casting, rising 32 mm above the rolling surface. Flanges with gentle bends gradually reach a distance from the working edge equal to the standard width of the wheel tire; then they run almost parallel to the working edges to the theoretical tip of the cross, from which they move along a curve of variable radius to the end of their raised part, where a minimum distance of 152 mm is ensured between the flange and the corresponding working edge.

Rice. 5. General view of a solid cast self-protecting cross

Malfunctions

Gearbox failure is characterized by strange sounds; while driving, the car moves jerkily, and a metallic sound is heard when changing gears.

The main gearbox malfunctions are:

- play in the hinges;

- deformation of the cardan shaft. This malfunction occurs when struck by a stone or when hitting a protruding obstacle;

- damage to the seals or their deterioration;

- damage to protective covers;

- wear of needle bearings;

- weakening of mechanism connections.

All defects that arise can be easily eliminated by car service specialists. Faulty elements are replaced with new ones, and loose connections are tightened.

If the crosspiece is faulty, the most correct solution would be to transport the car on a tow truck to a car service center, where they will diagnose the car using special stands, identify the faulty part and offer the best repair option. Important! Some owners try to carry out diagnostics in car services located in garage cooperatives. As a rule, there is no staff there, and one specialist is not able to know all the intricacies of repairs.

Therefore, car enthusiasts should not contact such car services. Apparent savings on repairs turn into additional, and often not small, costs. When performing work, our car service uses methods developed at manufacturing plants. After any repair work, the car owner receives a warranty for spare parts and all types of services and repairs.

Crosspieces with movable guard rails.

The main difference between crosses and a movable guardrail (Fig. 3) and conventional crosspieces is the presence of a movable guardrail, instead of one of the fixed guardrails, and a spring to return it to its place after the wheels pass along its groove. Supporting bridges are essential for crosspieces with a movable guard, and a carriage is often part of the structure in addition to the double pads. Various details, such as anti-lift devices and a retaining shoe, are intended to keep the guard in place in relation to the costal parts of the cross. Recently, crosspieces with spring guards have begun to attract more attention. Recent projects have eliminated many wasteful parts and now produce a cross that is more powerful and requires less maintenance. AREA has developed designs for 1/9, 1/10, 1/11 and 1/12 grade crosspieces. These designs have short spring rails and replace all the rivets in the reinforcing strips with bolts. In addition, clamping brackets attached to the main bolts and bolted to the carriage or pads replaced the former rivet connections. The carriages provide the crosspiece with the correct direction in profile and plan, and rivet joints, on the contrary, give unsteadiness and play due to corrosion or vibration under the composition. Although these new designs require greater articulation at the joint due to the short spring length of the rail, they have been used successfully on busy roads for several years. The short guard at the front of the cross allows the use of a shorter counter rail in a straight path, and this is its advantage. Crosspieces with a movable guardrail are used almost exclusively on main lines - at transfers and exits, where traffic occurs primarily along the main track. Properly designed shock absorbers ensure that the spring rail remains open as the train passes and closes with a slight click after the last wheel of the train has passed, without damaging the crosspiece.

Rice. 3. Crosspiece with a movable guardrail: 1 — length of the crosspiece; Lpp - front part; Lnm is the theoretical length of the front part; Lxn - tail section; L xm - theoretical length of the tail section; 1 — front liner; 2 - movable guardrail; 3 - fixed guardrail; 4 — guards for legs; 5—carriage; 6 — main liner; 7 — place of insertion of the short core rail; 8 — core liner; 9— theoretical tip; 10 - practical tip; 11 — guide bracket; 12 — spring cup; 13 — fuse for legs; 14— tail liner; 15 - long core rail; 16 — corner of the cross; 17 - short core rail; 18 — paired linings; 19 — front liner; 20 - fixed rail; 21— straight butt plate; 22 — movable guardrail; 23 - stepped bolt; 24 — curved butt plate; 25 — external spiral spring; 26 — internal spiral spring; 27 — rod; 28 — rod guide bushing; 29 — recess in the rail head; 30— spring cup bracket; 31— spring cup; 32 — movable guardrail; 33 - amplification band; 34- guide bracket; 35 — guide bracket bracket; 36 — cushion of the guide bracket; 37 — support for the bolt head; 38 — clamping bracket; 39 — main liner; 40— core liner

The guardrail spring rail is sharply bent to provide sufficient space for the guardrail spring rail to be able to open when the wheels of the train pass. A triangular recess is cut into the head of the spring guardrail to allow the flanges of the wheels of the train passing along the main track to pass through. The notch is 12.7 mm deep at the tip and disappears at the point of the core where the bandage completely covers both rails. This prevents impacts from worn flanges and unnecessary opening of the spring guard during the passage of rolling stock.

Cardan cross: review of faults and self-replacement

When the time comes for a planned replacement of the cardan crosspiece or (more likely) vibration, beating, noise and crackling begin in the area of the cardan, car owners are prepared to pay a significant amount for repairing the cardan. Most often the cardan crosspiece requires replacement. This part cannot be restored, it can only be replaced. It is not expensive, but replacement work will require removing the cardan, so be prepared to spend a whole day at the service station. If you are not afraid of difficulties, then you can change the cardan cross with your own hands.

Design and purpose of the cardan cross

The cardan serves to connect the gearbox and the rear (in a rear-wheel drive car) or front (in all-wheel drive) axle. Its task is to transmit rotation from the engine to the bridge or bridges. The connection point for these elements is the hinge, the main part of which is the cross. It has the shape of a cross, at the ends of which there are cups with needle bearings. The bearing is separated from the housing by a sealing ring made of rubber or plastic. For each car model, the dimensions of the crosspieces differ from each other.

How do you know if the crosspiece has failed?

This is the central link in the cardan. As we have already noted, it is the crosspiece that transmits torque between the gearbox and other units. That is, the shaft rotates precisely thanks to it. If a breakdown occurs on the road, every driver should be able to repair the car. This means you need to know how to remove the cardan and how to repair it. And this is especially difficult when you consider that the entire device often fails.

It is important to use a puller when disassembling; when removing the retaining ring, it must be undamaged. If you hear a knocking sound when driving the car, then it means you have problems with the driveshaft. Grinding of parts may also be heard. Never install a puller without first removing the retaining ring; this cannot be ignored. A couple of hundred kilometers will pass, and the cardan will completely fail, causing an accident.

The main reason why the cardan breaks is the gap in the hinge; the bearings can also wear out.

The size of the cardan is small, but this device can be the reason why the car does not move.

Problems with the driveshaft occur when the car is driven by a reckless driver, especially on a bad road. The hinge easily fails, as all the dirt from the road and water after rain get on it. Using a puller, you can easily dismantle the faulty part right on site. Also, the cardan does not work well if you move over rough terrain for a long time.

Possible crosspiece malfunctions:

- Cross play

- Needle bearing wear

- Wear of the cross itself

- Leakage and lack of lubrication

- O-ring failure

- Metallic ringing when moving

- Noise and crackling in the cardan area

Theoretically, the crosspiece is a very reliable part, the service life of which should be about 500,000 kilometers. But in practice, replacing the universal joint cross occurs after a mileage of 50-100 thousand kilometers. This is influenced by factors such as operating conditions, the manufacturer of the part, and the quality of the materials used in the manufacture of the part. If your car is often used in rural areas, then dirt and various bumps will shorten the life of your cross by several times. A common reason for crosspiece failure is simple inattention during routine maintenance. Often, no attention is paid to the lack of lubrication until the crosspiece makes itself known by vibration, noise or ringing.

Manganese crosses.

Manganese steel has been used in crosspieces since 1900. The abrasion and impact resistance inherent in both cast and rolled manganese steel has made it possible to use it in crosspieces under severe operating conditions, where two or three ordinary carbon crosspieces wear out in the same period of time. become. Due to the relatively high cost of manganese steel, its use on less stressed tracks is currently avoided and manganese steel is used there only for the wearing parts of crosspieces made of carbon rails. Manganese steel is used as a general casting for the core and throat of the crosspiece, and the adjacent parts are made from carbon rails. Such crosses are known as manganese insert, manganese center, manganese body, or prefabricated manganese crosses (Fig. 4). This design makes it possible to extend the service life of the crosspiece, taking advantage of the advantages of manganese steel without a significant increase in cost compared to carbon steel. Although at one time crosspieces were made entirely from rolled manganese steel rails, a more common design in areas of intense wear is a solid-cast or prefabricated manganese crosspiece. The first of these two cross designs is preferred for goods yards with steep curves, where axle loads are high and where switch work is intense.

Rice. 4. General view of the prefabricated cross with an insert made of manganese steel

The overall manganese casting works as a single piece, is easy to maintain and has a long service life. A solid manganese cross is not economical for 1/12 grades, which typically use a prefabricated manganese cross. This latter design is economical for all brands of crosses and is preferably installed on main tracks.

Prefabricated manganese crosses.

There are two types of manganese fixed crosses - prefabricated and solid-cast. The first type is most desirable for long transfers, since manganese steel is especially suitable for long thin cores, and such crosses require comparatively little maintenance. This type is also desirable for transfers on the main track and at ramps where a significant portion of traffic is diverted through the transfers, and for locations where high speeds are applied on station tracks. To ensure continuity of the working edges of the rails and castings, it is necessary to have a tight connection at both ends of the crosspiece and the use of powerful backing blocks, often equipped with flanges or hooks, to protect the transfer bars from premature wear and keep the crosspiece in the correct position. AREA drawings for prefabricated manganese crosses include grades 1/4, 1/5, 1/6, 1/7, 1/8, 1/9, 1/10, 1/12, 1/14, 1/15, 1/ 16, 1/18 and 1/20. The drawings call for a manganese steel casting for the center section, supported and bolted to carbon steel reinforcing rails. The entire casting is called the manganese body, the side parts of the casting are called manganese guardrails and the central part is called the core. The remaining parts have the same names as in ordinary prefabricated fixed crosspieces. In AREA designs for prefabricated manganese crosses, the manganese body of the cross protrudes significantly forward beyond the throat of the cross, and also beyond the tail, where it fills the space between the tail rails and serves to connect them, and also as a tail pad. The guard rails opposite the core have a full cross-section. The practical tip of the core in all types of manganese crosses, except those intersecting at an angle of 25° or more, is installed in the place where the width between the working edges is 15.9 mm, instead of the usual 12.7 mm. However, for ease of use, the theoretical tip of the core with a width of 12.7 mm is marked on the cross with a notch. For manganese crosses with angles of 25° or more, the practical core tip is 12.7 mm wide. The depth and width of the gutters are 47.6 mm and the edges of the bottom at the bottom are rounded to a radius of 21.4 mm.

Solid manganese crosspieces.

This type is intended exclusively for heavy work in station parks. Crosspieces that have an upper surface without raising are used in places where speed is not limited, and where speed is limited, solid manganese crosspieces with flanges on guardrails, or so-called self-protecting ones, are used. The construction details are relatively simple, as the crosspiece consists of a single casting with plates and bolts for attaching adjacent rails. These crosspieces contain double linings with hooks. Solid manganese crosspieces of grades lower than 1/12 are generally uneconomical. Therefore, AREA standard drawings provide only grades 1/4 to 1/12 inclusive. They are designed for medium to heavy weight rails. Due to the high cost of manganese steel castings, they are made to the minimum practical length. The solid manganese cross is an independent design. It has an additional projection at the rear end, which also includes a tail pad, and a projection at the front, both projections being inserts between adjacent rails. AREA recommends the use of 914 mm long butt plates for grade crosses from 1/7 to 1/12 for rail types 56 kg/linear. m and heavier and butt plates 610 mm long for the remaining crosspieces.

Troubleshooting

Before carrying out repairs, you need to find the cause of the problem. To do this, you will need to drive the car onto a pit or a lift. We put the transmission in neutral and climb under the car. We inspect the cardan, special attention should be paid to the condition of the crosspiece seals. Next, holding the crosspiece, we rotate the cardan itself. If the crosspiece requires replacement, the play can be noticed immediately. If there is no play, but various noises and squeaks are heard during rotation, then the crosspiece may not need to be changed. You just need to replace the lubricant. There are two crosspieces in the cardan and both need to be diagnosed. The rear universal joint crosspiece fails most quickly, since it bears heavy loads. When moving, dirt and moisture also fall more onto the rear crosspiece.

Determining the cause of extraneous noise

To determine the problem, you need to know where the driveshaft spider is located and how to access it. This will require an inspection ditch or a lifting mechanism, since the part can only be inspected from below.

Inspection stages:

- We turn on neutral gear.

- Let's look at the cardan. Be sure to pay attention to the technical condition of the seals.

- We check for play. We hold the crosspiece and begin to rotate the cardan. If play is detected, the part will have to be removed. If you only hear an unpleasant sound, you may only need to replace the lubricant.

- We examine the second cross.

Most often, the rear universal joint spider fails. It takes on increased load and works in more difficult conditions.

How to change the crosspiece on the cardan

To repair the crosspiece, it is necessary to remove the cardan. Before you disassemble, you need to know some nuances:

- Fill the nuts with waterproofing agent to make the fasteners easier to unscrew.

- Use a chisel to mark the cardan flanges and rear axle flanges. If this is not done, vibration may occur on the cardan.

- To avoid damaging the threads of the nuts, it is advisable to use a curved spanner.

- If the cardan bolts rotate, you need to fix them with a screwdriver.

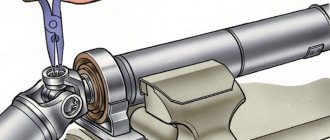

First, unscrew the four bolts on the propeller shaft, then remove the suspension bearing mount. After these procedures, we remove the cardan; it needs to be removed from the gearbox splined connection. Before removing the crosspiece, it is advisable to wrap the spline part with material to prevent sand from getting in there. Before removing the crosspiece, you need to prepare a tool: a hammer, pliers, a thick screwdriver and a round tube of suitable diameter. Clamping the shaft in a vice will make your work much easier. There are special pullers for removing crosspieces, but they are often not used even at service stations. However, many garage craftsmen are able to make such a device for themselves in 10-15 minutes. Next we get the retaining rings. Often, to remove them, you need to tap them with a hammer using a spacer. After this operation, the stoppers can be easily removed with pliers. Next, the cups are knocked out of the eyes. This is done with a hammer and the same spacer that was used when removing the retaining rings. Sometimes the cups fall out on their own; most often you will have to remove them with improvised objects.

Checking the D-Pad for Problems

To ensure long service life of the gimbal and retaining ring, it is important to check them carefully. To do this, remove the cardan to the surface using a puller. Fortunately, this part is small in size, which makes it easy to inspect the element for cracks and gaps. To do this, simply rotate the crosspiece parts in different directions. If there are problems, you will notice it immediately. Take the flange with one hand, the driveshaft with the other and rotate in different directions. Is there any play? This means there is a problem with the device.

You may have to completely replace the steering, but if only the hinge is broken, then its dimensions allow you to repair the part yourself using a puller. This way you will correct the operation of the cardan, which is the steering wheel in the car.

The steering is easy to change. To do this you need to take the following steps:

- the mounting bolts are unscrewed,

- the cardan is dismantled, fortunately the dimensions allow this to be done,

- the nuts should be unscrewed,

- the locking ring opens,

- the cross is removed.

Preparing the lugs and forks and installing a new spider

The repair will be carried out poorly if the eyes and fork are not cleaned of dirt and rust. This is done with a metal brush or sandpaper. All internal surfaces also need to be cleaned and lubricated before installing a new cross. Do not forget about the grooves of the retaining rings; they need to be cleaned with an awl or a thin screwdriver. Next, the cups are removed from the new cross, and the cross itself is inserted between the eyes. When removing the cups, you need to make sure that the bearing needles do not fall apart. If there is no lubricant under the new cups, the part should be changed, or lubricated yourself. The cups are placed on the crosspiece, then they need to be pressed in with a hammer until the locking grooves open. The repair of the cross is completed by replacing the retaining rings.

Installation of a new cross

Before installation, clean the lugs and fork from dirt and traces of corrosion. Dirt and rust can be easily removed with sandpaper. You should also check, clean and apply a layer of lubricant to the internal surfaces. The grooves for the stoppers must be thoroughly cleaned using a thin tool, such as an awl or a small screwdriver.

Installation process:

- We pick up a new crosspiece.

- Carefully remove the cups. Keep an eye on the bearings. When removing cups, they may fall apart.

- Be sure to check for grease under the cups.

- Install a new crosspiece.

- Place the cups, pushing them down gently until you see the grooves for the retaining rings.

- Install the retaining rings.

Installing a cardan on a car

When installing the cardan, you need to follow several rules:

- All connections must be thoroughly lubricated

- Avoid getting sand and dirt on moving joints

- Check the condition of the crosspiece seals. If they are worn out, replace them

- Achieve a complete match of the marks made when removing the marks. If they do not match, there is a high probability of vibration of the cardan and you will have to do balancing

First we insert the splined part, then tighten the four bolts on the cardan. Don't forget about attaching the outboard bearing. All bolts must be tightened well, and then checked again. If the driveshaft comes loose while driving, the car may be thrown off the road.

Sometimes repairs may not be necessary, you just need to inject. If you don’t know how to syringe the crosspiece, then you will need a large syringe and special lubricant. If you can't find lubricant, use lithol. The rear crosspiece especially needs to be sprayed, since the bulk of the dirt gets there. Many crosses have a special hole for injection. They must be thoroughly cleaned of dirt before the process. You need to syringe until the lubricant begins to pour out. Be prepared that most of the grease will be on the ground. It is better to collect a new portion of lubricant, but do not collect it from the ground.

Problems, cardan failures

Not often, but it does happen that the driveshaft knocks. Such knocking noises can occur during a sharp start or when changing gears.

Causes of noise:

- The bolts securing the flanges and the transmission coupling have become loose.

- Increased clearance in the sliding spline connection.

- Large gap in the cross bearings.

Reasons for vibration of the driveshaft when driving:

- the shaft is deformed;

- the cardan is installed incorrectly;

- shafts are unbalanced;

- the bushing of the intermediate coupling flange or the ring of the centering secondary shaft of the gearbox is worn out;

- the outboard bearing has increased clearance;

- the bolted connections of the transverse support have loosened;

- large gap in needle bearings and crosspieces;

- the fork connection has become loose;

- lack of lubrication in the shaft splines.

Why does grease leak?

Connections with lubricant and seals often become depressurized and lubricant leaks out (Litol-24, etc.).

There are only two reasons:

- The spline seal is worn.

- The crosspiece bearing seal is worn.

If you hear a crunching sound in the driveshaft area, it is recommended to go to the nearest service center and carry out diagnostics, or do it yourself.

How to eliminate the causes of cardan problems:

- Tap on the threaded connections, check if they are loose, tighten them.

- If there is a lot of play in the spline joint, then the shaft needs to be disassembled and examined; most likely it will have to be changed.

- If there is a large gap in the crosspiece, replace it.

- Replace deformed parts of the propeller shaft or replace them as an assembly.

- If the driveshaft was not installed according to the marks, disassemble it and install it according to the marks.

- If there is shaft runout, you need to check it for bent. Remove, twist. Of course, for this you need a special stand that will show whether the shaft is bent or not, but you can also see by eye whether the shaft is straight or not.

- Replace seals if grease is leaking.

How to check your work

You can check your work immediately after replacing the crosspiece and installing the cardan on the car. The verification process includes the same manipulations as when searching for cross play. The cardan should also be inspected for oil or grease leaks. Pay special attention to the seals. The second stage of testing is testing in motion. During a test drive, you can immediately hear vibration, noise or beating of the cardan.

The job of replacing the universal joint is complete, and you did it yourself, spending money only on spare parts. In addition, you have completely removed and installed the cardan, now if any unit of the cardan fails, it will not be difficult for you to replace it.

Source

Checking work

It can be done after the installation of the mechanism in the machine is completed. It is checked in the same way as when detecting play. In addition, the mechanism is examined for oil and grease leaks. The seals are also carefully inspected. In addition, they check on the road.

Pay attention to the presence or absence of extraneous sounds and the sensation of vibration. It is worth mentioning that you cannot carry out these procedures yourself. You can violate the angle of rotation, which will lead to wear of the part and its next replacement. It is better to turn to qualified specialists, pay money and enjoy the quality work of the craftsmen.